Types and purpose of sawing machines

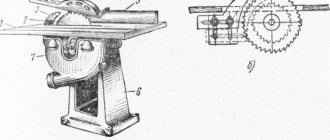

The purpose of sawing machines depends on the direct functionality and the materials being processed. There are woodworking machines, planing, sawing and sawmills in the form of full-fledged sawmills, format-sawing, longitudinal-sawing and cross-sawing.

Based on the type and type of cutters that cut the material, sawing machines are divided into circular saws, equipped with a circular saw, and those equipped with a strip or bending saw. Depending on the degree of hardness of the wood species being processed, the bending saw moves straight or along a curved path.

Wood processing is carried out with a simple steel saw. Artificial materials (brick, slate, tiles) and decorative stone (granite, marble) are processed using diamond and pobedite tips. Steel saw blades due to the existing small teeth and large abrasive ones made of fiberglass can cope with cutting metal.

Machines used for making briquettes

At modern dachas there is a lot of equipment that requires appropriate fuel for normal operation.

A question arose: is it possible to create briquettes from sawdust that can be used as fuel, for example, for a greenhouse?

You can find a lot of unnecessary materials at the dacha. It can be:

- sawdust;

- boards;

- wood remains;

- straw;

- branches;

- coal waste;

- dry leaves;

- cardboard;

- paper.

All these materials burn well, but to use them you need to grind them. To do this, you can use special machines, so-called shredders. You don’t need to make them yourself; special stores offer ready-made devices for sale.

For such work, a rotary machine is suitable, which, using knives, can grind plant material.

The cost of such a machine is affordable for any summer resident. This device is indispensable when it is necessary to obtain plant fertilizers.

This machine can also be used to produce fuel briquettes. However, this machine alone is not enough; you must have additional equipment.

Technological process

To make briquettes you will need clay and, of course, sawdust. They are mixed in a ratio of 10:1, water is added until the consistency of the solution becomes formative. It is very important that the clay evenly occupies the entire volume of sawdust. It is the main connecting element.

You can mix this mixture by hand, but if possible, you can use a construction mixer. He will do such work quickly and efficiently.

A variety of materials are suitable for forming briquettes:

- boxes;

- discarded pots;

- any container.

The best molding materials are boxes.

Such briquettes have a precise geometric shape and rectangular cross-section. In this form, they are easier to store, since storing them will not cause any difficulties. The formation of the future fuel should be carried out by pressing the finished solution.

The last operation of making briquettes is their drying. It's good when it's bright sunny weather outside. Briquettes dry very quickly.

To give strength to the briquettes, it is necessary to line the bottom of the molding box and its walls with paper before forming. Then pour in the prepared solution and press.

What kind of machine can you use to make briquettes?

Home craftsmen make such machines for making sawdust briquettes with their own hands. Briquettes are obtained in the form of bricks or round blanks.

Manufacturers of sawing machines

The choice of sawing machine manufacturer depends on many factors. This includes existing experience in working with power tools, expectations associated with its use, reliability and ease of use, value for money. Inexperienced buyers rely on user reviews, advice from colleagues and friends. More advanced ones - based on their own experience, knowledge of the basics of carpentry. The market for manufacturers of sawing machines is represented by the following participants:

- Makita Corporation is a Japanese corporation whose activities are aimed at producing professional power tools in the construction sector of the economy. There are more than a thousand different models in the range. They guarantee efficient processing of various materials. The quality of components and the reliability of the units have proven themselves positively in extreme operating conditions.

- Metabowerke GmbH is a German company that produces a wide range of equipment used in households and industry. With the motto “When Reliability is Needed”, they are committed to a combination of German practicality, efficiency and equipment durability.

- JET Equipment & Tools is an American company that produces equipment for wood and metal processing. The production of machines takes place in the USA, Germany, China and on the island of Taiwan. The development of machine tools is driven by innovative solutions from leading engineering minds.

- TechTronic Inductries is a well-known Japanese company. It develops and markets electrical equipment and garden equipment under the Ryobi brand. Products are assembled directly at our own franchise factories in the USA, Germany and China. The equipment has gained popularity due to its high quality, the introduction of advanced technologies, wide functional applications and affordable pricing.

- Einhell Germany AG is a German company that produces various tools intended for construction and repair work, gardening and vegetable gardening. Equipment assembly takes place in Asian countries. The company adheres to the concept of synthesizing excellent quality with simplicity in solving assigned tasks, combined with a loyal pricing policy.

- Black+Decker is a company that originated in North America. It produces a wide range of power tools for construction work, garden equipment and various household appliances. The company's products allow you to solve many problems related to arranging your own home or summer cottage.

- Stavr is a domestic manufacturer of construction power tools and equipment for work on a personal plot. All manufactured products are subject to quality control. When improving models, customer wishes are taken into account, which allows us to produce more reliable and safe models.

- Caliber is a Russian company that produces construction tools with a low price tag, without additional options or frills. Updating the product range and improving the company's earlier models allows it to quickly respond to growing customer demand.

- Zubr OVK is a Russian company that produces construction equipment. The products produced have proven themselves to be of high quality, reliable and easy to use, and their low price ensures good competitiveness with equipment from foreign manufacturers.

- Bosch is a popular German corporation. It is a reliable supplier of tools and household appliances around the world. Leading positions in the sales market are ensured due to the quality, reliability and wide functionality of the products.

- Proma-group is a Czech industrial corporation that produces more than 600 types of universal wood and metalworking equipment, manual and automatic. The testing carried out as part of product quality control allows us to achieve an optimal degree of reliability that meets international standards.

Which sawing machine to choose for your home workshop

When planning to purchase a sawing machine, you need to understand what it is for and how to use its 100% potential. There are a number of criteria that are worth paying attention to.

Mobile or stationary sawing machine

In other words, we determine how important the transportability of a sawing machine is. Whether a mobile saw model or a stationary one will be located in the workshop depends on the application that suits you.

The advantages of a mobile machine are its compactness and light weight, which allows it to be carried, ideal for the on-site nature of the work performed.

The downside is that the productivity of the machine is limited by certain dimensions of the parts being processed. More expensive stationary models are designed for spacious rooms that provide access from all sides. This freedom of action allows you to work with larger workpieces and put their production on stream.

Saw table material

Before purchasing a ready-made sawing machine, it is important to make sure that there is a standard table that serves for convenient placement of the workpiece during processing. The standard table is made of durable and mechanically resistant material - stamped steel, cast aluminum, cast iron. A cast iron table is not subject to deformation and is often in demand among professionals who process the material on a regular basis.

Table extenders

When working with large-format workpieces, you will need to increase the table surface area. Folding and sliding structures allow you to temporarily increase the area. Sometimes side stops are used for this.

What you need to know about the engine

Sawing machines are equipped with asynchronous or commutator electric motors. Most machines are connected to a fixed network. There are battery powered models. The adapter allows them to function for a long time. The engine power is proportional to its speed characteristics of the saw and the thickness of the cut. For optimal operating mode, a power of 1200-2000 W is enough.

For professional use, you should pay attention to power plants that support variable loads.

Disc rotation speed

For better cutting of wood, the linear frequency of movement of the teeth at the point of contact is important. Therefore, the rotation speed of disks with a larger diameter should tend to be smaller, and those of a small diameter should tend to be larger.

For stationary equipment intended for work outside of large workshops, it is 4000-4200 rpm.

Portable models rotate in an increased range -4500-6000 rpm. For universal units capable of cutting the hardest grades of steel, the speed is reduced to the detriment of the quality of the cut surface to 2000-2500 rpm.

Disc overhang and maximum workpiece thickness

The overhang of the blade depends on the maximum thickness of the workpiece cut at a time without turning over. For standard carpentry work, this figure is at least 50-60 mm.

Carriage

The carriage serves for precise fixation and smooth longitudinal movement of the part in relation to the cutting disk, which achieves deep cutting precision and reduces the risk of injury. Depending on the design intent of the manufacturer, the workpiece being processed or the working head of the machine may move.

Protractor and rip fence

The protractor is responsible for the accuracy of cutting wooden blanks at a certain angle. Its removable design is attached using clamps to the desktop or carriage. For more economical saws, the protractor is cast from aluminum alloys or plastic elements. Higher quality models are equipped with polished steel protractors. The parallel stop reproduces the required geometry of the workpiece. At the moment of cutting, it moves along the surface due to rigid fixation and lack of play.

Saw blade mounting hole

The most popular bore diameter for circular saw blades is 30 mm.

IMPORTANT! To effectively use cutting elements, adapter rings should be used for shafts of smaller diameter.

Equipment for sawdust production. How to make sawdust

Sawdust is produced at wood processing plants as industrial waste. New technologies make it possible not only to burn them, poisoning the atmosphere, but to use them through recycling - for the manufacture of various materials necessary in everyday life and production. Sawdust can be produced using equipment specially designed for this purpose. It consists of several elements:

- A wood cutting machine that crushes wood into technical chips,

- Dispenser-storage (hopper),

- Chipper for wood chips.

Such equipment is quite simple and relatively inexpensive. To produce sawdust, you can use illiquid wood, which is not suitable for making furniture, building materials and veneer. You can use dead wood and fallen trees from the forest. This way you get cheap material and contribute to the purification of nature. To produce pressed sawdust, you need more complex and expensive equipment called a granulator line. It consists of the following elements:

- Chopper,

- Receiver hopper and dispenser,

- Dryers,

- Thermal generator,

- Cyclone type fan,

- Dry product bins,

- Machines for the production of briquettes.

Sales of sawdust can be carried out in several directions. Pressed sawdust is in great demand in construction, where it is used for the production of insulation materials. You can also make pressed sawdust for livestock farming, where it is used as livestock bedding, cat litter, and briquettes for smoking. Fuel briquettes are made from sawdust.

kudavlozitdengi.adne.info

Best Budget Wood Sawing Machines

CALIBR-EPN-900

CALIBER-EPN-900

An affordable model designed for sawing wood products. A perfect cut is formed due to the universal design of the table with dimensions of 335x550 mm. A blade with a diameter of 200 mm, a rotation speed of 2950 rpm and an inclination angle of 90° guarantees a cutting depth of up to 43 mm. The kit includes parallel and miter gauges, a protective cover, a pusher, a riving knife and a wrench. Double insulation ensures user safety when working without protective equipment. Perfectly cuts boards up to 25 mm thick.

Characteristics:

- Power-900W.

- Disc diameter- 200 mm.

- Bore diameter -32 mm.

- Rotation speed -2950 rpm.

- Cutting depth -43 mm.

- Tilt angle -45°.

Pros:

- Tilt angle adjustment.

- Compact sizes.

- Affordable price.

Minuses:

- Lack of dust removal system.

- Small depth of cut.

Einhell TH-TS 820

Einhell TH-TS 820

Professional sawing machine, widely used in small carpentry and workshops. Ideal for processing wooden workpieces and fiberboard materials. The concept of the model includes connecting a vacuum cleaner, which keeps the work area clean. Compactness is ensured due to the modest size of the table - 500x335 mm, and the cable fastening allows for convenient transportation of the machine. A separate shield that protects the disk from external influences ensures the safety of the work process.

Characteristics:

- Power-800W.

- Disc diameter- 200 mm.

- Bore diameter -16 mm.

- Rotation speed -2950 rpm.

- Cutting depth -43 mm.

- Tilt angle -45°.

Pros:

- Measuring scale.

- Vibration resistance.

- Parallel stop.

Minuses:

- Low engine power.

ELITECH SR 1221

ELITECH CP 1221

An excellent table saw for the home workshop, Elitech CP 1221, is ideal for cutting boards and timber with a thickness not exceeding 45 mm. The technology of work is based on the competent design of the unit, which allows making high-quality and accurate cuts. The depth and radius of the cut are adjusted directly from the front panel. The delivery set includes cross and rip fences, keys, table extension, blade guard and saw blade.

Characteristics:

- Power-1200 W.

- Disc diameter- 210 mm.

- Bore diameter -30 mm.

- Rotation speed -4800 rpm.

- Cutting depth -48 mm.

- Tilt angle -45°.

Pros:

- Affordable price.

- High performance.

Minuses:

- Poor build quality.

- Lack of spare parts in stores.

RYOBI RTS1800

RYOBI RTS1800

Professional equipment widely used in furniture production and home carpentry workshops. An aluminum table measuring 560x590 mm with a retractable extension and parallel stops makes it possible to achieve precision cutting of various wood materials with a size not exceeding 510 mm. The machine is equipped with wheels for transportation. The saw blade is covered with a two-layer protective casing, ensuring the safety of the operator during work.

Characteristics:

- Power-1800 W.

- Disc diameter- 254 mm.

- Bore diameter -30 mm.

- Rotation speed -4500 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Affordable price.

- Soft start function.

- Overload protection.

- Availability of an emergency shutdown button.

Minuses:

- Plastic body.

- The table extension bends easily.

- Ruler with paper markings.

Choosing the right model

Choosing the right wood sawing machine ensures maximum efficiency, productivity, and convenience.

To make the right choice, you need to take into account the types and volumes of future work, all the capabilities and characteristics of the tool:

- power. Wood processing in domestic conditions is possible with a power of 350 watts, in industry - from 2000 watts, in sawmills volumes can reach 15,000 watts;

- depth of cut. The minimum indicators are 40 mm. Production machines can handle thicknesses of 360 mm or more;

- cutting width. This indicator affects the amount of wood waste; it is especially important to reduce losses when working with valuable species;

- Possibility of fine tuning. For accurate cutting, the device must be equipped with a scale with degrees, special rulers, workpiece clamps;

- type. To choose between a circular saw and a band saw, the scale of production, the tasks performed, and the type of wood are determined.

For processing valuable and hard woods, it is better to use belt mechanisms, since they are economical in terms of material. To work with large volumes of material or when increasing speed is necessary, it is better to use disk mechanisms. Do not forget about timely maintenance of any type of wood sawing machines.

Best Table Saws

R.IT PTS200-C master

P.IT PTS200-C master

Stationary electric saw PIT MASTER PTS200-C, designed in terms of functionality for sawing wood pieces at the desired angle. Perfect for home and carpentry workshop. It is convenient to use, the simple design is equipped with a pusher, transverse and parallel stops. It is possible to connect a vacuum cleaner.

Characteristics:

- Power-850W.

- Disc diameter- 200 mm.

- Bore diameter -16 mm.

- Rotation speed -2950 rpm.

- Cutting depth -45 mm.

- Tilt angle -45°.

Pros:

- Affordable price.

- Tilt angle adjustment.

Minuses:

- Low build quality.

- Small disk mounting diameter.

EINHELL TC-TS 200

EINHELL TC-TS 200

A universal machine with a wide range of tasks designed for carpentry work at home or in a small workshop. The unit allows you to cut products made of solid wood, chipboard, plywood and other similar materials. The work table, measuring 640x487 mm, is powder coated to reduce friction, and side extensions allow you to increase the work surface. The carbide-tipped saw blade ensures precise cutting. The cross fence with a wide angle of rotation up to 60° and the system of tilting the blade to the left help make more precise cuts at sharp angles.

Characteristics:

- Power-500W.

- Disc diameter- 200 mm.

- Bore diameter -16 mm.

- Rotation speed -2950 rpm.

- Cutting depth -45 mm.

- Tilt angle -45°.

Pros:

- Electrical protection of the engine.

- Tilt angle adjustment.

There are no cons.

BOSCH GTS 254

BOSCH GTS 254

The sawing machine from the German manufacturer Bosch GTS is one of the best machines of 2022 because it includes the ideal combination of power and degree of wood cutting. The die-cast aluminum parallel guide ensures extreme precision in cutting workpieces. The retractable work surface allows you to increase the dimensions up to 265 mm, and the metal stand guarantees an effective degree of stability.

Characteristics:

- Power-1600W.

- Disc diameter- 216mm

- Bore diameter- 30 mm.

- Rotation speed -5500 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Restart protection.

- High performance.

- Large cutting depth.

- Availability of a safety switch.

Minuses:

- Slight play in the miter gauge.

BOSCH GTS 18V-216 without battery and charger

BOSCH GTS 18V-216 without battery and charger A

modern mobile and compact machine, powered by a battery, ideal for working with wood, parquet, laminate and fusible metal. Compatible with GTS tables. A protective side guard and comfortable handle make the machine easy and safe to transport, and the brushless motor provides power identical to a contact table saw.

Characteristics:

- Supply voltage -18 V.

- Disc diameter- 216 mm.

- Bore diameter- 30 mm.

- Rotation speed -4600 rpm.

- Cutting depth -70 mm.

- Tilt angle -45°.

Pros:

- Large cutting depth.

- High performance.

- Compact size.

Minuses:

- High price.

- Does not work on discharged batteries.

Metabo TS 36-18 LTX BL 254

Metabo TS 36-18 LTX BL 254

Universal portable cordless saw Metabo TS 36-18 LTX BL 254 - high-tech equipment for sawing wood. Considered an excellent choice for building contractors. It is also useful in carpentry workshops. The device operates using two battery packs with a voltage of 18 V each. The folding design allows you to conveniently store and transport equipment. A powerful brushless motor guarantees high productivity in carpentry work, and a built-in dust removal device will clean the work surface of production waste.

Characteristics:

- Supply voltage -36 V.

- Disc diameter- 254mm.

- Bore diameter- 30 mm.

- Rotation speed -5000 rpm.

- Cutting depth -87 mm.

- Tilt angle -45°.

Pros:

- Large cutting depth.

- High performance.

- Quick change of saw blade height and inclination.

- Electrical overload protection.

Minuses:

- High price.

Safety precautions for those working with a circular saw

Before you start using the mini-version of circular equipment, you will need:

- check whether the starting toggle switch of the circular device, casings, and electrical wiring are in good condition;

- Make sure that the saw teeth are in proper condition and check their alignment.

- examine the condition of the tool: are there any cracks, damage, or chips on the surface; if at least one tooth is missing, the cutting element is thrown away;

- choose a shaft that will not hit, but should move towards the workpiece being processed.

At the stage of working with the tool you need:

- deliver raw materials to the sawing equipment after the cutting element has reached speed, this can be understood by a special sound;

- it is necessary to feed the material slowly and smoothly, avoiding bumps and jerks;

- move the workpiece along the work surface only using hooks, and it is forbidden to grasp the end with your hands;

- check in time whether the chips have been removed from the gap, wait until the disk completely stops rotating, use special devices.

- as soon as the trimming is completed, remove your foot from the pedal;

- remove remaining waste from the work surface using equipment designed specifically for this (hooks);

- All kinds of service activities are allowed only when the working disk is stationary.

Safety instructions

Not allowed:

- make attempts to stop the saw blade by pressing something on it;

- be within the standard workpiece ejection;

- make attempts to remove chips from behind the guard of the cutting element while it is still moving;

- work simultaneously on several workpieces without using a clamp;

- be opposite the end of the bar if it moves in the device;

- try to process lumber in an icy state;

- remove protective covers or attempt to open them.

By purchasing equipment from professionals, you are guaranteed to work in safe conditions. You shouldn’t take risks if you come across an option on the market at a lower price. These savings can be deceptive. Real circular saws last a long time, are easy to use and do not pose a health hazard.

TOP 3 best sawing machines with stand

BLACK+DECKER BES720-QS

BLACK+DECKER BES720-QS

A convenient and practical table saw from Black&Decker is designed for cutting wooden products of different shapes and structures. The machine consists of a durable metal table with a retractable part that expands the working surface. The saw blade guard opens automatically and protects the user from accidental damage. The built-in bag allows you to collect sawdust and keep your work area clean. If desired, you can connect a vacuum cleaner.

Characteristics:

- Power-1800 W.

- Disc diameter- 254 m.

- Bore diameter- 30 mm.

- Rotation speed -5200 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- High speed motor with braking function.

- Intuitive and safe operation.

- Affordable price;

- Adjusting the cutting angle.

Minuses:

- Slight play in the miter gauge.

Ryobi RTS1800EF

Ryobi RTS1800EF

The best sawing machine among similar ones, Ryobi RTS1800EF, is effectively and widely used by professionals. It does not go unnoticed by carpentry lovers either. Equipped with an aluminum table with good wear resistance, it allows you to evenly move the lumber towards the disk. Guides with stops recreate the precision of cutting wooden workpieces. The cutting element is a saw blade with 48 teeth. The table size is 560x710 mm, the package includes 2 wrenches, a folding frame and a support.

Characteristics:

- Power-1800W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -4500 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Soft start function.

- Availability of an emergency shutdown button.

- Electrical protection of the engine.

Minuses:

- Slight disc play in diameter.

- Severe bearing wear.

Encore Corvette 13M

Enkor Corvette 13M

A wonderful sawing machine, widely used in households and in industrial carpentry workshops. The machine is perfect for longitudinal and cross cutting of wooden workpieces. The cast iron work table provides sufficient reliability in operation, and the longitudinal stop with the function of instant fixation creates the conditions for excellent quality and accuracy of cutting. Wheels help transport the machine without unnecessary effort. The saw blade is equipped with a transparent casing that protects the owner from various injuries.

Characteristics:

- Power-1500W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -2950 rpm.

- Cutting depth -80mm.

- Tilt angle -45°.

Pros:

- High degree of stability.

- Ease of maintenance.

Minuses:

- High price.

Conclusion

I believe that among the many monotonous clones-copies-replicas of several successful European models, the Ryobi RTS 1800 . Power, a set of “adult” electronic functions and maintainability (if you have access to original spare parts) make it advisable to modify this machine to meet the needs of the home craftsman.

A professional attitude towards carpentry does not imply having free time to independently modernize inexpensive equipment. But the versatility of the Mogilev SDM 2000 M is worth it to introduce a soft start unit and understand the intricacies of the manipulations of setting up equipment and replacing equipment.

The best household sawing machines for price and quality

RYOBI RTS1800ES

RYOBI RTS1800ES

The competent design of the Ryobi machine has made it possible to find wide application in the field of high-quality and professional wood processing, both directly in production and in everyday life. Cast aluminum, used as the basis for the manufacture of the desktop, provides increased strength and excellent shock-absorbing qualities. The ergonomic handle allows you to quickly change the angle of inclination and depth of cut. Table dimensions - 650x710 mm. A compartment designed for storing components helps to fit seamlessly into the workplace. Overload protection increases the life of the engine in intensive work conditions, and the emergency shutdown button provides additional safety to its owner.

Characteristics:

- Power-1800 W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -4500 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Soft start function.

- Availability of an emergency shutdown button.

- Electrical protection of the engine.

Minuses:

- Manual adjustment of cutting angle accuracy.

BOSCH AdvancedTableCut 52

BOSCH AdvancedTableCut 52

Multifunctional sawing machine from the German manufacturer Bosch AdvancedTableCut 52 is ideal for straight, transverse and longitudinal processing of wood products. Used in repairs and construction related to flooring. The machine is easy to carry, lightweight, and takes up little space. A wide range of sawing jobs is achieved by adjusting the vertical and horizontal cutting angles by adjusting the rotary handle and pull lever. Advanced NanoBlade technology eliminates maintenance, sharpening, lubrication and tensioning.

Characteristics:

- Power-550W.

- Disc diameter- 220 mm.

- Bore diameter- 30 mm.

- Rotation speed -8200 rpm.

- Cutting depth -52 mm.

- Tilt angle -45°.

Pros:

- Vibration resistance.

- Quick blade replacement system;

- Wide range of wood cutting.

Minuses:

- Low cutting speed.

Einhell TC-TS 2025 U

Einhell TC-TS 2025 U

The dream of every professional carpenter is the Einhell stationary circular saw, which will reveal his creative potential, as it creates cuts of any complexity in solid wood and other materials. The carbide teeth of the saw blade can, if desired, be set at a given angle or at a certain height. Folding extensions on the sides of the work table increase the area and allow you to use larger workpieces during work.

Characteristics:

- Power-2000W.

- Disc diameter- 250 mm.

- Bore diameter- 30 mm.

- Rotation speed -5000 rpm.

- Cutting depth -85 mm.

- Tilt angle -45°.

Pros:

- Affordable price.

- Adjustment of tilt angles.

Minuses:

- Strong vibration.

- Low build quality.

- Unclear fixation of guides.

Metabo TKHS 315 C WNB

Metabo TKHS 315 C WNB

An excellent tool for use in the workshop, at home and in small-scale production. Designed for cutting various boards and wooden panels. The machine's galvanized steel construction ensures durability and strength during carpentry work. Working size of the table - 800x550 mm due to the extension, can be stretched in length. Maximum cutting accuracy is achieved due to the parallel stop with applied markings. Operational safety is at its best due to the protective casing, jamming locking mechanism and electric motor overheating, which ensures stability and reliability in operation.

Characteristics:

- Power-2000W.

- Disc diameter- 315 mm.

- Bore diameter- 30 mm.

- Rotation speed -2980 rpm.

- Cutting depth -85 mm.

- Tilt angle -45°.

Pros:

- Good dust removal.

- Adjustment of tilt angles.

Minuses:

- Slight play in the side support.

- There is no miter gauge with protractor.

Makita 2712

Makita 2712

Decent in quality and reliability, the Makita 2712 table saw is widely used for fast and accurate processing of any wooden workpiece. The durable aluminum table promotes efficient and comfortable working. The convenient tilt function of the saw blade allows you to cut workpieces at an angle of 45 degrees. A flexible cord 3 m long allows you to connect the equipment to the network.

Characteristics:

- Power-2000W.

- Disc diameter- 315 mm.

- Bore diameter- 30 mm.

- Rotation speed -2950 rpm.

- Cutting depth -85 mm.

- Tilt angle -45°.

Pros:

- Good dust removal.

- Adjustment of tilt angles.

- Easy to use.

Minuses:

- Weak fixation of the stop.

- Inconvenient guides.

DeWALT DWE7485

DeWALT DWE7485

Versatile table saw equipped with a heavy-duty aluminum fold-out table for regular use in the home workshop or fabrication shop. It combines perfectly with the DE7400 portable workbench of the same name. Possessing compact dimensions, it is equipped with a steel frame that protects internal components from various damages. The capabilities of the saw are limited to processing soft and hard wood and composite materials based on them.

Characteristics:

- Power-1850W.

- Disc diameter- 210 mm.

- Bore diameter- 30 mm.

- Rotation speed -2950 rpm.

- Cutting depth -65 mm.

- Tilt angle -48°.

Pros:

- Good dust removal.

- Compactness;

- Quick change of riving knife.

Minuses:

- There is no mechanical angle adjustment.

- Inconvenient guides.

Proxxon FET, 27070

Proxxon FET, 27070

High-quality equipment from the German manufacturer Proxxon combines creative technical solutions and the requirements of international quality standards. The company's machines are widely used in sawing large workpieces, for cutting at an angle in 2 planes, and for forming cuts to a given depth. Carbide soldering on the working disk produces a smooth and neat cut. Rubber, plastic and non-ferrous metal alloys are also used as machine processing objects. The desktop is made of extruded aluminum. Auxiliary pads and pushers help to saw small parts.

Characteristics:

- Power-200W.

- Disc diameter- 85 mm.

- Bore diameter- 10 mm.

- Rotation speed -7000 rpm.

- Cutting depth -22 mm.

- Tilt angle -45°.

Pros:

- Good dust removal.

- Compactness.

- Quick change of riving knife.

There are no cons.

STANLEY SST1800

STANLEY SST1800

Multifunctional table saw Stanley SST1800 is suitable for stable work with different types of wood. It is equipped with an overload protection system, ensuring its reliability and efficiency. The output power of the engine allows you to cut damp and frozen wood, and the convenient structure of the unit allows you to move the machine without extra effort, having first removed the supports. A work table tilted at 45 degrees helps to cut wood pieces at a given angle. The existing longitudinal stop guarantees the accuracy of the work. The cutting blade is covered with a durable protective cover for safe storage.

Characteristics:

- Power-1800 W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -4800 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Affordable price.

- Engine overload protection system.

Minuses:

- There is no clear fixation of the stop.

- Slight play in the extendable table.

Adviсe

To select the correct unit, the following technological features should be taken into account:

- The bed (steel, aluminum, cast iron) actively dampens the vibration that occurs during operation of the mechanism. The larger the size and more massive the mechanism, the less vibration occurs during operation. When choosing a home option, do not forget that in conditions of limited space, the lighter the frame, the more mobile it is.

- Working surface. Your choice of the right size should depend on the type of product being manufactured. If it is small in size, then the desktop can be from 40 to 90 cm. For door production, it is better to purchase models with an increased surface of up to 130 cm.

- Engine power. When making large cabinet furniture, you should choose equipment from 5.5 kW; for frequent processing of large parts, a mechanism up to 3 kW is useful; for infrequent use at home, a 1.5 kW motor is suitable.

- Engine type. The stepper motor is installed in inexpensive models. The disadvantages are the lack of electronics, and they are also inferior in accuracy and smoothness to other types of engines. The crescent type is more expensive, but has maximum precision and smooth movement in the process.

- Number of axes. Simple milling cutters process a blank in three axes; more complex designs provide the ability to create relief in four or five directions, and the tool head has greater freedom of movement.

- Replacing nozzles. The best professional and semi-professional models have a magazine of attachments with several types of cutters to speed up the work process. If you rarely change attachments, any milling device will do.

- Operating voltage. For home use, it is better to purchase a mechanism with a 220 volt connection, but it will have lower performance.

The best professional sawing machines

DeWALT DCS7485N

DeWALT DCS7485N

Professional table saw with a power of 1850 W from the German brand Dewalt has modest dimensions and light weight. The successful design of the compact body allows it to be easily transported. The speed of setting parameters and intuitive controls make this model stand out among its competitors. Its features include setting a certain angle of inclination. Extreme cutting accuracy is achieved thanks to the front and rear stops, a clear scale and a toothed guide. The cast aluminum work table offers durable corrosion protection. The overload protection system allows you to work with problematic wood.

Characteristics:

- Power-1850W.

- Disc diameter- 210 mm.

- Bore diameter- 30 mm.

- Rotation speed -5800 rpm.

- Cutting depth -65 mm.

- Tilt angle -48°.

Pros:

- Availability of a chip removal system.

- Engine overload protection system.

Minuses:

- Uneven saw blade insert.

Bosch GTS 10 XC

Bosch GTS 10 XC

This innovative model is equipped with a powerful 2100 W motor with a braking system, overload protection and a starting current limiting function. A wide table with dimensions of 640x705 mm and retractable elements allow you to work with long workpieces. Convenience and accuracy of cutting occurs due to the intuitive material supply system and precise adjustment. The parallel fence holds the workpiece stably and prevents it from slipping out. The fast spindle speed ensures a high-quality cut of wood of any density.

Characteristics:

- Power-2100 W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -3200 rpm.

- Cutting depth -79 mm.

- Tilt angle -47°.

Pros:

- Availability of a soft start system.

- Ease of setting up moving units.

- Spindle locking system.

- Availability of a device for eliminating backlash.

Minuses:

- High price.

BELMASH TS-250R – 220V

BELMASH TS-250R - 220V

The large circular saw Belmash TS-250R is designed for cutting wood blanks along and across wood fibers. The welded structure of the machine made of sheet steel can withstand significant loads. The holders are used for convenient storage of tools necessary for work, including cutting discs, stops, pushers and keys. The kit includes 2 auxiliary sections for the table, each measuring 252x685 mm.

Characteristics:

- Power-1800 W.

- Disc diameter- 254 mm.

- Bore diameter- 30 mm.

- Rotation speed -2800 rpm.

- Cutting depth -80 mm.

- Tilt angle -45°.

Pros:

- Wide range of cutting angles.

- Kickback protection system on the riving knife.

Minuses:

- Uneven table extensions.

Metabo BKS 450 Plus - 5.5 DNB 0104605000

Metabo BKS 450 Plus - 5.5 DNB 0104605000

The most expensive in the ranking of professional sawing machines with a powerful 5500 W motor, which, in combination with a disk with a diameter of 450 mm, provides the greatest cutting depth of up to 141 mm. The dimensions of the model exceed those of conventional representatives of this category of equipment. The width of the machine is 183 cm, height – 102 cm, depth – 75 cm, weight – 90 kg. The rotation speed of 2735 rpm ensures maximum precision when processing wood. Operational safety is achieved due to the engine braking system and overheating protection. The built-in dust collector will ensure the cleanliness of the workplace. The structurally robust and extremely reliable machine is suitable for universal use on a construction site or in a specific industrial sector. The engine mechanism is configured for continuous operation, and the hidden potential is sufficient for processing not only wooden materials, but also various alloys of non-ferrous metals, as well as plastic.

Characteristics:

- Power-5500W.

- Disc diameter- 450 mm.

- Bore diameter- 30 mm.

- Rotation speed -2735 rpm.

- Cutting depth -141 mm.

- Tilt angle -45°.

Pros:

- Large cutting depth.

- Overheating protection system.

Minuses:

- High price.