LVL timber appeared on the domestic market relatively recently. It consists of wood. Wood has been and remains the most popular construction and finishing material. Its new modifications appear, more and more advanced and functional.

Read also the article about innovative material – CLT panels

The improvement of wood as a building material is necessary, taking into account the specifics of a natural, natural, living material. Which is very vulnerable.

The main task of scientists who develop building materials is to maximize the improvement of wood. Namely, to give the wood qualities that will allow this material to be used without any fear in various fields. Including construction.

LVL timber is one of these developments.

LVL timber history of origin

In simple terms - glued peeled veneer, this is LVL timber. This material is very popular abroad. Mass production of this material in the USA began in the 60s of the last century.

And the first mentions of it date back to 1935. The first mentions were in the US Federal Forestry. The first company to launch mass production is Wayerhauster

Like all innovations, in our country, LVL timber became known and began to be used relatively recently.

Application of material

According to its properties, MDF is divided into the following types:

Decorative wall panels

Their installation can be carried out by anyone due to the simplicity of the execution of such plates and the thoughtfulness of the fasteners. One side of each blade has a groove, and the other has a ridge, and they form a lock between themselves. If this material is located in particularly sensitive places, then you can additionally secure it with construction staples or glue. All information about MDF wall panels in Leroy Merlin can be found in the article.

The advantages of such panels include:

- appearance;

- environmental friendliness;

- ease of installation;

- high thermal conductivity;

- noise protection

The disadvantages include:

- rapid flammability;

- susceptibility to mechanical damage.

Such canvases have characteristics corresponding to the price. You can learn about brick-like MDF wall panels from the article.

Moisture-resistant panels

These plates are universal. They have high moisture protection, so if a large amount of water gets on the moisture-resistant wall panels, they do not become deformed or destroyed, and mold does not form on them. Very similar in their properties to plastic.

In addition, they have a number of other advantages:

- high level of sound insulation;

- ease of processing;

- strength.

What are the dimensions of MDF panels can be found out here by reading the article.

Glossy canvases

They are used in the production of furniture. You can often see the front side of cabinets made by them, less often the sides are made from them. Due to the glossy layer, they can suit any interior. At the same time, it protects the material and extends its service life.

The slabs are treated with the following coatings:

- primer;

- polyester.

You can find out more about MDF wall panels for interior decoration here in the article.

After applying the first coating, the panels become highly glossy (acrylic). This provides them with an improved appearance and guarantees high strength characteristics. After this surface treatment, it becomes resistant to moisture and scratches.

The main disadvantage of all of the above panels is their fragility when bending, so manufacturers took this into account and released a new type of MDF.

Flexible panels

They are ideal for creating arches and curved structures. They are used in two versions:

- single-layer, which is attached to the base with glue;

- two-layer. This variety is capable of connecting with each other.

Flexible panels have a smooth surface, moreover, it can be painted, decorated and veneered, that is, they can complement the selected main type of panels.

Kronospan

Its abbreviation sounds like chipboard. This high-density material is suitable for laying floors and decorating walls. It has a thickness of 10 mm, so it has found its application in furniture for children's rooms. Because it is resistant to mechanical damage and reliable. You can find more information about the dimensions of laminated chipboard sheets in the article.

You can find out about MDF panels for ceilings here in the article.

What is LVL timber

The literal translation of LVL timber (Laminated Venner Lumber) is lumber made from laminated veneer. In the production of LVL timber, spruce, pine, larch and other coniferous wood veneers are used.

In general, LVL timber is a multi-layer, unique material of high strength. It is often used as frame elements, other load-bearing elements, as roof and floor coverings

How LVL timber is produced

The production process of LVL timber includes several stages.

First, using special equipment, the bark is removed from the tree trunk (the log is debarked). Next comes peeling, drying and sorting of the veneer. The best veneer is selected for the production of LVL timber. Without the slightest defect.

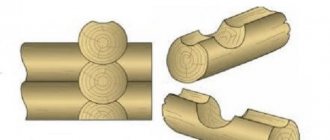

Afterwards, the veneer is glued together under a special press. The strength ratings of LVL timber are due to the fact that the veneer is glued together so that each layer is positioned so that the grains are parallel to each other.

How many layers

In LVL timber, as a rule, there can be up to 24 layers of veneer. But most often, timber is used whose thickness does not exceed 7-9 layers of veneer. The final stage of production is cutting the timber to the required dimensions and packaging it.

- The thickness of the timber may vary. In the range from 1.8 to 10.2 cm.

- The length of the beam can reach 18 meters, width - 1 -1.8 cm

Solid profiled

The timber is also made from a single log, only it is driven through special equipment, where it is given ideal geometric dimensions, a special lock profile is selected and, of course, planed to give it an aesthetic appearance.

Pros:

- low probability of warping - industrial wood drying technology makes it possible to achieve 10–15% moisture content in the final material with virtually no deformation consequences;

- does not require additional processing and finishing of the walls;

- high precision connections (no gaps);

- manufacturability - locking profiles greatly facilitate the construction process.

Minuses:

- all possible wood defects mentioned above;

- the need for additional time for shrinkage - after all, the existing possibility of shrinkage and warping of solid beams requires time for the finished walls to shrink.

- Construction from solid profiled timber

The price for a solid profiled timber kiln-drying is on average 12,000 rubles. per cubic meter More expensive than non-profiled, but the final result is much higher in quality.

Conclusion: after treatment with fire-bioprotection, subject to construction technology, it is perhaps the best choice in terms of price/quality ratio, but you must be prepared to deal with possible “surprises” of solid timber.

Where is LVL timber used?

LVL timber is used as load-bearing elements of the frame, as we said earlier. It is used in the construction of trade pavilions, kiosks, hangars, outbuildings, security structures, non-residential and residential premises, swimming pools, and for the formwork of monolithic buildings.

In addition to construction, LVL timber is successfully used for finishing premises; it is also used to produce door frames, window frames, door leaves, furniture elements, interior partitions, etc.

What is the difference between MDF and chipboard and solid wood?

Chipboards are chipboards made by pressing small wood chips with the addition of special glue. There is pressed, moisture-resistant, laminated, and extruded chipboard. The first and third types of this material are used for the production of inexpensive doors, as well as furniture.

The difference between MDF and chipboard is immediately noticeable, MDF is a homogeneous material, while chipboard consists of fairly large fragments of wood and voids, immediately visible to the naked eye

Comparative characteristics of MDF and other materials used for the manufacture of doors:

| Indicators and characteristics of the material | MDF | Chipboard | Pine | Oak | Beech | Alder | Ash |

| Flexural strength (kg/m3) | 22 | 33-47 (depending on brand) | 79 | 93 | 94 | 69 | 107 |

| Density (kg/m3) | 600-850 | Less than 600 | 450-500 | 720 | 490 | 690 | 750 |

| Hardness MPa (kgf/mm2) | 5,8 | 2,94 -3,0 | 2,49 | 3,8 | 3,8 | 2,4 | 4,1 |

| Moisture resistance | High | Average | Average | Average | Average | Average | Average |

| Environmental friendliness | High | Average | High | High | High | High | High |

Based on the table, it can be seen that MDF is superior to chipboard and solid wood in terms of hardness - 5.8 kgf/mm2 due to the homogeneity of the structure. Due to the increased hardness of MDF compared to other wood materials, it does not crumble, which facilitates the milling process. Moreover, at the exit from the machine you immediately get a finished, smooth surface, which is even suitable for painting without additional sanding.

Milling the panel relief in the top layer of MDF

The density of MDF is as close as possible to oak (690-750 kg/m3), since it is 600-850 kg/m3, compared to pine (450-500 kg/m3) and alder (490 kg/m3). Thanks to the high density, the reliability and sound insulation of door structures is ensured.

However, the low bending strength of MDF (22 kg/m3) indicates increased fragility and low impact strength in contrast to chipboard and solid wood. Therefore, MDF doors are more damaged by targeted impacts.

Why is it more profitable to purchase interior doors made from MDF than from solid wood?

Door structures made from 100% solid wood are the most expensive. In terms of environmental friendliness and manufacturability, natural material cannot be compared with any other. However, solid wood doors have their drawbacks - wood reacts to temperature changes and is afraid of high humidity, which can lead to delamination of the wood, as well as a change in its shape.

MDF is simply an ideal base for finishing with natural veneer - does not change size, smooth, hard, dense

MDF doors are an excellent alternative to expensive products made from solid pine, oak, beech, and ash. Their physical and technological properties are as close as possible to the characteristics of natural wood. They have proven themselves well during long-term use in the door industry. Products made from MDF are the best option for designing doorways in both residential and office premises.

What are the advantages of LVL timber?

- The strength of LVL timber is twice that of laminated timber. But laminated veneer lumber, before that, was considered the most durable material of its kind

- The uniformity of the structure of the entire canvas can also be attributed to the undeniable advantages of LVL timber

- LVL timber is not subject to deformation and practically does not shrink

What other advantages

- Does not rot because it does not absorb moisture

- It has high fire resistance, since the structure has no pores and burns worse

- The weight of LVL timber is much less than solid timber. Therefore, installation and any other use and transportation are simpler and easier.

- Choice of virtually any size, eliminating or minimizing waste

Assortment of mass-produced laminated timber from LVL veneer under the Ultralam™ trademark

Ultralam is manufactured in the form of slabs and beams with a length from 2500 to 20500 mm with a gradation of 500 mm, a width from 40 to 1250 mm, a height (thickness) from 24 to 100 mm.

Maximum deviations in length are ±5 mm, in width ±2 mm. Thickness deviations: from + (0.8+0.03δ) to – (0.4+0.03δ), where δ is the thickness of the slab or beam. The cost of LVL of Ultralam™ timber does not depend on its length and cross-section. LVL timber "Ultralam"™ (trademark "Ultralam") of types

R

have the following standard linear characteristics (standard sizes):

| Thickness, mm | 30, 33, 36, 39, 45, 51, 63, 75 |

| Width (Height), mm | 120, 150, 160, 200, 220, 240, 260, 300, 360, 400, 420, 450, 500, 600, 1250 |

| Length, m | 4, 6, 8, 8.5, 9, 9.5, 10, 10.5, 12, 12.5, 13, 13.5 |

LVL timber "Ultralam"™ (trademark "Ultralam") of types X

and

I(X)

have the following standard linear characteristics (standard sizes):

| Thickness, mm | 21, 27, 30, 33, 36, 39, 45, 51, 63, 75 |

| Width (Height), mm | 120, 150, 160, 200, 220, 240, 260, 300, 360, 400, 420, 450, 500, 600, 1250 |

| Length, m | 4, 6, 8, 8.5, 9, 9.5, 10, 10.5, 12, 12.5, 13, 13.5 |

LVL timber "Ultralam"™ (trademark "Ultralam") of types I

have the following standard linear characteristics (standard sizes):

| Thickness, mm | 21, 27, 30, 33, 36, 39, 45, 51, 63, 75 |

| Width (Height), mm | 120, 150, 160, 200, 220, 240, 260, 300, 360, 400, 420, 450, 500, 600, 1250 |

| Length, m | 4, 6, 8, 8.5, 9, 9.5, 10, 10.5, 12, 12.5, 13, 13.5 |

It is possible to produce LVL timber "Ultralam"™ (trademark "Ultralam") with other linear characteristics on individual orders.

What are the disadvantages of LVL timber?

- Since the timber is vapor-tight, it practically does not allow air to pass through at all. Therefore, rooms made of LVL timber must be equipped with good ventilation.

- The cost of timber is very high. But the physical advantages and possible choice of sizes more than cover this disadvantage

Glue included

- The presence of glue in the composition scares off many. But, LVL timber, made using the correct technology, is not handicraft, and contains an adhesive composition that is harmless to the environment and humans. And also meets all international requirements. It is important to check for material certificates when purchasing.

Why is marriage excluded?

At each stage, the material undergoes quality control. When fed into the peeling machine, the block is scanned by a laser. The information processed on the computer is transmitted to spindle clamps, which place the tree in a position that will ensure the best yield of sheets with minimal rounding. Damage is detected by cameras and scanners at the wood cutting stage, which minimizes product defects. Layers whose humidity exceeds 8% are automatically sent to dry.

Products undergo special tests and receive confirmation of compliance with standards. Therefore, when purchasing in a store, they ask to show certificates for the goods.