Areas of application of wood.

Construction. Wood is used in construction in forms such as square lumber (timbers, planks), veneer, plywood, railroad ties, posts, piles, posts, shingles, and fiberboard. The most consumed lumber is rectangular. Wooden houses, the main type of house for many centuries of Russian history, are now becoming increasingly popular. Wood is used to make carpentry, flooring, parquet, and wall cladding.

Furniture manufacture. Wood processing products such as wood fiber and particle boards are used. Solid wood furniture is highly valued.

Fuel and wood pulp. The use of wood as fuel throughout the world is still very important. Wood is an alternative fuel to coal, gas, oil, and electricity. For many small settlements, wood is the most accessible, cheapest type of fuel, requiring minimal transportation. Firewood is also used as a tribute to tradition or for aesthetic purposes, for example for heating fireplaces. The use of wood in the form of wood pulp has been continuously increasing in recent times and is projected to continue to increase for the foreseeable future.

In the pulp and paper industry, wood is a raw material for the production of paper and cordon.

Production of musical instruments. Only wood species are capable of creating the original sound of the vast majority of stringed musical instruments.

Artistic carving. Art and souvenir products.

Writing icons. It is carried out on wooden boards, which are prepared using a special technology.

Kids toys. Wood is an environmentally friendly material, and in all its properties it is suitable for making children's toys.

| Rice. 10.12. Wooden houses made of glued (left) and chopped (right) logs. Masters V.I. Ivanov, A.A. Kolos, A.G. Vaulin. | |

Sport equipment. Despite the massive use of polymer materials in the manufacture of sports equipment, wall bars, gymnastic sticks, bats, tennis tables, and other equipment continue to be made from wood materials.

Car finishing elements. Decorating the interior of a car with wood elements increases the prestige of the car.

Charcoal is produced by incomplete combustion of wood. It has a high specific surface area and exhibits pronounced absorption properties. For centuries, charcoal has been used in elevated temperature processes as well as in metallurgy. Russian industrialist Smirnov used coal to purify vodka. Currently, coal is a commercial product and is widely used in everyday life.

Chemical industry. As a result of chemical processing of wood, synthetic fiber, cellophane, alcohol, yeast, fiberboard, polymer-impregnated wood, wood laminated plastic and various molded products are obtained. Progress in the processing and use of wood has stimulated further development of forestry

Various folk art products are made from wood materials: children's toys, kitchen cutting boards, carved wall panels, icons of saints, boxes, photo frames, salt and pepper shakers, stands for napkins and business papers, doors and fragments of kitchen furniture and interior, carpentry tools , master models, building structures, engineering parts, furniture, artistic parquet.

Violin.

The violin is an amazing instrument made of wood, which has not changed its shape for several centuries (Fig. 10.13).

| Rice. 10.13. Violin making by modern masters. |

A good violin is as rare as a large diamond. Such violins usually have their own names and history. It happened that violin makers produced such a violin by chance once in their entire lives, but there were also masters who mass-produced top-class products—Cremonese craftsmen. The ancestor of these masters was Amati. Amati made violins from pear wood and protected them with his own varnish. A freshly made violin that is not varnished sounds best. The elongated soundboard of the violin along the direction of the grain of the wood from which it is made ensures that the sound wave is simultaneously separated from the entire contour of the soundboard. After all, sound waves travel faster along the fiber than across it. Deviations in the shape of the violin from the oval and the slot in the soundboard distort the sound wave, coloring the sound with overtones. An unvarnished violin sounds great, but it doesn’t last long, since oxygen in the air oxidizes the wood fibers, turning them into dust. In addition, such a violin will pull moisture from the air like a sponge, which will have a detrimental effect on the sound. So whatever one may say, varnish is still needed. If the varnish is soft, it will protect the wood well, but will dampen its vibration, and if the varnish is hard, it will accordingly be more fragile and, through its cracks, the wood will be destroyed by external influences. Amati’s “Know How” was the recipe for his varnish, which was precisely the golden mean. Among Amati's descendants there were no talented people to whom he could pass on his secret. Then Amati passed on his secret to his best student, Stradivarius , and the era of Stradivarius violins began. Stradivari improved the Amati varnish through practical experiments. His violins were more durable and sounded better than Amati's violins. In Stradivari's old age the situation repeated itself. That is, the direct descendants of Stradivari were unable to continue the work of their father, and Stradivari, during his lifetime, passed on his secret to his best student - Guarneri . Over the years, young Guarneri not only learned how to make violins, but also managed to steal a varnish recipe from Stradivarius. When young Guarneri revealed his origins to old Stradivari, he kicked Guarneri out. Without his own working capital and fixed production assets, young Guarneri could not start making violins and was constantly looking for a sponsor. This sponsor was the Order of Jesuit monks. The agreement was extremely simple. The Jesuits provide Guarneri with a workshop, tools and materials, Guarneri makes the violins, which he signs (Guarneri for Jesus), and the Jesuits buy these violins, deducting Guarneri's overhead from their cost. Thus, the Guarneri Violins with the name of God passed through the hands of musicians and became the property of the Jesuit Order. The Jesuits well understood the value of their collection and used it where money was powerless. For example, to solve their problems, the Jesuits made offerings to the French, German and British kings, both in the form of individual violins and in the form of string quartets by the same master, signed with the name of God. They say that one day Guarneri, having deceived the vigilance of the Jesuit guards, gave his violin to a wandering musician. Then the Jesuits found this musician, killed him and returned the violin. Now there are no Amati violins in the world, very few Stradivarius violins, but the violins of the young Guarneri have survived. In many countries, these violins, regardless of the actual owner, are the property of the state and cannot be sold abroad. In the USSR, violin competitions were held and the winners of these competitions were given violins for lifelong use. So such a violin was something like an order for a recognized musician, only for the musician himself such a violin is something more than an order. The opportunity to play such a violin brings the musician closer to the heights of professional skill.

The violin is considered a deified musical instrument. The names of the parts of the violin have been preserved: head, neck, chest, waist, darling. The violin was created as an analogue of the human voice. Until now, even with the most modern technology, it has not been possible to synthesize the timbre of a violin. Over the centuries, the technology, materials and methods of making a violin have been perfected, which have remained virtually unchanged since the mid-18th century. The violin has become one of the most classical instruments.

The structure of a violin is the most complex in terms of physics, acoustics and resistance of materials. Three types of wood are used to make a violin: maple, spruce and ebony (black) wood. Depending on the properties of the wood, various tool parts are made from it. Since the top is almost entirely responsible for the sound of the bass strings, the combination of softness and elasticity of spruce is ideal for it. The back, head and sides are made from maple. The back mainly works for the upper register, and the density of the maple corresponds to these frequencies. The neck is made of ebony. Ebony, due to its high rigidity and strength (by the way, it sinks in water) has maximum resistance to wear from strings. Only ironwood can compete with it, but it is very heavy and has a green color.

The combination of maple, spruce and ebony is used in almost all stringed wooden instruments: bowed instruments, guitar, balalaika, domra, lyre, zither, harp and others.

Many generations of craftsmen have experimented with various materials for making violins (poplar, pear, cherry, acacia, cypress, walnut), but maple and spruce best meet the acoustic requirements. This is confirmed by all modern research.

The best wood for making a violin is considered to be one that grows in the mountains. It's a matter of climate. In the mountains, wood is exposed to sudden temperature changes and is not oversaturated with moisture. Thus, the summer layers become smaller than on the plain and, in general, the relative elasticity increases, i.e. sound conductivity. According to established tradition, to make the back, craftsmen use wavy maple, which is distinguished by a beautiful wavy pattern. There is a known historical fact that wavy maple fell into the hands of Italian craftsmen. In the 18th century, Türkiye supplied Italy with maple for oars on galleys. The oars were straight-grained maple. But since it is difficult to understand its structure without sawing a log, batches of wavy maple often came in, to the delight of violin makers. By the way, working with wavy maple is much more difficult than with regular maple.

Summary.

Wood is a relatively hard and durable fibrous material consisting of cellulose, lignin, ash-forming minerals, organic substances, used as a building material and fuel, and in crushed and chemically treated form as a raw material for the production of paper, fiberboards, artificial fiber and other products . A tree consists of roots, trunk, branches. The cut obtained by sawing a log crosswise is called an end cut. A radial cut is along the fibers, passing strictly through the core of the log. A tangential cut is a cut along the fibers, parallel to the core and at any distance from it. The cross-section shows the main structural elements of wood: core; medullary rays; core; cork layer; bast layer; sapwood; cambium; annual layers.

The physical properties of wood include: appearance, smell, macrostructure indicators, humidity and associated changes (shrinkage, swelling, cracking, warping), density, electrical, sound and thermal conductivity. The mechanical properties of wood include: strength, hardness, rigidity, impact strength and others. All wood defects are divided into nine groups: knots; cracks; trunk shape defects; structural defects of wood.

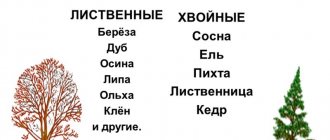

Tree species include deciduous and coniferous species. The main types of conifers include pine, spruce, larch, cedar, juniper, cypress, and Siberian fir. Deciduous trees are more numerous: oak, ash, beech, common birch, Karelian birch, linden, maple, apple and other types of deciduous trees.

Wood materials come in the form of sawn, crushed and laminated wood, as well as veneer. When sawing a tree trunk, you get: timber, edged board, unedged board, slab. The products of wood processing are wall panels: block house, plank, siding. The molding includes platband, plinth, planed boards, timber, lining. Wood flooring and parquet products include parquet flooring boards, deck boards, and flooring boards. Wood materials and products are used in construction, furniture production and in numerous other industries and crafts.

Questions for self-control.

1. What materials are wood?

2. What are the similarities and differences between coniferous and deciduous species?

3. What are the main parts of a tree, and what practical significance does each of them have?

4. What type of tree is larch?

5. What types of cuts are used when sawing a tree trunk?

6. What is the layer of wood around the core of a tree called?

7. How many layers does the tree bark consist of?

8. Name the representatives of kernel-free tree species?

9. What are the main chemical elements that wood is made from? Why does wood burn in an oxygen-containing atmosphere?

10. What types of cells is wood made of?

11. What characteristics of wood are considered physical properties?

12. What property of wood is characterized by its texture?

13. How is the water absorbed by wood located in the structure of the tree?

14. Why is there the following rule in mines: install wooden support with the butt up?

15. Within what limits does the density of wood vary? How is wood classified based on density values?

16. How is density related to the hardness of wood?

17. Why are wood products used in electrical wiring systems?

18. How are types of wood classified according to hardness values?

19. Why do many properties of wood have different values in the direction perpendicular to the end cut or radial cut?

20. In what directions does wood split and why?

21. What changes are considered defects? How many types of defects are identified?

22. What are the causes of wood cracks? What are the reasons for their appearance?

23. Under what conditions do trees with increased camber grow?

24. How does dryness of wood manifest itself?

25. What types of wood are characterized by such a defect as tarring?

26. What characteristics does pine wood have? What products is pine used for making?

27. What distinctive features are characteristic of larch wood?

28. What kind of wood is used to infuse cognac in barrels?

29. The wood of which hardwood tree has the most expressive texture?

30. What type of deciduous tree wood is classified as a non-core species, is it light, white, and is used in the manufacture of various products?

31. What types of lumber are sawn into a tree trunk?

32. In what areas and for what purposes are planed and peeled veneers used?

33. What types of products are included in wall panels, moldings, flooring and parquet products?

34. Why does thermowood acquire low hygroscopicity?

35. What type of wood is best to make deck boards from and why?

36. What types of trees are used to make violins and why?

37. How does the structure of trees grown in the mountains differ from the structure of trees grown in lowland areas?

Properties of coniferous trees

Coniferous trees are characterized by high resin content and a pungent odor. They differ from deciduous trees in a more pronounced structure.

Pine

This tree is the most famous among woodworkers. Stroyles has a color from almost white to brown. Trees growing at higher elevations with little moisture have a harder and stronger structure.

- Pines growing in moist soils have a looser structure.

- Dry pine material is easy to process - you need to plan along the grain and saw across it.

Furniture, structural bases, windows, doors, and stairs are made from pine.

Wood is perfectly decorated with varnishes and paints.

Spruce

Softer than pine, but difficult to process due to the large number of knots. It has an inexpressive texture.

- Spruce is more susceptible to rotting, but warps less.

- The material is poorly processed, but it glues easily.

- The knotty nature allows it to be used as a mosaic.

Spruce is used in structures that do not experience serious mechanical loads.

Fir

It is less durable than spruce, with the same scope of application.

Larch

The strength of larch exceeds that of oak. The wood has a red-brown color.

- Moisture-resistant material, easy to process.

- The highly resinous fiber quickly coats the processing parts of machine tools.

- The lumber does not warp, but with accelerated drying, cracks appear.

- Used for carpentry and carving work.

Paints well with nitrocellulose varnishes.

Cedar

The material is rot resistant. At the same time, it is not particularly strong. Endowed with a beautiful texture of various shades. It depends on the place of growth.

- Cedar is not susceptible to wood pests.

- The tree has a sharp, unique smell.

- Used to create wooden furniture frames.

- Suitable for cutting tools.

Typically, cedar is not polished, but coated with wax.

Juniper

The shrub has a trunk diameter of up to 10 cm. It has durable wood, with thin layers. The material is easy to process and has a special smell. Serves as a raw material for the manufacture of small items, mosaics and wood carvings.

Cypress and thuja

Trees with properties similar to juniper. They have wider dark wood. Successfully used for wood carving. Cypress does not develop defects during drying.

Yew

Contains red-brown wood with white sapwood. Hard and strong rock with many knots. Unaffected by insects and atmosphere. Easily amenable to carpentry tools, polished and painted. Good for cutting and making mosaics.

Cedar

The stateliness and beauty of cedar have long earned it a reputation as one of the most valuable tree species used in construction. This soft and light wood with a resinous texture and a recognizable, slightly balsamic smell cannot be confused with anything. The advantages of cedar are countless: it is unpretentious in processing, has excellent hydro- and thermal insulation, absorbs paints and varnishes well, is a natural antiseptic and also has a beneficial effect on health.

In many mechanical, physical, environmental and aesthetic indicators, cedar is superior to all other types of wood, but working with it requires a special approach. For example, the processing process is somewhat complicated by the knots and resin pockets present in cedar. Mostly in Russia, Siberian cedar is used, delivery of which to the construction site can take up to two months.

Spruce

Being one of the more demanding species, spruce is, nevertheless, widely used in the construction of log-frame houses, log houses from round logs and in the manufacture of internal supporting structures. This coniferous tree boasts an exceptionally straight trunk, whose length can reach 60 m and a diameter of 2 m - spruce is preferred in projects of buildings made of long timber (logs over 6 m in length and 36 cm in diameter).

The tan wood has very noticeable lines of resin channels and pockets that form a dotted pattern in cross section. Unlike pine, spruce cannot boast of durability in its untreated form and has relatively low impregnation, which makes timely processing of wood simply necessary. However, spruce also has its undeniable advantages - it perfectly withstands horizontal loads (suitable for slab structures and beam floors), and after drying and shrinking the house, it firmly secures any connections (structural, on nails and screws, etc.).

Pine

The continued popularity of pine in construction is due to several factors. This is one of the most common and accessible breeds in Russia and in the world, which is also quite easy to process (cutting, grinding, protective impregnation). Almost universal building materials with a uniform texture and characteristic resin channels are made from trees with a height of 20 to 40 m.

Pine log houses are distinguished by their rare strength, and the wood itself has high levels of air and moisture permeability, thermal conductivity and resistance to biological influences. A house made of such material will withstand any whim of nature, maintaining the most comfortable living conditions inside. Another advantage of pine is its relatively low cost, which allows it to be used in the construction of houses of varying complexity and size - in particular, frame houses, log houses made of round logs and houses made of gun carriages.