Rack for storing current stock of material

Bob Miller made this rack for himself in his workshop to store material that will be used in the near future. Storing the wood directly in the workshop allows it to acclimatize before work begins.

Equipment for a workplace for manual wood processing.

Technology (boys) 5th grade. Federal State Educational Standard

Lesson topic:

Processing of a workplace for manual wood processing.

The purpose of the lesson:

To give students an idea of what a workplace in a carpentry workshop is. Introduce the carpentry workbench, its structure and safe work on it.

Tools and equipment:

Carpentry workbench for wood processing. Set of tools. Safety instruction poster.

During the classes:

- Introductory part

1.1. Introducing students to the rules of behavior in the workshop.

1.2.Tell about the working hours during technology lessons.

1.3. Familiarize yourself with safety precautions in a carpentry workshop.

2. Explanation of new material.

Work with wood is carried out in a carpentry workshop. Each student will have his own permanent place of work. The workplace for working with wood must be equipped with a carpentry workbench.

The word "workbench" translated from German means "workshop".

The profession of a worker engaged in manual processing of wood is called a carpenter.

There are two types of workbenches: carpentry and universal (combined).

Construction of a carpentry workbench.

The workbench consists of a base 1, a cover 2, holes for wedges 3, a tool tray 4, a front clamp 5, a rear clamp 6, movable fingers 7.

Holes with wedges are needed to secure or support long workpieces.

Front and rear clamps are used to secure workpieces that need to be processed.

The tray is used to place the tools needed for work.

Retractable fingers are used to support long workpieces, for example when planing.

Workpieces and products are placed under the workbench, tools and accessories are stored.

Questions for students:

What cutting tools do you know? Chisels, hacksaws, chisels, drills, etc.

What are the types of measuring instruments? Rulers, compasses, squares, protractors, etc.

Rules for working in a carpentry workshop.

Working at a workbench most often requires standing; only some work is more convenient to do while sitting on a chair 2, for example, burning or sawing.

The height of the workbench should correspond to the height of the student. It's not difficult to check.

You need to stand right at the workbench, lower your arms down and place your palms on the lid.

If this does not require bending or bending your arms, then the height of the workbench is

correct.

Safety precautions when working in a locksmith workshop.

1. Work should be performed in overalls (apron or robe).

2. Fastening of workpieces must be reliable.

3. The tool must be neatly folded in the tray.

4.Everyone works only at his own workplace.

5.The tool must be in good working order.

When working, follow the rules for caring for the workbench.

- Protect the workbench cover from damage.

- Hammer and knock out wedges only with a mallet.

3. Only necessary tools and devices should be present at the workplace.

4. After work, the workbench must be cleaned with a brush.

3. Practical work.

3.1.Name the main parts of a carpentry workbench.

3.2.Check whether the workbench in the workshop is suitable for your height.

3.3.Practise securing workpieces in clamps.

4. Final part.

Checking completed work and pointing out errors.

Lesson summary behavior.

Wood sawing tools

You can cut wood or materials made from it using several types of tools:

All of them are manual and electric. The hacksaw is ideal for garden work; it is used to saw not too thick branches, boards, and blanks for carpentry.

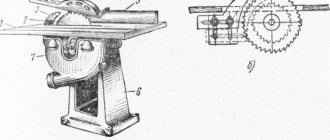

When constantly sawing wood at home, it is simply necessary to have a circular saw (circular saw). It cannot make shaped cuts, but it cuts through boards, plywood, and some types of plastic as quickly as possible.

If you need to cut down trees or prepare firewood, then in this case you use chain saws. There are also hand saws for logging, which require two people to work with.

Use a jigsaw to cut out shapes of arbitrary shape. It is suitable for cutting out blank models, artistic panels, various crafts, furniture parts, and kitchen appliances.

Grinding and roughening tools

To make wood perfectly smooth, you need a sanding tool. Small figures and wood parts are sanded manually with sandpaper and sandpaper, making monotonous mechanical movements.

To smooth the edges and ends of products, rasps are used. These are special files for wood with a large notch.

For large areas, electric woodworking machines are used, these include:

- grinders with grinding attachments;

- belt sanders;

- eccentric (orbital);

- surface grinding (vibrating).

A belt tool is more suitable for rough sanding, removing thick layers of paint or leveling a surface. Finer grinding is carried out using eccentric and surface grinding units.

Planers for planing

Wood must be planed with a plane. It removes a thin layer of chips, allowing you to get an even, smooth surface. Neither a joiner nor a carpenter can do without a plane. They are used by craftsmen of musical instruments, furniture, dolls, kitchen utensils and much more.

Advice! When choosing an electric planer, pay attention first of all to its power, blade width and planing depth declared by the manufacturer.

It’s a good idea to have a whole set of planes, or at least one universal one. As you master the work of a carpenter or joiner, you will need other types of planes.

For rough planing, a bearer is used; for finishing, a jointer or semi-jointer is suitable; the removal of tongues and grooves is carried out with a tongue and groove tool. There are also scrapers, moulders, and many other highly specialized tools for planing.

Chisels and chisels for chiselling

Tenons and grooves in wood for connecting parts are made with chisels and a chisel. This is a hand tool. To hollow out a deep and wide enough socket or eye, use a chisel. The working part of the chisel is a steel block sharpened on one side.

Using a chisel, shallow holes are hollowed out, the surface of the wood is cleaned, and parts are adjusted. The shape of the chisel blade can be flat or semicircular.

Before starting work, markings are applied to the part, then it is firmly secured in a clamp on the workbench and they begin to hollow out. The fibers are cut at an angle of 45–60°, deepened each time by 4–5 mm, and the shavings are immediately removed.

Variety of instruments

Wood processing refers to a large number of operations, and each of them requires its own tools. Wood can be sawed, drilled, planed, and objects of simple or intricate shapes can be cut out of it. The totality of all tools is divided into two groups:

In addition, they are divided into professional, amateur and intermediate categories. At home, it is most convenient to perform woodworking with amateur or semi-professional tools. In addition, their price is significantly less than professional ones.

Hand tool

Hand tools are those that require human physical strength to use. Since woodworking was done at a time when no one knew about electricity, all manipulations with wood can be done manually.

The ax is considered one of the most ancient in origin. It is still used at home - in many private households one cannot do without an ax.

There are hand saws, drills, chisels, planes and much more. They need to work carefully and skillfully. You can’t do it without proper practice and skills; you often need considerable physical strength.

Power tools

Electrical devices are easier to use. They allow you to complete the job several times faster and with less effort. Power tools for woodworking at home are available in mains-powered and battery-powered versions. When purchasing such units, you need to pay attention to their power, service guarantee and basic capabilities. Priority should be given to those functions that you plan to use most often.

It is worth noting that power tools can also be hand-held or stationary. Hand-held power tools for woodworking can be carried and performed while holding it in your hands. In the second case, the tool is fixed, human intervention is minimal, it is often a machine that can be a lathe, slotter, milling machine, or planer.

Hand tools

A hand tool assumes that the energy that powers its operation is the strength of the person using the tool; it is used in all woodworking operations.

- Hacksaws equipped with various types of blades are used for sawing boards in various planes. Round timber is harvested with two-handed saws, and with their help and with the use of bow saws, the harvested timber is cut. Jigsaws are used to make decorative design elements, as well as crafts and furniture of various designs.

- An ax is a construction tool and military weapon known from time immemorial. Axes are used by joiners and carpenters when performing various operations using wood (building houses, manufacturing structures and individual elements - windows, doors, etc.). Cleavers are used when preparing firewood.

- In the manufacture of wooden structures (windows, doors, stairs, etc.), various types of planes (sherkhebels, jointers, tongue and groove piles, etc.) are used to process the raw materials.

- When making grooves and tenons, and making holes, chisels and chisels of various sections are used.

- For drilling, hand drills and rotary hammers with drills of various designs (center, twisted, spoon) are used, as well as drills used for deep drilling.

- In the manufacture of furniture and various carpentry, clamps are used to tighten and fix the assembled elements into a single structure.

- Nail puller and pliers are indispensable types of tools when removing foreign objects from solid wood.

Electrical tools

Electric saw

For electric models, the source of energy that powers their operation is an electric motor, which in turn is powered by an electrical network or batteries.

Such models have certain advantages and disadvantages in comparison with manual analogues, these are:

Advantages:

- When using it, practically no human physical strength is used.

- High efficiency of use.

- The ability to withstand high loads that are beyond human strength.

- Multifunctionality.

Flaws:

- Dependence on the presence of electrical networks.

- Inconvenience of performing work due to the presence of an electrical wire.

- High cost compared to manual analogues.

- Availability of operating costs associated with paying bills for consumed electrical energy.

Electrical devices are used at all stages of working with wood.

The industry produces electric chain saws and circular saws, as well as jigsaws used for sawing various types of lumber. Electric planes and drills are used for planing and drilling.

For the convenience of working with electric hand tools, models powered by rechargeable batteries are available, which allows you to be more mobile when working with them. Such a tool is a screwdriver.

Sometimes wood milling and engraving machines are used for wood processing; these units are distinguished by high productivity and precision of mechanical processing of parts. Such machines are often used in production, since their cost is quite high, but depending on the model, they are also used at home.