how to calculate the volume of one beam or board?

Wood is one of the best materials used for the construction of country houses, dachas and cottages. With the modern development of technology, the durability and strength of wood is not inferior to other building materials, and in terms of comfort, wooden buildings are not comparable to brick or concrete.

Calculation of the weight of a cubic meter of wood.

When determining the necessary need for lumber for a particular building, it is often necessary to calculate how many pieces are contained in one cubic meter. Prices for lumber are most often indicated per 1 cubic meter, and the volume in construction estimates is also indicated in cubic meters.

How many timber and boards are in one cubic meter?

In Russian expanses rich in forests, log houses are installed by experienced craftsmen, for whom there is no need to calculate the exact amount of timber or boards. But a city dweller has to go to the construction market for materials, and in order not to overpay, it is better to know in advance how many pieces of the assortment are in one cubic meter.

The number of edged boards in 1 cubic meter.

The usual name for the unit of measurement “cube” means nothing more than one cubic m of volume. It is not difficult to find out the individual cubic capacity of any type of wood, since they are a parallelepiped; it is calculated by multiplying all its sides. It doesn’t matter whether the board has grooves or without them or what the shape of the lining is - the characteristics specified by the supplier are sufficient. Example: a beam with a cross-section of 100x150 mm and a length of 6 m has a volume that can be calculated using the formula:

V = axbxl= 0.1 x 0.15 x 6 = 0.09 m³.

To determine how much timber is in a cube, you need to divide the unit by the resulting volume of one timber:

1: 0.09 = 11.11 pcs.

If you calculate the length of identical beams for the project, then divide this quantity by 6 (the standard for manufactured lumber), and then get the quotient of the total length and the number of beams in 1 cube, then the total number of cubes for the selected structure will be known. Knowing this algorithm, you can always count the number of lumber, regardless of their shape, be it floorboards, slats, beams or logs.

If you buy rough plank or other unclean material, you can use the calculation standards offered by the seller.

Return to contents

Determining the number of logs in one cube

A log house is the most interesting and reliable option. Nature has endowed natural wood with excellent properties.

To determine the number of logs in one cubic meter, you need, as in calculating timber and boards, to first determine the volume of one log.

Here it is necessary to distinguish between two types of lumber of this type:

- rounded log;

- hand-cut log.

Scheme for calculating the cubic capacity of a log.

In the first case, the dimensions are more accurate than in the second, but still some prefer to build log houses from hand-processed logs.

Occupied log volume:

V = 3.14 x r² xl, here:

3.14 - number “pi”, constant value;

r is the radius of the log section;

l is the total length.

Thus, the volume of a unit of rounded material with a diameter of 200 mm and a length of 6 m will be equal to:

V - 3.14 x 0.1² x 6 = 0.1884 m³.

We find out the number of pieces of this lumber in one cubic meter by dividing the unit by the result obtained:

1: 0.1884 = 5.3 pieces.

Calculating the cubic capacity of logs is similar to calculations with a tree of rectangular cross-section. When calculating hand-cut products, take the average diameter size in the batch.

When performing engineering and economic calculations on your own, you need to be guided by drawings with the most accurate parameters of all elements and you need to take into account that waste is inevitable during construction, therefore, when determining the consumption, you need to set aside a percentage for them. In wooden housing construction, this figure can reach up to 20%. In order not to make mistakes in the calculations, you need to calculate as accurately as possible the amount of timber or other wood in one cube.

masterbrusa.ru

What affects the weight of the board?

The main factor influencing the weight of lumber is its moisture content and density.

Dry wood has a lighter weight, the difference can be up to 40% compared to the weight of wood with natural moisture.

Depending on humidity, the following types of wood are distinguished:

- Fresh (freshly cut) – has indicators over 71%

- Wet – from 46 to 70%

- Raw – 25-45%

- Air-dry – 19-23%

- Dry – 10-18%

As a rule, density also depends on humidity, but it may be less if the wood has internal defects or is damaged by a pest. Then voids can form inside, ultimately affecting the weight.

How many boards are in a cube | FOREST MERCHANT'S YARD

| Lumber | Size | Volume of 1 piece | Pieces per 1 m³ | m² to 1 m³ |

| Edged board | 20×100×6000 | 0.012 m³ | 83 pcs. | 50 m² |

| Edged board | 20×120×6000 | 0.0144 m³ | 69 pcs. | 50 m² |

| Edged board | 20×150×6000 | 0.018 m³ | 55 pcs. | 50 m² |

| Edged board | 20×180×6000 | 0.0216 m³ | 46 pcs. | 50 m² |

| Edged board | 20×200×6000 | 0.024 m³ | 41 pcs. | 50 m² |

| Edged board | 20×250×6000 | 0.03 m³ | 33 pcs. | 50 m² |

| Edged board | 25×100×6000 | 0.015 m³ | 67 pcs. | 40 m² |

| Edged board | 25×120×6000 | 0.018 m³ | 55 pcs. | 40 m² |

| Edged board | 25×150×6000 | 0.0225 m³ | 44 pcs. | 40 m² |

| Edged board | 25×180×6000 | 0.027 m³ | 37 pcs. | 40 m² |

| Edged board | 25×200×6000 | 0.03 m³ | 33 pcs. | 40 m² |

| Edged board | 25×250×6000 | 0.0375 m³ | 26 pcs. | 40 m² |

| Edged board | 30×100×6000 | 0.018 m³ | 55 pcs. | 33 m² |

| Edged board | 30×120×6000 | 0.0216 m³ | 46 pcs. | 33 m² |

| Edged board | 30×150×6000 | 0.027 m³ | 37 pcs. | 33 m² |

| Edged board | 30×180×6000 | 0.0324 m³ | 30 pcs. | 33 m² |

| Edged board | 30×200×6000 | 0.036 m³ | 27 pcs. | 33 m² |

| Edged board | 30×250×6000 | 0.045 m³ | 22 pcs. | 33 m² |

| Edged board | 32×100×6000 | 0.0192 m³ | 52 pcs. | 31 m² |

| Edged board | 32×120×6000 | 0.023 m³ | 43 pcs. | 31 m² |

| Edged board | 32×150×6000 | 0.0288 m³ | 34 pcs. | 31 m² |

| Edged board | 32×180×6000 | 0.0346 m³ | 28 pcs. | 31 m² |

| Edged board | 32×200×6000 | 0.0384 m³ | 26 pcs. | 31 m² |

| Edged board | 32×250×6000 | 0.048 m³ | 20 pcs. | 31 m² |

| Edged board | 40×100×6000 | 0.024 m³ | 41 pcs. | 25 m² |

| Edged board | 40×120×6000 | 0.0288 m³ | 34 pcs. | 25 m² |

| Edged board | 40×150×6000 | 0.036 m³ | 27 pcs. | 25 m² |

| Edged board | 40×180×6000 | 0.0432 m³ | 23 pcs. | 25 m² |

| Edged board | 40×200×6000 | 0.048 m³ | 20 pcs. | 25 m² |

| Edged board | 40×250×6000 | 0.06 m³ | 16 pcs. | 25 m² |

| Edged board | 50×100×6000 | 0.03 m³ | 33 pcs. | 20 m² |

| Edged board | 50×120×6000 | 0.036 m³ | 27 pcs. | 20 m² |

| Edged board | 50×150×6000 | 0.045 m³ | 22 pcs. | 20 m² |

| Edged board | 50×180×6000 | 0.054 m³ | 18 pcs. | 20 m² |

| Edged board | 50×200×6000 | 0.06 m³ | 16 pcs. | 20 m² |

| Edged board | 50×250×6000 | 0.075 m³ | 13 pcs. | 20 m² |

brus-profil.ru

The amount of wood in a cube. Calculation of lumber in one cube

When building a frame house, the main material is wooden beams. It is needed not only to create the frame of the house, but also for the construction of the roof, when installing the crowns of the log house, arranging internal partitions and other structures of the house. Due to the wide range of uses of wood, this building material has dozens and hundreds of positions regulating the size of the product. Knowing the exact dimensions of one unit, you can, without going into complex calculations, use simple formulas to calculate how many pieces of 6-meter timber fit in 1 m3 - to draw up estimates and optimize logistics operations for the delivery and storage of lumber at the construction site.

Features of calculations of lumber in different units

The volume of any rectangular physical object is the result of multiplying the length, width and height of the rectangle, in our case a wooden beam. Volume V = a x b x c, where the designations are: a - length, b - width, and c - height of the beam. For example, a product 6 meters long, 10 cm wide and 10 cm high will have a volume of 0.06 m3. But this is an ideal mathematical formula, and in practice, products in the same batch can have different sizes, which is allowed by the standards, but complicates the calculation of the volume of lumber .

Edged or profiled timber costs much more than regular timber, so the accuracy of the calculations is crucial - you will have to pay out of your wallet. The traditional measurement system when purchasing lumber is a cubic meter, but for timber for rafters, wall frames, floor beams and wood for flooring, it is more convenient to use linear meters. Also, the peculiarities of production in the woodworking industry allow for some variation in dimensions, in particular in length, which can vary between 3-6 meters in increments of 50 cm.

Different units of measurement and different approaches when calculating the required amount of timber can generate errors and inaccuracies, as well as cause a general misunderstanding of the situation - how to convert given units into others.

- For example, a product with a cross-section of 100 x 50 mm is required, and the total length of the batch is known - 100 l/m (linear meters). To find out the volume of a beam, you need to calculate the cross-sectional area of one unit, and to do this, convert mm to m2, then multiply the cross-sectional area “SS” and length “a”: 0.1 x 0.05 x 100 = 0.50 m3 . It is easier to calculate the cost of a batch - you need to multiply the volume of the batch by the price per 1 m 3.

- Or how to find out how many units of timber will be obtained in a certain volume of lumber? To do this, you need to know both the cross-section and the length of one unit. For example, there is data on the total length of the batch - 100 p/m, and a product with a length of 4 m is required, then how many pieces will there be in this batch? First, the volume of one product is calculated: 0.1 x 0.05 x 4 = 0.02 m3. When purchasing 0.5 m 3 of timber, 25 units are obtained, or 50 pieces per 1 m 3.

In individual construction, every ruble counts, so ordering, for example, 4 m 3 of edged or profiled timber, if you need 3.8 m 3, is uneconomical.

Example: when purchasing 52 lumber with a cross section of 100 x 180 mm and a length of 6 meters, the total volume of the timber will be equal to: 52 x 0.1 x 0.18 = 0.936 m 3. You can find out the number of pieces in this volume like this: divide the total volume by the volume of one unit. Let's find out the volume of one product: 0.1 x 0.18 x 6 m/p = 0.108 m3. Last calculation: 0.936 / 0.108 = 8.666 units. Since no one will cut lumber in the store, it is easier to pay this small difference for one unit than to buy the entire lot with the difference in price multiplied by the number of pieces in the lot.

Profiled timber, although of a more complex shape, is calculated using the same formulas. That is, to calculate the cross-sectional area of a profiled product, the height “c” must be multiplied by the width “b”. The height of the profiled beam is determined as the distance from the bottom surface, which has a groove, to the top point of the tenon.

When calculating to

buildingdraft.ru

Dimensions of eurolining

Manufactured according to Western European standard DIN 68126/86. The key difference from the domestic standard version discussed above is the presence of longitudinal ventilation grooves (see photo below this paragraph) on the reverse side, which work as stress compensators arising from changes in temperature and humidity, and also facilitate the removal of condensate due to air circulation.

Dimensions according to European standards: Thickness – 12.5-14-16-19-21 mm; Width – 80-100-110-120-138 mm; The thickness of the lining is calm for internal use - 12.5–16 mm, for external use - 18.5–22.5 mm. Length gradation at the discretion of the manufacturer. Packaged in packs of 10 pcs.

not in theory but in practice

- Tabular method of forest measurement

The methodology for calculating the volume of a round log, board or beam is simple and comes down to a 5th-6th grade mathematical problem. But in reality, everything is much more complicated: logs are conical, boards are often measured in inches, timber has chamfers, and there are other subtleties and differences between real wood products. That is why tables are so convenient, which summarize the data on the cubic capacity of the forest, taking into account such shape errors as the taper of the logs, the presence of bark, run-off, the complexity of the shape of the slab and plate and other nuances.

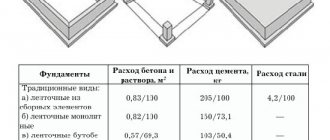

Figure 1. Table for calculating the cubic capacity of edged lumber.