One of the advantages of private home ownership is the ability, if necessary, to increase the usable area by adding an additional one to the main structure. In this way, residential or utility rooms are obtained for whom some functionality is no longer enough. In order for the extension to improve the living conditions of the owners, and not create problems for them, it must be built using existing technologies, and not according to the principle “somehow, as long as it’s cheaper.” Therefore, we will figure out how to properly attach to a house, relying on generally accepted methods and the experience of FORUMHOUSE users.

Important stages are design and approval.

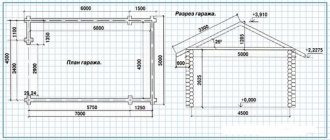

An extension to a log house can be made in the form of a veranda, terrace, garage, where a workshop or storage room can be located, it can be a summer kitchen or an additional room. But there are always two important stages between the idea of construction and its implementation: you need to create a project and then obtain a building permit.

The project allows:

- determine the scope of upcoming work;

- assess how difficult it will be to build an extension from timber;

- record the types of upcoming events.

The amount of materials is reflected in the estimate to determine the cost of construction. Design documents contain a lot of useful data, and therefore are a guide for builders.

For example, a project for an extension to a log house may contain the following information:

- the extension will have one or two floors;

- will it be necessary to make new openings for windows, doors, or carry out redevelopment;

- what communications in the house require installation from scratch, complete replacement or repair;

- technical documentation contains explanations of the junctions between the building and the extension, how the piping will be done, what the roof of the residential building will be like;

- what work needs to be done on the site: clearing the area, marking the foundation, depending on what type of foundation is chosen: strip or columnar (on bored piles). Each of them can be made by hand.

When choosing a material for finishing the facade, the architectural features of the existing house are taken into account.

1.1. Permission to build an extension to a house made of timber

Permission to build an extension made of brick or wood is not always required. It is necessary in case of construction of a capital structure. A canopy, covered terrace or a new porch for a summer house does not require approval, since they do not change the key building elements of the main building, do not affect utilities, or the foundation.

If, according to the project, the usable area of an additional room to the house (kitchen or room, second floor) becomes larger or the configuration and size of the roof changes, then it is also mandatory to obtain permits for construction. Then in the future there will be no problems with selling real estate.

Due to the extension, the territory it occupies on the site changes. If the building was one-story, but became two-story, then its volume and layout will change. All this data must correspond to the previously developed and then agreed upon project and be included in the new technical passport. If this is not done, then after unauthorized construction, according to the law, the premises will need to be brought into compliance with the current documentation.

Flooring assembly

The next step in building an extension for a wooden dwelling is to assemble the floor. At this point, the foundation should be completely ready for use. Let's look at what flooring installation methods exist:

- pouring screed;

- installation of wooden floor.

The first method is more expedient, but it will cost more. To fill the screed, you will need to remove about 35 cm of soil located inside the foundation. Next, a cushion of sand and crushed stone is poured into the bottom of the niche, after which beacons are installed (using a level). Upon completion of preparation, the screed is poured and covered.

A simpler and more environmentally friendly way is to install a wooden floor. For such a covering it is necessary to lay beams (floors). They are fixed to the foundation using special fasteners - anchor bolts. At the next stage, the corner connections of the beams are installed. It is worth saying that such connections are installed along the perimeter of the foundation of the frame extension.

Then it is necessary to lay the cross beams and insulate the structure using a suitable heat insulator. Finally, as in the case of a concrete floor, the coating is covered. Before starting floor installation, it is recommended to study photos of the different stages of this event. This will allow you to quickly understand all the nuances.

Method of attaching joists to a concrete base

You might be interested in: We build a utility block at the dacha with our own hands

Profiled timber for the walls of a house extension: material features

An extension to a log house can be made of any material. Often, among other available options, they choose construction from concrete blocks, bricks, wood (frame technology). At the same time, if you need to hire a mason to build masonry, you can make walls from blocks or wood with your own hands, following simple rules.

It is better to choose a similar material as a material for building an extension for a private wooden house if there is a task to build an additional warm room or veranda. Block or stone walls require a layer of thermal insulation (mineral wool is recommended) as well as decorative finishing. Such an extension to the house will cost more, and the building will also require a more powerful foundation.

Glued laminated timber has many advantages. This is profiled lumber, consisting of several lamellas of coniferous wood (cedar, spruce, pine, larch). This material has a landing groove at the ends, which ensures high-quality installation. The boards are glued together and then pressed.

Regardless of its purpose, an extension to a house made of laminated veneer lumber always looks noble and emphasizes the advantages of architecture and the design of the main building. The material is treated with protective compounds at the manufacturing stage, and therefore there is no need to carry out additional protective measures. The construction of an extension to a house is carried out quickly, and due to the stability of the material, no time for shrinkage is required.

A rounded beam or log is not suitable if the construction of an extension to the house needs to be completed quickly. In this case, a non-heavy frame structure is suitable. Its advantages include the following:

- low price;

- low draft rates;

- low load on the ground, which allows the use of a lightweight foundation, for example, strip or pile;

- high construction speed.

The use of foam blocks will also reduce construction time due to the high speed of construction of the external walls of the building. Installation happens quickly. Interior finishing can be done immediately. But increased costs will be required for decorating the walls outside.

Useful tips

Before construction, you need to take into account some subtleties. For example, it is not advisable to build an extension from foam blocks if it will house a bathroom or bathhouse, since this building material absorbs moisture, which contributes to its destruction. It is better to build an extension with a toilet and shower with an exit from the bedroom or corridor.

When building a garage, it is good to use shell rock or brick to build walls. The strength of these building materials allows them to be used in rooms with high humidity.

Frame garage attached to the house

In an extension with a veranda, instead of walls, you can use glass panels mounted on a metal frame. This design solution will increase the lighting of the veranda and allow you to admire the surrounding landscape in any weather.

It should be noted that modern construction technologies make it possible to quickly build an extension from any building materials.

Foundation of an extension for a house made of timber

When constructing even an ordinary building, such as a gazebo, calculations are performed to select the optimal type of foundation. If a major extension is being built, then many factors must be taken into account. The bearing load of the base and supports on which concrete floors are laid is determined if a second floor or balcony is to be built. A screw foundation is considered unreliable. To make pillars, it is better to use concrete blocks or bored piles.

In order for an extension made of laminated veneer lumber to serve for many years, you must initially create a solid foundation for the future veranda, porch or living space. For several reasons, a strip foundation is most often chosen - it is relatively inexpensive, suitable for any room - room, veranda, bathhouse. If necessary, you can choose the level of its immersion in the ground to arrange a cellar or basement.

The installation of a strip foundation with your own hands is done as follows:

- Before starting construction of the extension, preparations are made on the site: the area must be level, cleared of debris and vegetation;

- markings are applied, the boundaries are indicated in the project;

- a standard trench is dug from the corner; when choosing the size, take into account the width of the foundation (it should be the same as the thickness of the foundation of a residential building) and the space required for arranging the formwork;

- install the formwork. The manufacturing material used is boards or plywood, which are secured on the outside with self-tapping screws to make it easier to disassemble later. Immediately make holes for communications;

- A sand-gravel mixture is placed inside the trench and compacted;

- then they begin laying the reinforcement;

- It is necessary to fill the formwork with concrete in such a way that this happens simultaneously, without interruption.

When the foundation of the extension is ready, before the supports are attached, it is recommended to lay a layer of waterproofing along the perimeter of the structure on top of the base - any moisture-resistant material, for example, roofing felt.

If you build an extension on a foundation with similar load-bearing characteristics, then there is a high probability that due to uneven settlement a crack will appear at the junction of the two foundations.

note

To build a major extension, you need the same type of foundation as the main building, so that you end up with a single load-bearing structure.

In this case, the foundation of both buildings must have the same parameters in terms of width and height, as well as depth, then they will “behave” the same. The same technology is used when it is necessary to make an extension to a house from timber during reconstruction. The foundation under the old wooden structure and the new foundation must be identical.

Functional

As with the construction of a house, before constructing an extension it is necessary to determine the functionality in advance, since different purposes require appropriate construction manipulations. If you plan to make living rooms, enhanced insulation is necessary. Communications are immediately laid out for the boiler room, bathroom or kitchen. It’s easier to change your mind and plug a couple of plastic pipes into the wall than to decide that another bathroom is more necessary and dig into a newly built one.

Connecting the walls of the timber extension with the house

Not only a reliable foundation guarantees its strength and long service life. The comfort and safety of the attached object depends on the quality of fastening of the two buildings. The joint will need to be insulated and protected from moisture.

A brick building will behave differently than a timber extension to a brick house or a wooden frame structure. Stone and brick are stable materials that do not settle. Therefore, after the main construction activities, the joint will simply have to be sealed with polyurethane foam, followed by sealing with cement-sand mortar.

To properly connect a timber extension and an old brick or wooden house, it is not enough to make an identical foundation. The shrinkage process, especially if wood with natural moisture content is used, is inevitable. It is better to avoid using polyurethane foam - such a seam will simply deform and cease to be airtight. Therefore, the area to which the wooden frame adjoins must be designed in the form of a movable insulated connection. The photo is shown below.

This type of joining occurs when connecting a window frame and wooden walls in extensions made of timber or logs.

4.1. How to connect to a wooden house

There are three types of connections that are used to connect a timber extension to a log house.

First option. First, check the wall surface to ensure it is level. A block will have to be nailed to it. It can also be fixed to the cut ends of the log house. Before this, insulation is laid in the place where the frame extension will be connected to the wooden house.

If the block is fixed to the wall, then wood is selected for it on the opposite side (end). The result is something like a sliding tongue-and-groove joint.

If the walls of a residential building have a pronounced relief (wooden frame), then there will still be a distance between the block and the extension. You will need to use other methods. One of them is to make a groove directly on the facade. When joining, insulation in the form of tape must be used. This type of thermal insulation makes the expansion joint as airtight as possible.

In the area where the fastening unit is located, the timber is fixed to each other. This must be done in order to ensure uniform movement of the wall and prevent divergence of the crowns.

If you plan to use staples to connect the building and a frame extension made of timber, then after the fastening with mandatory insulation has been completed, you need to additionally consider protecting the joint from water. To do this, it is recommended to fix the panels - flashings - from above. After the active settlement of the frame extension is completed, new cracks and holes may appear, so the joint is caulked again.

4.2. Joining timber to a brick or concrete wall of a house: nuances

The details of attaching an extension to an existing brick house can be done in the same way as to a wooden one - using a beam with a groove. You can use a block, but it is problematic to fix it on the masonry, and when fastened with corners, it will interfere with the free movement of the wooden extension.

Therefore, it is better to use another option, which provides better insulation of the joint and adhesion of the extension to the house.

The working process

The process of building a brick veranda is a traumatic undertaking if you do not adhere to safety measures. Check the integrity of the tools, put on gloves. Masonry is carried out from floors or scaffolds, which are installed on a clean, flat surface. Prepare stepladders with a secure base and boards for transitions between recesses. If you have a helmet and mask, then it is better not to neglect them. Personal health is more important than mild inconvenience.

Pouring the foundation

The foundation is built on the same level as the housing

This is important, since otherwise you will need additional tightening tools. The brick veranda proposed in this instruction will be small; use a foundation made of pillars, since it is installed without reference to the foundation of the house:

- We dig holes 1 m deep, at the same level as the house.

- Crushed stone and sand are poured into the recess in layers.

- We pour the concrete base and insert brick support pillars. The top of the pillars should be equal to the height of the base of the house.

The first step is to pour the foundation.

If there is a need to build a long veranda, we build a strip foundation:

- Dig a trench.

- The formwork is installed a little higher than previously required.

- Pour the concrete. From time to time it needs to be moistened with water, otherwise cracks will appear.

This is useful: practical advice on pouring a foundation for a veranda.

Wall forcing

Before forcing out the walls, be sure to make sure that the base of the veranda is even. Waterproof the floor, after which you can begin laying out the walls:

- Stretch horizontal ropes along the base of the foundation. They are a kind of level for evenness of brick laying.

- Lay out the main brick course. There is insulation on it and then another row of bricks.

- Don't forget to measure and leave compartments for the door and windows. Install concrete lintels in them.

- When you reach the last brick row, stir the reinforced concrete belt. Install a metal mesh and fill it with concrete. The belt will prevent cracks from forming in the walls.

- Allow time for the belt to dry.

- Secure temporary roof rafters.

Correct roof

What material the roof will be built from is up to you to choose. But usually they choose the same one for the roof that was used for the house to which the veranda is attached

Please note that the process of constructing a roof can be simplified. Special coatings are sold in roll form in stores.

They are very easy to fix in any position.

Step by step process:

- Build a sheathing horizontally from wooden boards. Laying the boards depends entirely on the materials chosen. They are laid out either tightly or at intervals.

- Choose the angle of the cover. This is necessary for proper drainage of natural precipitation.

- Lay the rolls on the crate.

- Nail the rolls to the boards. To securely fix the rolls, unroll them carefully. Don't leave any uneven spots.

- At the edges, bend the roof over the sheathing by 10 cm.

- Secure the edges. If your rolled sheets are made of metal, then use nails specific for this.

- Don't forget to overlap the covering.

Window installation

Installing windows and doors is the final stage of building a brick veranda. Before you start work, remember that we fix all joints, as well as openings, tightly. The absence of drafts and drops of moisture on the veranda will depend on this.

Follow the following algorithm of actions:

- Consider what size your window frames will be. When choosing large frames, there may be problems with waterproofing and the passage of cold air flows from the street.

- To construct window sills, place the board in the window opening.

- Cover the lower space between the wooden board and the trim with clapboard or other convenient material.

- The frame is installed between the bottom board and the top of the garter.

As a decoration, you can carry out cosmetic finishing of the outer part of the gazebo. Twisted plants outside and landscaping the room inside will also have a good effect on the appearance of the extension.

Timber extension: walls

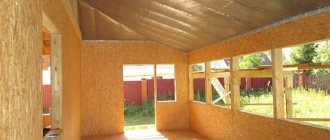

An extension made of timber has one common wall with the house, and the rest are made on the basis of a frame or without it. In the first option, the wooden frame is covered with OSB boards or boards, and insulation is pre-attached inside.

This option will be cheaper since the material is used only for making the frame. On the outside, a special cladding is used to imitate timber. You can cover the walls of your house with your own hands. To do this, you need to fix the sheathing on the facade, to which the external finishing is nailed.

If you want a house made of timber with a warm veranda, bathhouse or additional living space to look like a single whole, then choose a frameless assembly.

Project

The design of the extension can be left in the hands of professionals who previously helped with the design of the house. Or you can make a drawing and schematic design yourself. You can take options from the Internet as a basis, but you must take into account the peculiarities of building the house itself.

What

you should pay attention :

- purpose of the extension;

- passage of utility networks through the site;

- type of construction;

- type of material.

The most important thing is to decide on the purpose of the device . This can be not only a living space, but also a garage, veranda or porch.

The choice of material, its thickness, as well as other indicators depend on this factor. During the project, it is necessary to identify the laying of utility networks.

If they are located close to the house, then you need to think about how to construct the foundation so as not to damage the network. At this stage, you also need to consider whether communications will be supplied to the extension and in what way.

The type of construction can be of two types - frame or solid. When using timber, it is better to use a frame type of base. From here the material and its parameters will be selected.

Roof installation

The roof is installed using standard technology, taking into account the characteristics of the building materials used. The roof can be gable or single-pitch. In both cases, the rafter system is made simply: the sheathing is installed along the load-bearing elements, and then the roofing material is attached.

note

In order for a house made of timber to look harmonious, the roofing material must match or be identical to the roof covering of the main building.

Among modern materials there are the following popular varieties: soft roofing, ondulin (Euro slate), metal tiles (in the form of profiled metal plates imitating tiles).

The roof of the extension can be made separately or be shared with the house. The second option is carried out during the reconstruction process, when, for example, an attic room (bedroom, children's room) is built and the configuration and size of the roof of the old house is changed entirely. It is difficult to do such a volume with your own hands; it is better to hire professionals.

How we are working

Leave a request

We will contact you and give you a free consultation

We coordinate the departure

Our specialist will visit your site to make the necessary calculations and take measurements.

Commercial offer

Based on the data collected by a specialist, we prepare an estimate for you and send it for your approval.

We conclude an agreement

If you are satisfied with everything, we conclude an agreement and carry out all the necessary work.

All planned activities are carried out in accordance with the schedule, without delays - plumbing, electrical, connection of communications and other types of work are performed by our qualified specialists. The quality is confirmed by a guarantee certificate.

Contact us if you need a timber extension. There are no difficult tasks for us: a porch, a veranda, a garage, a second floor or a bathhouse - we will build any object.

Glazed verandas

A beautiful view can be obtained by constructing an extension using double-glazed windows. There are several ways you can go here. Firstly: you need to choose what kind of veranda will be - warm or cold. Secondly: whether the design will be framed or frameless. In addition, the glazing can be partial.

Modern solution - extension with frame glazing

For cold frame glazing of a veranda or terrace, it is better to use an aluminum profile. The plastic frame is more familiar, but less aesthetically pleasing. Cold glazing uses a single pane of glass. It cannot be used in the construction of a warm extension, since the resulting condensate will flow down during the cold season, which will lead to rotting and destruction of the structure.

The use of impact-resistant glass in construction will help protect against unforeseen incidents, and tinting will help hide it from view and the sun, as well as add originality.

This is all important because it determines whether the extension will be used all year round or seasonally. And, of course, the price will depend on the complexity of the design.

By cooperating with us you get

Guarantee of meeting deadlines

- Delivery of the project is always on time

- In case of delay, we incur a penalty of 3% per day

Transparent, fixed estimate

- No hidden extra work

- You pay only for what you need, and you choose what you need yourself!

Daily photo and video reports

- Work progress reports via WhatsApp or email

- You will be in the know, even if you cannot be present on site.