Articles

All photos from the article

It is quite difficult to find a construction task for which thin boards would not be used: these products are almost universal, and the variety of shapes and sizes of manufactured parts allows them to be used almost everywhere.

In our article we will talk about the production technology of such material, and also analyze where and for what it can be used.

Every builder needs this material!

Description of building material

Types of lumber

As a result of woodworking, logs are sawn into several pieces of different sizes. At the same time, several different parts can be cut from one blank at once - this way we not only save wood, but also expand the range of products produced.

Lumber can have different shapes and sizes

We describe the main types of products obtained from solid blanks in the table:

| Variety | Description |

| timber | A part with a square or rectangular cross-section (the ratio of length and width is not less than 1:2). The size of the smaller side is 80 mm or more. They are used as frame elements with high load-bearing capacity. |

| Bar | The configuration of the material is similar to timber, but at the same time it has smaller dimensions: the side side is up to 80 mm, the cross-sectional area is up to 32 cm2. The bars are used to form lightly loaded frames, for the manufacture of auxiliary elements, etc. |

| The board is thick | A rectangular product with one cross-sectional side at least twice as large as the other. The thickness of the board is 40 mm or more. Used to form high-strength decking, as well as blanks for the production of flat parts. |

| Thin board | Wooden panel with a width of at least 80 mm and a thickness of 8 to 40 mm. Has a very wide range of applications. |

It is the last variety of lumber listed in the table that is the subject of consideration in our article. This is quite logical, because it is thin boards that make up a significant part of all products used for construction and repair.

Thin board production technology

The manufacturing technique for such parts can be divided into two stages:

- first, blanks of the desired shape and size are made from the log;

- then the blanks are used to form products with the stated parameters and performance properties, for example, a thin terrace board or façade plank.

Log cutting options

The production algorithm itself looks like this:

- Logs are used as raw materials, which undergo primary sorting, calibration and drying. It should be noted that the price of products is largely determined by the wood used: thus, common pine will almost always cost less than rarer and more difficult to process oak.

- The log is fed to the sawmill, where it is sawed in accordance with the task. The cutting is usually carried out along the grain.

Rough cut

Note! Most often, the workpiece is either spread onto unedged boards, or slabs are removed from the surfaces, forming a beam. Then smaller parts are cut from this timber.

- As a result of these actions, we obtain the so-called sawn board, which can already be used in construction.

Additional operations

However, the technological process is not limited to this.

Depending on what material is required, the following operations can be performed:

- drying - carried out either in special chambers or on areas protected from direct sunlight and precipitation. As a result, the moisture content of the wood is reduced, making the products less susceptible to deformation;

Heat treatment of workpieces

- heat treatment – drying, accompanied by exposure of the workpiece to hot steam and high (up to 2000 C) temperatures. After this, we get a so-called thermal board, which can be used for facade work without fear that it will swell upon contact with moisture;

- processing on a planing machine - performed to level all surfaces;

Note! The planed thin board has smooth edges, which allows it to be used for finishing and making various structures without preparation.

- profiling - performed either on a planing or milling machine. At the same time, protrusions and depressions are formed at the ends, which make it possible to connect several parts into a lock.

Milling the lock on the end

Western thuja boards

Boards made from thuja occidentalis have a pleasant color with a reddish-brown tint. Boards made from this wood have a silky structure. Most often, such boards are used for the manufacture of greenhouses or fences, for finishing facades.

Boards made from thuja occidentalis are extremely resistant to rotting. They are practically resistant to insects, but susceptible to mechanical damage and lose their color over time.

Types of boards and their use in construction and repair

As we noted at the very beginning, thin lumber is used almost everywhere. But still, if you do the work yourself, you should select wooden blanks that best suit the task at hand.

Thin coniferous board with locks on the ends

We will give a few examples below:

- Unedged boards, as well as planks that have not been processed on a planer, are most often used in rough work. They are used to construct wooden floors and ceilings, temporary partitions, hidden structures, etc. Sometimes these materials are used for the installation of lathing - frames to which this or that finishing material will be attached.

- Planed boards are an excellent raw material for both construction and the furniture industry. It is from planed blanks that carpentry products are made - window and door frames, frames for them, window sills, platbands, furniture panels, etc.

- Thin floorboards, as well as lining, must be equipped with locks at the ends. Thanks to the tongue-and-groove fastening system, we are able to lay a floor or sheathe a wall/ceiling with a minimum number of cracks, ensuring effective thermal insulation.

Photos of the plank floor installation process

- Separately, it is worth mentioning the facade panels. As we noted, the instructions for their manufacture provide for multi-stage processing, which seriously increases the cost of the material. But this produces products that, despite their small thickness, have enviable strength and resistance to external influences.

However, this is only a small part of the problems that can be solved using such products. So the demand for thin boards will continue for a very long time.

Cedar boards

Cedar boards have a porous structure, so they lend themselves well to painting and varnishing and retain their properties. The main advantages of cedar boards:

- Plastic.

- It has good sound insulation and thermal insulation.

- The material is insect-resistant and rot-resistant.

It is worth noting that cedar boards are quite soft compared to other conifers and require painting or varnishing as protection.

Wood quality

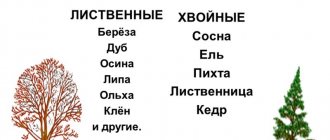

Deciduous wood is divided into three grades, coniferous - into five. The best grade lumber is called selected (marked with a horizontal stripe or the letter “O” ), the remaining grades are designated by numbers 1-4 (marked with the corresponding number of dots, vertical stripes, or just a number).

The quality of lumber is assessed based on the worst side or edge. The grade is determined by the presence/absence of knots, rot, cracks, warping and deformations, wormholes, the degree of precision of machining (non-parallelism of planes and edges is regulated by GOST 24454-80 ).

- 1st grade wood is used for the manufacture of elements of building structures, windows, doors, stairs (for standard sizes of stair elements, see this article ), finishing of floors and walls.

- The 2nd grade is used for flooring, load-bearing building structures ( category II ), formwork, lathing and planed parts ( GOST 8442-75 and GOST 475-78 ).

- Grade 3 is used for the manufacture of load-bearing structures ( category III ).

- The 4th grade is suitable for the manufacture of containers and small workpieces.

The permissible humidity of the 4th grade is not standardized. The humidity of other varieties should not exceed 22% . If this value is exceeded, the lumber is called “raw” - a significant loss of its strength occurs.

Type of cutting pine boards

Depending on the cutting, all coniferous boards are divided into 4 types:

- Core - cut from the core of a tree and only 1 board of this type can be produced from one tree.

- Central - cut from the central part of the trunk and 1-2 boards of this type can be produced from one tree.

- The extreme ones are cut out after cutting the sides of the tree.

- Croakers are the outer boards that are cut when sawing wood longitudinally.

Legend

In the designation, the material is written in plain text (board, block, timber), then a number indicating the grade, type of wood (coniferous or individual species - pine, spruce, larch, cedar, fir), cross-sectional size in mm. and designations of the regulatory standard.

Example: Board - 2 - pine - 40 x 150 - GOST 8486-86

Responsible manufacturers also indicate length and cubic capacity in their price lists, i.e.: Board - 2 - pine - 40 x 150 x 6000 - GOST 8486-86 Quantity per cube: 27 pcs

Red spruce boards

Red spruce boards can range in color from light yellow to red-brown. This material lends itself well to painting, staining, has high strength and is easy to process.

It is worth noting that red spruce boards must be impregnated with an antiseptic; the material is easily rotten.

Canadian spruce boards

Canadian spruce boards have a soft and fine texture, but are highly durable and easy to process. The color of Canadian spruce boards is light yellow and fades over time.

As a rule, such material is used for interior work, since it cannot be impregnated with an antiseptic.