What is wood brushing

Many designers resort to the procedure of brushing or artificially aging wood. This is a great way to make your interior look original and expensive.

- Brushed wood retains all its physical properties, but acquires a new, spectacular, original appearance.

- Such a decorative technique is appropriate in the interior of residential premises, cafes, shops and other places with a non-standard character.

- Aged wood easily adds special expressiveness to any setting and brings a hint of the place’s involvement in the depths of history.

The complex technology gained popularity due to the extraordinary effectiveness of the result. It is considered one of the most popular types of decorative wood processing.

With its help, furniture, finishing panels, doors, stairs and other wooden structures are stylized as antique.

Compliance with safety regulations

Brushing must be done in protective clothing, special glasses and gloves, and when using chemical solutions or the accumulation of large amounts of dust, in a respirator. You should also be careful when working with machines.

We hope that our master class and your imagination will help you make unique things that will be the subject of admiration for everyone around you, will make the interior of your rooms original and refined, and will last for many years, delighting the owners and guests of the house with their appearance.

Methods of aging wood, advantages of brushing

There are 3 ways to age wood artificially. Each of them has its own nuances. At home, it is most acceptable to use brushing.

Forced aging of a wooden surface is carried out in the following ways:

- Mechanical impact. The treatment is carried out by applying metal brushes to it. Simple processing is called brushing, and grinding after applying tinting compounds is called patination.

- Chemical change. A chemical composition based on alkali and ammonia is applied to the surface of the wood. As a result, the color of the upper layers changes, creating the effect of time.

- Heat treatment. Lightly burn the wood surface. After heat treatment, the material is sanded with a wire brush and tinted.

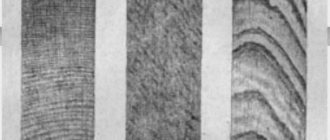

Brushing in any form leads to a beautiful structuring of the surface. Soft fibers are removed, the material acquires additional density and texture with a bright pattern of annual rings.

Useful tips

Here are some useful tips that will make your work easier and make your results even better:

- Before starting work, the workpiece can be fired. This is done using a torch. Firing performs two functions - practical and aesthetic. The first is that during the procedure the soft fibers of the wood soften even more. As a result, they are easier to remove, so the texture of the workpiece becomes more prominent.

- The aesthetic function is that part of the burnt wood remains in the depth of the grooves on the board. This makes the material more contrasting and beautiful.

- If you need a less pronounced, non-contrasting texture, use special brushes for brushing. Their fibers are not wire, but polymer. Thanks to this, such brushes act more gently on the wood and leave less deep grooves without completely removing the soft fibers.

- If polymer brushes are used, it is better to sprinkle them with abrasive. This will make the processing more effective and better emphasize the texture of the wood.

- The finished board can be treated not only with stain, but also with silver or gold paint. It should be applied to protruding parts or recesses. This will emphasize the contrast of texture. Apply silver or golden paint with a sponge and lightly blot the surface with it.

- If you need to paint the recesses, use a thin brush. If silver or golden paint is applied to the wood, it must be varnished - otherwise the paint will quickly wear off.

Types of wood for brushing

Hard or medium-dense wood types are suitable for brushing. During the processing process, it is necessary to remove the upper softer layer, but not damage the entire thickness.

During brushing, soft wood can crumble and delaminate.

Therefore, when choosing a material, attention should be paid to the following species:

- Oak;

- Nut;

- Pine.

In addition to the density of the material, the presence of a bright natural pattern is important. Otherwise, the decorative effect will be lost. Patination, as a subtype of brushing, is carried out on wood with both a dense structure and a weak texture and pattern. Such options include cherry, maple, and beech.

Advantages and disadvantages

This method of wood processing has its advantages and disadvantages. Any master takes them into account before starting to work with wood.

The advantages of brushing include:

- Improving the technological properties of wood by increasing strength and resistance to moisture.

- Achieving a visual effect, improving the texture and texture of the fibers.

- Variety of materials to work with.

- Possibility of subsequent processing and tinting.

The only downside is the complexity of the brushing technology itself. The work is energy-intensive and requires a certain amount of time. Dust can accumulate between the treated wood fibers, which requires constant care.

Types of wood processing

Brushing wood can be done with your own hands, but on a small scale. This is a long and labor-intensive process that is difficult to perform on a large scale without special equipment.

If large elements need to be processed, then it is better to do it in a factory. The result can be deep and light. In the first case, brushes with thick metal teeth are used.

For light brushing, it is enough to take a tool with synthetic hard bristles. Depending on the strength of the impact, the scale of the effect of the treatment changes.

What you need for work

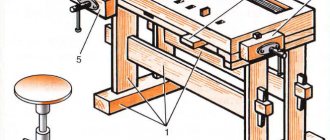

Brushing does not require a large set of tools and materials, but the process will take time.

Before starting work, you need to prepare the place and everything necessary for the procedure:

- Brushes with bristles of different thicknesses;

- Sandpaper;

- Decorative compositions (tone, stain, wax, oil);

- Finishing varnish.

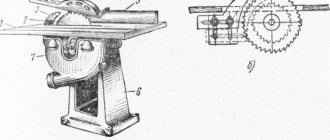

This kit will help you do a small amount of work manually. Professionals require hand-held grinders or specialized machines, as well as additional devices for brushing.

Use attachments for drills and grinders. The mechanized process is easier, but requires experience in using tools.

Main stages of brushing (step by step instructions)

The entire process of brushing wood with your own hands includes 4 stages. Each must be performed carefully, following the sequence. The result depends on this.

Surface preparation

A pre-cleaned, dry wood surface is suitable for work. The material must initially be treated with a coarse brush.

- This will remove all soft fibers from the surface.

- When processing, you will have to handle the material carefully; you should not press the brush too hard.

- The processing is carried out along the grain along the entire plane, preventing damage to the structure of the wood.

If a power tool is used for manual processing, the number of revolutions should not exceed 1500-2200.

Grinding

Grinding is done using brushes with a synthetic surface. Move strictly along the fibers. They strive to eliminate all roughness.

To remove accumulated dust, periodically tap the product on the back sides. Sanding can be done either with a special machine or with coarse-grained sandpaper.

Polishing

To give the product smoothness and a slight glossy shine, the surface must be polished.

- This can be done using a soft brush and fine abrasive sandpaper.

- The work can be done using the rough side of a dishwashing sponge. Take a new, dry copy.

To obtain a slight correction of the natural pattern, you can run the tool across the grain of the wood. This method should not be abused.

Is it really that simple?

No, not all of them. Of course, if a small part is being textured, for example, the lid of a wooden box, there will not be any particular difficulties. But when processing large surfaces or mass production of parts, a technology that seems simple at first glance reveals many pitfalls.

What should you be prepared for?

When working with large volumes of wood, the performance of a conventional drill or angle grinder is often not enough. Working under wear increases the likelihood of tool failure. This problem is partly solved by reducing the speed, but this is reflected in a decrease in process productivity.

Holding a tool operating at maximum speed requires considerable physical effort. The brushing process itself is very long and requires constant monitoring, otherwise the uniformity of the relief cannot be guaranteed; Another common defect is the appearance of burns.

Working with resinous wood has its own specifics. Due to high friction, brushing brushes heat up the surface being treated. This leads to resin bleeding, which adds headaches during the work and finishing stage.

Coloring or tinting

To give wood a more impressive appearance, staining or tinting is usually done.

To do this, use a water-based stain.

- The coating is done with a brush or sponge; it is important to carefully rub the tone along the fibers.

- If, during painting, fluff is visible that rises during the processing process, then it is necessary to stop the process, dry it and sand the wood again.

- Only after this can painting be continued. It is permissible to use complex methods of color changing, which are performed strictly in accordance with the instructions.

Brushing wood is called a great way to change the ordinary appearance of the material.

As a result of step-by-step preparation, the product receives a unique charm. Such items become a real highlight of the interior, a luxurious addition to it.