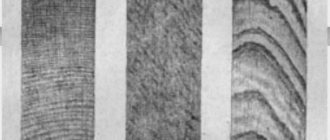

A knot is a defect or defect in wood that determines the grade of the product. It represents the part of the branch enclosed in the trunk. It has its own system of annual layers and cellular structure, which is directed towards the surrounding fibers at a certain angle. They are darker in color than the trunk and branches. Such defects are characteristic of every wood. The more such defects, the lower the grade and value of the tree.

Effect of defect on wood

The effect of defects on the quality of wood depends on the type and size, quantity and location of the defect. In addition, it depends on the type, purpose and size of the lumber. Small fused or healthy knots cause the least harm. Decayed defects do not pose a danger to coniferous and deciduous species if storage conditions and wood processing technologies are observed. Knot rot does not spread to the trunk and branches.

In general, knots reduce the strength of the growing areas of tree branches. In addition, they reduce the hardness of lumber during stretching and bending along the grain. Such defects are characterized by increased hardness, which complicates the processing and finishing of the product and increases the consumption of raw materials. In addition, they violate the homogeneity and integrity of the product.

But at the same time, knots increase strength during longitudinal chipping and transverse compression. Therefore, such wood is suitable for use as finishing materials. Such products are characterized by an aesthetic and elegant texture, which is achieved through “eyes”, and a unique decorative effect. Knotty wood is suitable for furniture and interior decoration. How and with what to decorate the inside of a wooden house, read the article on the blog “MariSrub”.

Secure the knots where they are located.

Before you start machining the wood, block the free movement of the knot, fill cracks and voids with 5 minutes of epoxy glue. When the epoxy dries, it forms a transparent layer in the gaps and crevices, so the knot retains its natural appearance and acquires hardness for subsequent processing. Using a non-epoxy adhesive will create white opaque circles or create a different color around the knot, indicating that it is not natural rings. Here are two approaches to fixing loose and loose knots.

[/column-group] [/column-group]

Types of vices

- Oval, round and oblong shape;

- Based on their appearance, open and overgrown knots are distinguished. In the first case, they come to the surface of the log. In the second, marks are left on the surface of the product, including stains, blisters or edges;

- According to the fusion of the defect with the wood, they distinguish between fused (if more than 3⁄4 of the perimeter of the knot cut has fused), partially fused at 1⁄4-3⁄4 of the cut, unfused (up to 1⁄4 of the perimeter) and falling out non-fused, which do not adhere to the tree;

- There are five types based on location. Edge defects extend to the edge, face defects to the layer, end defects to the end, edge defects to the edge. Stitched knots extend onto two edges of the same side;

- Depending on their location relative to each other, defects can be single or scattered, grouped or branched. In addition, they can be located on the same length of the product, exceeding the width of the material;

- According to the method of exit, defects are classified as one-sided, when they appear on one or two adjacent sides, or through, which pass through the wood;

- Based on the condition of the wood, they are distinguished between healthy, light and dark healthy, healthy with cracked knots, defects with decay and rotten defects. Tobacco knots are completely rotten and loose wood that is easy to grind into powder.

Types of wood knots

a) Fused knots can be healthy and horny. A healthy knot has no signs of rot; its color is somewhat darker than the wood surrounding it, which is explained by the fine-layered nature of the knot and the different direction of the annual layers in its cross-section. Healthy knots, completely fused with the wood, do not fall out, since their annual layers and the layers of the trunk are firmly connected to each other. The horny knot has healthy wood; richly impregnated with resin, tannins or other substances; the color is much darker than the surrounding wood, and usually has increased hardness.

b) Unfused knots form holes or rotten areas in timber that weaken the wood. These knots are divided into falling out hard, black tar and loose. A falling out solid knot in sawn timber and plywood is solid wood and is not directly connected to the annual layers of the trunk and can easily fall out when the wood dries. A black resin knot is a black resinous mass that partially or completely fills a rotted knot; Such knots are found only in coniferous species.

A knot is called loose, the wood of which has completely lost its original structure and has softened to a significant extent.

Depending on the position in the tree trunk and the plane of the cut when sawing, knots can emerge on the surface of the lumber in the form of a circle, an oval, or a tire. In sawn timber there are stitched knots that look like strips wedging towards the core. Usually the end of such a knot extends to the edge of the board or beam.

In lumber of deciduous and coniferous species, especially pine, there are so-called clawed knots that appear on the surface of the board in the form of two symmetrically located strips or highly elongated ovals that wedge towards the core.

In sawn materials, the size of a knot is taken to be the distance between two tangents to the contour of the knot. The size of a knot extending onto the edge of the edge of the board is determined by the distance between the tangent to the contour of the knot and the edge of the edge. The size of the knot is expressed in millimeters or in fractions of the width or thickness of the lumber.

In lumber, a distinction is made between through knots, i.e., those extending onto both opposite planes, and non-through (one-sided) knots, extending onto only one plane.

Use of wood with knots

It is not recommended to use knotty wood for the manufacture of small carved elements and carvings with flat or three-dimensional relief. In this case, the defect is clearly visible. However, the texture of some knots and the pattern of wood weaves look original, elegant and picturesque. Such raw materials are suitable for the manufacture of finishing materials that will organically fit into the interior of a wooden country house.

Overgrown and old knots with curls around them are suitable for creating thin curved carved elements. To build a house or bathhouse, choose high-quality, selected wood with healthy, light-colored knots of short length. The lower part of the trunk, where the minimum number of defects is observed, is suitable for this.

Fused knots with a diameter of up to 10 mm are allowed, as they do not have a negative effect on the strength and hardness of the wood. Defects with a diameter of 10-25 mm are allowed in the amount of three to four pieces per linear meter of lumber.

For high-quality lumber, you cannot use products with tobacco and unjoined falling knots! Such defects are allowed for materials of the second and third categories (grades B and C) in an amount of up to four pieces per 1 m2 for each wood, except for birch, beech and alder.

Lumber for building a house

High-quality lumber for construction and finishing must have a yellow or light yellow color, be free of wormholes and rot, mechanical damage and manufacturing defects, without resin pockets and large knots.

A smooth and even knot-free side is characteristic of profiled timber and rounded logs, since such lumber undergoes careful machine processing and is properly dried.

Modern logs and beams, lining and various finishing materials are necessarily treated with protective materials to prevent rotting and mold formation, and to preserve the color and original properties of the wood for a long time.

The MariSrub company constructs wooden houses only from durable and reliable lumber. We produce logs and beams ourselves, carefully select the wood and control every stage of production. We comply with GOST requirements! Our own production guarantees high quality lumber and low prices. You don't need to overpay intermediaries!

When manufacturing lumber, we use condensation drying and treatment with protective agents. This prevents rotting and drying out of the wood, reduces the formation of cracks and reduces the number of manufacturing defects to zero. We antisepticize the already assembled log house and carry out the procedure while finishing the house.

We carry out a full range of works on the construction and finishing of wooden houses made of timber or logs. The turnkey offer includes individual design or modification of an already completed project, production of lumber and installation of a log house. We offer installation of foundation and roofing, protective treatment and insulation of the house, exterior and interior finishing, connection of utility networks.

Defects of wood and wood - growths, knots

In order to avoid further unnecessary losses in labor and material, if the material we use does not meet the standards in such indicators as trunk structure, appearance and shape, physical condition and absence of injuries, we will study the types of damage to wood, or, in other words, vices. Deviations from these standards occur during tree growth due to unfavorable climatic conditions, mechanical damage and, ultimately, natural aging. Knowledge of the defects of wood allows the master not only to successfully combat them, but also to turn them to his advantage.

The main defects of the trunk shape are: camber, curvature, rumpiness, swarms, growths.

Tapering is an excess of the norm for reducing the thickness (camber) of the trunk as it moves away from the butt. The trunk slope rate is 1 centimeter per 1 meter of length. With a larger run-off, unreasonably large waste occurs during the preparation of lumber

Curvature is the curvature of the trunk along the axis of the tree. If the trunk has one bend, the curvature is simple, if there are several and in different places, then it is complex. The presence of curvature in round timber makes it difficult to use for sawing, because increases the amount of waste. In individual work, craftsmen use crooked wood creatively. They have no waste - everything goes into use: for fences, fences, tools and equipment, furniture and dishes, for various decorative ideas. And for some products or structures, only crooked wood or wood with some other defect is required.

Buttiness is a strong thickening or increase in the diameter of a tree trunk in its butt (root) part in relation to the rest of the trunk. The roughness leads to a large amount of waste when sawing this part of the trunk into boards. Lumber obtained from burred wood is of low quality due to the presence in the wood of a large number of boards cut, running obliquely, and dragged, but in the manufacture of furniture, dishes, decorative items and sometimes in construction, burred wood, on the contrary, leads to the use of wood with minimal losses.

Swarms are a defect organically associated with the presence of root-hole, namely longitudinal depressions in the butt part of the trunk. As mentioned above, in cross section such a trunk has a grooved-ribbed outline, where the grooves are these very swarms. In another way, this cross-section of the trunk is also called star-shaped.

The growth rings, following the outlines of the trunk, create an interesting wavy, incomparable pattern. When sorting trunks for cutting into boards, part of the trunk, starting from the place where the groove begins to appear, is rejected due to the predisposition of lumber made from this part to warping and reduced strength compared to the rest. This defect is quite successfully used in the manufacture of such household items as, for example, sculptures-pots, a resting corner in the form of a table and several chairs that imitate the setting of the fairy tale “Masha and the Bear”, a shelf or a cascade system of shelves for flowers, a wall panel in the form a set of cross cuts of different thicknesses, an original lamp or, finally, a decorative bench wall, etc.

Growths are thickenings that form in most cases on deciduous trees (birch, maple, alder, oak, etc.), and sometimes on coniferous trees in a limited area of the trunk, having different sizes and shapes.

There are two types of growths - burls and burls: the first are the result of an internal disease of the tree, as a result of which growths with a smooth surface most often form on the butt part of the tree; the second are growths that appear on the trunk in places where dormant buds appear intensively, and their surface is more prominent, and when peeled from the bark, their relief resembles numerous drops. Their processing is very labor-intensive due to the spatial complexity of the placement of layers, most often spherical. However, this same circumstance gives the growths a beautiful curled texture, which makes them a valuable source material for obtaining veneer with an extraordinary pattern, so valued in furniture. In individual use, growths can be presented as a number of household items and applied arts - a writing instrument, a flower vase, a candlestick, a mask.

The main defects of wood are: knots, cross-grain, curl, heel, double core, internal sapwood, false heartwood, sprouting, cracks, resin pockets, tar, cancer, wormholes and rot.

Knots - the most common defect, inevitable for all types of wood, are the bases of branches enclosed in the wood of the trunks, usually differing from the main wood in a darker color, and also due to a more compressed arrangement of layers and greater hardness and strength.

This leads to difficult processing of the barrel due to frequent changes in the direction of the layers, leading to inevitable work with a planing tool “against the grain”, which results in the formation of a large number of burrs, breakdowns, and sometimes chips with further weakening and cracking of the product. Coniferous wood is especially famous for this deficiency.

Of course, such wood is of little use for carving. Experienced artists - carpenters, carvers, having such wood at their disposal, plan in advance ways to bypass unfavorable places or ways to use them to obtain greater expressiveness of the product being manufactured. Likewise, knotty veneer can provide interesting food for artistic imagination in intarsia or marquetry.

Strong, healthy knots, if they are free of rot and other defects, are quite suitable for work as a material. They have a picturesque texture, good workability, and sometimes interesting outlines, thereby providing the master with a kind of blank for a particular product, subject to some targeted modification. Knots can be used, for example, in the manufacture of original hangers, door handles, stands made from cross cuts of knots, etc.

Cross-layer - observed externally on a tree when longitudinal cracks in the bark are placed in a helical line along the trunk, creating the effect of twisting the trunk relative to its stationary root system. Most often this is observed in trees standing on a hill and at a sufficient distance from others, which can shade it. As a result, the tree seems to follow the sun and, like a sunflower, twists its trunk.

The nature of this phenomenon allows us to predict the behavior of lumber made from this wood - the boards will warp and twist, which in turn will significantly reduce the mechanical properties of the wood, as well as its value, due to the great difficulty of processing it. Such boards require sharpening in one direction, great care when chipping, driving in nails, staples, as well as holding cutting tools in the direction strictly towards the run of the layer. Where such a vice really turns into an advantage is in the manufacture of veneer, and the pattern of cross-laminated wood is incomparable and good in all species, giving them additional richness and intrigue.

Curling is a wood defect caused by entanglement, waviness of layers, growth of one into another, most often found in the butt part of deciduous trees. When twisted, the layers are arranged frequently, which increases the strength of the wood, but makes it difficult to process - wood with disoriented layers is difficult to carve.

The texture of such wood is very beautiful and expressive. Curling with wavy layers is most often observed in birch, maple, walnut and on growths (burls and burls). The so-called Karelian birch is distinguished by its great curliness, for which it is valued in furniture and artistic products. Curlyness can give a sudden interesting effect both in various household crafts and in the performance of sculptural works.

Kren - this very word, meaning tilt in Russian, indicates the cause of the real vice.

It is in the wood of curved and inclined trunks that a displacement of the core in the direction of the slope is formed, and with this a distortion in the width of the annual layers - narrowing on the side of the slope and expansion on the opposite side. This in turn causes a violation of the homogeneity of the wood, because in the zone of dense arrangement of layers, the wood is denser and stronger, and on the opposite side it is naturally weaker. Such heterogeneity leads to uneven shrinkage, and therefore significant longitudinal warping, due to the occurrence of unbalanced stress forces in its fibers. Transverse sections of such trunks can be used as a material for making various kinds of household and artistic crafts and the spirit of folk art, when decorating residential premises, and longitudinal sections after appropriate processing are of interest as decorative panels for decorating the interiors of public and entertainment buildings.

A double core is a phenomenon most likely explained by the presence in the seed of a double growth center that did not separate during stem growth and was preserved during further development.

Very often, such trees bifurcate in the butt part, very close to the ground, and then, as a rule, a list is observed in these trunks. But in cases where the trunk is divided, but grows like an ordinary tree with the only difference that the cross-section of its trunk before branching is an oval with two clearly defined trunks, fused at some point with their annual layers, which then turned into a single system of layers common sapwood and then bark.

Also, a double core can be observed in the place of preparation of an ordinary normal trunk for its bifurcation. In this case, in the part of the trunk with a double core, a closed sprout may be observed, i.e. overgrown bark until the trunk is completely divided into two independent ones.

Internal sapwood is wood in which the core has a group of annual rings-layers that have the properties and structure of sapwood.

At the end of the trunk it is clearly visible in the form of one or several rings of different widths, lighter than the core of the wood, most reminiscent of a confectionery product - fruit roll. This phenomenon occurs most often in the trunks of deciduous trees, such as oak and ash. It should be noted that this defect does not in any way affect the work of the carver or make it difficult, but the decorative effect of alternating light and more porous rings with dark and denser ones can be successfully used when deciding on interior design.

False heartwood - occurs in non-core wood species, such as birch, alder, maple, and is the presence in the inner part of the trunk of an area of darker color of various shades, reminiscent of heartwood.

| False core: a - steep; b - star-shaped |

Unlike the latter, the false core is not only round, but star-shaped and lobed, and the quality of the wood is no different from ordinary representatives of deciduous sapwood. This vice, or rather, deviation, is successfully used in decorative techniques for interior design.

Sprouting is a phenomenon characterized by the ingrowth of dry wood or bark into the trunk as a result of external mechanical damage to the trunk. Ingrowth can be complete or partial and, accordingly, germination can be open or closed. Sometimes it can reach the core of the trunk. This defect significantly deteriorates the quality of the wood, and often makes it unsuitable for use in carving.

Cracks are breaks in wood along the fibers in tree trunks, formed as a result of shrinkage, frostbite in severe frosts, or an internal crack between the annual layers, the so-called frostbite. It is undesirable to use such wood for carving, and if someone decides to use such a material, then first they need to either plan out the cracks or seal them with homogeneous dry wood. Only after this can work begin.

Cracks : a - metic; 1 - simple in round timber; 2 - in sawn timber with a flat edge, edge; b - hatching: 1 - in round timber; 2 - in lumber (slab, edge, end); c - shrinkage cracks: 1 - in round timber; 2 - in timber (slab, edge, end); g - frost: 1 - in round timber; 2 - in lumber.

Resin pocket - the very name of this defect explains its nature as a certain void or cavity formed between the layers in coniferous wood and filled with resin. In addition to the fact that such a defect reduces the strength of the wood, it also makes working with it more difficult because the resin envelops and contaminates the tool. Serious difficulties arise in connection with this defect in the finishing of products - grinding, painting, impregnation.

Resin pocket : 1 - on the end surface; 2 - on the radial surface; 3 - on the tangential surface

Tarring is a consequence of injury to a coniferous tree trunk. The defect is expressed in the impregnation of all the wood at the site of this injury with resin.

The color of the tarred area is darker than the surrounding wood. The wood at the site of tarring is much heavier than the base wood and is of little use for carving. The strength of the wood at the site of tarring is significantly weakened.

Cancer is a violation of wood tissue on the surface of the trunk with penetration deep into the middle of the trunk, resulting from infection by parasitic fungi and bacteria.

| Crayfish on a tree : 1 - crayfish on a tree 2 - cut |

In coniferous species, along the borders of the infected area, abundant gumming occurs. At the same time, throughout the entire period of the disease, wood does not grow in the affected area, the affected area does not heal, but on the opposite side, as if to compensate for the loss, due to increased growth, a peculiar swelling (tumor) is formed, characteristic of this defect. Such wood, as you can already understand, is not suitable for carving. After cleaning the wood from the affected fibers, the remaining part can be suitable for the manufacture of decorative sculptures and other decorative products used in the design of both interiors and exteriors.

Wormhole is a violation of the wood structure by larvae and wood-boring beetles as a result of their penetration of freshly cut, unsanded timber through the bast layer of the tree.

When clearing such trees of bark, traces of the progress of pests are clearly visible on the surface in the form of winding, intricate passages, different in shape, configuration and combined into a system inherent in one or another type of pest. Damage to a tree, depending on the depth of penetration, can be superficial (burrows are made in the bark and bast layer), shallow (burrows penetrate several centimeters deep) and deep (burrows penetrate the wood right through). A tree affected by a wormhole is unsuitable for the manufacture of lumber used in construction, in the manufacture of critical parts, furniture, etc. The passages of woodworms, combined into complex systems on the surface of wood freed from bark and bast, can be of interest to an artist with taste and imagination. Processed pieces of such wood can be used as original crafts and souvenirs, such as boxes, pencil cases, flowerpots, candlesticks, etc.

Shili - damage to wood with its further destruction in dead, reliable and felled trees under the influence of wood-destroying fungi.

Internal rot : 1-4 - characteristic location of internal rot in tree trunks; a-b - trunk sections with internal rotten rot

The most common is internal rot. The destruction of wood is so severe that it turns into powder or, having lost the connection between the fibers, is torn out and plucked out in bunches from the trunk. Wood of all species without exception is susceptible to this defect.

Such wood is not suitable for carving, for construction and for the manufacture of frames, doors, parquet, paneling and veneer.

Similar articles:

- Round timber

- How does nature create patterns on wood?

Materials and tools for cutting with a jigsaw- Anatomy of a tree and its growth

- Anatomy of a tree and its growth

- Black pine, or Austrian