If you are a fan of creating beautiful and comfortable objects from wood with your own hands, then you will definitely try to equip your workshop. A cozy room with all sorts of gadgets and tools will definitely inspire you to create new masterpieces. But making complex parts with your own hands without a woodworking machine is quite difficult. With the help of such an “assistant” you can easily create real works of art from wood. But all this is possible if you choose the right machine. And how to do this will be discussed in the article.

Versatile tabletop woodworking machine

Advantages of wood cutting machines

The presence of professional equipment radically changes the entire production process, including in the field of carpentry. The advantages of purchasing a machine include:

- Possibility of unique wood processing. Using the machine, you can give any shape to the processed base.

- High equipment performance. All professional machines have sufficient power to ensure long-term uninterrupted operation.

- Precision performance with proper handling of the equipment.

- High quality. Just after a little training and “breaking in” of the tool, you can produce interior items and souvenirs for sale or to order.

- All models from a quality manufacturer are safe to use. If the device overheats, the automatic shutdown system is activated. This feature significantly extends the service life of the machine.

- Most woodworking equipment does not require complex maintenance; just regular inspection of components and cleaning of the working part from shavings and dust is enough.

- Low noise level.

The advantages also include a large selection of woodworking machines, each of which is designed for specific tasks. The future owner should only indicate the scope of work and, in accordance with this, select the most suitable equipment model.

Pros and cons of universal machines

household universal machine Corvette

The production of finished products from lumber takes place in several stages on different types of machines. First, the trunks are cut at a sawmill, after which the board goes to a surface planer, router or jointer. The multifunctional device allows you to carry out the entire technological process at home or in a workshop, saving significant money.

Advantages of universal woodworking equipment:

- functionality: you can carry out several operations without leaving the spot;

- ease of operation and maintenance;

- benefit: purchasing one device is much more profitable than purchasing several;

- feasibility: some processing operations are performed quite rarely, so there is no point in buying a separate mechanism;

- quiet operation: suitable for home use;

- compact: many options are hidden in a small and even desktop case that can be installed on a desk, kitchen table or workbench.

Flaws:

- Cannot be improved or altered;

- the implementation of some functions may suffer at the expense of others;

- They are not suitable for serious production - it is more profitable to place a person at a separate machine for each operation.

Before purchasing all-in-one woodworking equipment, you need to carefully consider the required features. Perhaps those missing from the model you like can be replaced with hand tools.

Types of sawing machines

There are many areas of use for woodworking machines, and many types of equipment. One of the most common types is the sawing machine.

Such devices are designed for sawing logs and timber. Depending on the operating principle, the following types of machines are distinguished:

- Sawmills, which refer to stationary equipment that makes longitudinal and transverse cuts using a linear saw. The installed saws perform reciprocating movements, and the master only guides the working part. Such devices were among the first to be developed, are large in size, and are quite difficult to maintain.

- Sawmills have now been replaced by circular saws. Depending on the model, such designs can be manual or automatic. Circular saws cut logs in a vertical and inclined plane.

Also included in sawing machines are band models. The working part is presented in the form of a rotating belt.

Such designs are quite cheap, but are intended primarily for harvesting primary material, since they do not have sufficient accuracy.

What kind of work can be done on such equipment?

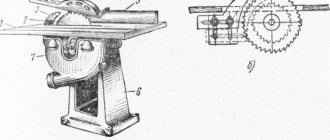

A universal woodworking machine is a compact piece of equipment. This feature is reflected in its design and functionality. As a rule, the machine is driven by a single electric motor. The torque, which puts all the tools into operation, is transmitted using a belt drive. All mechanisms are most often controlled using pulleys.

All working tools are located on a special table. It is made taking into account the laws of ergonomics. The convenient device allows you to perform multiple tasks simultaneously. Of course, everything will depend both on your skill and on the features of a particular brand of machine.

The versatility of a woodworking machine implies the presence of many functions. In general terms, each such equipment should be able to:

- cut material. For these purposes, the machine is equipped with a circular saw. Some models may also have knife processing units;

- drill holes. This function, along with sharpening, is the most popular. But due to the features of the universal machine, drilling can only be carried out in a horizontal plane;

- milling. This function is most often combined with drilling. It is enough to simply install the cutting tool using a special spindle head;

- surface grinding. Not a single wooden part can do without this treatment. For grinding, you can use either abrasive discs or a belt;

- planing block or jointing. This work requires a lot of space, so a significant part of the desktop is devoted to it. Also for jointing, a cutting shaft is built into the machine.

Of course, some manufacturers may offer a more expanded list of functions, but such additions always lead to an increase in cost. Although the listed set of capabilities is quite enough for most carpentry work. Such a universal woodworking machine will be quite useful for both DIY enthusiasts and professional craftsmen (for example, in the production of furniture).

In addition to universal woodworking machines, the industry also produces more specialized ones. For example, surface planers. Such equipment is designed for planing workpieces to the required thickness. In addition to thicknessing machines, others are also produced, but in most cases they can be replaced by one - a universal one.

Types of planing machines

Another variation of woodworking equipment is planing machines. Such structures are designed to remove the outer layer of wood. In this case, the cutting part is located deep in the material being processed.

The following types of planing equipment are distinguished:

- One-sided models that process only one plane of a wooden workpiece.

- Double-sided models capable of removing both the top and bottom layers of wood from a part.

- Often special rimming machines are used that process 3 or 4 edges of the workpiece.

There are also jointing machines that remove a layer of wood at a given angle.

Cutting with a jigsaw

the most popular tool today . Professionals and home craftsmen value it, first of all, for its universalism. Having low weight and small dimensions, it copes well with shaped, transverse and longitudinal cutting of sheet wood. Can make curved and straight cuts, rectangular holes and round holes of various diameters.

There are household and professional jigsaws. Home models are low-power, but for domestic use their resources and functionality are quite sufficient. They can cut wooden pieces up to 70 mm thick. The total time of use is no more than 20 hours per month. They are produced mainly in Poland and China, but there is also a compromise Hungarian version - the inexpensive, functional BOSCH PST 700 E Compact .

The requirements for professional models are more serious. Therefore, these instruments are usually produced by brand companies in Japan, Sweden and Germany. They are highly productive and can withstand heavy loads, cutting wood up to 135 mm thick.

Saw blades or jigsaw files differ in size, teeth, color, tail shape and, of course, the material from which they are made. When working with wood, blades made of HCS (carbon steel) are used.

Features of using lathes

Lathes are used to remove a piece of wood in a circular manner. Similar designs have found their application in the furniture industry, and are intended for the manufacture of decorative cases, facades, and fasteners for sets.

All known models differ in engine power, housing size, installation method and degree of automation:

- Manual models are purchased, as a rule, for home use. Using this design, you can successfully produce a small furniture set for your home or to order. On the case there are power buttons, speed controllers and other technical parameters. All changes are made manually.

- Automated equipment has a template for producing specific parts. The specified parameters are entered into the machine operating program, but control and maintenance are performed by humans.

There are also automatic designs that are widely used in furniture production. These machines operate according to specified algorithms and are not used in everyday life.

How to choose the right model

The selection of a suitable model of a multifunctional machine is made based on a combination of several factors:

- size, design of the machine (desktop or stationary);

- set of functions;

- price.

When considering the option of interest, you need to pay attention to the number of knives on the planing shaft. The more there are, the cleaner the surface, but the more difficult it is to install and configure. In addition, you need to check what the spindle rotation speed is (if there is a milling function), the rotation speed of the knife shaft and saw blade.

Each of them has its own requirements - for a cutter, a speed of 5-6 thousand rpm is recommended, but for a saw blade, more than 3 thousand rpm is not recommended - the tool overheats and begins to dangle in the cut, which is fraught with undesirable consequences.

Expert opinion

Levin Dmitry Konstantinovich

It is also necessary to pay attention to the size of the machine and determine whether it will fit in the workshop. It is necessary to provide a reserve of space so that you can freely work with sufficiently long workpieces. Another important parameter is the supply voltage. Some models require 3-phase power, which is not available in every area.

Woodworking combination machines are useful and effective equipment for the home workshop. With their help, you can make any wooden products, from simple furniture to fence slats or slats for a greenhouse. The quality and composition of products are limited only by the skills and experience of the master, but not by the capabilities of the equipment.

Wood drilling machines

In furniture cases or facades, many interior items require through or blind holes. Woodworking drilling machines are used to perform this task.

Distinctive features of such devices are the ability to drill to a given depth and maximum accuracy.

The following types of drilling machines are distinguished:

- With vertical type of action. The spindle has a vertical direction.

- There are spindles with horizontal direction.

- Spindles are available for deep drilling.

Some modern machines can operate on an inclined axis, which is used for the manufacture of complex wooden structures.

Today, drilling equipment is often replaced by milling machines, which greatly facilitate the work of the master. Such devices are more convenient in practical use, which determines the buyer’s choice.

What popular brands are there on the market?

In addition to all the characteristics and parameters of the machine, when making your choice you need to pay attention to the manufacturer’s company. The equipment is expensive, so the quality of workmanship must be at a high level. Today, there are several dozen models of universal woodworking machines on the market.

Before you go to the store, you should get a general idea of the existing brands. To do this, you can use both the websites of the manufacturers themselves (here you can find out about the characteristics of the equipment) and specialized forums (here users leave their opinions about specific models). Having more information will make it easier for you to make the right choice.

Many experts recommend purchasing FDB Maschinen products. Equipment from this company is very popular among professional buyers.

If you need to equip a mini-workshop, which will be the main place of your work, then machines from FDB Maschinen are what you need. They are distinguished by a wide range of functions and reliability.

If we talk about the disadvantages of such equipment, experts identify two main ones. Firstly, the high cost of the machines. Even the cheapest professional model will cost you more than 50 thousand rubles. Secondly, very often when a breakdown occurs, you have to wait a long time for the delivery of a new part.

If high productivity is not important to you, then you can purchase a cheaper version of a woodworking machine from a manufacturer such as Performax/ Jet/ Utool. Its products are also of high quality, but at the same time the cost is much lower than that of the previous company. Machines from domestic manufacturers are even more affordable. Thus, products under the Sturm (Energomash) brand are very popular on the market.

In addition to the affordable price, such equipment has another advantage - ease of repair. In the event of a breakdown, you can do all the work yourself. Parts are always on sale, and replacing them does not require special skills and knowledge.

Choosing a woodworking machine for your carpentry workshop is not an easy task. Here you need to understand what functions it will perform, how to install it and connect it to power, and much more.

And of course, the choice of machine brand is important. After all, the service life of your new equipment will depend on the manufacturer, or rather on his conscientious work. Therefore, there is no need to rush, you need to weigh all the pros and cons and then your purchase will bring benefits and not disappointment.

Wood bending machines

Interior styles such as Baroque require not simple furniture, but furniture with relief facades and details. Woodworking bending machines were developed specifically to solve such problems.

- The main purpose of such structures is to give the wooden surface the desired shape.

- The device is equipped with special clamps and forming heads.

In appearance and principle of operation, a bending machine resembles a hydraulic press, which gives the workpiece a complex shape, relief or imprint.

Multifunctional household woodworking machine: scope of application

You can buy a universal woodworking household machine for both semi-professional and home amateur workshops. Such devices are multifunctional and are capable of performing various operations with wood.

A multifunctional woodworking machine for the home copes with the following tasks:

- cutting wood;

- wood planing;

- milling;

- grinding;

- drilling wood, etc.

This versatility is due to the ability to replace the working tool. Thus, by installing a planing element, you turn the device into a planing apparatus, and if you buy knives for woodworking machines, you can saw wood beams. As a result, instead of numerous types of equipment, one machine is enough to operate, which saves space, effort, time and money.

Another feature of household woodworking machines for the home is the gradual consumption of electricity, which allows you to save on utility bills.

A multifunctional woodworking machine will be useful in both professional and home workshops

Equipment for assembling parts

Woodworking machines also include assembly structures. Such devices are capable of fixing adjacent parts using screws or nails.

Also on the list of tasks performed you can find the processing of fixation points, upholstery work for future furniture, and the application of various decorative coatings.

Comparison of different models of woodworking machines

Both domestic and foreign manufacturers of woodworking machines are represented on the modern market. Among Russian manufacturers, the companies that have proven themselves best are Corvette and Ant. In the foreign market, Jet, Maxita and Hitachi are distinguished by their reliability.

To make an informed choice, it is worth comparing the characteristics of different machine models and finding the option that best suits your needs. We compared the models BELMASH UNIVERSAL-2000, STAVR SDM-3/2000, KRATON WM-Multi-08, ENKOR Corvette-320, as well as the leading models of household multifunctional woodworking machines Ant.

Comparison of performance of machines of various models:

| Machine model | BELMASH UNIVERSAL-2000 | STAVR SDM-3/2000 | KRATON WM-Multi-08 | ENCOR Corvette-320 |

| power, kWt | 2 | 2 | 1,6 | 1,5 |

| Rotation speed, rpm per minute | 6000 | 3800 | 8000 | 3500 |

| Cutting depth, mm | 97 | 85 | 75 | 70 |

| Platform size, mm | 700x474 | 530x150 | 746x210 | 964x210 |

| Weight, kg | 39 | 61 | 35 | 123 |

| price, rub. | 20600 | 30940 | 31429 | 39610 |

It is worth noting that the functionality and reliability of parts of domestic models is not inferior to foreign ones, while they are noticeably cheaper. The only complaints can be about the build quality, since most models are assembled in China.

Helpful advice! You can save significantly by purchasing a domestic machine and using video instructions to assemble it yourself. This way you will get an excellent quality unit without extra costs.

Comparison of performance of various models of Ant machines:

| Machine model | SD-3-00 | SD-3-02 | SD-3-03 | SD-4-00 | SD-4-01 | SD-5 | SD-6 |

| Power consumption, kW | 2 | 2 | 2,7 | 2 | 2,7 | 2 | 2 |

| Rotation speed, rpm per minute | 4200 | 4200 | 4200 | 4200 | 4200 | 4200 | 4200 |

| Cutting depth, mm | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

| Dimensions, cm | 3x65x100 | 73x56x58 | 73x66x58 | 73x56x38.5 | 60x66x38.5 | 60x50x45 | 60x50x66 |

| Weight, kg | 75 | 70 | 75 | 50 | 60 | 40 | 50 |

| price, rub. | 46130 | 46130 | 49350 | 36340 | 39570 | 26770 | 31720 |

Photos of woodworking machines

Cutting with an electric chisel

This power tool has become indispensable for every wood carver. Essentially, it combines an ordinary hand chisel and a mini-machine for processing wood. In a professional environment, it is also called a pneumatic or mechanized scraper .

An electric chisel works on the principle of a jackhammer. Nozzles are attached to the electric handle with a motor. They come in three types: straight, semicircular and angular.

The tool is used for processing soft and hard wood, as well as wood growths (burls, burls). An electric chisel allows you to remove a large amount of material without much physical effort, so it is excellent for roughing. At the same time, there are also very compact models. For example, a tool from Proxxon fits in your hand and can be used to work with small objects. But even tree trunks are processed with large models to create real sculptures.

CNC plasma cutting

Plasma machines are the latest generation of CNC milling and engraving technology. Equipment of this type is intended for plasma arc cutting and milling of wood.

The machine looks like this: a supporting frame, including connecting elements and two drawers for water. Cutting is carried out with a milling spindle to a thickness of up to 16 mm. The maximum operating speed is 2.5 m per minute.

The units have a very stable design, allowing processing to be carried out with high precision. One of the best models of this type is the German machine High-Z PlasCUT-1350 . In addition to working with wood, he excels at cutting, milling and engraving metal, plastic and other materials.

Manufacturers of sawing machines

Construction stores are filled with all sorts of options for such equipment, so quickly choosing the right model can be difficult. Experts recommend taking a closer look at units from well-known manufacturers, the quality of which is confirmed by positive user reviews:

- MakitaCorporation - the main activity of the Japanese corporation is related to the production of professional-type electric and gas tools for construction work. The range includes over 1000 models, ensuring efficient processing of any materials. The advantages of the units include the reliability of the engines and the quality of components. They are often used for work characterized by extreme loads.

- Metabowerke GmbH is a German company that produces equipment for industrial and manual processing of materials. The Metabo brand's core slogan, “when you need reliability,” guarantees users the purchase of a powerful, durable and ergonomic tool that ensures efficient construction work in the toughest conditions.

- TechTronic inductries is a Japanese company that develops, produces and sells power tools and garden equipment under the Ryobi brand. All products are assembled at our own factories in the USA, Germany, and China. The popularity of the models is due to high quality, equipment with innovative technologies, the ability to carry out most of the assigned tasks, and low price.

- Einhell Germany AG is a German company that produces tools for construction, repair work, gardening and recreation. Its innovative products are represented in markets in more than 90 countries. The models are assembled mainly at Asian enterprises. In its work, the company adheres to the principle of combining simple solutions with high quality, which allows it to produce goods at an affordable price.

- Zubr OVK is a Russian company producing construction equipment. The brand’s devices are valued for their high reliability, quality, ease of use, and low price. By constantly updating the range and improving previously released units, the company is able to timely meet the growing needs of users.

- Bosch , a German corporation, is a reliable supplier of construction tools and household appliances. The brand's leading position in the market is due to the quality, reliability and functionality of its products.

Laser cutting

Today this is the fastest and most economical way to cut wood material. It is carried out with a gas CO2 laser, that is, without mechanical contact with the workpiece. This allows cutting along the most complex contours and with the smallest detail. It is impossible to achieve such precision with any other tools or machines. And the use of computer programs makes it possible to turn work into the most waste-free production possible.

Any wood material can be cut by laser. Even the veneer is only 0.6 mm thick. In general, technology opens up very great opportunities, allowing you to cut out original stories. The work of decorators and furniture makers cannot do without this installation.

True, the principle of operation requires high qualifications. Wood is a flammable material and therefore requires constant cooling. To do this, the machine blows into the cutting zone, which is controlled by the operator. In this way, maximum purity of processing is achieved (no carbon deposits are formed) and at the same time heat treatment of the part is carried out (it looks more contrasting and lasts longer).

Different types of wood are cut with a certain beam power and blowing force. And, if the workpiece is knotty, then this complicates the process even more. “Aerobatics” requires cutting plywood, because... glue layers burn hotter than wood. Yueming CMA series machine is perfect .

Waterjet cutting

The unique technology “TECHTRAN” , developed by Soviet scientists for the defense industry, and only relatively recently became available to the general public.

The principle of operation is to cut any sheet materials with an ultra-fine jet of water. Mixed with abrasive, it is fed under very high pressure to the cutting head, where it turns into the finest hair. The jet output speed allows you to cut even metal, not to mention wood.

Nowadays, a CNC system has been introduced into the technology, which makes it possible not only to cut, but to program the processing of material according to any sketch. Cutting accuracy – 0.1 mm. At a speed of up to 100 m/hour, the cut of wooden material is cold, the part does not heat up and does not deform. The cut edges are clean and do not need any finishing.

Vladislav Permin, specially for Equipnet.ru