Corner connections

There are many other types of joinery joints. Corner joints are included in a separate group.

In this case, knitting occurs at a certain angle. Such connections are divided into box and frame types. The most commonly used joints of this type are:

- Overlay. This is a simple, but less reliable type of combining parts. At the end, choose material up to half the thickness of the workpiece.

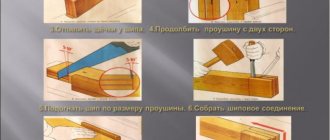

- Frame straight tenon. This is the main type of corner joints. The thorn fits into the socket. It can be single, double or triple. The choice is made depending on the strength requirements of the part. The nest may be open on one side. It's called deaf. If the nest is open on both sides, it is called end-to-end. There are holes open on three sides. They are called an eyelet, which is located at the end. The nest may also be in the middle part.

- Oblique dovetail spike. This is a strong connection and is preferable to a straight tenon. A joint of this configuration is not sawed in a direction parallel to the edges. The base of the tenon should be 1/3 of the thickness of the bar. Its end should be 3/5.

- On the dowels. This is knitting on dowels or round insert dowels. The connection is less durable than a tenon connection, but at the same time it is more economical. In this case, there is no need to make an allowance.

- On the mustache. The ends are cut at an angle. This joint is used both for bars of the same and different widths. The angle of the cut may be different.

Rally

When considering carpentry joints of wood parts, it is worth noting such a variety as joining. It is used for joining narrow parts. This allows you to obtain a workpiece of greater width. In rare cases, this technique is used to increase thickness.

The front sides are veneered. They are covered with wood, which belongs to the category of valuable species. Cohesion involves the following types of connections:

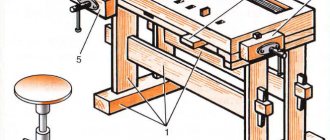

- Into a smooth fugue. In this case, an adhesive composition is used. The edges of the parts are firmly welded to each other. Then they are glued together. Next, the workpiece is placed in special equipment. These can be presses, workbenches or squeezes. In this case, screws, wedges and other fasteners are often used. The adhesive composition dries under pressure. It is squeezed out along the joint line.

- Dowels and spikes. Holes or sockets are made in the edges of high-quality jointed parts. Rectangular spikes or round protrusions (dowels) are inserted into them. In this case, the spikes should have a thickness of no more than 1/3 of the thickness of the parts.

- Into the tongue. A groove is selected in the middle of one of the edges. This is a tongue and groove, which should be no more than 1/3 of the thickness of the part. A ridge is made in the opposite edge, the configuration of which corresponds to the groove. Such connections can be rectangular or trapezoidal.

- At a quarter. In the edges, choose material up to half the thickness of the workpiece. Longitudinal recesses are made of the same size. They are called quarters.

- On the rail. It differs from a tongue and groove joint in the shape of the grooves. They additionally select a rail.

- On dowels. The grooves are chosen in the form of grooves tapering upward and along the length. They have a trapezoidal shape and a depth of 1/3 of the thickness of the part. Keys that have a beveled edge are driven into the grooves. It corresponds to the type of groove. This connection prevents the shields from warping.

- To the tip. A block is glued to the end edge of the shield. In this case, the shape of the tongue-and-groove can be rectangular, triangular or another profile. This connection is used for ends that are difficult to finish.

Varieties

You may be interested in: A shoemaker without boots - the meaning of the expression

There are different types of joinery joints.

They are regulated by GOST 9330-60 and may belong to one of the groups specified in the standard. Connections can be as follows:

- By lenght. This allows you to combine parts that are adjacent to each other at their ends. This category includes splicing and extension. One of the most commonly used options is the spike type connection. There are several types of such combinations. What carpentry tenon joints do you know? Each carpenter has his own experience in using such joints.

- Along the edge. This type of combination is called cohesion. It is used for two or more workpieces to obtain a wide part.

- Angular end. The principle is similar to carpentry tenon joints. But in this case the parts converge at a certain angle. This technique is used in the creation of furniture.

- Angular medians. When creating such a connection, one part adjoins the other either at its end, or crosses it completely at a certain angle. In the first case, the connection is called adjacency, and in the second - intersection. This technique is used primarily to create shields.

- Box knitting. Used for connecting wide elements. Most often, such joints are made when assembling boxes and crates. This type of connection can also be end or middle.

The joining method is selected in accordance with the purpose of the product.

Types of splicing and extension

There are many varieties of connections of the presented type. The most common method is wedge-shaped tenon joints. In this case, a large bonding area is formed. This ensures tight compression. The tenon joint is characterized by ease of marking and creation. In this case, wood processing can be done using a machine.

What carpentry tenon joints do you know? There are many varieties of them. When splicing with ends and a half, you can create various parts that are not subject to significant loads, for example, plinths, panel trim. In this case, an oblique cut is made at an angle of 45º. In this case, a miter box is used to achieve precision cutting.

If the part will be subject to load, the cutting must be sharper. It's called an oblique mustache. In this case, there is a wide spike along the entire length. This allows you to create a strong connection. It is even used for curved parts at bending points.

If the parts are subject to transverse compression, a direct overhead cut of half a tree is made. Often the overlay is additionally fixed using two dowels. To prevent the overlay from moving, the ends are cut at an angle. The combination of parts is stronger using a straight tenon with shoulders.

If the parts are subject to tension, they are spliced using a dovetail tenon. But such parts require support from below.

If the parts are almost flat, you can make a double dovetail tenon. But this is a rather complicated technique, so it is used quite rarely.

If parts have a bottom support, they also experience pressure from above and tension. In this case, a double dovetail connection would be the best option.

What tenon joints would be acceptable if the parts are supported at the bottom and are subject to forces that move them in opposite directions? Often in such cases, splicing with a round tenon is used.

Splicing and extension

In lessons on carpentry tenon joints, much attention is paid to this particular type of joining. They have a lot in common. Splicing is the connection of two parts located horizontally along their length. Extension allows you to increase the length of parts that are vertical in relation to each other. This, for example, could be a pillar block.

Joining and joining is one of the main types of joints in carpentry. They are used to produce long beams and posts. Typically, long parts are not cut from one board. This technique is used in the construction process. Also, during the repair of joinery, extensions or splices may be required.

Using the presented technique, stair railings, building trim beams, skirting boards and other similar products are obtained.

More often, hardwood is used to create long parts. Small bars are cut from it, which are glued together in width and length. The process of creating such blanks even involves the use of business waste from the woodworking industry.

You will be interested: Pavel Yakovlevich Golovachev: biography, participation in battles, awards

Carpentry joints of parts of the presented type are also used to create door panels and window frames. In this case, coniferous wood is more often used. Modern adhesive compositions are highly durable. With their help, it is possible to create an almost invisible seam.

There are several main methods of extension and splicing:

- Back to back. In this case, the elements are connected at the ends. They are cut flat at a right or other angle.

- Half-wood overlay. The part most often has a square or rectangular cross-section.

- Spikes. This is a special protrusion of the appropriate shape. The second part has a recess that corresponds in configuration to the protrusion. The joint tenon can be round, flat, or oblique (for example, a dovetail joint, which is often used during construction work).

- Wedge-shaped lock.

Box connections

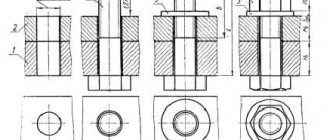

Box joinery joins the corner joint category. They are widely used in the production of furniture and carpentry. Such connections can be made using straight or oblique tenons. Their number depends on the width and thickness of the parts (boards). A spike is made at both ends of the parts being connected. The part that has an eye on the edge has one more protrusion.

Box-type connections can be blind, through, flush or semi-flush. The choice depends on the application of the products. Through joints are used for parts that are located inside the workpiece, as well as on the front sides if subsequent coating of the surfaces with plywood is planned.

If the part is open only on one side, the workpieces are connected in a semi-flush manner. If they are open on all sides, the hidden technique is used. Insert tenons can be used. But this type of joint is the least durable.

Box junctions are created using straight through tenons and grooves with a ridge. They can be rectangular, triangular, trapezoidal in shape. Grooves are used if it is undesirable to have protruding ends on the outer edge.