Wood planing

TO

category:

Carpentry and joinery work

Wood planing

Next: Chiseling wood

Wood is planed in order to obtain a smooth surface of wooden parts and give the rough blanks the correct shape and exact dimensions.

Depending on the degree of surface cleanliness and the dimensional accuracy of the parts being processed, manual planing of surfaces is divided into rough (for sherhebel), medium (for a plane) and fine (for a jointer).

Machine planing has one degree of planing purity.

Based on the shape of the processed elements, a distinction is made between planing of flat surfaces (straight parts with a square or rectangular cross-section) and profile planing (parts with a curved outline and a figured cross-section).

Hand Planing Tools

Tools under the general name of planing are used for planing.

Every plow consists of a wooden or metal block, a steel cutter (piece of iron) and a wedge.

To make it easier to work with plows, some of them have handles on the blocks. The plow cutter is placed in a special socket of the block, the so-called tap hole. The lower part of the block (sole) has a narrow slot for the cutter to exit, called the span.

The leading edge of the span provides support for the chips. To prevent the leading edge of the span from collapsing, an insert made of hard, low-wear wood (boxwood, backwood, etc.) is embedded in the sole of the block.

The angle between the back of the tap hole and the plow base is called the cutter attachment angle. It is equal to the cutting angle.

The cutters in all plows protrude beyond the plane of the sole - from 1 to 3 mm in plows for rough planing and from 0.1 to 0.3 mm in plows for fine planing. The cutters are either solid or welded - with a working part made of high-quality tool steel.

Blocks and wedges are made from dry (no more than 12% humidity) hornbeam, beech, maple and ash wood. The sole of the shoe must be smooth, clean and free of distortions and curvature.

The following planes are used for planing flat surfaces of wood: bearer, sherhebel, planes (single and double), sander, jointer, semi-jointer, tsinubel (Fig. 130).

The bearer is used in carpentry for rough sharpening of logs, beams and boards. The width of the piece of iron is 50-60 mm. Planing with a bear is carried out by two workers, who usually sit astride the material being planed, facing each other. For this purpose, the bear has four side handles.

Rice. 1. Tools for planing flat surfaces: a - bear; b - sherhebel; c - plane; g - double plane; d - jointer

Scherhebel is used in carpentry and joinery work for the initial stitching of parts before processing surfaces with a plane. Sherhebel has a piece of iron 30-40 mm wide, protruding 3 mm beyond the plane of the sole. The cutting edge of the piece of iron is oval, thanks to which it is possible to plan wood not only along, but also across the fibers without tearing them. Scherhebel removes narrow and thick chips, leaving quite deep hollows in the wood.

A single planer is used to level the surface planed with Sherhebel. The blade of the iron is straight with slightly oval edges.

A double plane differs from a single plane in that it has a second, chip-breaking piece (hump). The closer the edge of the hump is located to the cutting edge of the cutter, the cleaner the processed surface is. A double plane is also used for clearing burrs and chamfering edges.

The sander is used for cleaning burrs, twisted places and ends only in carpentry work. It is a shortened double plane with a cutting angle increased to 60°. Removes very thin shavings and can be used on very hard wood.

The jointer is used for precise processing of large surfaces under a ruler and for aligning (jointing) edges. The length of the jointer block is 700-900 mm, width 85 mm, height 75 mm, width of the iron 65 mm. There is a cylindrical insert in the front of the block (impact button); hitting the button knocks the jointer piece out of the tap hole.

In addition to the listed tools, planing tools include a cycle, which is a plate 100-150 mm long, 60 mm wide and up to 1 mm thick. It is often made from old hacksaw blades, bow saws and band saws.

Cycles are used (in carpentry) to clear hardwood after processing it with a double plane. Cleaning the scrapers gives a high surface cleanliness.

The following plows are often used for shaped planing of wood: humpbacks (wooden and metal), zenzubels, folding gobels, tongue and groove, fillets, figares, staff gobels, federgobels, ground tubes and moldings.

Humpbacks are used when processing concave and convex surfaces. Therefore, their pads have a concave or convex sole, respectively. The sole of a metal humpback is made in the form of an elastic steel plate, which can take a concave and convex shape with the help of special screws. The humpback's iron is the same as that of a double plane.

Zenzubel is used for selecting and cleaning folds of different sizes. Last length 250 mm, width 40 mm, height 80 mm. The sole of the last is straight. To throw out the chips, a sink is made in the side of the block. The gland of the zenzubel has the shape of a blade, its width is 20 mm at the blade and 7 mm at the tail; it is inserted into the block from below and secured with a wedge from above. The blade can be straight or beveled.

The rebate serves the same purpose as the zenzubel, but it can only select a rebate of one specific size. After selecting the fold (quarter) with a folding tape, they must be cleaned with a zenzubel.

The tongue and groove pile is used for selecting the edges of tongue and groove boards. It consists of two blocks connected to each other with screws. One of the blocks has a hole for the piece of iron, and the second is a guide bar. The depth of the tongue is adjusted with screws, and the width depends on the width of the iron.

The tongue and groove has a set of pieces of iron of different widths.

The fillet is used to plan grooves of various depths and widths with different radii of curvature. There are fillets with glands of different profiles and sizes. The cutting edge of the iron is rounded.

Rice. 2. Tools for figured planing: a - humpbacks; b - zenzubel; c - tongue and groove; g—fold tapestry

Figarei is used in carpentry for selecting a wide profile or wide chamfer on the edges of solid wood panels. It has a wide figured or inclined sole, a figured or oblique piece of iron up to 90 mm wide.

The headstock is used in carpentry for profiling posts (thin blocks) covering gaps in places of detachable joints, etc. The blocks come in different widths. The blade of the iron and the sole are usually concave.

Federgobel is used to select ridges on the edges of boards that are inserted into the tongue. The federgobel iron has a U-shape.

The primer is used for cleaning the trapezoidal groove in the direction across the fibers and for sorting it after cutting along the edges with a reward.

The molding is used for shaped processing of the front edges of parts.

Sharpening and adjustment of hand planing tools

A piece of iron with a straight or oval cutting edge is first sharpened on a wet sharpener, and then on a fine-grained whetstone. After sharpening, the final editing (finishing) of the blade of the piece of iron on the whetstone is carried out.

The blades of tools intended for profile planing, in cases where the profile of the blade does not allow them to be sharpened in the above manner, must be sharpened with files of the appropriate shape, having a fine notch. Straightening after sharpening with files should be done with shaped hardwood blocks, soaked in oil and sprinkled with emery powder.

Rice. 3. Techniques for sharpening pieces of iron: a - sharpening on a wet sharpener; b - sharpening on a block; c - editing on the touchstone

Techniques for sharpening bits on a sharpener and whetstone, as well as straightening and finishing blades on a whetstone are shown in Fig. 3.

When sharpening a piece of iron on a wet sharpener, you need to hold it with both hands. With one hand, hold the piece of iron motionless, slightly moving it across the width of the working surface of the sharpener, and with the other hand, lightly press the piece of iron with the cutting edge against the sharpener.

When sharpening a piece of iron on a block, you also need to hold it with both hands. Sharpening is done using linear and circular movements. To keep the block motionless, it is usually placed in a special nest, hollowed out for it on a wooden stand.

The whetstone, just like the sharpener, must be moistened with water. When dry sharpening, the iron heats up and the steel of the blade loses strength; When sharpening, the piece of iron must always be at the same angle to the working surface of the sharpening tool and adjacent to it with the entire plane of the chamfer. You should not press the sharpening tool hard with a piece of iron, as this will not speed up the sharpening and may worsen its quality.

The editing of the piece of iron on the whetstone is done using circular movements of the chamfer. The whetstone should be moistened with water or lightly oiled. When making final adjustments to the touchstone, the piece of iron must be turned either with the back or the front side.

After finishing sharpening and straightening, you should check the sharpness of the iron blade by running a finger moistened with water across it in several places, or by holding the blade up to the light. When the iron is rotated around the transverse axis at a sharp chamfer, the transition from illumination to darkening should occur immediately along the entire blade.

The straightness of the blade is checked by applying a ruler to it with the edge; The presence of a right angle between the blade and the edge of the piece of iron is checked with a square. The sharpening angle is checked with a special template, which is a plate with angles of 20, 25, 30 and 45° cut into it.

Setting up a manual planing tool involves setting the pieces of iron to the required chip thickness. The glands of the mole cricket and sherhebel extend beyond the plane of the sole of the block up to 3 mm. When setting up single and double planes, the blade of the pieces of iron is released by a very small amount (0.1-0.3 mm) so that the thinnest chips are removed.

The correct installation of the piece of iron is checked initially by eye inspection, and then by trial planing with a tool.

When checking by eye, the instrument must be held with the sole up, the front end facing the eye. The blade of the iron should protrude evenly across the entire width of the sole without distortion.

If during test planing it turns out that the tool removes too thick chips, the output of the piece of iron must be reduced somewhat. This is done by lightly hitting the rear end of the block with a mallet. In cases where the tool does not plan or takes too thin chips, the output of the iron should be increased. To do this, you need to lightly hit the front end of the block with a mallet, or, if this does not give results, lightly hit the top of the piece of iron with a hammer.

In Fig. Figure 4 shows the basic techniques for disassembling, assembling and setting up a plane. During all operations, the plane must be held in the left hand, holding the piece of iron with the thumb through the blade.

Planing techniques with hand tools

For planing timber, workbenches equipped with special clamping devices and stops are usually used.

Before planing, you must carefully examine the surface of the wood and determine the direction of the fibers and annual layers, as well as the presence of defects.

Before starting work, you need to select the necessary tool and check its condition (adjustment). You should stand at the workbench to the left as you plan, slightly half-turning, turning your right shoulder towards the workbench; The foot of the left leg should be parallel to the workbench, the body tilted slightly forward. When planing, only your hands should move; The less the body moves, the less tired the worker gets.

Rice. 4. Techniques for assembling and setting up a plane: a - inserting a piece of iron; b - holding the piece of iron; c — releasing the blade by hitting the front end of the block; g—releasing the piece of iron by hitting its top with a hammer; d - securing the piece of iron by hitting a wedge; e - checking “by eye” the correct release of the piece of iron

You need to plan at full swing in a straight line, pressing evenly on the tool. Do not press too hard on the tool, especially at the ends of the parts, so as not to “overwhelm” them. During the return movement, the rear end of the tool must be slightly raised, otherwise the blade can be damaged (grinded).

Planing with a sherhebel should be done at a slight acute angle to the direction of the wood grain, since when planing along the grain, the material can be imperceptibly re-planed against the specified dimensions. When planing across the grain, flakes are obtained at the edges of the material.

Planing with planes is carried out along the grain. Deviations from this rule can only be allowed when cutting through (cleaning) twisted areas on the surface of the wood with a double plane.

Rice. 5. Planing the end: a - in the usual way; b - using the bottom

Planing of surfaces should be performed without removing the jointer from the material along the entire length of the material. It is advisable to joint the edges of the boards in pairs, this makes it easier to achieve the required jointing accuracy.

Planing of the end of the part must be done before planing the plates and edges, so as not to spoil the planed surfaces with flakes. When trimming parts, the plane must be held obliquely to the direction of planing. Trimming is done first from one side to the middle of the end, and then from the other side. Narrow bars end up on a special device - a bottom, or with a stand of an auxiliary bar. The quality of the planed surface is checked either by eye (by viewing against the light) or by applying a ruler to the planed surface.

Planed bars must have mutually perpendicular edges. The correctness of planing “into the corner” is checked with a square.

The correctness of the jointed edges of the boards is checked by applying the jointed edges to each other, and there should be no gaps between them.

The check is also accompanied by an inspection of the quality of the planed surfaces (absence of roughness, scoring and other defects) and control measurements of the dimensions of the processed parts, taking into account permissible deviations.

Planing with hand electric planers

Manual electric planers are used for planing logs, beams and boards, planing floors and planing various blanks for joinery. There are several types of electric planers with a blade shaft rotating from an electric motor. Recently, planes of the I-24 and I-25 brands have been used, the electric motors of which have an external rotor, which is also a blade shaft. The rotor has four knives. The planing width of the I-24 electric planer is 100 mm, and that of the I-25 is 60 mm.

Rice. 6. Manual electric planer I-24: a - general view; b and c - planing techniques

The I-24 electric planer has a rigid frame in which a three-phase squirrel-cage electric motor is mounted.

An aluminum drum with four knives attached to it is pressed onto the engine rotor. The planing depth is adjusted by lowering the front panel using special screws. The knife shaft is protected by a safety valve, which ensures safe planing.

The planer can be used as a tabletop permanently installed planer. To secure the electric planer (on a workbench or wooden frame), there are four special legs with holes for bolts. For planing parts “in the corner” there is a removable guide ruler. The electric planer has a hand brake, which ensures a quick stop if necessary.

When planing with electric planers, you can remove chips with a thickness of 1 to 2 mm.

Figures 6, b and 7, c show techniques for planing wood with electric planers.

Electric planers, as a rule, operate from a lighting network with the cord plugged into a regular outlet. The operating mode for electric planers is the same as the mode established for other hand-held power tools. When working with them, you must follow the general safety rules when working with electrified tools.

Planing wood with a plane

Planing is a type of cutting. There are two types of planing - manual and machine. The surface of parts processed by planing is smooth and clean.

When planing, it is possible to cut wood along the fibers, across them and from the end (Fig. 30). The following tools and devices are used for planing.

Rice. 30. Types and techniques of planing wood

Sherhebel (Fig. 31, A) is a small narrow plane with a semicircular cutting edge of a piece of iron. It is used for initial peeling or removing large allowances from workpieces. After treatment with Sherhebel, an uneven, bumpy surface is obtained. The angles of sharpening and installation of the cutter are the same as for the plane.

A plane consists of a metal or wooden block and a cutter, the so-called piece of iron. In metal planes, the cutter is secured with an adjustable screw, in wooden planes - with a wedge (Fig. 31, B).

The leading edge of the cutout in the plane block prevents chips from chipping and ensures their correct formation, which ensures a clean surface finish.

Fig.31 A. Planing tool and its adjustment

Rice. 31 B. Types of planes

To obtain an even cleaner surface, double planes are used, having cutters with an overlay, the so-called counter-iron, or hump (see Fig. 32). The overlay does not allow the cutter to go deeper into the wood than the set depth, and thereby protects the surface of the workpiece from the formation of scuffing.

The cleanest surfaces are obtained when planing with double iron planes.

Cutters for planes are made of tool steel grade U7 or U8.

Rice. 32. Planing device

The angles of sharpening and installation of the cutter in the plane are shown in Fig. 36.

Planes are available in various designs and sizes. Many modellers prefer to make their own blocks, adjusting the shape and weight of the plane to their liking.

The jointer (see Fig. 31,A) is an elongated double plane. It is used to obtain precise planes, for example when gluing panels and blanks.

The shaving is a special plane consisting of a cutter and a short metal block with two handles on the sides. It allows you to process convex and concave surfaces. The shavings are very convenient for making screws and museum models (Fig. 31, B).

Techniques for setting up a plane and jointer are shown in Fig. 31,A.

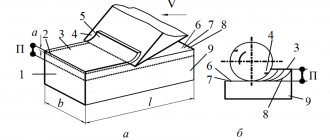

The bottom is a device for planing. It consists of a lining, a guide pad and a thrust pad. The latter can be fixed at different angles.

An example of using the bottom is the processing of the edge of the plywood frame of a flying model (Fig. 32).

The frame is placed on the bottom so that the side to be processed protrudes slightly beyond the edge of the lining; with your left hand, the frame is firmly pressed against the thrust lining.

The plane is held with the right hand on its side and planed along the lining.

When working, make sure not to tear off the guide pad. Over time, it still wears out and the edge of the part processed on the bottom turns out to be non-straight. Then the guide plate must be checked with a square and the correctness of its edge restored.

A broach is a device for planing and calibrating thin slats, etc. It is a board with a number of grooves having depths equal to the frequently used sections of slats.

For ease of use, the broach is clamped in the vice of a carpentry workbench or screwed to the work table.

The slats, made on a saw with an allowance of 0.5 mm per side, are placed in a suitable groove and, holding the plane with your left hand, pull the slats towards you with your right hand.

After stretching the rail 2-3 times, check its cross-section and proceed to processing the other side of the rail (see Fig. 32).

Rice. 33. Benchtop mechanical (electric) jointers

Jointer

It’s worth considering the design of this machine from the fact that it can be single-sided or double-sided. If a double-sided machine is used, then two adjacent surfaces of one workpiece can be processed at once. There are also machines with manual feed or with mechanized feed. If with manual feeding everything is simple and clear, then for mechanical feeding it is necessary that an automatic feeder be installed nearby. In some cases, an integrated conveyor feed mechanism may be used instead. Also, these machines are equipped with devices such as chip collectors, which are used for chips and dust. It is connected to the factory exhaust network.

Mechanical planing

Mechanical jointer (Fig. 33). To equip model laboratories, clubs and children's technical stations, you can use a manual electric jointer. A mechanical jointer mounted upside down on a table can do most rough planing work.

The electric jointer consists of a sliding block, a motor and a knife drum.

The material is fed towards the rotating knife with simultaneous pressure. To prevent accidents, serve using a wooden block or pusher.

The quality of planing depends mainly on the correct sharpening and installation of knives in the drum. It is necessary to ensure that the knives are positioned above the table surface exactly the same and parallel to the table plate. Strong vibration of the jointer during operation can loosen the bolts securing the knives, so the bolts must be periodically tightened with a wrench until they are fully tightened.

It is very useful to have in a small workshop a combined machine (Fig. 34) from the Dzerzhinsky plant or a similar one, in which a jointer, a circular saw and an emery wheel for sharpening the tool are mounted on one shaft and bed.

Rice. 34. Combined planer-saw machine

From the book by O.K. Gaevsky “Aircraft modeling” 1964

Preparation for use

Preparation for work includes the stage of technical adjustment of the unit, as well as checking its performance. As for the technical setup, it is as follows. Knives that are installed on jointing machines must have a straight shape. Using a ruler and a feeler gauge, deviations from straightness are monitored. The gap allowed between the ruler and the blade is only 0.1 mm if the blade length is up to 400 mm. If the blade is up to 800 mm long, then the gap can be 0.2 mm. As with an electric planer, the knives must be balanced in weight. Installation of knives is carried out sequentially. The device has a chip breaker. Knife blades should protrude above this element by no more than 1-2 mm. To check the machine, it is necessary to have a test block, which is usually made of hard, dry, seasoned wood. It also has precision machined edges. The cross-section of the edges can be 20-30 x 50-70 mm and a length from 400 to 500 mm.

Description of the process and its purpose

Gouging technology involves blowing out molten metal with a jet of compressed air. It is used to remove part of the metal from the surface entirely or in strips, including:

- for removing fragments in welded structures;

- creating grooves and understatements in thick-walled parts;

- cutting out defects;

- samples of poor-quality seams.

When gouging with a carbon electrode, its ability to melt metal with an arc is used. In this case, the graphite itself practically does not burn, only the copper coating melts near the arc. The holder of a special design, the planer, has holes for gas outlet next to the clamp. In addition to the power cable, a hose for compressed air, carbon dioxide or argon is connected to it. The air is pumped by a compressor, gas is supplied from a cylinder.

Plasma gouging uses gas to simultaneously melt metal and blow it out. The plasma arc instantly heats the metal to its melting point and above. It literally evaporates from the gouging and cutting area.

The disadvantage of this treatment is the release of large amounts of harmful gases. The operation of the equipment is accompanied by loud noise.

The classic method of repairing welded structures and cutting defects is oxy-fuel cutting. The oldest and most productive method is based on the principle of heating using a gas burner. When welding, filler wire is added, which melts along with the edges. For gouging and cutting, it is enough to heat the steel so that it begins to oxidize. The liquid, molten metal is blown out along with the gas.

With the development of electric arc and plasma welding, oxygen gas cutting is used to remove profits and accumulators from castings. Cracks, sinks, and sagging are washed out using a planer.

When gouging metal defects in castings, the flame of a gas burner is also used as a control tool for highlighting and eliminating cracks and cavities. In a stream of burning gas, the edges of the cracks heat up faster than the main body of the part and glow in narrow stripes of orange and yellow.

At the beginning of gas gouging, the starting point on the part is heated to red. In this case, the mouthpiece should be positioned at an angle of up to 70⁰, the flame core should touch the surface of the part. After heating the surface of the sheet, the nozzle rises by 15 mm, and after oxygen is released, the angle of inclination decreases depending on the gouging depth. The depth of the groove is also increased by increasing the oxygen pressure.

In the mass production of machines using the oxygen gas method, rough cuts of grooves and grooves are made in large parts for further cutting. They work mainly with low-alloy steels. Carbon and high-alloy steels after oxy-fuel gouging require heat treatment to relieve stress from local heating.

All types of gouging can be done in any position of the part

You just need to be especially careful when working with the ceiling so that molten metal does not drip onto the welder

The thermal conductivity of carbon and alloy steels is lower than that of simple steels. When heated and sharply cooled, they become heated with a change in the crystal lattice. In this case, internal stresses arise, which can lead to destruction of the part. It is necessary to do normalization or annealing to align the structure and relieve stress.

Equipment and tools

In addition to 15×25 carbon electrodes with copper coating, OZR-1 is used for gouging and cutting copper alloys and cast iron. For steels – electrodes of the ANR-2, ANR-2M grades.

Plasma cutting machines are divided into groups according to power and productivity:

- air-plasma manual;

- portal;

- portable for work on the road.

Hand-held devices can be used at home and in small workshops. The rest of the equipment is for industrial cutting in stationary and field conditions.

Gouging, especially with electrodes and a special cutter, is available for use at home when repairing various mechanisms and pipelines. It is used mainly for cutting welds or foundry blanks at metallurgical enterprises and in the repair of metal structures.

Varieties

A metal planing machine can be longitudinally planing or cross-planing.

The principle of processing workpieces on these varieties is fundamentally different. Longitudinal planing machines are designed for processing relatively short surfaces, so in them the movement is received by the table to which the workpiece is attached, while the cutter is installed in the cutting head of the support and does not move relative to the machine bed. In a cross-planing machine, the opposite is true: the cutter moves, but the semi-finished product installed on the table is stationary. Planing machines are inferior to milling machines in productivity because they have an idle stage when the workpiece or cutter moves to a new position. But the drive is not so energy-intensive, because rotational movement of the working tool (as in milling machines) requires increased work from the drive motor.

The classification of the metal-cutting equipment under consideration can be made according to other parameters:

- By drive type. Units are produced with a hydraulic drive for the movement of the table (or tool), as well as with a crank-rotary drive option. For the former, the speeds of the moving units are constant, while for the latter they can vary according to the characteristics of the processing technology. To do this, it is enough to reinstall the rocker mechanism stone to a new position.

- By the number of working surfaces that can be processed simultaneously. Four-sided metal planing machines can process simultaneously on all edges of a semi-finished product, while double-sided ones can only process on opposite sides. Accordingly, the support of machines of the first type has a more complex design and is designed to install four cutters. Single-sided machines are predominantly small-sized.

- By drive power. Small-sized machines are limited in their functionality, but attract consumers with their low price and compactness, so they can be installed in small metalworking factories, or even in private workshops.

- According to the configuration of the movement of the tool or table. For complex trajectories, shaped metal planing machines are produced, which are equipped with a CNC system. They find application in small-scale production, when it is necessary to obtain complex flat surfaces on products. The qualifications of the worker are not particularly important in this case, since all movements are carried out according to coordinates entered into the system’s memory in advance.