Production and use of lumber

Lumber is made from hardwood or softwood. To obtain high-quality products, during manufacturing the wood is thoroughly dried and treated with protective agents. This prevents rotting and drying out, the appearance of mold and rot, and the formation of cracks.

Based on the degree of humidity, dry products with a humidity of 8-10% are distinguished, which are used for the manufacture of parquet boards and panels. Wood with a moisture content of 12-15% is considered universal and is suitable for the manufacture of floor boards, skirting boards and trim, fillets and interior doors. Materials with 18% humidity are used for lathing and rafter structures, and exterior finishing.

The result is a high-quality and reliable dry material that is resistant to the negative effects of moisture and steam, insects and ultraviolet radiation. It is lightweight. Such products are easy to cut and saw, lay, coat with paint, varnish and oils. Lumber is characterized by easy and quick installation, simple processing and availability, environmental friendliness and naturalness.

Types of raw materials used in the production process

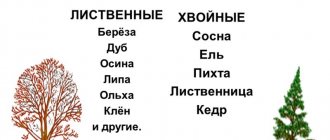

For high-quality production, only pre-prepared material is used as a primary raw material, that is, wood materials cleared of knots and bark. If we consider the types of lumber, we can say that coniferous species are used for supporting structures. Hardwood for interior finishing work, both in industrial and domestic premises.

If we consider the cost, then the cheapest option would be poplar, as well as birch. Pine or larch will not be much more expensive.

Birch is rightfully considered the lightest in weight; it also has a very beautiful appearance and an affordable price, due to which it has gained high popularity among buyers. As for larch, it has good resistance to moisture and is thereby protected from the occurrence of fungus and mold.

Material - birch

Of course, there is also beech and oak; their use is mainly coordinated on floor coverings and solid furniture. Pine is used quite rarely due to the content of a large amount of resins, which ignite quite quickly, but at the same time during the processing process, pine simply has no equal.

Types of lumber

According to the processing method, edged and unedged materials are distinguished. The first option is the most popular, since the sides of the product are cut and processed. The result is smooth and even sides, an attractive and aesthetic appearance. The trimming method of processing expands the scope of application of products and extends the service life.

The following assortment is produced:

- The beam has a rectangular or square cross-section with a side of over 100 mm. Used in construction and finishing. They produce profiled and laminated timber;

- Bar - a beam with smaller dimensions, which is used for rough work and arranging sheathing;

- Board is a finishing and building material with a thickness of up to 100 mm and a width greater than twice the length. They make floor boards, edged and unedged, planed and unplaned;

- Sleepers are beams that support the rails;

- Obapol has an outer unsawed side and an inner sawn side. Used to create formwork for foundations and sheathing, for collecting firewood, making scaffolding and fasteners;

- A slab is a side part of a log with one sawn and one unsawed surface. Represents a board convex on one side. Suitable for making firewood and flooring, formwork, constructing outbuildings (shed, greenhouse) and building fences;

- Lining is a wooden finishing material with smooth, even sides and high-quality processing. We present narrow slats with convenient tongue-and-groove fastening. Used for covering floors, walls inside and outside. A block house is also distinguished. This is a type of lining that is flat on one side and imitates a log on the other.

For construction and finishing, it is important to choose products without rot, knots, wormholes and other defects. Choose the highest (selected) or first grade lumber with the required moisture content from a reliable manufacturer. Good products are made in compliance with GOST and must have quality certificates. In addition, the rules for transporting and storing wood must be observed.

Technology lesson notes

6th grade

Module:

Technology of processing of structural materials and elements of mechanical engineering.

Chapter:

Wood processing technology and elements of mechanical engineering.

Subject:

Production and use of lumber.

Lesson objective:

Study of the production process and methods of using lumber.

Goals:

Educational:

- To familiarize students with the process of production and use of lumber.

- Learn to distinguish types of lumber.

- Developmental:

- To develop curiosity among schoolchildren.

- Ability to analyze.

- Apply the acquired knowledge in practice.

- Educational:

- Improve environmental education of students.

- Instill an active life position.

- Foster initiative and independence.

- Career guidance:

- To create students' interest in professions

Forester, forester, carpenter.

Methodological equipment of the lesson:

- Material and technical base:

- School workshop

- Computer and media projector

- Didactic support:

- student workbook

- posters: “Wood processing products”,

“What can be obtained from one cubic meter of wood”, “Defects of wood”, “Practical work”.

Film "Sawmill Frame"

- Materials for monitoring students' knowledge:

Game “Is the statement true?”

- Cards: “Defects of wood.”

- Literature:

Textbook "Technology" 6th grade.

Magazine “Holiday at School” – 2005

Vocabulary work:

sawmill frame, saw set, cut, falling rollers, trolley.

Lesson type:

A lesson in acquiring new knowledge and skills and applying them in practice.

Methods:

Verbal, visual, practical.

During the classes.

- Organizing time.

- greetings

- checking student attendance

- teacher filling out a class register

- checking students' readiness for the lesson (notebooks, pens)

- getting students in the mood for work.

Teacher - Hello guys.

Uch. Guys, please tell me, do any of you like the autumn forest?

Scientist Yes!!!

Uch. Why do you love him?

Scientist Because in autumn the leaves of the trees turn different colors and it becomes very beautiful; you can collect mushrooms, nuts, etc.

Uch. What else does the forest give us?

Scientist Wood!

Teacher. How do trees turn into boards and beams?

Learned!!!???

Teaches: It’s okay, today we will learn everything, and so the topic of our lesson is “Production and use of lumber.”

- Updating students' knowledge:

First, let's remember what we talked about in previous classes.

Game “Is the statement true?”

The class is divided into 2 groups. The teacher asks questions to the groups. If the student gives the correct answer, the teacher hands over the sheet. (Guys must collect as many leaves as possible, i.e. points)

- Cracks are defects in wood. (Yes).

- Larch does not shed its needles in winter. (No)

- Cedar is a hardwood (no)

- Plywood is made from sawdust (no).

- All materials made from wood that have preserved its natural state are called timber (yes).

- The ripeness of wood is determined by taxators (yes).

- The work of foresters is supervised by forest rangers (yes).

- Wood moisture content is characterized by its moisture content (yes)

- Fiberboard stands for particle board (no)

- Sticks, logs, ridges and logs are timber (yes).

Guys. Please name the wood processing products, i.e. what is obtained from wood?

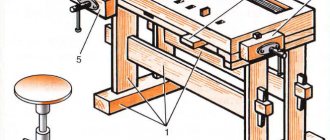

(FIG. 1.)Wood processing products.

Fine. In the last lesson we studied the topic “Defects of wood”. Now I will give you cards where you need to show with arrows the defects of the wood. Time for task 1-2 minutes.

Presentation by the teacher of new material:

Teacher. And so “Production and use of lumber.” In grade 5, we already became acquainted with the main types of lumber. Who will help me remember them?

- Student. Beams, whetstones, edged and unshaped boards.

Teacher - correct. We know that lumber comes from sawmill frames. Has anyone seen how a saw frame works?

(Teacher shows a drawing of a sawmill frame)

Logs are transported to sawmill frames using chain log transporters

.

The sawmill frame consists of a saw frame with a set of vertically mounted strip saws. A set of saws in a saw frame, installed at a certain distance from one another to cut boards of a given thickness, is called a set.

The saw frame is mounted on guides. It can make vertical movements up and down using a crank-slider mechanism driven by an electric motor.

At the front and rear of the sawmill frame there are driven, rotating grooved double rollers that drop the log forward.

In front of and behind the frame, carts are installed on rails to accommodate logs and boards.

Principle of operation. The log is thrown from the log hauler onto a cart installed in front of the frame and falls between two falling, rotating grooved rollers. The rollers grab the log and push it onto a saw frame with saw blades moving up and down. The saws cut the log into lumber, which is grabbed by grooved rollers located behind the frame and fed to a cart installed behind the frame.

This is how boards and beams are obtained.

Edged boards are obtained by sawing logs in 2 steps.

To better consolidate the knowledge gained, let’s watch a video clip of how a sawmill frame works.

Vocabulary work

.

Sawmill frame, saw set, log hauler, cut, falling rollers, cart.

- Practical work.

- Induction training. The children are given circles of different diameters (ø20-ø30) - this is the cross-section of the logs.

- Teacher - Guys, there are circles in front of you. Imagine that this is a cross section of logs. Your task is to determine what kind of lumber can be obtained from these “logs”. To do this you need to have a ruler and a pencil. We know that our floorboards are from 40mm to 60mm thick, planks are from 20mm to 30mm, timber is 200mm on sides, timber is 100mm on sides.

– Teacher – Safety briefing:

- Instructing the teacher on completing homework.

- Teacher - Guys, I present to your attention a simple storage device - a product that is mounted on the wall, where you can hang keys, brushes, and anything else needed in the household. Your task is to develop your own individual drive based on this drive. Those. For the next lesson you bring me a sketch of the drive where you can already put down the approximate dimensions.

- Summing up the lesson.

- Teacher - And so today, guys, we studied the topic “Production and use of lumber.”

What new things have you learned about yourself?

- Teacher - Well done. Lesson grades.

- Message from the teacher about the achievement of the lesson goal.

- Message about the topic of the next lesson “Drawing of a part. Assembly drawing".

Wooden house from the manufacturer

The MariSrub company independently produces construction and finishing materials from durable, selected pine. This wood is distinguished by its high density, resistance to wear and moisture, long service life, aesthetics and original textured pattern. We carefully monitor the selection of raw materials and product quality, comply with GOST requirements, standards for storage and transportation of lumber.

When harvesting wood, we use condensation drying, which thoroughly, carefully and evenly dries the material inside and out. As a result, the products do not crack and last longer. In addition, condensation drying prevents the formation of manufacturing defects. Read more about this drying method here.

Each material is treated with protective compounds. We offer timber and logs of various sizes, we select suitable products for the construction and finishing of the house. We carry out a full range of work, including developing a project, manufacturing and installing a log house, building a foundation and covering the roof.

We build wooden houses from timber and logs according to individual and standard designs. We carry out utility networks, install windows and doors, stairs and interior partitions. We do the finishing, hydro- and sound insulation, insulate the structure and treat it with protective agents. We guarantee high quality and efficiency of construction!

Main classification

Attention! The main aspects that can affect the classification of a material are, of course, shape, dimensional parameters and mechanical characteristics.

Currently, classification occurs according to grade 6, let’s consider the first 3.

- Beam. This material is a kind of log, which is hewn from all sides and is used in the process of building houses, and its use can be traced to large window elements or stairs;

- Bar. This type is a smaller copy of the previous version, it can be unprocessed, planed or adjusted to certain dimensional parameters. Its area of application is the manufacture of furniture, the production of lathing, frames, and gazebos;

Bruschi

- A board made of logs or timber. Maybe also not edged or edged type. In addition, classification can be carried out according to dimensional parameters.

Types of material

Initially, it should be noted that the determination of grade will depend on an assessment of the worst side of the edge and section.

Lumber that belongs to the highest quality category should not have any signs of rot, mold or fungus on its surface. In addition, there should be almost no knots or deep cracks. This material is used in automobile and ship buildings.

If we consider materials of the first grade, then the peculiarity is that such lumber should not have large dry knots, large cracks, overgrown bark, young layers of wood, traces of mold or mechanical damage.

Options, the technology of which involves the production of second-grade material, are used in the production of furniture. As for external features, there must be no large cracks, visible decay, traces of parasites or noticeable mechanical damage.

Classification by variety

There is, of course, the last grade, which may have visible defects and during construction work can be used exclusively for household and utility rooms.

Production types of wood

Nowadays, there are main methods for the production of processed wood material: milling and planing. During the construction process, the necessary elements are combined into one whole, after which a reliable building will be created. Such buildings do not require additional strong foundations or additional finishing work.

- Glued laminated timber. It is made from whole boards or individual pieces. The material itself will consist of lamellas firmly attached to each other. As for additional indicators, this option has high strength and resistance to external influences;

- Plywood. This type consists of glued layers of wood. Due to high strength and excellent flexibility, the final material is highly popular in the production of furniture, interior and exterior decoration;

- Fiberboard. It is obtained in the process of pressing under the influence of high temperatures and the addition of a special additional agent. The outer sides of the sheet may be smooth or one of them will be embossed;

- Chipboard. The composition includes exclusively small particles with the addition of resins. Waste wood material is used in the production process. No synthetic adhesives are used during the production process. This option is used preferably in the furniture or construction industry;

- Lining. Lumber of this type is used for a variety of finishing works. Even taking into account that the material will have a small thickness, it is very durable and resistant to all kinds of deformations, the possible formation of cracks or cracks. In addition to all this, the material has an attractive appearance. Also significantly affecting the high popularity is the simplicity of the installation process and low cost.

Lining

That is, lumber is a unique product obtained from wood material, and nowadays builders simply cannot imagine the work process without such products.

You can see how lumber is produced in our educational video: