Application

Using the chain carriage included in the mini sawmill, you can cut all types of wood - from hard oak to knotty pine.

The accuracy of setting the sawing parameters is set by the operator, and almost all models of chain saws provide a smooth surface that is easy to process in the future. The removal of sawdust, which is formed during the sawing process of wood, is carried out by a saw chain, and at the end of the process, the boards can be finally cleared of waste. The carriage is adjusted to a distance of 2 meters between logs (for longer logs) or 1 meter for shorter pieces of wood, which is suitable for cutting fruit trees. The mini chain sawmill with carriages model F2 is made of durable aluminum alloy, which has a protective coating. The maximum weight of timber that can be processed using these carriages is 1000 kg, with the longest processed log being 3800 mm. If it is necessary to work with long logs, the frame can be extended with fragments of the same type, which are available upon additional order. Also, several log lifts can be installed on or next to the frame, which allows you to process long logs with high productivity, while maintaining all the accuracy parameters.

Key Operating Principles

The chainsaw is always held with both hands, tightly gripping the handle with all fingers (the thumb of the left hand should be located under the front handle). The saw should be placed closer to the body - this way the arm muscles will tire less (there is no need to be afraid of the proximity of the saw). In addition, in this position it will be easier to maintain balance and maintain full control over the process.

Your legs should be spread wide, with your knees bent for stability, but your back should be kept straight. If the mechanic needs to change position, he must first turn off the engine by activating the brake. If you need to move the chainsaw over a considerable distance, it is recommended to cover the tire with a casing.

It is better to learn to use a chainsaw on horizontal, not too thick logs at first. Once you feel confident and strong in your hands, you can learn to fell trees. To cut logs or beams straight, you need to make marks with a pencil and then gradually move along these marks. It’s good if you have the opportunity to watch how experienced sawyers work.

Preparation stage

Before cutting down a tree, you should make sure that surrounding objects (railway rails, buildings, power lines, highways, etc.) will not be damaged as a result of the falling trunk. There should be nothing unnecessary within a distance of two lengths of the tree being cut in any direction. In addition, if the place is crowded, then it is necessary to use warning signs - this is a must.

Pay attention to the following points:

- whether the tree grows straight or not;

- is there a slope of the soil;

- what is the strength of the wind and in which direction does it blow.

This ultimately determines in which direction the trunk will fall. You need to be especially careful with rotten, dry wood. It may behave unpredictably for the lumberjack and may not fall as planned. A damaged tree can be identified by external signs (dry branches, damaged trunk). Experienced fellers determine the quality of wood by tapping the trunk - a healthy tree “rings”, while a sick tree sounds dull or inaudible.

The ground around the tree must be cleared of bushes and other growth - this is another important preparatory action. It is necessary to remove everything that could impede the safe movement of the master with the chainsaw during the felling process.

How to saw

The sawing procedure itself usually goes like this. The lumberjack stands to the right of the trunk and makes a guide cut on the natural slope side at a 45-degree angle to a depth equal to about a quarter of the tree's diameter. This undercut should be as low as possible - this will make it easier to fell the trunk (and the stump will not be too high). It is also worth keeping in mind that the undercut seems to indicate in which direction the tree will subsequently fall to the ground.

A horizontal cut is then made on the opposite side of the tree—the main felling cut. There should be some small distance between it and the inclined undercut - this gap is needed so that the tree does not collapse prematurely.

During the work, it is necessary to monitor where the trunk is tilting in order to have time to react if something goes wrong. When the tree begins to fall, you need to quickly remove the chainsaw from the cut, turn off the engine and leave the dangerous place.

If, having caught on another trunk during felling, the tree does not fall completely, then professional help will be required. Leaving it unattended, as well as trying to correct the situation on your own, is prohibited.

There are times when a chainsaw bar gets stuck in the trunk. There is no need to panic and suddenly pull it out, especially if the tool is in working condition. First of all, you need to stop the engine. And then you should manually tilt the barrel little by little until the chainsaw slips out.

Longitudinal sawing of logs

Before cutting the logs, the optimal method is chosen, which depends on the size of the required lumber, the desired surface quality of the boards, the type of wood and technical capabilities.

They start cutting only after inspecting the log, after which it is freed from bark and branches. If there are no flaws on the log, then processing is faster, and the lumber is of higher quality.

Cut the logs

Depending on the orientation of the growth rings, different types of log cutting are used:

- Radial view - the cut passes along the radius of the growth rings. They obtain high quality lumber that does not deform.

- Tangential view - the log is sawn tangentially to the growth rings. The lumber is of low strength.

- Parallel view - the cut runs parallel to the grain of the wood.

For sawing in the direction of the grain, the simplest method is a circular cut. First of all, the croaker is cut off. After this, the log is turned 180 degrees, and then the second slab is cut off. To obtain boards, the log is constantly turned.

For high-quality sawing of logs in different ways, the following general rules are used:

so that the log does not move during processing, it is securely fixed; if sawing is done with a chainsaw, then use a chain for longitudinal processing

In order for the cut to be smooth and the saw not to be pulled to the side, the chain must be well sharpened and not sag; for sawing by hand, they try to select logs of short length; before sawing, the log is marked for a certain type of cut; sawing logs into boards begins with cutting the slab; special attention is paid to safety measures at all stages of sawing logs. Sawing logs on their own is carried out using various cutting tools. Sawing logs on your own is done using various cutting tools.

Sawing logs is done on your own using various cutting tools.

Electric or gasoline saws

A gasoline saw has advantages over an electric model:

- the workplace is not connected to a power source;

- higher power;

- thanks to soft start and speed control, the risk of saw chain breakage is reduced;

- continuous operation for up to an hour, there is no need to interrupt the cut to allow the saw to cool down;

- You can work in any humidity, for example during rain.

Mini disc sawmill

One or two disks separated by an insert are used as a cutting element.

This sawing machine is widely used because of its advantages:

- simple design, equipped with an electric or gasoline engine;

- easy to use;

- accuracy of cutting logs according to marks;

- high productivity when sawing logs.

The main requirement for a circular saw is a durable frame and a powerful engine.

The peculiarity of independent longitudinal cutting of a log is clearly visible in four simple methods.

The advantage of sawing logs with a chainsaw

The method of cutting logs using a chainsaw has several advantages.

The ability to work under any conditions - the chainsaw is not afraid of humidity, so specialists can cut logs during the rain; in this case, the equipment will not deteriorate.

High productivity - it is allowed to carry out woodworking throughout the day, but it must be taken into account that the power of the device must be at least 7 horsepower.

Autonomous device - the equipment runs on gasoline and does not depend on electricity; the workplace can be mounted in any area where it will be more convenient to carry out the process.

Chainsaw components

Ease of use - the chainsaw is equipped with a soft start and adjustable chain rotation speed; these conditions ensure that beginners in this business obtain high-quality results.

The undoubted advantage is that the equipment costs much less than a small sawmill. During a breakdown, repairs are inexpensive and do not take much time.

Types of log cutting

Before you start cutting the workpiece, you need to decide how to get a high-quality final product with the least amount of waste. The wood is uneven in quality; the lower part of the trunk produces the most valuable lumber. When sawing logs, you can obtain the following types of lumber:

- timber - lumber, more than 10 cm thick and wide. The most common type is four-edged timber, square in cross-section. Used as a building material and in furniture production;

- board - lumber, up to 10 cm thick and twice as wide as the thickness. Boards are obtained from logs or beams and are used in construction and in the furniture industry.

Having theoretical knowledge and practical skills, you can make boards and beams with your own hands.

Preparing for sawing or felling

Any mature tree, large or small, even if it grows near a house on a private plot, is protected by law.

Therefore, before cutting it down, you need to get a felling ticket.

After this, you need to determine the state of the tree and choose a method for its removal, taking into account:

- physical capabilities;

- equipment availability;

- experience in the field of tree felling.

Physical capabilities

To remove a tree, you need good:

- coordination of movements;

- endurance;

- force;

- flexibility.

If you have a problem with any of these parameters, it is better to invite a specialist.

Problems with endurance will lead to the fact that after each performed action you will have to rest, while the tree will be in an unstable state and can fall in any direction.

Lack of strength will prevent you from using an ax and chainsaw effectively, and problems with flexibility will force you to use all tools in an awkward position, which dramatically increases the likelihood of mistakes and injury.

Equipment

The main tool needed for any method of cutting down a tree is a chainsaw.

If it is not there, you can use

- axe;

- two-handed saw;

- hand saw (large-toothed wood saw).

Under no circumstances should you use a grinder (angle grinder) or any discs, because the wood will clamp the disc, after which the tool will be torn out of your hands, and given the enormous speed of rotation of the disc and the high power of the motor, serious injuries are possible. Also, you should not use a hacksaw for metal, because its shape and blade are not intended for such work.

Without a chainsaw, the process of felling a tree will require much more effort, and the likelihood of errors will also increase.

To cut down wood with a guy wire, a winch and door springs are useful, which can be replaced with a rubber band or tube.

For cutting with dropping or hanging, you will need strong ropes or cords with a diameter of 7–10 mm, which can be purchased at hardware or sports stores.

You will also need a mounting belt or a climbing harness, and the latter is preferable, because it will stop the body more gently when falling.

It is necessary to purchase various blocks and carabiners in construction or sports stores. When cutting down large trees, an aluminum folding ladder with a wide cross stop at the bottom is very useful.

Yield percentage

The average volume of output that should be obtained can be calculated in the following ways:

- According to the diameter of the trunk. Suitable in cases where all the sawlogs are the same size. To make the calculation, calculate the volume of one trunk and multiply it by the entire cubic capacity. The method has a slight error. The downside is that it takes a lot of time and human resources to accept products.

- By volume of transport. With this method, the volume of finished lumber for each type of transport is calculated separately. The method is used for large volumes of lumber, as it significantly speeds up calculations. Has a large percentage of error.

- Using measuring frames. This method has a high level of accuracy. When measuring, the curvature and thickening of the trunk are taken into account, which is impossible when calculating manually. The method also allows for immediate sorting of lumber, taking into account its further consumption.

- By multiplying the stack volume by a certain factor. The calculation has a high level of error. The method is used when measurements need to be carried out urgently.

Correct calculation of output affects the cost of future products. This indicator largely depends on the type of wood and how the wood was cut.

Universal device for longitudinal spreading

The universal device Big Mill allows you to accurately cut logs, even those whose diameter reaches 500 millimeters. In this case, the exact thickness of the boards can be set based on a special ruler, which the operator will find on the device stand (applied directly to it). Many craftsmen create their own devices, focusing on the model of this type of universal attachment.

How to unravel a log lengthwise using a universal device? Follow this algorithm of actions.

- We take a couple of even boards, connect them, forming a T-shaped structure with an angle of 90 degrees. This design will act as a ruler, allowing the tool to move smoothly. In this case, the docks need to be twisted in such a way (taking into account the dimensions of the device for longitudinal release) that the power unit does not touch the ruler (it should be placed at a distance of 10 millimeters above).

- Creates a pair of stops, which are ready-made from two parts (L-shaped). These components will prevent the log from rotating when it is cut. For reliability, the boards are secured with metal corners.

- Rolls the log onto the stops (it is easier to roll those whose diameter is relatively small). If you need to install a large log on supports, you will need to ask someone for help.

- We connect the ends of the log and the stops using self-tapping screws (take those that are longer than the rest). You should not use nails, since the second longitudinal cut will require you to rebuild the entire structure.

- The T-shaped structure, which acts as a ruler, is attached to the stops with clamps.

- The ruler is connected to a chainsaw, on which a universal device has already been installed.

- Now we adjust the thickness of the boards that you want to get in the end. When setting this parameter, do not forget about the thickness of the saw and the gap between the T-shaped structure and the blade (10 millimeters).

- We turn the material for cutting away from ourselves by 30 (this will make cutting longitudinally much easier).

- We make a cut lengthwise.

- He removes the ruler, unscrews the clamps, and removes the stops at the ends.

- We place the T-shaped structure on the plane that we got after the first cut, secure the guide element with self-tapping screws.

- We fix the log as securely as possible in order to make an accurate second cut in the horizontal plane. It will run perpendicular to the first cut.

Overview of some options

We will tell you about the two most popular designs that provide the best quality when working, and you yourself will determine which is more convenient and preferable in your case.

Homemade option

First, let's look at how to make a device for sawing logs with a chainsaw with your own hands.

The instructions for carrying out the work are as follows:

- It is best to use a frame from an old school desk or a square pipe with a side of 20x20 or slightly larger.

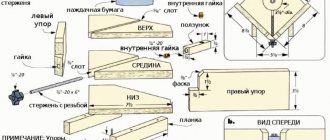

- First of all, two clamps are made, these are elements 50-60 cm long, at one end of which a crossbar with two holes for tightening bolts and a small protrusion in the middle for clamping the tire is welded, an element of the same configuration is attached on top, the photo below shows ready-made elements, as you can see, everything is quite simple, and if you have a welding machine on hand, you can make them very quickly.

The clamps should be sized so that the width of the bolts is slightly greater than the height of the bar

- To longitudinally saw a log with a chainsaw, you need a support frame, the width of which should be 7-8 centimeters less than the length, two elements 10 cm long are welded perpendicular to two of the sides, they should be a little larger so that the clamps fit into them, you need install two fixing bolts; for this, a hole is drilled and nuts are welded in order to screw the fasteners into them; a handle is welded in the middle for ease of movement.

- The system is assembled in the following way: first, the clamps are inserted into the grooves, after which the chainsaw bar is inserted and carefully fixed. The distance is selected depending on the thickness at which sawing needs to be done. To understand how this is done, look at the photo, which shows the assembled structure, the price of the issue is several metal elements and rental of welding for an hour.

This is what the device looks like after assembly

Now we’ll tell you how to cut a log into boards with a chainsaw using this design:

- You will need two sawhorses to serve as supports, they should be of such a height as to ensure ease of work.

- A reliable metal strip or durable board is best suited as a guide. You can make this element from a corner or other metal products.

- A log is placed below, which needs to be set to the desired height, after which work can begin. After the first pass, the log is raised to the desired height and the process is repeated.

The work is quite simple, the main thing is to set everything accurately and fix it securely

Ready solution

The Big Mill Timberjig option is very popular; it is a special kit for equipping a mini sawmill. Sawing logs into boards with a chainsaw using this device is simple and effective.

By purchasing this option, you get everything you need; we’ll tell you how to organize the cutting of logs:

The design is very well thought out and is simple and reliable.

- First you need to connect two strong and even boards together, as a result you should get a T-shaped structure. This will be a stubborn ruler.

- Next, make two L-shaped stops; the delivery set includes corners that are designed specifically for these purposes.

- Roll up the log and place it on comfortable and reliable bars. Attach supports to its ends with self-tapping screws; you should not use nails, since they are much more difficult to remove later.

- Next, a ruler is attached to the installed wooden supports; this is done using clamps, which are also included in the kit, remember that the cut line does not go along the edge of the guide, but 10 millimeters higher.

- Before cutting a log into boards with a chainsaw, we recommend raising one side by about 30 degrees, this will make it much more convenient to work. Fix this position with the help of two supports; if something is not clear to you in the description, look at the photo, everything is shown clearly on it, in addition, the kit always comes with instructions with detailed diagrams.

How to cut a log into planks with a chainsaw? This device allows you to do this easily and quickly

How to cut a log into boards with a chainsaw at home

The fallen trunk can be cut into logs on the ground if you plan to use the wood for kindling and firewood. There is no need to explain how to cut a log crosswise with a chainsaw, the technology here is simple, the main thing is to secure the log well so that it does not sway or move during cutting.

But if the trunk is good, you can cut the log into boards with a chainsaw at home and get absolutely free building materials needed in your own household.

In order to cut a log lengthwise with a chainsaw, you need several devices:

- The bed or frame where the log will be secured. To make it, a corner, channel or pipe is used that is thick enough to support the weight of the log.

- Chainsaw with attachment. You can use a gas cutter, debarker, vertical or horizontal attachment. The most accurate and efficient disintegration of the log is ensured by the horizontal attachment, but it can only be used if the length of the saw bar is no less than the thickness of the log. If you don’t have all this, you can do without an attachment - just make two simple devices with which cutting logs into boards with a chainsaw will be easy and simple.

- Sawing logs into boards with a chainsaw can be done independently without prior sanding - it’s easier to do this later.

Let's look at the easiest way to cut a log into boards with a chainsaw, that is, without specialized attachments. It is necessary to make two simple clamps, welded (the best option) or assembled using bolted connections.

These clamps are T-shaped and approximately 500-600mm long. Another plate or corner is attached to the short “stick” using bolts, and between them there should be a distance slightly greater than the thickness of the chainsaw bar.

The clamps are attached to a homemade carriage with a handle - when cutting logs into boards with a chainsaw, the carriage will move with its help.

Holes are made on the clamps - this will allow you to adjust the height when cutting the log lengthwise with a chainsaw.

https://youtube.com/watch?v=Grj15rGGYRQ

After the first cut of the log with a chainsaw has taken place, it is raised to the required height and the next cut is made according to the same pattern.

Chainsaw sawmill

This type of design is the easiest to manufacture, but it will also require special skills, tools and experience working with them.

This type involves installing the carriage on guides, but is not mandatory. You can use a flat wooden plank as guides, along which the carriage structure will slide easily. It allows you to remove the first layer evenly. The cutting plane on the log is used as subsequent guides.

Attention! The absence of a frame and carriage adds a number of difficulties. The craftsman may have problems holding the log in one position. It is impossible to start work without proper fixation, as this can lead to injury.

You cannot start work without proper fixation, as this can lead to injury.

The step-by-step process for making a carriage for a chainsaw will look like this:

- Let's make the base. To do this, we weld together a pipe measuring 25x25 mm.

- Perpendicular tubes, the size of which is 30x30 mm, are welded to the base on opposite sides. They are necessary for attaching the moving part that holds the saw and sets the thickness of the planks to be cut.

- Nuts are welded into the side parts of the guides. With their help, it will be possible to fix the moving parts at the desired height with bolts.

- We make the moving part. It consists of two pipes with a T-shaped end. The end of the pipes is made in the form of a vice, clamped with bolts and nuts. These clamps will hold the chainsaw blade. Pipe size – 25x25 mm.

- To prevent the saw chain from rubbing against metal parts, two metal plates of the required sizes are welded onto the internal parts of the vice. They completely depend on the thickness and width of the chainsaw blade.

- We assemble the carriage into a single structure, select the desired height and install the saw. The sawmill is ready for use.

The video below fully describes the carriage manufacturing process. In addition, the author of this device notes the main difficulties and some inaccuracies that he made during the assembly of the sawmill. This will allow you to avoid such mistakes and make the device for sawing logs more practical.

Bottom line! This carriage design is suitable for personal use and one-time sawing of wood. It is not suitable for commercial purposes.

How to operate a chainsaw correctly - what are the instructions silent about?

We will not give you advice to look at the instructions before starting work - well, who looks there, you might think! Frankly speaking, the instructions supplied with the tool do not always clearly and intelligibly explain how to use it and how to adjust it. Manufacturers of inexpensive saws are especially guilty of this - it is simply impossible to tension the chain using the instructions, because the manufacturer skimped on high-quality printing, and the image of the parts is completely blurry.

We will try to convey to you the basic safety rules as clearly as possible! The first rule is to protect your hands, face and body!

- Clothing should fit snugly to the body, not hang down or dangle. No scarves, laces, bracelets or chains! Once under the chain, they can pull you too!

- Wear strong, thick gloves that will comfortably hold the saw. Gloves will protect your hands not so much from the saw itself, but from lashing branches.

- Wear sneakers that don't slip.

- Protect your eyes! Glasses made from glass that does not splinter are best.

- A helmet, special headphones or earplugs will not be superfluous.

Never leave the saw running unattended and always hold the tool with both hands. First, get comfortable on small branches, conveniently located. At first, your hands get tired quickly, so don’t plan large volumes on the first day after purchasing the instrument. And the tool itself first needs to be tested on small branches.

Using a chainsaw for longitudinal cutting

Let's consider the technology for manufacturing these lumber using a carriage:

The carriage is made by sequentially cutting off opposite sides. First, cut off the top of the slab until a flat, even surface is obtained. Then the log is turned over, laid on a flat cut surface, and the operation is repeated on the opposite side.

The beam is made by sequentially removing the slab. First they make a carriage, then remove the slab from the sides in a similar way

It is important to ensure that the sides are perpendicular to each other. An unedged board is made from an unsanded log (with the bark not removed)

The most convenient way is to remove the slab, lay the log on the resulting flat surface and sequentially cut the boards to the required thickness

An unedged board is made from an unsanded log (with the bark not removed). The most convenient way is to remove the slab, lay the log on the resulting flat surface and sequentially cut the boards to the required thickness

After each pass, the saw is lowered by the thickness of the board plus the thickness of the chain cut.

To make an edged board, first make a carriage, then cut off a slab from one of the sides and lay the resulting three-edged beam on the middle face. After this, the boards are cut sequentially, the side surfaces of which will be parallel, and the width of all boards will be the same.

Figure 5 - Types of lumber

If you have certain experience and skills, you can cut grooves, quarters and other longitudinal relief shapes. To do this, you need to position the workpiece taking into account the reach of the saw frame and the depth of the chain insertion into the material. Such work is quite complex and requires precision and sufficient width of the support area.

Stages of work

To cut a workpiece quickly, you need to proceed in stages:

Take a board of the required size and decide on the tool. If the workpiece is large, you should use a hacksaw with large teeth. For smaller wood materials, use a saw with smaller teeth. The necessary markings are applied with a pencil and ruler. Draw lines that are barely visible to the naked eye. You need to follow the well-known proverb: “Measure twice, cut once.” First make a drink. To prevent the canvas from wobbling, experts advise holding it with your thumb or a special device called a miter box. This makes the procedure much easier. Cut the wood straight, do not sway the body of the tool from side to side

If the hacksaw gets stuck in the material, carefully release it and try cutting again.

If you follow the recommendations, the procedure will go without problems. No special skills are needed to implement it. Anyone can cut the material.

Some useful tips

A sawmill is an impressively sized unit that is quite dangerous to operate, so before you start assembling it, you should carefully consider the place where it will be used. It should be well lit, ventilated and have free space. The nearby warehouse for finished boards will greatly facilitate the process of processing the material. For a sawmill with an electric motor, you should very carefully install the necessary switches and automatic machines, as well as install the wiring.

Since the most dangerous elements of the unit are all its cutting and moving parts, when assembling the structure they should be given special attention. Before using the assembled equipment, it is necessary to check all fastenings and components, as well as the stability of the structure.

Before starting to operate the assembled equipment, it is necessary to check all fastenings and components, as well as the stability of the structure.

Conclusion

You can cut logs or beams into boards without a sawmill or other massive equipment; an ordinary chainsaw, after a little modernization, can become your best assistant. The video in this article will help you understand this topic even better.

Attachments and accessories for chainsaws

There are several reasons for this wide range of jobs performed by chainsaws. First, this is the presence of a massive (in relation to its own weight), small-sized, reliable and undemanding internal combustion engine, capable of operating in the most demanding conditions. The diaphragm type carburetor and sealed fuel supply system allow the saw to operate in various positions, except perhaps completely upside down. The successful design of the centrifugal clutch firmly protects the systems and components of the chainsaw from overloads and breakdowns. How to cut a log lengthwise To cut a log lengthwise with a chainsaw. Simplicity of power take-off is also important; You can simply connect any device to the output shaft of the tool. And, in the end, the advantages of a chainsaw include autonomy, which allows you to use it anywhere.

However, do not forget that amateur chainsaws are not designed to work all day in intensive mode.

The procedure for performing preparatory work

To cut a log lengthwise, you need to perform the following sequence of actions:

- Take two straight boards and attach one to the other at right angles. The result is a strong guide line.

- To support the manufactured ruler, you need to make stops from boards.

- Moving the trunks must be done using a tilter.

- The log should be placed on a comfortable base.

- You need to secure the frame to the chainsaw bar using nuts.

- The supports of the leading ruler must be attached to the ends of the log, checking the horizontal position with a level.

- Self-tapping screws must be used to secure all brackets and structural elements. Nails are not suitable for these purposes, since they are difficult to remove in the future without causing damage to the structural parts.

- The leading ruler needs to be attached to the supports using brackets and its height adjusted taking into account that the cut will not go along it, but approximately one centimeter higher.

- The log needs to be rotated and the second board secured so that it rests on the ground and supports the log.

Work order

Before starting sawing, it is necessary to free the prepared logs from bark and remaining branches and carefully inspect them for any possible defects. This will allow you to choose the optimal cutting pattern and thereby reduce the amount of possible waste.

When sawing logs longitudinally, care must be taken to ensure that the resulting boards have the same density across the entire width. Since the density of the trunk wood on the north side is much greater than on the south side, the cut is made in a plane directed from east to west (or vice versa).

The first operation when longitudinally sawing a log with a chainsaw is to remove the slab from two opposite sides of the trunk. As a result, a double-edged beam is formed, which is then sawn into boards of equal thickness or other lumber, in accordance with the selected sawing pattern. The output is an unedged board, from which the edges are subsequently removed.

If there is a false core or other defects in the log, it can be rotated 90° or 180°, as with the circular sawing method.

Sawing logs at home

Situations often arise when it is necessary to produce a relatively small number of boards or beams for personal needs. In this case, the purchase of sawmills and other equipment is impractical. If you have certain knowledge and skills, it is much more profitable to cut logs manually, using an electric or gasoline chain saw. This is a rather labor-intensive process, but in some cases it is completely justified.

Most experts agree that using a chainsaw is preferable. Such saws, unlike electric ones, have more power and are able to work without interruption for a long time. In addition, when using a chainsaw, no electricity is required, which allows you to carry out work remotely from power sources (for example, directly on plots).

When cutting logs into boards using a chainsaw, you will need special devices: a device for securing the log, a frame attachment for the chainsaw and a guide along which the cut will be made. The attachment frame is attached to the chainsaw bar so that the distance between it and the chain can be adjusted. This will allow you to get boards of varying thicknesses. It is better to choose a special chain for longitudinal cutting, which differs in the angle of sharpening of the teeth. Sawing logs into boards with a chainsaw with how to cut logs into boards. A metal profile of the required length or a flat, rigid board is quite suitable as a guide.

Maintaining safety during work

To avoid malfunctions and accidents, you should follow safety precautions when working with materials and tools:

- When working, do not allow third parties, especially children, onto the work site.

- During work, you should use protective equipment against noise and sawdust that fly away during cutting.

- It is necessary to have a first aid kit with everything you need to use in case of cuts.

- When using a circular saw, it is necessary to put on a protective guard.

- Do not pour gasoline into a heated chainsaw tank.

- Use the chainsaw only for its intended purpose, do not turn it on at full power if it is not in operation.

- There is no need to put too much pressure on the saw while working.

- The log for cutting should be installed on the right side.

A chainsaw serves as a convenient tool that can be used to make boards yourself. On

Preparing for work

The first thing to start working with a chainsaw is its assembly.

The assembly diagram of different models is practically the same. The saw bar and chain are installed on the saw, and the chain is tensioned. The chain can be considered correctly tensioned if it does not sag on the bar and can be easily turned by hand. If you have to apply too much force to turn the chain, it means it is too tight and you should loosen its tension a little.

Next, you need to check the sharpening of the chain; for this, the cutting edge of each working tooth is visually inspected. The edges must be smooth without dents or nicks.

The next step is refueling the chainsaw. The fuel mixture is prepared in a certain proportion, which can be found by reading the user manual supplied with the saw. Basically, the fuel mixture is diluted in a ratio of 1:50, that is, for one liter of AI-92 gasoline, you need to add 20 grams of oil for two-stroke engines.

Important: when pouring fuel and oil for chain lubrication into the tanks, you need to be extremely careful and not mix them up. If you pour oil into the fuel mixture tank, the chainsaw will not work.

To restore functionality, you will need to flush the fuel tank with gasoline, as well as clean the fuel line and carburetor, which is quite difficult.

Features of a homemade sawing option

It is easy to saw a log into boards using a homemade tool. Manufacturing the equipment is simple:

Diagram of a homemade sawing machine

As a support, you need to use a frame from a school desk or a pipe with a cross-section in the form of a square, its optimal size is 20x20, more is allowed. Build two clamps, mount a cross member with two holes for tie bolts at one end, and make a protrusion in the middle for the tire. For longitudinal sawing of logs into boards, it is important to make a support frame; its width must be 7–8 cm less than the length. Then two elements 10 cm long are welded to both sides, holes are made for the bolts, and a handle is attached in the middle for ease of operation. After this, insert the clamps into the grooves, the tire is installed, and everything is carefully fixed.

Working with a homemade tool is not difficult; for this you will need two sawhorses, they will serve as a support, and you also need to prepare a metal strip or board, the element will be a guiding element. A log is placed underneath and the required height for work is adjusted.

Technique for sawing logs lengthwise

The difficult part in this process is making the first cut; for this you need:

Drawing of a board cut lengthwise

- Mount the leading ruler; it consists of two boards fastened together at an angle of 90 degrees.

- Place the log on the supports and secure its position firmly.

- Check if the log is level using a level.

- Using self-tapping screws, secure the guide ruler to the supports.

- Fix another guide in a horizontal position; the element will rest against the ground, but at the same time fix the log.

- Saw the log.

During the second cut, specialists may not use a leading ruler; the resulting board will serve as a guide. The second cut is made perpendicular to the first.

Secrets of cross cutting

A crosscut saw is used to produce firewood or decorative interior elements. Sawing is carried out according to the following principles:

Types of cuts

- Place the log in a horizontal position on wooden supports, the height should be 0.5 m.

- Clean it from the bark.

- Using an ax or saw, make small marks along the entire length; they should be located at the same distance from each other.

- Make a cut along the cuts.

Cross cutting does not require the use of special devices or attachments. An ordinary chain is perfect for such work, but its rings must be strong.

What to consider when felling trees near your home

It is quite difficult to cut down vegetation, including large trees, growing around houses. Such an event requires a special technology. The following factors may indicate the need for felling:

- the stem part is located at an angle of more than 45 degrees;

- the plant has a tall and thin trunk;

- there are cracks and hollows or rotten areas.

Buildings and structures located in close proximity, electrical communications and utility networks often greatly limit the area of work. In this case, preference is most often given to felling not entirely, but in parts, by hanging and lowering already cut elements. This option requires the mandatory use of special equipment or tying and lowering the cut fragments using nearby trees.

After cutting, a stump remains, which is most often removed by uprooting, which allows for high-quality leveling of the soil surface on the site. To reduce labor costs for such activities, it is recommended to fell trees by cutting off the roots. This cutting is not done directly, but at an angle to the direction of root growth. You need to dig up the roots with a shovel, having first removed the bark from the top of the roots and tapped the soil, which will reduce the risk of the ax becoming dull during the cutting process.

Felling trees with an ax and a regular saw has been used less and less recently, which is due to the availability of electric and chainsaws among country property owners. However, in particularly difficult cases, it is advisable to seek help from specialists who, using special equipment, perform such work very quickly and as efficiently as possible.

A chainsaw with the proper power is capable of cutting down any tree trunk for which the length of the cutting part is sufficient. You need to carry out the work very carefully, adhering to all the rules

Particular attention should be paid when there is a risk of unpleasant situations due to too thick, icy or contaminated wood. You need to take into account all the factors that can complicate the work, and use the chainsaw carefully, constantly monitoring your actions and the work of your partners

In the article we will talk about how to properly cut down a tree with a chainsaw - diagram and instructions.

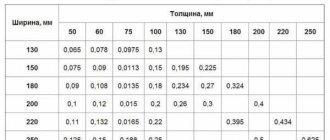

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use a computer program that greatly facilitates the calculation, and the price of which is quite affordable.

Material yield after cutting wood

Or the source could be a regular sawmill reference book. The result is a table that is used as a basis. The sawmill attachment should always be oriented to its data in order to obtain more lumber of any type of wood.

Debarkers

By design, debarkers are divided into drum and disk. The first ones are used mainly for removing bark from logs (cinders); the disk ones cut out mounting grooves, cups, recesses, etc.

The working part of the devices consists of a drum or cutter mounted in a bearing unit. Like most chainsaw attachments, debarkers are driven by a V-belt drive. a driven pulley on their axis for this purpose.

. To rip a log with a chainsaw, you need a support frame. By selecting the diameters of the pulleys and changing the engine speed using the accelerator, you can obtain the optimal rotation speed of the working tool, which provides the necessary processing parameters.

DIY chainsaw carriage. Blueprints

Since the price of professionally produced equipment (similar to that described in the previous section) ranges from 2500 to 3000 US dollars, it is not difficult to come to the conclusion that you can make your own carriage design for longitudinal sawing of timber.

Depending on the size of the chainsaws used, the dimensions of the carriage assembly, as well as its appearance, are shown in the figure.

The manufacture and assembly of a carriage for a chainsaw is carried out in the following sequence. First, the drive motor is prepared for installation. To do this, remove the drive pulley and install the engagement clutch, resulting in a finished cutting head. A support bracket must be made for the motor mounting plate. By changing the diameter of the pulley, you can control the cutting speed of timber - up to 2.5 times faster than allowed by the base engine speed. To reduce the temperature and eliminate the possibility of engine jamming, its output shaft is ground so that the chain drive sprocket, without taking into account the dimensions of the central bearing, fits tightly to the bracket.

The presence of a belt drive on the shaft that drives the chain protects the engine from vibration and shock generated by the chain. All that remains is to adjust the gearing to get the correct chain speed. Then it is necessary to install bearings on the drive shaft for more intense operating conditions, with increased load-bearing capacity.

Most home renovation and construction work requires the availability of the necessary materials. Buying boards or timber of the right size is not a problem, but sometimes you need lumber of a certain size. Planks of one or another type of wood, non-standard thickness or width are often required. Finally, there are simply several logs from which to cut boards. It is possible to solve such problems; you only need a DIY chainsaw carriage.

This simple device allows you to make a carriage, timber or boards of the required thickness from logs of any type. This device is especially valuable because it makes it possible to process non-standard logs - short, uneven or strongly curved. Let's take a closer look at this issue.

Devices for longitudinal sawing of logs (mini sawmills)

Device for vertical cutting of logs

. The simplest is the device for vertical sawing of logs, shown below.

It consists of an adapter (1), attached to the tire at its base, and a guide (2), which determines the straightness of the adapter's movement. The guide is installed on the board (3), which in turn is attached to the log being cut.

The main purpose of this device for a chainsaw is to ensure the straight movement of the bar. With its help, you can not only dissolve a log into two or four parts (quarters) or cut a beam out of it, but also saw it into boards or beams. However, in the latter case, you will have to rearrange the board with the guide each time, and it will not be possible to achieve great accuracy when sawing. The unfixed end of the tire may move to the side, as a result of which constancy of the parameters and complete parallelism of the sides of the beams or boards are unlikely to be achieved.

Device for horizontal cutting

.

Using the device shown in the photo below, logs are cut in a horizontal plane. Compared to a device for vertical cutting, it has increased functionality and accuracy, allowing you to cut boards or beams of the same thickness.

A device attached to the tire in two places. beginning and end. has a frame structure that ensures the rigidity of the device. The mounting location (1) can move along the tire. This allows you to set the required cutting width (according to the diameter of the log ). within the length of the tire. The guides (2) can be installed at any distance from the tire, thereby ensuring the required thickness of the cut beams or boards. The first horizontal cut is carried out using a guide frame (3) mounted on the log and serving as a base surface for the guides (2). For subsequent cuts, the flat surface (4) obtained in the previous pass is used as the base surface. During operation, to avoid pinching the saw, wedges are inserted into the cut to prevent the cut from narrowing.

If it is necessary to cut logs whose diameter exceeds the length of a standard bar, a more complex device is used, which uses a long bar. In this case, the saw’s native lubrication system does not provide high-quality lubrication of the entire chain, so it becomes necessary to install an additional system consisting of a tank and a hose that supplies lubricant to the end of the bar. To ensure oil supply by gravity, the tank is placed on a rack above the tire.

Machines for longitudinal cutting of lumber. Video materials

Related Links. Additional Information

- Directory of woodworking machines

- Manufacturers of woodworking machines and equipment

- Manufacturers of household woodworking machines

- Manufacturers of chipping machines

- Classification of woodworking machines

- Machines for longitudinal cutting of lumber

- Sawmill frames. Classification

- Lumber. Basic concepts. Terms and Definitions