Frame houses are a fairly new type of construction work, but popular, allowing you to save a significant amount of time and money. By studying the relevant reference literature and having certain construction skills, you can build a full-fledged house three times cheaper than the cost of the same building made of stone. How to correctly calculate a frame house and choose materials? What needs to be taken into account during future construction?

Calculating materials for building a frame house is an important step. You can determine the approximate amount of costs, calculate financial losses and possible risks. The calculation of materials for a frame house may be more than what was expected to be invested in the construction. Therefore, you can reduce the area or number of floors of the building, and choose more economical options for building materials.

- Materials for roof installation

DIY foundation

Calculating the cost of a frame house must begin with the foundation. There are three main types of foundations for frame houses - strip, columnar and pile-grillage.

Types of foundation.

The calculation of the foundation of a frame house should take into account not only the selected material, but also the size of the construction work, the future load of the structure, the degree of swampiness of the soil, the groundwater level, wind differences and weather conditions for the area.

It is recommended to install a columnar foundation for low-rise construction of a small area, for example country houses. Pile-grillage - for multi-storey buildings and during construction on problem areas in terms of soils and temperatures. Calculating the cost of a frame house in this case will take into account the number and length of piles or pillars to increase the strength of the structure.

The cost of a strip foundation for a frame house will depend on the depth, the chosen reinforcement option and the material for the formwork. When installing formwork and pouring cement yourself, you can save up to 30% of the cost of the foundation. On average, depending on the size of the building, construction work to install the foundation will cost from 22,000 rubles.

Scheme for calculating a foundation on piles.

When calculating the construction of a frame house, it will be necessary to include the cost of a sand embankment for leveling the terrain, reinforcement and formwork - made independently or purchased as a ready-made house kit from the factory. Also included in the calculations for frame construction is the cost of concrete - purchased independently or ordered from a construction company along with concrete mixers and a team of builders.

On a note

The installed foundation must be dried for a sufficient period - from several weeks to a whole month. A strip or pile-grillage foundation is usually covered with film and left for the winter, but in the hot season, a few weeks are enough to dry.

What is a cubeturner and how to use it?

Kubaturnik is a standard table in which a number of data are entered that form a general impression of the material used. In addition, such knowledge is vital for those who are going to organize their own construction of a frame house. In order to accurately make calculations, you need to know the physical dimensions of the board, timber or slats

Calculation of lumber for a frame house is carried out for each type of cut separately, but the system is always the same, so it is important to know the basis

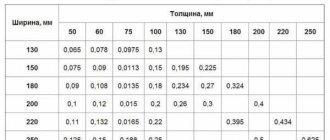

Board cubic meter table.

For example, we will take a board with dimensions of 25*175*5000 mm. This type of board is rare, which is why it was chosen. Dimensions are initially indicated in mm, but during calculations they are always transformed into m, i.e. 0.025*0.175*5 m.

The volume of 1 board is calculated by the formula V=abc, where a is length, b is width, c is height. Thus, V=0.025*0.175*5=0.021875 m³. This is the volume that will be used in further calculations. Typically, companies involved in the procurement of lumber do not provide such accurate data, because... 3 decimal places or 0.022 m³ are enough for the client, although they themselves make extremely accurate calculations.

From the above it follows that the volume of 1 m³ is V1=1/V or V1=1/0.021875=45.71428571428571 m³. In this case, reduction is not only possible, but also necessary, because The board will not be cut upon purchase, i.e. There are only 46 boards in 1 m³. When calculating several m³, you must always start from the basic dimensions of 1 copy or use the full result obtained, which is very inconvenient.

There are often cases when a person purchases lumber for a one-time job that requires knowledge of the area: lining, laminate, parquet, all kinds of exterior finishing materials for a frame house. To do this, first calculate the area of 1 board S=ab, or S=0.175*5=0.875 m³.

Timber cubic meter table.

Having this indicator, you can calculate the required number of boards for any room. For example, a room has an area of 25 m², therefore, 25 * 0.875 = 21.875 = 22 boards are required. In this case, the solution will be incorrect, because when filing, part of the width will go to waste, so you need to add 10%, rounding up 22+10%=25 pcs. This indicator can be used for calculations (most often in cubicles the amount of lumber per 10 m² is indicated).

The above is the data that is necessarily included in the cubeturner or is calculated by hand. Every self-respecting company tries to organize such a table for its materials, because... This greatly simplifies work activities not only for managers, but also for clients. The dimensions depend not only on the wishes of the production organizers, but also on the sawmill itself, because Chain sawmills create too many shavings, and in this case, the production of thin boards will be unprofitable. Whereas on a circular saw there are almost no chips, and this frees up your hands.

Additional aspects

Similar calculations are carried out not only with a 25*175*5000 mm board, but with all edged materials.

Calculating a frame house is not difficult, but it is very important to always remember about the error. It depends not only on the natural shrinkage of the tree, but also on the cutting style

Those. when cutting “Canadian bowl” the error is taken to be 5-7%, whereas when using the Russian analogue it is 10-12%. Another 1 dependence is the type of tree, because hard varieties are less susceptible to shrinkage, soft ones more.

Anyone can make detailed calculations of wood for a frame house. To do this, the main thing is to follow all the instructions correctly, and at the same time not be afraid of making mistakes, because it is impossible to make a serious mistake, and small shortcomings will only lead to a maximum delay of 1-2 days in construction and tiny additional financial injections.

Calculation of building walls

The main factor when calculating the walls of a frame house will be their area, number of floors, as well as the total load on the building. Multi-storey construction requires the installation of thick walls, ceilings and load-bearing structures.

On a note

Racks are the basis of a frame house; their construction requires not only boards, but timber.

The boards have several standards, height 50 or 100 mm, width - 100 or 200 mm. Calculation of a frame house based on the cost of boards for racks will depend on the degree of moisture content of the wood, the quality and type of the wood itself. The number of racks also depends on the chosen cladding and insulation option. The average cost of a technical board per 1 m3 is from 7000-8000 rubles.

We calculate the cost of the frame racks.

The height of the racks depends on the number of storeys of the building and the height of the ceilings, but in general it ranges from 2.5 m; in technical rooms - bathrooms and storage rooms - it can be about 2 m. Using a calculator to calculate a frame house, we set the pitch between the racks, which depends on the selected width insulation and mounted wall panels.

When building a frame house covered with OSB panels, the calculation of lumber will depend on the thickness:

- OSB-3 plate 6 mm 1250-2500 mm - from 500 rubles.

- OSB-3 plate 8 mm 1250-2500 mm - from 600 rubles.

- OSB-3 plate 12 mm 1250-2500 mm - from 800 rubles.

For independent installation of racks and panels, you will need additional devices and equipment, which must be taken into account when calculating the materials of a frame house using a construction calculator - special screws, galvanized angles, drills and hacksaws for wood, nails, a hammer. Despite such costs, self-installation of walls will reduce online calculations for the construction of a frame house by a third.

Insulation

Insulation is the type of work that any developer can do independently.

Types of insulation

Insulation sheets, slabs, rolls, soft and hard - any of them are laid between the supporting posts of walls, floor joists, floor beams, roof rafters. The thickness of the insulation corresponds to the width of the lumber of the posts and joists, usually 15 cm, which is sufficient for average Russian conditions.

Inexpensive insulation is the basis of calculations

The most budget-friendly insulation options include glass wool. Basalt or stone wool is a little more expensive. In total, for a house 6 X 6 m you will need about 30 m3 of mineral wool, which in monetary terms will be 60,000 rubles.

There are many insulation options, some of them can be combined:

- For example, for attic insulation you can use expanded clay in bulk form or blow out the ceiling with ecowool;

- It is better to use insulation boards of smaller thickness, but with a large number of layers;

- Warm electric or water floors can be installed in the floors of the first floor, and this is a different approach to insulation, and not always much more expensive.

- The cost of waterproofing and vapor barrier will be approximately 3,500 rubles.

- You can take the cost of insulation with insulation as the basis for calculation: 63,500 rubles.

We calculate the cost of insulation

Installation of insulation is required already during the process of laying the floor, then during the installation of walls, ceilings and roofs. In the case of multi-storey construction, it is necessary to lay additional insulation of inter-storey floors.

Table with insulation calculations.

Online calculation of a frame house will vary, from low prices for polystyrene foam to impressive amounts for ecowool. If you are aiming for long-term living, then you should not skimp on its insulation.

Pay attention to the treatment against rodents and pests, and the environmental friendliness of the insulation material. In the middle price category there is mineral wool or glass wool, which is often used to insulate frame houses. Loose insulation materials are recommended for insulating roofs or flat roofs.

Insulation procedure

- Estimate and installation of the selected vapor barrier material to protect the insulation from damage and getting wet;

- Installation of intermediate sheets of plywood for internal cladding;

- The thickness of the insulation, which will depend on the thickness of the racks, is on average chosen from 100 to 250 mm;

- When choosing insulation - stone or mineral wool, take into account the wind and waterproof film and its installation in the calculation of the frame house;

- Take care of the ventilation gap to prevent moisture from accumulating inside the walls.

Insulation in the frame.

After sufficient insulation of the house, interior wall cladding and finishing are carried out.

Calculator device

The timber house calculator is always available online. Its interface is designed in such a way as to be understandable even to a person without special construction education.

Some calculators allow you to immediately calculate the final cost of materials, for which there is a separate column in the data entry fields - price per cubic meter. Find out how much a cube of timber costs in your region, enter the number in the required field and all you have to do is press the calculation button - the result will be instantly displayed on the screen of your device.

Timber calculator for tablet - allows you to calculate the cost of materialsSource apkpure.com

The timber house construction calculator can be used to accurately determine the required amount of adjacent lumber when building a house.

You can calculate:

- Brusa;

- Inter-crown insulation;

- Dowels and lumber;

- Crowns and the amount of insulation between them.

The program allows you to calculate not only the number of structural elements, but also the full volume of required consumables.

Calculation of the required amount of timber per house

We must remember that any online log house calculator operates on the basis of a specific algorithm and usually produces only approximate results. To be confident in the operation of the online service, it will be useful to know how to calculate the amount of timber per house yourself.

The entire calculation procedure can be divided into the following list of stages:

Knowing the purpose of the future building, it is necessary to select a beam of the appropriate section. Next, you should write down the dimensions of the house (length, width, height, number of floors and partitions, number of rafters and beams, roof area);

For calculations, a drawing in basic projections is quite suitable. Source tirazisdm.ir

The formula determines the total required cubic capacity of the material and the perimeter based on the future dimensions of the housing:

M = S*L*2+S1 (m)

where M – perimeter, S – length, L – width, S1 – number of partitions;

Next, calculate the total area of the building:

N = M*L (m)

where N is the total area, M is the length of the perimeter, L is the height of the building;

The result obtained must be multiplied by the length of the beam and the required total amount of material will be obtained.

For example, how many cubes of timber are needed for a house 8x8x2.9 with one ceiling - calculation example:

M = 8x8x2+1 = 129 (m);

N = 129×2.9 = 374.1 (m);

374.1×0.15 = 56.115 (cubic meters)

where 0.15 is the length of one side of the beam.

It is not difficult to calculate timber for a house using an online calculator. It should be taken into account that the final amount of material will be slightly larger due to the fact that windows and doors will be cut down in the future log house, but these costs are often covered by scraps that inevitably appear during any construction.

Calculation of the cost of a frame house

The roof is the second element on which you should not skimp when calculating a frame house with your own hands. Only in this way can it reliably prevent the building from leaking.

On a note

The cost of the roof will depend on its shape - single-pitch, gable or complex. It is also worth considering insulation of the roof and residential attic.

Roofing materials.

Materials for roof installation

- Board for rafters with a section of 150*50 mm;

- Boards for installing sheathing - purchased based on the parameters of the future roof;

- Materials for installing fasteners - corners, nails, screws;

- Polystyrene foam or stone wool for insulation;

- Materials for steam and waterproofing;

- Foam for processing joints;

- Flooring - roofing felt, slate, tiles or other material for final finishing.

Roof

When calculating the roof structure, it is necessary to take into account not only its total weight, as well as the loads exerted on the attic floors and beams, but also the weight and properties of the roofing material.

It is also worth paying attention to the roof structure, during the construction of which it is necessary to take into account the wind rose prevailing at the construction site. The side from which the wind blows more often will experience the greatest load. The material required for construction is selected based on this criterion.

If you do not take into account the wind rose, then the roof on one side of the building may begin to leak, become leaky, and the roofing material without the required fasteners and reinforcement may be damaged by strong wind gusts, not to mention a hurricane or other natural disasters.

When building a roof for a frame structure, you need to consider the following nuances:

- You should not build high or sharp roofs in areas where strong winds prevail. Or you will need to significantly strengthen the structure, which will undoubtedly affect the final cost of construction;

- When installing the sheathing, you can reduce the distance between the posts, which will strengthen the structure;

- To construct rafters, you should use only strong timber with a large cross-section, which will make it possible to increase the strength of the roof;

- You should give preference to a more rigid roofing material, for example, use slate instead of metal tiles or corrugated sheets;

- In areas where strong winds blow, it is better to use a rigid roofing material such as slate.

Windows and doors in a building

You can use a program to calculate a frame house, where the parameters of windows and doors will be specified. The calculation will depend not only on the selected material, but also on the number of chambers in the double-glazed windows.

Counting windows and doors.

Double-glazed windows made of plastic cost an average of 4,000-5,000 rubles, the cost depends on the number of cameras, sashes and size, and the price of door windows will be 15-20% more. Doors - metal or plastic - will cost from 5-6 thousand, also depending on the thickness of the material, locking system, handles.

Frame

The main thing in calculating the cost of a frame is an accurate calculation of lumber. One of the important components of this cost is the transportation of the material. A shortage of two or three boards can result in large additional costs for the delivery of long lumber.

The most popular board size

The most common type of board is 50 X 150 mm; they are used for strapping, such as floor joists, vertical posts, and crowns. A total of 6 meter boards of this section will need 70 pieces to construct the frame. (for a house 6 X 6 m, one-story). The average cost of one board is 300 rubles, a total of 21,000 rubles.

Preparing the finish

When calculating the material for a frame house using the calculator, you need to include external and internal finishing. The desired amount of costs for a frame house will depend on your taste. The outside of the building can be finished with either cheap siding or wood and stone panels, inside from suspended ceilings and expensive plaster, to wood trim and painting.

If there are difficulties when calculating a frame house project, you can turn to specialists for help or purchase a ready-made kit from the factory.

Video description

For an example of calculating the amount of timber for a house, see the video:

How much timber is needed for the roof?

When calculating the amount of timber for the roof, you need to understand the principle of its installation - in fact, these are just beams laid in 60 cm increments. That is, knowing the length of the wall on which the roof will rest, and dividing it by 0.6, we get the required number of beams .

The length of the beam depends on the configuration of the roof slopes and is calculated as the larger side of the triangle, plus about 0.4-0.5 m for the overhang.

Calculation of the length of roof slopesSource berserkheroes.ru

Most often, timber with a cross section of 100×150 mm is used for roofing.

To get a complete picture of the cost of a roof, these calculations will also be useful:

Online roofing calculator

To find out the approximate cost of various types of roofing, use the following calculator:

Calculation of the amount of timber for the floor and ceiling

The same principle is used here as for the roof, but the calculations will be simpler since all the beams lie horizontally. Knowing the step at which the logs are planned to be laid (usually the same 60 cm), we divide the length of the house by 0.6 and get the number of beams.

Similar actions are carried out to calculate ceiling beams, and by adding these two numbers, you can calculate their total linear length.

The volume in cubic meters can be obtained by multiplying the linear length of the structural beams by the cross-sectional area of the purchased timber.

Online construction calculators are quite popular services that can be used on any electronic device from which you can access the Internet. But we must remember that online counting tables that allow you to calculate the amount of timber per house are not a panacea, and they were created only so that an inexperienced person, knowing the size of the house, can roughly imagine the quantity and cost of the necessary building materials.

Criteria for calculating the pitch of racks

Looking ahead a little, we can say that the standard spacing of frame house posts is a distance of 600 mm

It is important that it is measured not between the edges of the beam, but between its centers. That is, with a rack thickness of 40 mm, the actual distance between them will no longer be 600 mm, but 580 mm (we fold back 20 mm on each side)

Now let's look at where these numbers come from and why they are used in the construction of almost all frame houses.

And they were taken from calculations made on the basis of the following criteria:

- Mass of the house.

- Insulation dimensions.

- Dimensions of the outer skin.

- Dimensions of the internal lining.

Let's briefly consider each of these points in order to understand how the pitch of the racks is calculated when designing any frame house.

Peculiarities

Frame construction involves the use of wood frames and various types of insulation. Designs of this type are simple. Relatively few materials are used in the construction of such buildings. Installation work begins with the calculation of all parameters and the drawing up of a detailed house plan. Designing frame houses involves several successive stages.

- Planning the dimensions of the building. It is important to immediately decide what size the frame house will have. Technically, such structures are limited only in height. All other characteristics can be adapted to the personal needs of an individual or family.

- Design of individual rooms. At this stage, owners optimize the parameters of the premises for themselves. Here you select their location, size, shape, location of windows and more.

- Selection of building materials. It should be understood that a frame house is not only wood. During its construction, various substances can be used that are needed for finishing walls, forming a roof, and insulating it.

- Calculation of the quantity of materials. This step depends on all other procedures, as they are closely related.

Calculation of building materials for a frame house cannot be carried out perfectly accurately. There is always a small margin of error that needs to be taken into account. It depends on the following characteristics:

- low quality materials. Wood and other products may differ in quality, which does not always allow them to be used to their full potential;

- multiplicity of products. Many products are produced with standard dimensions, so it is not always possible to accurately calculate the required quantity;

- installation errors. Working with any material involves using a tool with which it is impossible to obtain ideal measurements or form the structure correctly.

Metal or plastic shed

Recently, ready-made frame structures made of plastic or metal have become very popular in arranging outbuildings on sites. Their purchase will cost more than organizing a wooden shed on your own, but they are assembled in a short time and are resistant to weather influences. Metal structures, of course, are much heavier than plastic ones. The elements are packaged in boxes and are easy to organize with your own hands according to the instructions. What makes many people prefer them is that to use them they do not need to devote several weeks to preparing the foundation or treating the elements with an antiseptic or varnish. The only important maintenance measure is periodic washing.

Adviсe

Frame construction is very popular today. Using this technology, you can get a residential building in a few months or even weeks. It all depends on the structural features of the house.

When performing calculations of such structures, you should adhere to the following simple tips:

- The procedure can be simplified if special sandwich panels are used as wall materials. They are produced in the form of original slabs, which directly include a wooden frame and insulation;

- if the number of piles for the foundation is being calculated, it is important to take into account not only the weight of the future building, but also the structure of the soil. The durability and reliability of the entire structure depends on this;

- The type of foundation should be selected depending on the type of soil. The best option for frame houses are pile or strip foundations. But technically, other types of foundations can be used as supports;

Selection of lumber

The choice was limited to a meager supply of dry, but not sawn, or sawn, but damp wood. After deliberation and calculations, pine boards 50x150 were chosen for tightening the rafters, forcing walls and gables, 50x200 for laying floors and rafters, 25x150 for jibs and sheathing.

A careful examination showed the presence of knots, unevenness in thickness and width, so one had to be careful when choosing boards for constructing the frame: defects in the wood could lead to a decrease in the reliability of the structure. To calculate the strength of the structure and design of openings, the book Advanced Wall Framing was used.

What does it depend on?

Designing “frameworks” is a complex process that requires significant experience in the construction of such structures. To obtain the quality characteristics of the future building, it is important to first calculate all its technical parameters. This process depends on several basic criteria.

- Temperature conditions. Frame houses are built from several individual components that are responsible for the strength and level of thermal insulation. If the building is planned to be used in harsh winters, then the thickness of the walls must be increased accordingly or better materials must be used. All thermal insulation coefficients of such buildings can be found in special tables. This step is initial and involves a thorough analysis of the annual temperature over several years.

- Type of materials. The construction of dome or classic frame structures can be carried out using various products. There are many alternative materials that can easily replace each other. This dependence is very closely related to the previous point.

- Type of building. A frame house (“frame house”) can have either a standard or complex shape. Calculating a simple building is somewhat easier, since you do not need to take into account many characteristics. This also includes the number and size of openings that will be used to form windows and doors. Roofing parameters also play a significant role in the calculations of frame houses. Such elements can have different shapes and designs.

Facade

The decision to use imitation larch timber as cladding for a 6x6 frame house was made due to environmental friendliness, relatively low cost and the ability to change color. A ventilation gap should be provided under such cladding and a sheathing with protection from insects and mice made of mounting mesh should be installed. Galvanized nails of 50 mm were chosen as fasteners.

Tikkurila products were chosen for the finishing because the primer and paint preserve the wood structure and have significant durability. A total of 10 man-days were spent on cladding and painting.

metal mesh against rodents

lathing for imitation timber

installation of imitation timber from scaffolding

imitation timber

coat the joints

window bypass

sheathing completed

facade painting

final view of the 6 by 6 house