Solid wood furniture always looks expensive and status-worthy, and, unlike other interior items, it never goes out of fashion. If necessary, it can be easily updated by varnishing, tinting or repainting.

Another plus is 100% environmental safety, as well as durability - such furniture can last for tens or even hundreds of years. The characteristics of the finished product will largely depend on the type of wood used for its production.

Tree species - pine

Among Russian tree species it has found very wide application. Pine wood is pale yellow or yellow-red. It is of medium hardness and quite easy to process. The straightness of the trunks makes this type of wood popular in the construction of houses. It planes well along, but poorly across. The glue sticks the pine together well and firmly.

It can be used for many crafts and is used in inexpensive doors, furniture, and window frames. At high humidity, pine may turn blue. On hot sunny days, resinous pine trees can release resin.

Cross-layered.

A tree trunk does not always grow evenly throughout its life. For various reasons, the trunk can twist around an axis and at the same time, its constituent fibers form a spiral. In scientific terms, this phenomenon is called tangential (tangential) inclination of fibers or in everyday life - “oblique layering”.

Cross-layered wood is measured as a percentage; a deviation of the fibers of 1 cm per 1 m of length is 1% of the cross-layered wood. Cross-layering significantly reduces the tensile and bending strength of wood, especially if the cross-layering is more than 5%.

The boards obtained from such a trunk have an oblique direction of fibers, running steeply inward from one wide side of the board (face) to the other. The fibers are short, the board is fragile when bending and is unsuitable for cutting into bars.

Larch

A very hard tree species. It is considered one of the best for construction and carpentry work. Its wood is red. It is significantly more resistant compared to oak. In water, it can increase its strength to such an extent that it is problematic to drive a nail into a page. An example of strength is Venice, which stands on larch.

Larch is very difficult to process (it is recommended to process only freshly cut trees), but the surface after processing is smooth. It hardly warps. The disadvantages of larch include its tartness, as well as its high specific gravity.

Tree rings.

The first thing that catches your eye on a cut of freshly cut wood is a clearly defined pattern in the form of concentric circular stripes surrounding the core. These are the so-called “annual layers”, which are most evident in trees grown in places characterized by sharp temperature changes between seasons. The wood of southern tropical species is distinguished by layers with a blurred boundary of rings and less variation in color and width.

Darker and denser layers of wood are autumn, wider and lighter layers belong to spring and summer. Understanding the structure of the annual layers of wood is of significant practical importance, since the properties of wood depend on their size and structure. The worse the conditions in which the tree grew, the smaller the rings and the denser and stronger the wood, and by the number of annual layers it is possible to determine the age of the part of the trunk where the cut was made.

Cedar

It is considered a variety of pine, but with different properties. Its wood is pinkish in color, which tends to darken quickly and significantly in the sun. Cedar is a soft tree and is well processed; it has a pleasant smell and antibacterial properties. Moths do not tolerate this material. Cedar is used in construction, for making furniture and various crafts. Carvers enjoy working with this material.

Cedar is a healing tree and is used in folk medicine. Its wood is resistant to rot and is not susceptible to wormholes.

Popular types of wood for furniture production

Let's look at the types of wood that are most in demand for making furniture.

Pine

It has a brown, yellow-beige or white tint with small pinkish streaks. For furniture production, pine grown on hills with sandy soil or dry hills is considered the best. Pine, which grew in humid areas, has a loose structure, and it requires long-term drying before starting production. Pine wood is soft and easy to scratch and damage.

Advantages:

- Compliance. Pine is easily planed along the fibers, but poorly planed in the transverse direction. When cutting, it’s the other way around: it’s easy to cut a log crosswise, but it’s very difficult to cut it lengthwise.

- Easy to glue.

- Depending on the structure and color of the wood, pine can be used both for the production of furniture with further varnishing, and for frames or products with hard veneer veneer.

- Like other conifers, pine has a pleasant aroma and releases substances that have a beneficial effect on human health.

Spruce

Spruce is softer than wood. Its trunk contains many knots, which make it difficult to process wood for the production of furniture panels. Spruce absorbs moisture better than pine, so it rots faster. Due to its low strength and not very expressive structure, spruce is more often used for mosaic finishing or for the manufacture of structures that are not subject to serious operational loads.

Advantages:

- Spruce sticks well.

- The wood is almost not subject to warping.

In addition to spruce, Siberian fir can be used. These trees have approximately the same characteristics.

Larch

Larch is valued for its good performance characteristics and unusual slightly reddish tint.

Advantages:

- High strength is the best indicator among conifers.

- The tree is little susceptible to warping.

- The wood can be used to produce carved parts.

One of the disadvantages is that larch contains a lot of resins, which is why tools quickly fail and processing difficulties arise. Due to improper drying, internal cracks may appear on the wood.

Yew

Yew wood has a red-brown color with veins. It has good strength, but it also has a lot of knots.

Advantages:

- Wood is not subject to wormhole.

- Yew demonstrates resistance to temperature changes.

- It is easy to plan and sand.

Oak

A cross-section of an oak tree shows large medullary rays, as well as light sapwood. Thanks to the combination of aesthetic characteristics and durability. Oak that has been left in water for a long time takes on a unique dark purple color with a greenish tint. Wood is difficult to polish and requires equipment with highly hardened cutters.

Advantages:

- Although wood has high viscosity, it is at the same time very easy to process.

- Oak bends easily and is resistant to rot.

- Wood lends itself easily to artificial aging.

Ash

Ash is similar to oak in many qualities, but it is lighter in color and does not have noticeable pith rays. It must be treated with an antiseptic, since wood with high humidity is easily susceptible to wormholes. Ash is also not polished very well.

Advantages:

- After steaming, ash bends easily.

- When dried, it practically does not crack.

- By bleaching, you can give ash a non-trivial shade of gray hair.

Maple

Maple almost never cracks, but does not tolerate dampness well. The most valuable types of maple are “sugar” and “bird’s eye”, as they have a beautiful texture.

Advantages:

- Maple is easy to process, split and polish.

- It has a homogeneous structure without pronounced fibers.

- Due to the lack of a pronounced core in maple, it is easy to paint, as well as varnish and stain.

- Staining gives wood the opportunity to imitate valuable wood species.

Beech

Beech is no less durable than oak. However, it is highly hygroscopic, so it should not be chosen for furniture that will be used in high humidity (in the bathroom or kitchen). Beech is not very good at polishing.

Advantages:

- Increased decorative characteristics: beech has a beautiful texture both when cut radially and tangentially.

- The wood is easily dried and processed, and does not crack.

- The material is easy to paint and bleach. When varnished, its beautiful natural shade is preserved.

Hornbeam

Dense hard wood with a greyish-white hue. Hornbeam is often called white beech, but its texture is less pronounced and often has a cross-ply structure, which makes it difficult to prick.

Advantages:

- The hornbeam does not warp.

- If dried well, it can become harder than oak.

- Wood can be easily finished and etched.

Alder

Alder is a soft species that does not have a pronounced structure. It darkens quickly in air, so it is usually used for painting under mahogany or ebony. In dry areas the wood may be susceptible to wormhole, but it is resistant to rotting in high humidity.

Advantages:

- Alder dries quickly and does not warp significantly.

- Wood is easy to polish.

- Wood lends itself well to carpentry.

Walnut

The older the walnut, the darker and more expensive its wood. American black is considered the most valuable.

Advantages:

- Walnut has a wide variety of colors.

- Although the wood is dense, it is easy to process.

- Walnut contains a large amount of tannins, which is why it is easy to dye. It can get either a smooth white color or imitate ebony.

Birch

Common birch has a high density, but is not very resistant to rotting, so it is used mainly for the production of plywood, chipboard and veneer. It takes a long time and is difficult to dry, cracks, warps and is subject to wormholes.

Advantages:

- The wood has a beautiful uniform color.

- Birch bends well.

- Can be used to imitate valuable species.

It is worth highlighting Karelian birch, whose performance characteristics are higher. It has an unusual texture and a pink tint. Wood is expensive, so it is mainly used for cladding.

White acacia

The hardest of hardwoods with high friction resistance and elasticity. The dry material is difficult to process, therefore it is mainly used for cladding soft wood.

Advantages:

- Polishes well.

- In the air, white acacia wood becomes darker, as a result of which it acquires an expressive texture and a rich yellow-brown hue.

Linden

Linden wood is used to produce turned shaped elements. It contains few tannins, which is why it does not stain well, but can be stained well. Requires antiseptic impregnation.

Advantages:

- Linden is durable and flexible.

- The wood is resistant to dampness.

- It has a beautiful creamy or white shade.

Tree species - linden

It has light white wood. Easy processing makes it popular among carvers. Linden is not afraid of dampness and warps a little, however, it is affected by fungi. After drying, its strength improves. Sometimes floors are made from it (they are warmer than pine), furniture and baths are made. Linden is used in baths because of its unique smell, which lasts for several years.

It is used in many items where wood needs to be processed without much difficulty. For example, in shoe lasts, parts of wooden tools.

Features of choice.

When choosing carpentry material, you must follow certain rules. The best choice is boards cut as close to the middle as possible, the so-called “medium” and central ones. They warp less from shrinkage when drying.

The more perpendicular the annual layers are to the side face of the board, the less it warps. The maximum yield of such boards is obtained with the so-called “radial” cut. Radial cutting and sawmill equipment designed for this is the topic of a separate article. In short, with radial cutting, sawing occurs from the center of the log to its edges and an individual cutting map is used. This is the main difference from the classic “tangential” cutting scheme, when sawing the log and carriage is carried out sequentially in the horizontal (manual band sawmills) or vertical (frame and disk sawmills) direction.

When cutting softwood into boards, you need to discard the soft core. This, of course, increases the amount of waste during preparation, but there will be less of it during operation, and the final products are more reliable, stronger and more beautiful.

Wood with wide annual rings is easier to process, but is subject to significant shrinkage; wood with small annual rings is more beautiful, but at the same time heavier. Heartwood is denser and heavier than sapwood and is preferable for facing work. In general, the greater the difference in color between the annual rings, the more interesting the wood is.

Wood defects are revealed by external inspection and by a fresh cross-section. Boards with a spiral direction of longitudinal fibers (slant), with internal cracks, both radial (metic) and annular (otlup), the wood of which is colored by putrefactive fungi (blue), with a large number of knots, resin pockets, tobacco and falling knots, are subject to rejection. .

Beech

Mainly distributed in Europe. Its wood is considered hard and has a reddish-brown color. Beech wood of mountain origin has the highest quality. Its strength is slightly inferior to oak, but it is a champion among tree species that are used for ornamental work. It lends itself very well to planing and turning on a lathe.

Beech is resistant to splitting, but has poor resistance to cracking. It cuts well, but at the same time crumbles across the grain in fine carvings. It is used for interior decoration, making parquet, furniture, and musical instruments. When wet, beech warps.

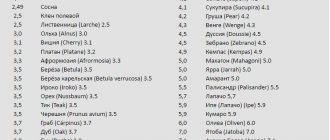

Types of wood by density

Wood for furniture production must have strength, wear resistance and resistance to deformation. These characteristics are determined by the density of the wood, which refers to the ratio of mass to volume of the tree.

Taking into account the density, wood is divided into the following types:

- Soft (less than 540 kg/m3) : pine, spruce, linden, aspen, fir, alder, cedar, poplar, chestnut.

- Hard (from 550 to 740 kg/m3) : oak, larch, birch, beech, walnut, apple, maple.

- Very hard (more than 750 kg/m3) : mountain ash, white acacia, hornbeam, iron birch.

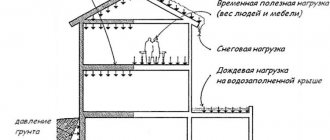

Joinery joints

Any carpentry and furniture product consists of certain elements - bars, frames, gratings, boxes, panels, as well as various small and profile parts.

To obtain the correct connection, the parts that are connected should be given a geometric shape of the required accuracy. A block is a simple structural element of appropriate length, varied cross-section and shape. The maximum cross-section of a solid block is 100×50 mm. Bars with large cross-sections are practically impractical, since they are not dimensional stable enough during shrinkage, swelling and warping.

A frame is a structural element-unit consisting of four bars connected at the nodes by various ties. Most often, within the framework, the bars are in the same plane. It happens that the frame has additional bars - a middle and. In a vertically standing frame, the vertical bars are called pillars, and the horizontal bars are called transverse.

In frames, long bars are called longitudinal, and short bars are called transverse.

A lattice is a frame with a large number of mullions located in a vertical or horizontal position, or possibly both.

The box most often consists of four bars connected with finger joints. Vertical or horizontal bars in a box are called imposts.

The shield can be heavy, or massive, and light. A wooden slab of varying thickness, assembled from slats or bars, is a heavy shield. A panel assembled from four or more bars, sheathed on both sides with plywood or fiberboard, is called lightweight. To reduce thermal conductivity and sound conductivity, the space between the sheathing is filled with thermal insulation material.

All kinds of profile parts used in carpentry and furniture work are named depending on their purpose.

Cornices are attached at the top of the cabinet, partitions - between the wall and the ceiling, baseboards - at the bottom of the walls, partitions, cabinets, pilasters - along the height of the walls, sometimes along the vertical bars of the cabinets. Slabs are used in frames when dividing them into separate parts, thereby obtaining a lattice, or dividing the window frame into smaller parts. Layouts - thin, narrow slats with a smooth or profiled surface - are used to close the joints between panels, bindings, etc. Beads - small cross-section bars - are used for fastening glass in bindings, simultaneously replacing pins and putty. Kalevki are bars of various sections and sizes with shaped notches selected on their front side (rollers, jibs, heels, belts, etc.). Kalevki give bars, cornices, layouts, glazing beads and other parts a more beautiful look.

Smaller profile parts include slats, strips, bosses, etc.

Bars, boards, and panels have their own names on individual sides: narrow sides are called edges, wide sides are called faces, and the place where the face and edge separate is called an edge. When cutting a board, bar, or panel at a right angle to the fibers, an end side, or end, is obtained, and at an angle of 45°, an end side is obtained.

During the manufacturing process, individual parts have to be spliced along their length and connected at different angles.