Modern technologies have made it possible to largely automate all processes for processing metal products and have minimized manual labor, however, for small-scale production and the manufacture of unique products, manual methods are still widely used, thanks to which artistic metal processing is carried out. At the same time, it is possible to replace many labor-intensive processes with automated ones.

Casting

The mold must be made of a metal whose melting point is higher than that of the raw material.

Those metals that have a high degree of fusibility can easily be modified using molds. This method is called casting, it is one of the oldest, but even today it remains relevant and often used. Even before our era, people mastered and widely used casting.

Before starting work, you need to make a mold. The choice of material can be any convenient, for example, wax, sand, if you plan to manufacture several identical parts, the form can be used many times. In the case when the future metal product will have a complex structure, it is advisable to make several molds for different parts, and then connect them to each other by soldering.

Casting can be classified according to casting metal:

Sand casting is a widely used casting method in the industry.

- cast iron;

- copper;

- gold and silver.

By design and materials of molds:

- temporary forms - earth, sand;

- shell;

- permanent – wax, plaster, metal.

By casting method:

- centrifugal;

- under pressure;

- classic.

After preparing the molds, you need to bring the metal to liquid form - melt it. This can be done in a special furnace; in ancient times, metal was melted in cauldrons over a fire. The melting point of different metals is different, so if there is no automated heating detection, it is necessary to monitor the process and after the metal becomes liquid, it is poured into the mold.

Metal casting at home

When the material has hardened, the product can be removed from the mold; to achieve perfectly smooth surfaces, the workpiece is cleaned and ground.

At the stage of heating and melting the metal, various components can be combined to obtain improved characteristics, for example, copper and tin form a more durable alloy - bronze.

Forging

Processing heated metal with a hammer is forging, and it is also the oldest method. Under uniform blows of the hammer, the metal workpiece gradually acquires the required appearance, however, alloys of different compositions behave ambiguously during forging - cracks and breaks appear.

Hot forging - deformation of hot metal with a hammer

The degree of malleability of the metal to such processing is measured in the value of malleability. Depending on this parameter, a distinction is made between cold and hot forging.

Precious and non-ferrous metals (gold, silver, copper) are soft enough that they can be processed by cold forging.

Table of melting points of the most common metals

Iron and alloys based on it can be forged only in a heated state. Heating occurs in a special furnace to a temperature of 1000°C, then the metal can be deformed, bent, and, in general, given the desired shape.

Based on the principles of forging, an artistic processing technique was developed - cutting. It consists in giving the sheet of metal an openwork appearance.

Cold forging is changing the shape of a product by hammer blows of varying strength. As a result, the metal quickly loses its ductility, becomes compacted, and hardening appears. The next step is annealing, which is used to remove the formed hardening.

In modern conditions, cold forging is often used in the jewelry industry.

Handmade artistic metal forging

Five main types of artistic wood processing

Mosaic is the depiction of ornaments or scenes using individual elements. Includes varieties:

- inlay

- intarsia

- marquetry

- block mosaic

Inlay is the decoration of surfaces with wooden plates cut into them. If the inserts differ from the base in color or texture, then such inlay is called intarsia. If decorative pieces of veneer of various types of wood are used in mosaic canvases, resulting in a holistic, as if painted, image, then we are talking about marquetry. You can immediately distinguish block mosaics by the presence of thin plates with the same pattern, glued to the surface to be decorated.

Wood carving is essentially the creation of an image using carved elements. Flat, for example, outlines the contours of the image using notches; with a contour, the silhouette is created using simple lines, and geometric uses ornaments of simple geometric shapes for this purpose. The most interesting effect is obtained as a result of relief carving - the pattern acquires volume.

Pyrography is a relatively new processing method; it consists in the fact that the design is obtained through the process of burning wood.

Turning - it involves turning various products from wood that amaze with their completeness, natural beauty, perfectly smooth shapes, and unsurpassed play of light and shade.

Wood painting is a continuation of the previous method. Simple floral patterns turn into real works of art. There are even certain styles of ornaments (Gzhel, Khokhloma).

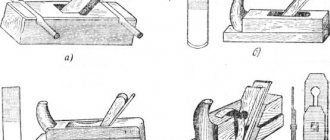

Coinage

Embossing a relief on a thin metal sheet or plate is called embossing. This process is carried out using a hammer and a special rod. As the hammer hits the rod, it leaves a mark on the plate or gives it a three-dimensional appearance. The hammers are called accelerating hammers, and the metal is preliminarily cold rolled to obtain the desired thickness.

Artistic embossing of products requires high precision due to the complexity of the forms; accordingly, you need a material that can be easily processed

This is the initial stage, preparatory, after its completion they proceed directly to artistic decoration. This is a very delicate and painstaking work, for it they use a whole set of rods of various shapes and sizes, they are called mints. It is much easier to carry out embossing on several small plates, which can then be joined into a single three-dimensional object by soldering.

Even in ancient times, a method of chasing figures was invented. It consists of several processes: first, thin sheets of metal, mostly precious, are pressed onto a tin or bronze model, then a shape or design is given using hammers, and finally the sheets are carefully removed from the mold and soldered together.

Often, the artistic processing of metal by hammering can combine the processes of engraving, casting and carving.

There are three types of minting technique:

- from sheet metal;

- for defense or casting;

- embossed.

The traditional method of minting is on the thinnest sheet with rods, and the processing is completed and the artistic form of the cast products is completed in two other ways. Modern casting techniques make it possible to achieve ideal shapes and designs of the product, however, various defects can often occur:

- shells;

- growths;

- neslitins;

- skew;

- roughness.

Embossing is a process of embossing using matrix boards, which are called basma boards, from which another name for the technology is basma. The embossing process is carried out as follows: a wooden matrix is prepared, which will display the relief of the future product.

Basmen board

A thin gold or silver sheet is placed on the matrix, then covered with a thicker lead sheet. The blows applied by the hammer fall on the lead cushion, which becomes compacted and acquires the relief of the matrix, repeating all the contours, volumes and patterns. The metal, sandwiched between the lead gasket and the matrix, takes exactly the same shape.

When the embossing process is completed, the lead pad is removed and the layer of metal - basma - is carefully removed; it has softer design features than the matrix, as if smoothed out. The thicker the sheet layer, the smoother the image will be, so it is not recommended to use metal larger than 0.3 mm for basma.

Basma, as a minting technology, is used for forging products such as iconostases, frames, book bindings, caskets, and to create portrait images.

Metal minting technology

Metal-plastic

At first glance, this method of artistic metal processing resembles embossing, but still has a number of distinctive features:

Metal plastic is performed on very thin metals up to 0.5 mm

- firstly, thinner sheets of metal are used - foil, no more than 0.5 mm thick, and for minting they mainly use from 0.5 to 1.5 mm.

- secondly, the use of sculptural tools - stacks, hammers are used for chasing;

- thirdly, the metal-plastic technology resembles sculpting, smooth lines and movements, while embossing has rougher deformations as a result of impact force.

Metal-plastic was invented back in the Middle Ages; in Russia, products made using this technology came into fashion at the beginning of the 20th century. The metalworking method became so popular that it was introduced into the curriculum for schoolchildren. Frames, iconostases, pectoral crosses and other decorations were made using metal plastic.

To start work, it is necessary to anneal the metal, tin sheets do not require annealing, zinc sheets only need to be heated once, and brass, copper and tin sometimes need to be heated several times. After annealing, the metal cools slowly. A sketch is first prepared - a drawing of the future product drawn on transparent paper.

Then this sketch is applied to a sheet of metal and traced with a special tool, pressing, thus imprinting a relief on the foil. This procedure is repeated on both sides of the sheet until the desired shape is obtained. For convenience, rubber or other soft but elastic material is placed under the bottom of the workpiece.

Wood dyeing

Wood dyeing is carried out to imitate the color of valuable wood species, enhance the natural decorative qualities of wood materials, and eliminate the different shades of parts in the product. For surface dyeing of wood with a transparent finish, organic and synthetic dyes, mordants, humic dyes and coloring compounds are used. The most widely used are aqueous solutions of dyes with a concentration of 1-4%. Soft water is used to prepare dyes. Hard water is softened by boiling, adding 0.1 - 1.5% soda ash, ammonia water. Dissolve the dye in hot water, first in a small amount, and then add the required amount.

To imitate mahogany, acidic dark red, reddish brown No. 3 is used; ZV dyes; to imitate walnut wood - light brown No. 7, 16, 16B, 163, 17, walnut brown No. 12, dark brown No. 8N, etc. Alcohol-soluble dyes are used: brown No. 33 and 34 - walnut wood, red No. 32 - under mahogany.

As mordants, potassium and sodium chromium are used, which give a brown color; iron sulfate - for coloring from gray to black; copper chloride and copper sulfate for coloring in yellowish-brown tones.

Humic dyes (substances of natural origin) are called stain, walnut stain, dissolve well in water, and color wood brown.

When dyeing by hand, the surface to be painted is generously moistened with a dye solution with a swab or foam sponge, then wiped dry with a dry swab along the wood fibers. The color tone of the entire surface should be uniform, without spots, stripes or drips. Drying painted parts requires 1.5-2 hours at a temperature of 18-23°C.

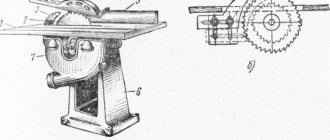

Engraving

Planar engraving

One of the main methods used for artistic processing of various metal products is engraving. It involves applying a relief or linear pattern to a workpiece using a cutter. Engraving can be of two types:

- planar – two-dimensional engraving, which involves processing the surface of the product;

- defensive - creates a three-dimensional image of relief, sculpture.

The most common planar engraving, its purpose is the final stage of decorating various products. The result of such processing will be the creation of contour drawings, patterns, tone compositions, inscriptions, and type works.

Armor engraving with metal sampling

Improving engraving technology, in the 17th century they already used machines for which wood lathes became the prototype.

A very interesting engraving technique for blackening, the design is cut deeper, and then it is blackened with a special substance, resulting in an original image that effectively stands out on the product.

Armor engraving is the creation of a three-dimensional relief or sculpture from a metal sheet. It can be convex, the pattern will be elevated above the background, and in-depth, when the pattern cuts into the workpiece and is located below the background.

Mechanical aging of wood

This method is usually called brushing or texturing wood. The name comes from the English language, where the word “brush” means “brush”.

It is known that the structure of wood has soft and hard fibers. If you remove soft fibers with a brush, the surface becomes embossed.

Only tree species with an easily processed structure are processed mechanically: walnut, oak, spruce, pine, larch. Texturing does not work for maple, cherry, or beech.

Wood processing is carried out with two brushes:

- Brass wire brush - breaks soft fibers. They will “fluff up” and stick out.

- Nylon abrasive brush - smoothes the surface. The abrasive material is contained in the nylon hairs of the brush.

The prepared planed workpiece is processed with a grinder. At this stage of brushing with a disc, grinders destroy the soft layers of wood.

Brushing with a grinder

Use a metal brush clamped in the drill chuck to smooth out sharp corners and protruding fibers left behind by the grinder.

Wire brushing

The metal brush is replaced with an abrasive version. A new brush is used to polish the surface, and at the same time highlight the structure of the wood.

Treatment with a nylon abrasive brush

In any case, the workpiece acquires an antique appearance only after being coated with varnish or oil. Unlike varnish, oil penetrates deeper into the fibers and can change their color.

A dark shade of oil visually ages wood. It is applied with a wide brush along the fibers.

Dark oil finish

To better absorb the oil into the fibers, rub it with a rag. The procedure of applying, drying and rubbing in the oil is repeated several times. They strive to give the workpiece an antique look.

Rubbing oil into fibers

In addition, to protect the oiled surface from external influences, it is covered with a layer of varnish or paint. A good result is achieved by coating with a glossy or matte water-based varnish.

Gloss varnish coating

As a result, the varnish flows into the unevenness of the wooden workpiece and a smooth antique-looking surface is obtained.

Wood after brushing

the video “Aging Wood” FORUMHOUSE YouTube channel .

Wood brushing

Brushing technology

Etching

One of the subtypes of engraving is etching. His technique is simple: a metal product must be coated with wax or resin, then a design, inscription or other decor is scratched onto this coating. Next, the product is placed in an acid or alkali solution, under the influence of which the scratched images are etched and the surface becomes dull.

Chemical etching stainless steel, natural metal color

This technique came into widespread use in the 16th century and was most often used for inscriptions on goblets. In modern conditions, many craftsmen have begun to actively use it because of its originality and unusualness, when it is necessary to make a thing in a vintage style, to artificially age it.

Decorative metal processing

In order to give the metal a different color and tone from the original, various methods are used:

Processing scheme for metal blackening

- blackening;

- matting;

- oxidation.

Blackening is most often used for artistic decoration of silver, copper and gold items. First, an engraving is applied, then the grooves are filled with niello - an alloy of lead, sulfur or tin. The finished product is annealed, excess ink is removed, and the surface around the design is polished to create contrast.

Matting or creating a texture on the surface of metal products is the creation of an effect different from polishing. The surface texture of the product can be finely lined, finely pitted or matte. These effects are achieved using various techniques:

- grinding;

- etching;

- processing with ground pumice;

- quartzization.

Often the surface of the product after casting is covered with a crust; it can also be cleaned to obtain a matte effect.

Oxidation is used for silver, it is treated with chemicals, sometimes using electrolytic methods. The technology is simple: a silver product is immersed in a solution, potassium dichromate is often used, this is an electrolyte, a current is connected and under this influence the silver changes color.

Electrochemical oxidation of steel in alkali solution

Smoking (pickling)

Smoking (or "pickling") wood should not be confused with roasting. Smoking is a chemical treatment that gives wood a unique smoky tone, while roasting is a thermal treatment that is used to restore wood texture after staining. Roasting is most often used when working with coniferous wood, while smoking is excellent for valuable wood species, the solid structure of which is smoked uniformly and efficiently.

Smoking can be considered deep toning: a special chemical composition (“mordant”) penetrates the structure of the wood and changes its natural shade. This effect cannot be achieved with conventional staining, which only changes the color of the outer wood layer. Smoked wood changes color completely, throughout the entire thickness of the board. Therefore, even after sanding the floor, the smoking effect will not disappear.

The name of parquet products made from smoked wood usually contains the word Smoked.

In the Amber Wood line of parquet products, smoked wood is used

in some types of solid boards in the Jade Collection.

Decorative wood processing is a special craft with a long history and traditions. It is important that additional processing methods leave wood as a natural and environmentally friendly material, not changing its properties in any way, but only emphasizing its natural advantages.

Methods of decorating metal products

Decorating items made of precious metals is also to some extent akin to processing, the most common being filigree and enameling.

Depending on the design, the openwork pattern can be soldered onto metal or take on a relief shape

Filigree is a fairly ancient technique. The term itself consists of two Latin horses - “phylum” means thread, and “granum” means grain. Filigree is a collection of thin threads intertwined and decorated with polka dots. This technique was first used in ancient Egypt in the second millennium BC.

From those times to this day, filigree has been exclusively handmade. There are many techniques, they are named after the cities or localities where they are widespread. But in general they can be classified as follows:

The development of filigree art, suspended by the Mongol-Tatar invasion, flourished again in the 15th-16th centuries.

- soldered;

- openwork;

- volumetric.

Brazed filigree is the simplest way to decorate metal products. It is a wire pattern, with decorative elements, which is soldered to a sheet of metal; it will act as a background. Perforated filigree can also be used, when after soldering the base is removed by sawing it out.

There may be enameled filigree, when after soldering the pattern to the base, the space is filled with enamel. The openwork technique involves soldering wire elements together, without using a background, so the product becomes like lace.

Volumetric filigree is presented in such products as vases, goblets, boxes, caskets, etc. To obtain such an item, the elements are first prepared, which are then connected to each other by soldering or attached to the base.

Enamel is a substance obtained by melting glass or other inorganic materials that have an oxide composition. The enamel is applied to the metal in a liquid state and left to harden.

The variety of colors and the ability to paint on enamel have made this technique in demand and popular for many centuries. Products with the addition of enamel are most often found in jewelry, as well as in home furnishings.

Finishing of wood products (Part I)

Author:

Sozykina Tatyana Nikolaevna

technology teacher

Sholokhovsky village

Rostov region

MBOU secondary school No. 8

Humanity has long learned to use natural materials, the most accessible and beautiful of which is wood.

Once in the hands of a true master, it acquires a soul and comes to life.

People used wood to make everything from locks to watches. This is due to its environmental friendliness, availability, strength, ease of processing and, with good preparation and finishing, high durability.

Finishing is used to protect wood products from the effects of external physical conditions - temperature, air humidity, and sunlight.

Finishing is the final, final operation in the process of manufacturing wooden products. In addition, it should protect the material from pests and give the item a beautiful appearance.

Transparent

Opaque

Imitation

Special

Each piece of joinery must have an external finish, that is, its surfaces are covered with paint, varnish, polish or other finishing material. Purpose of external finishing:

1) to give the product a beautiful appearance; 2) protect the product from the harmful effects of light, air and moisture, from mechanical damage and thereby increase its service life; 3) ensure the hygiene of the product.

Transparent finish

consists of applying colorless or colored transparent finishing materials to the surface of the wood, which shade, reveal and preserve the natural color and texture of the wood.

Opaque finish

completely hides the texture and color of wood, since pigmented, opaque materials are used for it.

Imitation finish

- veneering with veneer, textured paper, sheet plastic, pressing finishing films - improves the decorative properties of ordinary wood species, giving them the appearance of valuable species or other natural materials.

Special finishing

- performing various decorative works directly on wood - wood mosaics, inlay, burning, embossing, carving.

For all types of finishing, the wood surface must be well prepared. A poorly prepared surface cannot be properly finished.

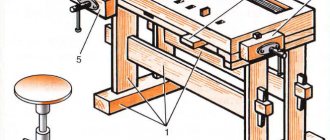

A distinction is made between carpentry and finishing preparation.

Carpentry preparation consists of sealing knots and other defects with glued inserts, final leveling and cleaning the surface. There should be no dirty spots, roughness, waviness, sandpaper scratches, tears or other defects on the surface to be finished.

Carpentry preparation.

The wood is carefully sanded. Glass and flint sandpapers on paper and fabric are used for sanding wood. Before grinding, new glass skins must be rubbed against each other by working surfaces in order to somewhat dull the too sharp edges of the grains. If this is not done, the sandpaper will leave a lot of scratches on the sanded surface.

For sanding for a clear finish, flint sandpaper is considered best.

Stages of finishing preparation.

Detarring.

Resin solvents are used for degumming. Most de-resinants are flammable or harmful to human health, so a soda solution is more often used. Deresining solutions are applied with a grass brush or cotton brush.

Whitening

. The surface of wood with contaminants is subjected to bleaching. The disadvantage of the first two remedies is their slow action. Whitening compounds are applied with a grass brush, cotton brush or spatula. Wash them off with soap and water or soda.

Stages of finishing preparation.

Lint removal

. To remove lint, i.e., the ends of cut fibers, moisten the surface of the wood with water at room temperature and then allow it to dry. The fibers swell when wetted, and when dry they warp, raising their tendril ends upward. These tendrils are called lint. They are removed by sanding the surface, dry after moistening, with fine-grained dull sandpaper.

Pore filling

. Porous filling increases the density of the finished surface, makes the surface smoother and improves the adhesion of the finishing film to the wood. Wood fillers include pumice powder, talc, chalk, wax, rosin, synthetic resins and other filler materials. Currently, our industry produces a large number of ready-made porosity fillers.

But most paints and varnishes emit solvent vapors that are harmful to humans. This requires strict adherence to safety regulations during finishing work. The main ones of these rules require:

1) varnishing should be carried out only in a well-ventilated area; 2) do not keep paint materials open; 3) when performing operations involving strong release of harmful fumes, use a respirator; 4) when performing operations involving heavy contamination of hands, use rubber gloves; 5) do not keep utensils that have been released from paint and varnish materials in the workplace.

There should always be warm water, soap and a dry, clean towel at the workplace.

For safety reasons, you should also try to replace manual processes with mechanized ones.