If a man has golden hands and likes to furnish the house at his own discretion, he must have a carpentry workshop at his disposal. Woodworking is a fun and creative activity. Wood is a pleasure to work with, and the workshop smells like a forest. Many interior items and furniture are made from wood, so there is always an object to make.

To equip a carpentry, you will need a lot of machines and hand tools. As you know, all this is expensive and not everyone has the opportunity to buy factory-made machines. Today, Reconomica introduces you to a young man who managed to equip his carpentry workshop by spending only 100 thousand rubles.

Features of working with wood

A carpentry workshop is a small room with special equipment where products from natural wood are made.

Before organizing work, it is recommended to find out what products are manufactured by competitors in your region and what is in greatest demand. This assessment makes it possible to select an assortment and calculate approximate income and costs. The easiest option is to start making wooden furniture or organize the production of decorative items right at home. The assortment will be small, but if you make original things, the customer base will quickly increase. The main factors that influence the success of a carpentry workshop are regular customers, the number of orders per month, and the originality of the products.

It is proposed to manufacture the following wood products:

- Furniture: kitchen tables, chairs, cabinets, shelves, furniture.

- Interior elements: balusters and steps for stairs, window and balcony frames, doors.

- Small ready-made buildings: garden gazebos, doghouses, fences.

- Bath furniture and items for the steam room: rollers, benches, steamers.

- Construction material: parquet boards, arched elements, decorative beams.

- Decorative elements: picture frames and mirrors, flower stands.

Beginners are advised to choose one or two areas and expand as the workshop grows.

The product has its target user: individuals; construction companies that deal with turnkey finishing of houses and apartments.

You can sell products in various ways:

- Wholesale sales for legal entities.

- Retail sales in own retail outlets or stores.

- Sales at annual fairs.

- Order and delivery of goods through the online store.

Beginning entrepreneurs are recommended to start with retail and wholesale sales through other entrepreneurs who have specialized or construction stores. Additionally, a group is launched on social networks, through which sales are also carried out.

In a month of work, a small carpentry workshop can produce 5 sets of wooden furniture for a total cost of 150-300 thousand rubles. The price of raw materials and labor costs will cost you 70 thousand rubles. Monthly net income is 100-150%.

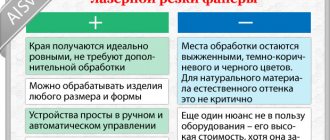

The pros and cons of the idea are as follows:

- Opening does not require huge investments.

- At first, you won’t need to hire a large staff of employees.

- You can even organize work in the garage.

- It's difficult to come up with your own original products.

- In large cities with numerous competitors, it is difficult to break through and exhibit your products in large construction centers.

- Wood is a capricious material, so only a professional can work with it.

What equipment is desirable to have when organizing the production of furniture from chipboard

In this case, the set of machines must include the following types.

Format-cutting

This equipment is intended for cutting slab and sheet materials. These format circular saws (this is what, technically correctly, the mentioned machine is called). The device ensures that cuts are made in the required direction (transverse, longitudinal). It is equipped with cutting (main) and scoring (additional) discs, which allows you to get an even cut edge in one pass. Allows you to cut at the desired angle and obtain beveled edges.

There are similar products from different brands on the market. But all such products have approximately equal performance.

The difference in price is determined by the brand, the length of the permissible stroke of the carriage, the presence of additional devices and units, and the ability to tilt the cutting tool.

When purchasing, you must choose a model whose stroke length is at least 10 cm greater than the maximum dimensions of materials supplied for cutting.

Increased productivity and adjustment accuracy is achieved by equipping the longitudinal ruler and transverse ruler stops with electronic actual position indicators.

Band saw vertical

The main advantage is the ability to make curved elements and the small area required for installation (very important for small businesses).

If necessary, you can replace machines of the mentioned type with models with a vertical table designed for cutting.

Edge banding

They are offered by manufacturers in manual and automatic versions. Used for applying edges made of various materials to panels.

The designs differ in the tasks they solve. Edges can be applied to: end, curved and straight panels. Such equipment ensures the formation of an edge with a thickness of (0.4-5.0) mm and a width of ≤10 mm. average feed speed in automatic mode, 5 mm/sec.

They are in demand when processing natural (paper, veneer) and synthetic (ABS, PVC, melamine) materials.

Edge trimming is carried out after cutting the workpiece on a format-cutting machine.

The type of machine is selected taking into account the range of furniture produced.

Drilling

Each manufactured product is assembled from several elements. therefore, they have holes for installing fittings and fasteners. This can be done as accurately as possible using multi-spindle (from 2 to 23, in the vertical plane, from 2 to 35, in the horizontal) drilling and filler machines.

Most models allow corner drilling. The required accuracy is ensured by pneumatic clamps with which the workpiece is fixed on the table. You can drill blind, through holes.

Copy-milling

This device ensures precise execution of panels and grooves within the contour of the workpiece. Allows you to produce complex elements of decorative finishing of facades and make shaped details. They differ from a conventional milling machine by the presence of a cutter with which the probe is synchronized. This allows you to produce the required number of parts according to the specified size and shape.

Choosing your concept

Where to start your business? At the first stage of organizing a business idea, you should not spread yourself thin and try to produce various interior items, furniture and building materials at the same time. Equipment costs at the first stage are small, so it is important to think through the specifics of your business in advance.

Today wooden furniture is in great demand. As an additional line, it is recommended to produce furniture and interior items for the bathhouse. The zest and originality of the products are important, and this will be easier to achieve if you choose a narrow focus.

Machines for working with wood are also selected depending on the specifics of the workshop. It is not recommended to buy an expensive universal line before the business reaches profitability.

Having chosen a line for your production, you should come up with an original name. The name should speak about the specifics of your wooden products. At the same time, the name should be easy to hear and well remembered. Example: in the city of Yoshkar-Ola, a carpentry workshop was opened for the manufacture of furniture and items for the bath with the name “Bath Things”. The buyer already knows from the name what the manufacturer does and what products can be purchased.

Whether it is profitable to start a business in a big city, where competition is great, also depends on the originality of the product. It is possible to produce products from a special type of wood, for example from bog oak. Since few people work with this type of wood, you will have your own clients, and you can make good money from them.

Business benefits

Own carpentry is a profitable business that has such advantages as:

- demand for manufactured products;

- annually growing demand for products;

- minimum investment at the start;

- stable and good income regardless of the season;

- several options for selling products;

- possibility of expanding the range and range of services.

The demand for custom-made wooden furniture, doors or windows is really growing every year. At the same time, the turnover and income of carpentry workshops increase. Therefore, it is already clear from the advantages that the decision to start such a business is the right one. But what and how much money do you need to start?

Register

To legalize a small carpentry workshop, an individual entrepreneur is initially registered. But in the future, when expanding, you will still have to register an LLC. The fact is that it is not profitable for large construction organizations to cooperate with individual entrepreneurs.

To register an individual entrepreneur, you will need to collect the following documents:

- Copies of passport and TIN certified by a notary.

- Application for registration of individual entrepreneurs.

- A receipt from the bank confirming your payment of the state duty.

A sample application for registration can be found at the tax office. The application shall indicate the code of the type of activity. The following OKVED codes are suitable for organizing a carpentry workshop:

- 31 “Manufacture of furniture from all materials except: stone, ceramics and granite” (general code).

- 31.02 “Making furniture for the kitchen.”

- 31.09.2 “Production of other types of furniture and parts” (the code is suitable for the manufacture of shields for radiators, wooden window sills, decorative interior items).

It is recommended to indicate the main activity code 31, and select the remaining two as additional ones. So, when expanding your business, you will not need to open an additional type of activity. When registering, additional types of activities are entered into the documentation free of charge; in the future, you will have to pay for each code.

Immediately after registration, the entrepreneur is automatically placed on the unified tax system (UTII). But for a beginning carpentry workshop, it is more profitable to switch to a simplified system (income minus expenses), since you should not expect much revenue in the first year.

Paperwork

To register a company, you should contact the tax service at the location of the legal address of the object.

Package of documents for registration of individual entrepreneur:

- passport - original and a copy of all pages;

- TIN - if available;

- written application of the established form P21001;

- check for transfer of duty - 800 rubles;

- tax form statement.

Documents for LLC:

- application for registration, sample P11001;

- passports of those who will become founders, plus copies of all pages;

- fee payment receipt;

- minutes of the founders' meeting. If the founder is one person - his decision to form an LLC;

- articles of association;

- application for the tax form chosen by the founder.

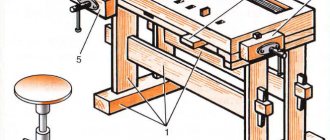

How to choose a place

To organize a small carpentry workshop, it is enough to rent or own a garage or basement. By owning a garage, you can save 15 thousand rubles on rent per month. When making decorative elements from wood, you can organize a carpentry business at home, since expensive and massive equipment is not needed.

The premises requirements are as follows:

- Area size – at least 50 sq. m (craftsmen must move freely between machines, plus there must be a small area left for placing raw materials).

- The length of the workshop is at least 4 m, since some machines are 2-3 m long.

- To prevent finished products and raw materials from being deformed, the temperature inside the workshop is maintained in the range of 15-18 degrees.

- Humidity - no higher than 35% (therefore, if a carpentry workshop is located in a semi-basement, then daily humidity measurements must be taken, because wood absorbs moisture well from the air and just as easily releases it; therefore, with sudden changes in humidity, the wood cracks, and the raw materials can twist due to for internal stress).

- The room should be well lit (if there is daylight, you will save on energy bills).

- The workshop must have access to electricity (380 V and 220 V sockets); for this purpose, an agreement is concluded with the local energy supply company and a three-phase line is installed; the price of the project and installation will be from 70 thousand rubles.

- Equipped with an extractor hood.

A small area in the premises must be equipped for workers: changing lockers are installed; if there is no sewerage system, a dry closet is installed. You also need to ensure the availability of drinking water for employees.

It is important to follow fire safety rules. Therefore, there should be an emergency exit in the room, and a shield with a fire extinguisher, a shovel and a bucket should be placed on the wall. A small box of sand is placed below.

Electric jigsaw

A tool for sawing wood along a guide or along a width due to the reciprocating movement of the saw blade. There are dozens of models of jigsaws, it is difficult for an untrained user to choose a tool, so let’s listen to the master.

Stanislav Stadnichenko: – The jigsaw is very insidious, it’s the easiest thing for them to ruin a thing. I do not recommend saving on equipment and buying files made by Leroy, Castoram or Obi. Branded items, for example, Bosch, work longer than others, more efficiently, and of better quality. And if you want to minimize mistakes at first, start learning carpentry under the guidance of practicing masters.

The expert's choice is the Bosch PST 650 jigsaw. Indispensable for straight and shaped cuts. Advantages: low vibration system; durable metal sole with adjustable angle of inclination made of aluminum alloy; the ability to blow away sawdust during the process, which improves visibility of the working area.

The weight of the model is 1.6 kg, and the ergonomic handle with a soft anti-slip pad allows you to control it as precisely as possible during operation.

A high-quality tool saves time, increases productivity, and protects the craftsman’s mood. When choosing a jigsaw, remember the Russian proverb - “The miser pays twice.”

Equipment for your production

To save initial capital, you can try to assemble some of the equipment yourself using ready-made drawings from the Internet. The rest of the equipment is purchased according to the estimate, which is described in detail in the business plan. You should not purchase equipment at a low price or used. The reputation of your small production and turnover will depend on the quality and productivity of machines and tools.

To equip a small carpentry workshop, the following equipment is purchased:

- Lathe – 1 pc.

- Vice – 2 pcs.

- Circular or miter saw – 1 pc.

- Planer – 2 pcs.

- Thickness gauge - 2 pcs.

- Electric drill – 2 pcs.

- Milling cutter – 1 pc.

- Jigsaw – 2 pcs.

- Electric planer – 2 pcs.

- Grinding machine – 2 pcs.

- Hand tools (screwdrivers, hammers, saws, pliers, etc.).

- Roulette – 2 pcs.

- Vernier calipers – 2 pcs.

- Moisture meter – 1 pc.

- Spray bottle for applying paint and varnish coating and antiseptic – 1 pc.

On average, you will need to spend 350-400 thousand rubles on manual, power tools and machine tools. The proposed list is designed for 2 carpenters, but if more workers are planned in the workshop, then the number of tools increases. More detailed step-by-step instructions with prices and calculations are presented in the business plan.

Additionally, equipment costs include the purchase and installation of two carpenter's tables, a locker for workers' clothes, and several chairs. This is about another 50 thousand rubles.

Consumables are purchased monthly for work: wood (timber or board), oil, brushes, paints and varnishes, fasteners, belts for sanding machines, wood glue. Costs are at least 25 thousand rubles. The profitability of the workshop is 20-22%. You will have to invest at least 550 thousand rubles in the business. The payback period for a small business with low turnover is 10-12 months.

A circular saw

Without a circular saw in the workshop it’s like being without hands.

At first, I combined a workbench with a construction circular saw. I bought a hand-held circular saw from the store and mounted it underneath the table. I used a building rule as a guide, which I clamped at both ends with clamps. A very convenient duo. Due to its design, the saw can be completely hidden down without removing it from the table. In just a minute the table turns into a workbench.

If you follow my example, then make the tabletop from thick laminated plywood. It will create the necessary rigidity and weight for the workbench.

If the workshop is located in the garage, then the table will have to be rearranged often. Together with the saw, the structure will have a decent weight, so it is better to provide folding wheels for the table legs.

We select personnel

A business idea in the form of a carpentry workshop can only be implemented by a knowledgeable person who is capable of performing some types of work himself and understands woodworking. Therefore, you won’t need many employees at first.

To complete the staff you will need:

- Carpenters – 2 people.

- Worker for painting and impregnation of blanks and finished products – 1 person.

- The controller who will check the quality of products and perform a managerial role is 1 person.

- Cleaning lady – 1 person.

The workshop will be open during the day from 10:00 to 19:00. Weekends – Saturday and Sunday. Carpenters can work in pairs or in shifts of 1/1, 2/2 or 3/3. It is worth agreeing with the cleaning lady to work in the evening, for 2 hours.

The project organizer assumes management functions. He also controls each process and checks the quality of blanks and finished products. Employees are paid by the piece - 10-15% of each finished product. But you can offer a salary system. It is less beneficial for this project, since craftsmen need motivation to work.

The cleaning lady is paid once a month with a strictly established salary. Incentive bonuses or rewards are possible at the owner's discretion.

Four-axis milling machines equipped with CNC

They differ from the models discussed above in the presence of an additional rotary axis, or with the implemented ability to move the spindle fixed to the portal along the Y axis.

The first option provides for the presence of a rotary axis, the design of which includes heads with a cylindrical tip and a clamping chuck connected to the motor (provides rotation of the workpiece). The headstocks are able to move in space, providing adjustment of the distances between structural elements.

The second involves placing the 4th axis directly on the spindle (it is the spindle that is deflected to process the workpiece at the required angles). Disadvantage: the angle is ≤90°.

For those who plan to seriously engage in furniture production, we recommend the M1 1325 RD model from the Wattsan line, which has unique performance characteristics:

- The dimensions of the workspace are 2500*1300, which will allow the production of furniture of any size;

- the two-phase motor has a long service life;

- the weight of the machine exceeds 1000 kg, which reliably compensates for any vibrations;

- the frame is made of a welded reinforced profile and will serve the owner for a long time in any operating mode;

- This model allows long-term continuous operation, thanks to the built-in water cooling system.

Promotion and promotion

To promote the workshop, the pricing policy and product range of competitors are analyzed. You must offer wholesale and retail customers better prices and better quality with less loss for yourself.

The following advertising options are offered:

- Social media. The group displays a catalog of finished products with prices. The group is promoting itself and attracting potential buyers from your and neighboring regions. Every 10th user can become a regular customer, but for this you need to interest the person. Therefore, it is better to entrust the promotion of the group and its promotion to specialists.

- Printing of color catalogs and price lists of your products. Catalogs are distributed to hardware stores and companies that provide turnkey finishing.

- An advertisement in a periodical in your region with a small photo of the most attractive set or product.

- Wholesale customers are provided with a discount card or bonus program.

In a few months, your products will be noticed and interested wholesale buyers will appear.

What is needed to open a carpentry

To start such a business you need to be a good carpenter yourself or find such a specialist. The workshop must be properly organized:

- a separate place for storing materials and products;

- availability of the necessary equipment;

- comfortable workplaces for craftsmen;

- high-quality lighting;

- and etc.

You also need to understand that even with high demand for products, immediate profits should not be expected. All investments will pay off no earlier than in 8-10 months.

Moreover, you need to know that a carpentry workshop is a business with a minimum profitability of 25% to 35%. To destroy such a business you need to try hard. Therefore, you should not be afraid of bankruptcy or working at a loss.

There are 6 steps to start this business.

Step 1. Registering a business with the tax office.

Step 2. Search and rent space for a workshop.

Step 3. Purchase of tools and equipment.

Step 4. Purchasing materials.

Step 5. Organizing an advertising campaign.

Step 6. Search for buyers of manufactured products.

All the steps presented are a short version of the main points of the business plan. Let's look at each in detail.

Eventually

Opening a carpentry workshop begins with analyzing the market in your region and choosing your original and popular wood products. You will need a small room, a garage or semi-basement with an area of 40 square meters will do. m. 3 people are hired for the work. The biggest expenses are renting the premises and equipping them.

When registering at the initial stage, it is enough to open an individual entrepreneur. You will have to invest at least 550 thousand rubles in the business. A small business will pay for itself in 11 months, but if there are a lot of clients, then in 6-7 months. Wooden products are expensive, but will never lose their relevance. Therefore, the business will only expand and bring more and more profit to its owner.

What kind of room is needed for a carpentry shop?

To organize a carpentry shop, you can use a garage, an unused workshop at an existing enterprise, or a hangar. You can build a workshop on your own site or adapt outbuildings for this. The layout of the carpentry workshop should be thoughtful so as not to clutter up the passages, not to carry objects around unnecessarily, and not to create a pile-up of tools, raw materials or finished products.

The workshop premises should have:

- heating - it is necessary to maintain the air temperature at about 20 ° C, air humidity at 35%;

- lighting – artificial and natural;

- three-phase electricity;

- water supply, sewerage;

- fire retardant treatment of ceilings and walls;

- fire extinguishing means (4.5 kg fire extinguisher, box of sand).

Material selection

Before you start making furniture, you need to decide on the raw materials to be used. Let's look at which breeds are the most popular and what they are used for:

- Deciduous:

- Oak – massive furniture.

- Alder is light and elegant furniture.

- Beech – bent products, stairs.

- Ash – for interior decoration and carving.

- Walnut is predominantly expensive furniture.

- Maple - veneer.

- Conifers:

- Pine – window frames, door panels.

- Spruce – doors with good thermal insulation.

- Exotic wood species:

- Red – decor, musical instruments.

- Black – used for small items, such as boxes. Furniture made from this type is the most expensive.

Lamellar routers

The best tool for creating a flat, even surface on one side of a board is a router. Perhaps this is also the best tool for processing a second surface strictly perpendicular to the first. There are lamellar cutters of various shapes and sizes. But they all perform the same functions.

We also recommend reading: Details about the lamellar router

Description of services

The range of manufactured products can be quite wide. In cases where an entrepreneur is just starting his activities and the implementation of a business plan for a carpentry workshop is his first project, then it is best to choose one direction. After the business develops and makes a profit, it will be possible to expand the staff and choose a second activity in parallel:

- The manufacture of doors and windows is constantly in demand. Undoubtedly, wooden window frames are fading into the background with the advent of PVC windows, but wooden doors are gaining popularity. Wood material is still valued.

- Making kitchen utensils. This option has a lot of variety. You can make cutting boards, bread bins, rolling pins, coasters, trays, cutlery and much more. These products are valuable, but have a low cost; if produced in large volumes, you can make a good profit.

- Production of souvenirs. This includes magnets, amulets, key rings, and boxes.

- Making furniture - chairs, beds, chests of drawers, cabinets, tables.

- production of desktop and educational toys. If the finished product is coated with varnish or paint, the cost will drop significantly. This is due to the fact that many parents choose environmentally friendly materials for their children. But it is worth considering that if toys are made for children, then they must be perfectly smooth and you will definitely need to obtain a quality certificate for all products.

When implementing a business plan for a carpentry workshop, you should understand that it is quite difficult to compete with large furniture factories. Therefore, producing identical furniture is not the best option. The bet should be placed on exclusive products that are produced in single copies. In this case, you can show all your creative talents. But do not forget to analyze the market, as it often happens that it is difficult to find buyers.