It is difficult to name areas of life in which trees or products made from them would not be used.

Therefore, the question periodically arises - what to do with various plant and wood waste and products of the woodworking industry, how to get rid of them, because this material, being in an uncontrolled state, poses a serious danger.

In this article we will look at various ways of using or recycling wood and any waste from sawmilling and woodworking, you will find out what is made from wood and its waste, and we will also discuss issues related to them.

What is wood waste?

Wood waste refers to any materials that are obtained as a result of forest maintenance or commercial wood processing, but are not the final product. Therefore, waste can be either whole trees or any fragments that remain after they are cut down or processed.

Most often, waste is classified as:

- tree trunks cut down during site clearing;

- branches cut from trunks;

- stumps left in the ground;

- bark;

- croaker;

- all kinds of trimmings;

- fallen leaves;

- sawdust;

- shavings;

- wood chips

Ideas for using waste lumber

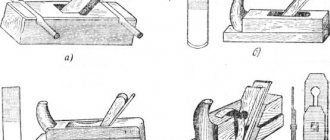

Let's consider what products can be made from scrap boards in your free time.

The list of crafts that we will discuss below includes the following categories:

- a country stool is a necessary thing in everyday life that you can not buy, but make from improvised means;

- a chair that will not only serve as a comfortable element of the surroundings, but will also become an interior decoration;

- lampshade for a lamp, which will look natural in the interior of a house decorated with wooden paneling;

- New Year tree, which will come in handy on the eve of the winter holidays.

Of course, the list of crafts is incomplete, so you can add your own ideas to the ideas already proposed by leaving a comment on this article.

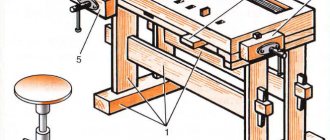

Assembling the stool

The photo shows a stool that you can make yourself

To assemble the stool we will need:

- cutting boards 60 cm long and at least 2 cm thick;

- self-tapping screws for assembling all the parts together;

- paints and varnishes for finishing the finished product.

Tools you will need:

- wood hacksaw;

- screwdriver with drill function;

- sandpaper to level the cut line;

- brush;

- container for mixing paints and varnishes.

Bottom view of the stool

The manufacturing instructions are as follows:

- we cut blanks for the seat from two boards;

- we prepare 4 blanks for the legs;

- in the lower part of the blanks for the legs we make an oblique cut, as shown in the photo;

- We connect the blanks for the legs together with self-tapping screws, so that the cut corners are on the inside of the structure;

- We attach the seat on top of the legs;

- We sand the finished product with sandpaper to remove splinters and irregularities from the ends.

Important: When tightening the screws, we recess their heads so that they are flush with the surface of the lumber used.

As a result, we know how to make a simple and yet reliable stool within half an hour, which will be an excellent addition to a set of homemade country furniture.

Article on the topic: How to build a bathhouse from 100x150 timber

In order for the finished stool to last as long as possible, after assembly it should be covered with a layer of varnish or paint. As a result, if you accidentally forget your own outdoor furniture, it won’t cause much harm.

Assembling the chair

Do you dream of designer furniture, but the high price is stopping you from buying it? It turns out that a designer chair that can decorate any interior can be made with your own hands and the material costs will be very small.

A designer chair that is not difficult to make

So, in the photo there is a chair, the price of which can be several hundred dollars. Meanwhile, it is enough to use your imagination and it will become clear that anyone can make such an element of the surroundings.

What is required to assemble a similar chair?

- A large number of small planks that can be split from waste construction lumber;

- The frame of an old chair that you wouldn’t mind sacrificing in the name of creativity;

- Glue for working with wood.

We make small boards for finishing the chair as follows:

- We place a piece of board on its edge at the site of the cross section;

- With precise blows of the ax we break off chips about 1 cm thick.

The frame of an old chair is the basis for creativity

It is clear that the chips will not be of the same thickness, but this is not important, since the finished chair will have to be covered with many such parts and the difference in their thickness will not be noticeable.

As glue, you can use compounds designed for working with wood. But the disadvantage of such compositions is that they take a long time to dry. And in addition, you will have to provide strong pressure on the slats for the entire time necessary for drying.

Given the number of parts, fulfilling this condition will not be easy at all. Therefore, we recommend using two-component compositions based on epoxy resins and a hardener as glue. Such compositions dry quickly, as a result of which it will be easy to assemble the chair.

Article on the topic: Which thermal insulation is better for a house made of timber

The assembly instructions are simple. The frame used is checked for strength and, if necessary, strengthened.

Next, the wood is primed and then covered with planks. The order of pasting is arbitrary, but you need to try to ensure that the surface of the glued chips is located approximately at the same level.

It is advisable to coat the finished chair with wood varnish. As a result, the craft will look great and will last a long time.

Assembling the lampshade

Chandelier made from planks

If there are a lot of unnecessary wooden planks, you can make a lampshade approximately the same as in the photo.

Manufacturing instructions are as follows:

- from the bars we assemble the base of the lampshade in the form of a ring or hexagon;

- along the outside of the base, we attach strips with self-tapping screws that will block the light from the lamp, creating more comfortable darkened lighting;

- if the room has a wooden ceiling, we attach a homemade structure directly on it around the lamp;

- For aesthetic appeal, sand the finished product with sandpaper and cover it with a layer of wood varnish.

Important: Given the proximity of a hot lamp, the inner surface of the lampshade is not varnished.

Assembling the Christmas tree

Extraordinary, but easy to make “Christmas tree”

Maybe such a tree will be unsightly in appearance, but there is no doubt that it will be original.

The manufacturing instructions are simple. We attach planks of constantly increasing length to a long board at equal intervals. These strips will symbolize the branches of the Christmas tree, and therefore they will need to be properly painted and decorated.

Hazard class according to FKKO

According to the FKKO classification, clean wood waste belongs to hazard classes IV–V, that is, they do not pose a danger to nature , but there are situations in which the level of danger increases sharply.

For example, any waste doused with machine oil or gasoline is classified as hazard class III.

Despite the fact that dead wood, brushwood and fragments of trunks are classified as class V, that is, they are considered non-hazardous, they sharply increase the rate of spread of forest fires. Indeed, unlike living plants, in which sap flow maintains a high level of humidity and also reduces their flammability, these debris quickly lose moisture, which is why they become much more flammable and flammable.

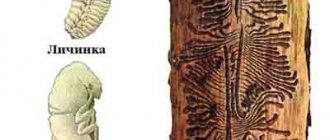

Willow weaving

Coastal thickets near the site - Klondike. There they obtain willow branches for crafts. The fences are made according to a simple scheme: pegs are hammered in, then rods with the bark removed are passed between them.

Willow, hazel, and aspen have the best branches for weaving

Nice decor - wicker baskets in which flowers are planted.

Baskets in flower beds give the area a rustic feel

You can knit the frame of any animal from strong branches, and then braid it with vines.

Unusual wicker decor - sea turtle

But the most interesting creation is the living tree. Chopped willow twigs are intertwined and rooted. All buds on the trunk are blinding, except for the top ones.

Rooted willow branches grow into a new tree resembling a palm tree

For a special occasion, an arch made of wicker is installed. A hut on chicken legs is not only a decoration, but also a feeder for birds. Box beds are ideal for growing greenery. Any flower bed fenced with a fence changes its appearance. Armchairs made of wicker will transform a relaxation area. Canopies and openwork are woven from wicker backs for benches Modern garden decor - balls made of wicker Having achieved mastery in weaving, you can create the figure of a girl Children will like mischievous piglets made of wicker A hare made of wicker enchants at first sight We suggest you read: How to make a roof for a bathhouse with your own hands

Who makes them?

Any activity associated with the extraction or processing of wood is also a source of waste, and the type of waste directly depends on the activities of the enterprise or organization.

When logging, waste can be whole trees or individual parts , it depends on the purposes for which the cutting or sawing is carried out.

The purpose of thinning is to free up living space for young growth of certain species, and sawn or felled wood is a by-product.

Sometimes it is recycled, but often it is left in place, where it rots for many decades, gradually turning into driftwood. If the purpose of felling is to extract industrial timber, then after the work, including the removal of the extracted material, sawdust, branches or foliage remain on the ground. You can read more about the reasons for cutting down trees, as well as methods for performing this work, in the Trees section.

The trunks, which are also called canes or logs, are cut down and cleared of branches, and delivered to sawmills, where they are cut into boards, timber or other lumber. The main product at this stage is lumber, and the waste is slab and sawdust.

Another consumer of logs is wood processing enterprises that produce building materials, as well as various chemical products.

At such enterprises, the waste consists of bark and various trimmings.

Finished boards are supplied to construction sites, as well as various processing enterprises, including furniture ones. At construction sites, the main type of waste is all kinds of trimmings, but processing enterprises, in addition to trimmings, also produce shavings. Many enterprises immediately process waste into wood chips, because it is easier to dispose of or sell.

Logs

A type of firewood is logs, often a cylindrical section of a tree trunk or branch. You can’t make beautiful furniture from these, but logs can have many uses in interior design. Starting with art objects...

...and ending with self-leveling floors made from thinly sliced wooden “slices”.

Some “interior designers” decide to experiment more boldly: they create a stylish mini-bar, a mirror frame or a hanger from logs.

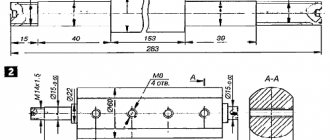

Equipment for processing wood and other forest resources

All equipment can be divided into 3 types, that is, intended for:

- sawing and uprooting;

- recycling;

- processing.

Sawing and uprooting

The main tool for manually cutting down trees is a chainsaw, which is used to carry out almost all work within the city.

Together with it, it is often necessary to use not only hand tools (an ax and a ladder), but also various mechanisms , including hydraulic lifts and cranes.

For uprooting, excavators are used, including those with uprooting grips, or bulldozers with special knives, as well as all kinds of cutters. In addition, when cutting and uprooting, you have to resort to the help of trucks, because the material dumped or removed from the ground has to be delivered to the place of processing or disposal.

Disposal

The main equipment used for wood recycling are all kinds of shredders and wood chippers, which turn wood into wood chips. Household shredders are small in size and operate on a 220 V network, while industrial devices are equipped with powerful electric (380 V) motors or internal combustion engines (gasoline or diesel fuel).

Some models are manufactured in a mobile version, for which they are equipped with either a trailer or a suspension for installation on a tractor.

Most wood chippers are not well suited for processing grass and leaves, so their own models of wood chippers are being developed for these materials.

However, there are devices that, although not very efficient, can process wood and fallen leaves or grass .

To facilitate the labor-intensive manual collection of fallen leaves, various devices are used that work on different principles, but the most effective and popular are garden vacuum cleaners. Some vacuum cleaners not only collect, but also shred leaf matter, making it take up less space and be better suited for most disposal methods.

Shredded wood residues are converted into any popular product, and are also used for heating or used in the garden.

Recycling

The following types of equipment are used for processing lump and shredded wood:

carpentry machines (circular saw, jointer, surface planer, milling machine, etc.);- presses, including granulators;

- dryers;

- shredders;

- debarking machines;

- complex lines.

Using old polyethylene

It is unlikely that the film will be used to equip a new country greenhouse or even a small greenhouse, but individual plants can be placed in spring protective structures - film cubes.

In addition, you can cover anything with old film... the same piles of sand for construction, stacks of bricks or decorative tiles for arranging a summer house, bulk materials, feed. You just have to fold it several times, and even old and worn plastic film will become a good protection against moisture.

Article on the topic: How to properly paint a house made of laminated veneer lumber

It will also find excellent use in major construction projects. The film can be used to cover foundations and only poured areas so that the concrete does not dry out and crack in the sun.

In the issue of film, we moved a little away from the main topic of crafts and leftover building materials, but now we are returning to it.

Profitable business in processing wood waste

Despite the fact that waste wood and other forest resources, under many conditions, can be burned or disposed of in a landfill, they are a valuable resource with great potential for subsequent processing.

The recycling business can be very profitable if the costs of purchasing and delivering the material are low. In addition, the demand for finished products and the transportation costs associated with their delivery to the buyer are of great importance.

If these conditions are met, any of the processing methods described in the article can become a very successful business, because such products are in steady demand, and wood is a renewable resource, so there will always be waste.

more detailed information about various types of profitable wood processing business in these articles :

- Business in the production of wood chips for smoking: selection of equipment, search for raw materials, wholesale and retail sales, calculations of possible profits.

- How to organize a business for the production of OSB boards: technological, organizational and economic aspects.

- Wood concrete production - enterprise overview and business plan.

- Sawdust processing as a business - removal and disposal for profit.

- Charcoal production as a promising business.

- Wood waste recycling as a profitable business.

Toolbox

You can create order in your area using the same boards. Other building materials and household utensils can be easily hidden from prying eyes if you construct wooden boxes from timber. No special technique required. The work is carried out according to the scheme: sketch, measurements, execution of the frame and cover. This design will not stand out from the overall interior, while it will hide some objects from neighbors.

Unusual and useful ways to use table salt at home and in the garden

Prospects for processing and disposal

Since wood is a renewable resource, there will always be waste, which means that its processing and disposal of wood waste will always be necessary.

Wood processing products will also always be in demand , because they are made from natural and environmentally friendly materials, unlike their plastic counterparts.

In addition, recycling wood waste allows it to be used again, and also reduces the amount of greenhouse gas emissions into the atmosphere, one of which (carbon dioxide) is released when wood is burned. Therefore, any use of wood waste for the manufacture of other products benefits the Earth's ecology, and in many cases, is also a profitable business.

Also, the use of waste to produce energy or various popular products reduces the number of trees cut down , because many materials that are made from wood can be made from trimmings and other types of waste.

For this reason, processing wood waste and obtaining some other product from it will be in demand until humanity moves to a new level of development and stops cutting down forests in order to then make various necessary products from wood.

Log garden furniture and decorative items

Even fragile wood will serve the cause of beauty. Small crafts are usually made from the bark.

Birds will happily visit your feeder if you make it out of bark.

A birdhouse made of plywood will be transformed if you cover it with bark.

Birdhouses made from natural materials will attract birds to the garden

In order for a hedgehog to appear in the garden, you need to glue the pine cones to a plastic bottle wrapped with twine.

For naturalness, berries and acorns are attached to the hedgehog’s back.

Cement pots are decorated with cones, pressing them into the solution. If you paste the box with cones and attach a handle from a branch, you will get a decorative basket. The basket is made by stringing cones onto a wire frame. To make a Christmas tree for the street, glue the cones onto a cone made of waterproof material. If you need closed cones for a wreath. , hold them for 30 seconds in wood glue To make the cones open, dry them in the oven Any corner of the garden will be decorated with a watchful owl made from bark Compositions with cones will decorate the interior of a gazebo or house Unique birdhouses are created from pieces of bark and scales of cones Ordinary plastic flowerpots can be pasted over with pieces of bark To make a basket made of bark, attach it with a stapler to a wire frame. Set up a hobbit house made of bark, branches and moss in a secluded corner with your children

Tags: can, do

« Previous entry