The largest warehouse of larch products in Moscow. All varieties, more than 1000 m3 of products in stock.

+7 +7 Call daily Mon-Fri 9:00 - 18:00 Sat 09:00 - 15:00 Sun.

Day off More details

Wood is one of the most popular materials of natural origin. It is used in construction, for the production of furniture, carpentry, souvenirs, etc. Wide application possibilities are the result of natural development and the unique qualities inherent in wood.

Strength, elasticity, wear resistance, ability to retain heat, ease of processing and other properties have made wood a leading material for the manufacturing industry and construction.

To understand how to work with wood, let's look at the structure of wood in more detail.

Sound and non-core breeds

All breeds are divided into two categories - those in which differences between the center of the trunk and the edges are visible to the naked eye, and those in which these differences are not.

If the cut of the tree is uniformly colored and there is no prominent dark core, then the species is coreless. If the dark center is clearly visible, then the rock is sound. Heartwood trees are more durable, since it is the core that has the strongest structure and consists of dead cells (covered inside with resin). Soundwood species include oak, ash, larch, pine, and coreless birch.

Properties of wood

In most species, the core has greater mechanical strength and a darker color compared to sapwood.

Sapwood has higher humidity compared to the heartwood zone and is less resistant to decay and insect damage.

Many conifers (pine, spruce, larch, cedar, etc.) have resin ducts, which are thin channels in the wood filled with resin. They are absent in fir, juniper, and yew. Resin increases the wood's resistance to rotting.

In accordance with GOST 20022.2-80, a classification of wood is established according to resistance to decay and impregnation with protective agents, the speed of depreservation and the vulnerability of objects of protection, as well as the classification of wood protective agents.

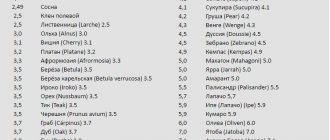

According to their resistance to decay, wood species (Table 1) are divided into 4 classes: resistant, medium-resistant, low-resistant and unstable, and the classification is carried out both by sapwood and core.

Table 1. Wood resistance to rotting

| Class | Wood type | |

| Sapwood | Core | |

| Persistent | Scots pine, ash | Siberian cedar pine, Scots pine, larch, oak, ash |

| Medium resistant | Spruce, Siberian pine, larch, fir | Spruce, fir, beech |

| Low-resistant | Birch, beech, elm, hornbeam, oak, maple | Elm, maple |

| Unstable | Linden, alder, aspen | Birch, linden, aspen, alder |

According to their impregnation with protective agents, wood species (Table 2) are divided into the following groups: easily impregnated, moderately impregnated, difficult to impregnate.

Table 2. Impregnation of wood with protective agents

| Class | Wood type | Wood type |

| Sapwood | Core | |

| Easy to soak | Scots pine, birch, beech | _ |

| Moderately soaked | Siberian cedar pine, European larch, hornbeam, oak, maple, linden, alder, aspen | Siberian pine, Scots pine, aspen, alder |

| Difficult to soak | Spruce, Siberian larch, fir | Spruce, European larch, Siberian larch, fir, birch, oak, elm, beech, ash |

What is wood made of?

In addition to the core, wood has layers such as sapwood, cambium, bast and cork. The width of the sapwood is determined by the number of annual rings, and the size of the ring is determined by the width of the early and late layers. The early layers are lighter and located closer to the center, the later ones are darker and are located near the cortex.

Layers have different functions. The early ones serve to nourish the tree, the later ones for protection from mechanical damage, insects, etc. Nutrients are distributed along “vessels” - transverse lines that are located along a radius from the edges of the trunk to the center.

These are the core rays, which are up to 1 mm thick and are responsible for the texture of the wood. They are always clearly visible in a cross section. In deciduous trees, sap flows through them, which is collected by cutting these vessels (for example, birch or maple sap).

In conifers, these vessels are filled with resin, which is also collected when necessary. It is interesting that the resin flows through a single system, since all passages are combined into it.

All rocks have a particularly fragile and quickly deteriorating part - the core. It is very small and does not exceed 2-5 mm in diameter. In deciduous trees it is greater. In order for a tree to grow and develop, it receives nutrients from a small layer of cells - the cambium. This is the layer next to the bark.

The layers of wood appear due to the fact that the process of producing nutrients occurs in a certain “season” from spring to autumn.

Deciduous scatter-vascular tree species

Multiple vascular. The later part of the annual layer is dense and very narrow. The vessels on the cross section are poorly visible or not visible at all. This group of breeds includes the following.

Beech

mature wood species; there is no kernel in it, but often there is a so-called false kernel, colored red-brown (the initial stage of rot). Healthy beech wood is white with a reddish tint. Sometimes the wide peripheral part of the sapwood has a lighter color than the inner part, corresponding to the position of the core. The annual layers are clearly visible in all sections due to the narrow dark strip running along the outer edge of the annual layer.

Numerous medullary rays are clearly visible on all sections: on a cross section they have shiny, light and dark (depending on the lighting) lines; on a radial section, the rays are found in a mile of shiny stripes or spots of varying widths and lengths, sometimes light, sometimes dark compared to the main background of the wood.

In a tangential section, the rays have the appearance of dark spindle-shaped short strokes, giving the section a characteristic speckled pattern. Beech wood is dense, has high strength, but is not resistant to decay. This greatly limits the scope of its application in construction. Beech grows in the Caucasus.

Macrostructure of beech wood: 1 - end cut, 2 - radial, 3 - tangential

Birch

Birch is a sapwood species; Its wood is white with a slight pinkish tint. Annual layers on all sections are poorly distinguished. Birch wood, like beech wood, rots relatively easily (in damp and poorly ventilated places). More often, birch is used to make plywood, planed blanks and joinery for rooms with normal temperature and humidity; Birch is well processed, it is easy to imitate valuable species (mahogany, ebony, etc.), so it is widely used in carpentry and finishing work.

Especially valuable for finishing work is the so-called Karelian birch with its twisting and knotty arrangement of wood fibers, which gives a beautiful pattern.

Alder

Alder has no kernel. The wood is light and soft, light brown in color with a pink tint (when dry). Annual layers are visible in all sections. Alder is used in the same way as birch.

Chemical composition of wood

Mineral and organic substances are concentrated in wood. Mineral components remain in the ash after burning wood. These are sodium, potassium, magnesium, calcium and iron salts.

Organics make up 99% of the wood's mass. The majority are carbon and oxygen (50 and 44%, respectively), 6% are hydrogen and 0.3% are nitrogen.

Organic substances are included in the structure of the cell or are located outside it. The first group includes cellulose, lignin, etc. The second group includes essential oils, pectins, tannins, etc. From the second group, the tree receives properties such as taste, color, aroma, resistance to bacteria and mold. These substances are easily extracted from wood by dissolving the fibers in various solvents.

Deciduous trees have less inorganics, conifers have more. The bark contains more extractive substances, and the ash contains more salts that are soluble in water. Therefore, bark is an equally valuable raw material for processing, agriculture, and light industry.

Features of coniferous wood

Coniferous wood is characterized by a clearly defined outline of the annual layers.

Coniferous woods: early wood, loose and melted, differs sharply from the dark-colored, dense structure of late wood. The following tree species belong to the coniferous group.

Pine

Pine is a sound species; the core is mostly brown-red, the sapwood is yellow-white. In logs and boards, pine can be easily recognized by its knots: in the cutting plane they have an oval shape, as they are located at an acute angle to the axis of the trunk; in addition, at a certain distance they are arranged in a whorl, that is, in groups of 3-4 knots; There are no knots between the whorls.

Macrostructure of larch wood: 1 - end cut, 2 - radial, 3 - tangential

Ore pine grows on deep, loose sandy loam or light loamy soils, on rocky and elevated places; The wood of such pine is fine-grained, resinous, and has narrow sapwood. Myandy pine grows in low-lying clay soils, usually together with spruce, birch and aspen.

Its wood is loose, wide-grained, less resinous, the sapwood is wide, and is inferior in quality to ore pine wood. Pine wood is widely used in industrial and residential construction: it is also used for sleepers, poles, piles, wooden pipes, etc.

Pine is used in carpentry and in the production of building parts (windows, doors, door and window frames, etc.).

Larch

Larch is a sound species; the kernel is reddish-brown; The sapwood is light, narrow, and differs sharply in color from the core. Late wood is highly developed, dark brown in color; The early wood is light, but somewhat darker than that of pine.

Larch wood is hard and highly resistant to decay. This is a good building material, which is especially valued in hydraulic and underground structures. Larch grows mainly in Siberia.

Cedar

Cedar is a sound breed; the kernel is light brown; The sapwood is wide, yellowish-brown, and differs little in color from the core. Late wood within each annual layer is poorly developed and consists of narrow, dense and dark-colored strips. Cedar wood is light, soft, and its mechanical properties are lower than those of pine; used as round timber and lumber, as well as for joinery and construction parts (window and door frames, partitions, etc.). Within Russia, cedar grows in Siberia, the Urals, and the Far East.

Spruce

The color of the wood is white, with a faint yellowish tint. The early wood is light and highly developed; late wood is dark-colored and dense. In boards and bars, spruce can be recognized by its knots, since on the longitudinal plane of the cut they have a rounded shape, and there are individual small knots between the whorls. Spruce wood is less resinous than pine; when used in damp places, it quickly rots. Spruce, like pine, is widely used in industrial and residential construction, and is the main type of raw material in pulp and paper production.

Wood defects

Unfortunately, the structure of wood cannot be imagined without its defects or defects. They are also an integral part of the tree. These include knots, cracks, cores, wormholes, sprouts, wane, blue spots, etc.

The quality of lumber depends on the presence and number of defects. Not all defects are “congenital”; some appear when an already cut tree is improperly stored or used.

GOST 2140-81 regulates and divides all defects into groups. The first includes knots as the most noticeable defects. Then there are cracks and curvature of the trunk, then the standard draws attention to veins and spots that should not be on the cut surface.

The following groups comprise defects that arise during the processing or storage of materials. These are fungi, foreign inclusions, coloring, damage by pests, warping.

Density

Wood density (bulk density) is the ratio of wood mass to its volume, expressed in kg/m3. The density of wood depends on its moisture content. All indicators of the physical and mechanical properties of wood are determined at a humidity of 12%.

There is a close relationship between strength and density . Heavier wood is generally more durable. Density is determined by the amount of wood substance per unit volume.

Based on density at a humidity of 12%, wood can be divided into 3 groups:

- light density - up to 550 kg/m3 (balsa, Siberian fir, spruce, willow, pine, aspen, linden, alder);

- medium density – 551–700 kg/m3 (horse chestnut, walnut, birch, cherry, larch, teak, beech, oak, sweetener, sycamore, maple);

- dense species - from 771 kg/m3 and above (ash, plum, pecan, boxwood, persimmon, apple, olive).

The density of wood is of great practical importance. Denser wood is less saturated with antiseptics and is less susceptible to abrasion in places such as floors, stairs, and railings.

Depending on application

The properties of wood of various species are considered and compared depending on the type of product being manufactured.

Construction elements. The most popular types of building wood products are rounded logs, solid timber, laminated veneer lumber, structural beams, roof and ceiling building elements (boards and beams), frame elements, solid wood wall panels. For this category of products, the properties of wood such as strength and resistance to biological damage are important.

Floor coverings. Floor coverings are placed in a separate category, since today most enterprises are trying to ensure product quality in accordance with the requirements of European standards, which have a gradation not only in quality, but also in the appearance of the product (by the direction of the fibers - radial, tangential, mixed; by the presence of a nucleus, medullary rays, etc.). Floor coverings include: floor boards, parquet strips, parquet boards, deck boards.

This category also includes staircase elements (steps and railings). For this category of products, such properties of wood as hardness, density, shape stability, and abrasion are important.

Finishing materials, furniture and carpentry elements. Wood is widely used for interior and exterior decoration. For cladding a house, a board is used that imitates a rounded log or timber. For interior decoration, finishing boards (lining and eurolining), furniture panels for the manufacture of furniture, window sills, doors, wall panels and other elements of carpentry are widely used. For this category of products, stability of shape and wood density are important.

Other types of products. These are various board materials: chipboard, chipboard, fibreboard, MDF, OSB, etc.

In the next issue we will talk about the areas of application of coniferous wood.

____________________________________________________________________

Wood protection

How and from what should wood be protected? What new technologies can specialists offer?

Classification of wood by heartwood and sapwood

The color is affected by the variety and age of the tree. The intensity of color is affected by the concentration of dyes and chemicals in the soil.

All tree species are divided into types:

- Kernel - dead substances are located in the middle of the trunk, often dark in color. These varieties include: larch, oak, pine, juniper, apple tree, ash.

- Sapwood – consists of living microorganisms, and has a lighter shade. It includes maple, linden, pear, and birch.

- Mature wood species. The main difference is that the color of the nutrient layer matches the color of the core. It is the most expensive and reliable material. It includes beech.

Sapwood and mature wood species can form a false core. Such wood is distinguished by its fragility, uneven shade across the cut, and unclear shapes.

Hardness

Hardness is the ability of wood to resist the penetration of harder bodies into it. The degree of hardness is influenced by the moisture content of the wood.

According to this parameter, all tree species at 12% humidity can be divided into three groups:

- soft - end hardness 40 MPa or less (pine, spruce, cedar, fir, juniper, poplar, linden, aspen, alder, chestnut);

- hard - end hardness 40.1–80 MPa (larch, Siberian birch, beech, oak, elm, plane tree, rowan, maple, hazel, walnut, persimmon, apple tree, ash);

- very hard - end hardness more than 80 MPa (white acacia, iron birch, hornbeam, dogwood, boxwood, pistachio, yew).

Hardwoods are more wear-resistant than softwoods. This is essential when processing with cutting tools: milling, sawing. And also when constructing floors, stairs, railings, since wood is subject to abrasion during use. In the production of parquet and solid wood parquet boards, rocks with a hardness of at least average are used.

Tree trunk structure

All wood has a general structure. It includes:

- The nucleus formed after the death of cells. Often dark brown in color.

- The sapwood of wood is the part through which beneficial substances and liquids flow from the rhizome to the crown.

- The cambium is a layer of living cells. It promotes regular growth of the trunk in thickness. Thanks to the cambium, the age of the tree can be determined. It is he who is responsible for the growth of tree rings.

- Bast part. It is a conductor of organic substances produced by leaves to the root system.

- The bark is the tough outer layer. Protects the barrel from mechanical and natural damage.