Synopsis of a technology lesson in grade 5 “Species of wood, parts of wood. Types of lumber"

Bolotnikov Sergey

Synopsis of a technology lesson in grade 5 “Species of wood, parts of wood. Types of lumber"

Lesson summary 5th grade

Types of wood, parts of wood. Types of lumber.

Goal: to familiarize students with the importance of wood as a structural material in the national economy of the country, its species, structure, main types of defects and uses, to teach how to identify wood species and types of defects by the appearance of samples.

Tools and equipment: sets of samples of lumber, veneer, plywood, samples of wood with defects, instructional and technological cards.

During the classes:

I. Introductory part.

1. Consolidation of the material covered.

Repetition of covered material.

Questions:

1. The wedge should protrude above the table top to a height less than the height. (blanks)

2. What is the name of the discipline we are studying? (Technology)

3. The base of the workbench is (underbench)

4. It can be cutting and measuring. (Tool)

5. The profession of a worker engaged in manual wood processing. (Carpenter)

6. Serves to secure workpieces. (Clamp)

7. Wooden blocks intended for supporting workpieces (Wedges)

2. Communicate the purpose of the lesson

I. Presentation of new material.

Forests occupy an area of over 700 million hectares in our country. Despite such enormous forest wealth, everyone must treat the forest with care, as it significantly affects the climate, flora and fauna. In addition, the forest is of great economic importance. Its main product - wood - is used in construction, furniture, match production, chemical industry, etc. Forest resources in our country are protected by law.

- Let's compare the properties of wood and materials such as metal and stone.

We come to the conclusion that wood is a light, durable material that can be easily processed with cutting tools and has a beautiful appearance.

At the same time, wood also has negative qualities: easy flammability, warping when dried, rotting.

— What tree species do you know and what types are they divided into?

Deciduous and coniferous.

Trees with foliage are called deciduous, and those with needles are called coniferous. Deciduous trees include birch, aspen, oak, alder, linden, etc.; Conifers - pine, spruce, cedar, fir, etc.

- What does a tree consist of?

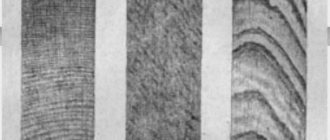

From a trunk, root, twigs, leaves or needles. Wood as a natural structural material is obtained from tree trunks by sawing them into pieces. Rice. 3

The tree trunk has a thicker part at the base and a thinner part at the top. The surface of the trunk (Fig. 3) is covered with bark (7). The bark is the “clothing” for a tree; it consists of an outer cork layer and an inner bast layer. The cork layer of bark is dead. The bast layer (6) is a conductor of the juices that nourish the tree. The wood of the trunk consists of many layers, which are visible in the section as growth rings (4).

- What can you learn from them?

You can determine the age of the tree. The loose and soft center of the tree is the pith (1). Heart-shaped rays extend from the core to the bark in the form of light shiny lines (2). They serve to conduct water, air and nutrients inside the tree. Cambium (5) is a thin layer of living cells located between the bark and wood. Only as a result of the activity of the cambium does the formation of new cells occur. “Cambium” comes from the Latin “exchange” (nutrients).

To study the structure of wood, three main sections of the trunk are distinguished (Fig. 4). Section (1, passing perpendicular to the core of the trunk, is called end. It is perpendicular to the growth rings and fibers. Section (2, passing through the core of the trunk, is called radial. It is parallel to the growth layers and fibers. Tangential section (3) runs parallel to the core of the trunk and is removed from her at some distance.

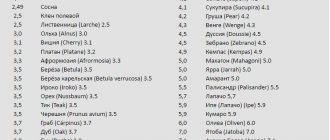

Wood species are determined by their following characteristic features: texture, smell, hardness, color. (Show how to identify wood types using the poster.)

The disadvantages of wood are also defects: knots (Fig. 5p, wormholes (Fig. 5.6). They limit the use of wood in industrial production, but can be valuable in the manufacture of decorative products.

Rice. 5

Let's move on to considering lumber and wood materials.

When longitudinally sawing tree trunks on sawmill frames, various lumber is obtained (Fig. 6): beams (a, b, bars (c, boards (d, e), plates (e, quarters (g) and slabs (h)

Rice. 6

Lumber has the following elements: layer, edge, end, edge.

(Indicate on the poster. Plywood is widely used as a construction material.)

- How do you get it?

By gluing three or more thin sheets of wood - veneer - onto each other. Veneer means “sliver” in German. The veneer is cut (peeled) with a sharp knife of a special peeling machine while rotating a log about 2.0 m long (Fig. 7). In this case, the log, like a roll, is rolled out into a veneer strip. The veneer strip is cut into square sheets, which are dried in dryers, coated with glue and laid on top of each other so that the direction of the fibers in them is perpendicular to each other. The sheets are glued together under a press. This is how you get plywood.

Plywood is stronger than wood, almost does not dry out or crack, and bends and processes well.

—Where is it used?

In construction, furniture manufacturing, mechanical engineering, aircraft manufacturing.

— You’ve probably heard the word chipboard, but what does it mean?

Particle boards. They are obtained by pressing and gluing crushed wood in the form of shavings, sawdust, and wood dust. The slabs are made with a thickness of about 10-26 mm. They are durable, almost do not warp, and can be processed well with cutting tools.

-What are they made from?

Furniture, doors, partitions, walls, floors. However, over time they release substances harmful to health, so they are not recommended for use in residential areas.

— What is fiberboard?

Fiberboards. They are pressed into sheets of wood pulp that has been steamed and crushed into individual fibers. They have a pleasant gray color, smooth surfaces, and bend, like plywood. They are used for interior decoration: cladding walls, ceilings, floors, in the production of furniture and doors.

— What is the common disadvantage of plywood, chipboard and fiberboard?

They are afraid of dampness.

Sh. Practical part

1. Students cut a block of soft wood (pine, linden) along and across the grain with a regular knife. As a result of this operation, they come to the conclusion that wood is easily split along the grain with little effort, but it is impossible to split across it, even with great effort.

2. Students try to identify wood types from samples, look at samples of lumber, plywood, chipboard and fiberboard.

Check whether the samples can be easily processed with any tool (file, hacksaw, etc.).

IV. Final part .

Summarize the lesson, note the most active students during the discussion of the material.

Clean the workshop.

Wood processing technology

Spruce.

(Slide 6) In terms of production and processing volumes, spruce wood ranks second after pine. But the quality of the wood is lower in terms of such indicators as product strength and the presence of knots. Otherwise, spruce is a complete substitute for pine. The advantages of spruce wood include: absence of odor, the presence of mostly small knots, less tendency of the wood to turn blue, the same color of sapwood and mature wood - close to white.

Larch.(

Slide 7) It grows mainly beyond the Urals and is used less frequently than pine and spruce: Products made from larch are very durable and serve reliably in conditions of variable humidity. Larch wood is distinguished by very low knots - even small knots cannot be found on a significant part of the lumber. Larch wood is straight-grained, it is heavier than pine and has a higher resistance to impact loads. It pricks easily. It is more difficult to process larch wood than pine wood - it is resinous; lumber is dried under soft conditions. Effectively used in structures where high resistance to decay is required. Products made from larch look very impressive, so they are often finished with transparent materials.

Cedar.(

Slide 8) Cedar wood is distinguished by its resistance to rotting. The wood is pinkish-white in the sapwood and brown in the heartwood. It is close in strength to spruce and fir. The annual layers are almost invisible, so the wood cuts smoothly in all directions and is very easy to process. Cedar is widely used for the production of furniture, pencils, and battery veneer is made from it.

Hardwood

. The economic importance of deciduous trees is reduced by two factors: smaller reserves compared to coniferous trees and the tendency of wood to rot in atmospheric conditions. On the other hand, the variety of other properties, including the richness of texture, and the strength characteristics of many hardwoods make them irreplaceable.

Oak.

(Slide 9) The wood is hard, has few knots, is characterized by high strength, rot resistance, and relative straightness. The oak has a beautiful texture in all cuts. Widely used in furniture production (often in the form of sliced veneer). Suitable for painting, finishing with varnishes and mastics. Parts and entire products are often made from oak in the plywood-planing and parquet industries, in the production of riveting, mechanical engineering, and construction. The color of the wood is light brown in different shades. The material is heavy, but, nevertheless, it is well processed, bent and polished.

Birch.

(Slide 10). Birch wood is white with a reddish tint, the annual layers are hardly noticeable. It is characterized by density and high strength, especially under shock loads. Weight and hardness are average. Low resistance to rotting at variable humidity. It is well processed, planed, bent and polished. Has significant resistance to splitting. Birch wood is used to produce peeled veneer and plywood. The high density of wood determines birch as a valuable material in ornamental and turning works, and in the manufacture of furniture. It imitates valuable species well and is easy to paint and polish. Birch is dried under soft conditions, since often as a result of drying, lumber warps in areas with the inclusion of a false core. Before drying, it is recommended to keep birch lumber until it is air-dry. Birch is used widely: it can be seen in building structures, furniture, containers and parquet are made from it.

Topic: Wood and timber

Wood and wood 5 classes.

Item:

Technology

Topic:

Wood and timber

Section:

Woodworking

Class:

5

Textbook:

Simonenko V.D. Textbook on technology. 5 grades Option for boys. M., Ventana-graf, 2013

The topic of our lesson today is “Tree and Timber”

.

Today in class we will study:

· Wood texture and its use.

· Main wood species and features of processing of these species.

· Use of wood in the national economy.

We will also learn in practice to determine the species and defects of wood, and to use this material economically.

Wood

- it is a natural material... (list the positive properties of wood).

TRADE wood is the wood of the trunk

Texture is a pattern on wood obtained by longitudinal sawing.

The growth rings blend into lines to create texture.

Wood species are distinguished according to the following characteristics: - color; - smell; - texture; - hardness;

The following types of wood are distinguished:

- deciduous - coniferous

Here are the main tree species that you will work directly with in school workshops...

Laboratory and practical work:

Make a table and fill in the main characteristics of tree species.

| № | BREED | COLOR | TEXTURE | PROPERTIES | APPLICATION AREA |

| 1. | Pine | ||||

| 2. | Spruce | ||||

| 3. | Alder | ||||

| 4. | Aspen | ||||

| 5. | Linden | ||||

| 6. | Birch | ||||

| 7. | Maple | ||||

| 8. | Oak |

Characteristics of tree species

| № | BREED | COLOR | TEXTURE | PROPERTIES | APPLICATION AREA |

| 1. | Pine | Reddish | Soft, resinous | cuts well | Windows, doors, floors, drawers |

| 2. | Spruce | White, with a yellowish tint | Soft. Knotty. | Don't warp. | Musical instruments, construction parts. |

| 3. | Alder | Red, dark | Soft | easy to cut | Plywood, furniture, packaging. |

| 4. | Aspen | White, with a greenish tint. | Very soft. | Easy to process. | Production of matches, boxes, toys, packaging shavings. |

| 5. | Linden | White, with a pink tint. | Very soft, light | easy to cut. | Pencil making, wood carving material |

| 6. | Birch | White with a brownish tint. | Solid, elastic, uniform. | Easy to process | Production of plywood, furniture, chipboard, fiberboard. |

| 7. | Maple | Red-brown. | Hard | well processed, decorative. | Furniture, dishes, decorations, veneer |

| 8. | Oak | Brown, dark. | Very hard | easy to process | Manufacturing of parquet, furniture, decorations. |

You can see the use of wood in the national economy and the stages of its processing in the video: the use of wood in the national economy

Internet sources:

https://castle.pri.ee/?page_id=885

https://rutube.ru/video/6b1acaa5eb68bfe6daefb926a1f4327f

Abstract on technology on the topic “Working with wood” (grade 5)

Notes (5th grade)

Topic: Operations and techniques for planing wood in the manufacture of products.

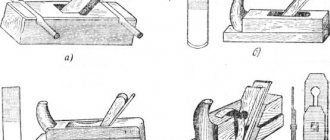

Wood planing-

This is the cutting of chips in order to process the workpiece to the desired shape, size and create even and smooth surfaces on it. (Planed boards, bars, slats).

The workpieces are planed with special planing tools - planers.

Sherhebel

They perform primary, rougher planing of surfaces, and

use a plane for

final, finishing.

Jointer

much longer than a plane. It produces smooth, flat surfaces on long workpieces.

Topic: Operations and techniques for drilling holes in wood.

The technology for joining wood parts involves making holes in them.

Holes

in details they can be

through and non-through (deaf).

Through-

passes through the entire part;

Deaf -

does not come out, but is performed to a certain depth.

Drill holes with various drills.

Screw, center and spoon holes are used to make holes in wood.

drill.

Topic: Joining wood parts with nails, screws and glue.

Parts in wood products can be joined together with nails, screws or glue.

Nail-

This is a fastener consisting of a cap, a rod and a point. Depending on their purpose, they come in different sizes.

Screw-

This is a fastener consisting of a head and a rod with a screw thread. They come in different lengths and thicknesses, as well as with different head shapes.

The screw heads have slots -

straight or cross-shaped grooves on the head for screwing in or unscrewing screws with a screwdriver.

Many wood parts are joined with glue.

Adhesives

There are

natural (natural) and synthetic (artificial).

Synthetic

have become more widespread and are produced ready for use. (PVA glue is a viscous white liquid).

From natural

glues used in school workshops

are casein and carpentry.

Topic: Finishing products, sawing with a jigsaw, burning, stripping and varnishing.

Jigsaw-

This is a hand tool with a replaceable tensioned narrow file.

For sawing with a jigsaw, a special sawing table is attached to the rear clamp of the workbench .

After cutting out the inner contour, the file is unfastened and removed.

The cut out areas are cleaned with sandpaper or needle files -

small files with a fine notch.

Burning-

This is one of the types of decorative finishing of the wood surface.

The design is applied to the product using an electric burner.

The surfaces of wooden parts, when making them clean, smooth and even, are cleaned with files, sandpaper or sandpaper.

Rasp-

a file with a large notch for rough cleaning.

It is convenient to clean the products with a wooden sanding block,

covered with

sandpaper -

a sheet of paper or a piece of fabric with grains of hard minerals glued to the surface.

Varnishing-

This is one of the ways to finish finished products.