Chiseling tools

For chiselling, chisels and chisels (flat and semicircular) are used.

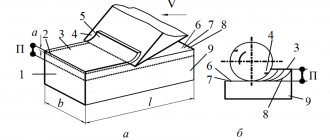

A carpenter's chisel consists of a steel blade, a handle, a ring and a cap (Fig. 1, a). The chisel handle is made of hardwood or impact-resistant plastic. Chisels are manufactured in lengths of 315, 335 and 350 mm with blade widths of 6...20 mm. The sharpening angle of the chisel chamfer is 25...30°, and the sharpening angle of the side edges is 10°. Flat chisels are used to select small nests, clean quarters, grooves, tenons, lugs, chamfer and adjust joints of wooden parts (Fig. 1, b).

Fig 1 - Standard sizes of the hammer and chisel

When processing rounded surfaces of workpieces and sockets, semicircular chisels are used. The length of the chisels is 240, 250 and 265 mm; width of flat chisels - 4...50 mm, semicircular - 4...40 mm; sharpening angle - 25...30°.

Device characteristics

A chisel is a tool that is used to gouge out grooves and sockets in materials of different densities. The device helps to make non-standard holes of the desired diameter and shape. The device is suitable for rough work with impact actions.

Appearance

The design of the tool depends on the tasks it will perform. Despite the apparent differences, structures of different types have common features. The equipment consists of working and additional parts. If the first part is present in all models, then the second has 2 varieties. In hand tools, a handle is used, in mechanisms, a shank is installed in a chuck.

The working part of the chisel is made in the form of a peak, blade or bowl with sharp edges. In drilling models, a special head of complex design comes into contact with the rock. The shape of the smooth handle should fit comfortably in the palms. To prevent the part from breaking when struck with a hammer or mallet, a retaining ring is installed on top along the perimeter.

Chiseling tools Source wikipedia.org

Shanks are used for automatic tools. The tip is inserted into the device socket, after which work begins. The structure and size of the parts depends on the device to which they are connected. Types for light rotary hammers are similar in parameters to a traditional chisel. Heavy jackhammers and drills use massive elements.

Materials

The working parts of the tool are made of steel. The grade of metal alloy depends on the tasks that the device will perform. For industrial operation (drilling), calibrated and hot-rolled steel is used. Strong parts are obtained from pobedite or nickel-tin options.

Metal alloy tools Source i0.wp.com

For manual models, carbon tool types are appropriate. Steel has high hardness, so the equipment holds an edge for a long time. The chisel handle is made from strong wood, less often from composites. The ring (head) on the handle is often made of bronze.

Size and weight

Characteristics depend on the type of device. The diameter of the drilling equipment varies from 75 to 650 mm, while the weight reaches 700 kg. The length of the handle for manual structures is 12-14 cm, the working part is 11-18 cm. For carpentry models, the blade width is 6, thickness is 25 mm, for carpentry models it is 4 and 8 mm.

How to distinguish from a chisel

Visually, both tools are very similar, but have different operating principles. Gouging with a chisel is carried out by pressing the hands, the chisel is set in motion by hitting a hammer (mallet). The first device is more elegant and thin in size, the second has a thick blade and a crimp (head) ring on the handle.

Differences between different tools Source e-pard.com

Wood chiselling techniques

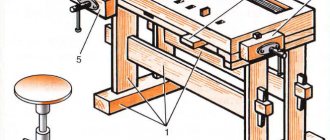

To obtain a through socket, first mark it on two opposite sides of the workpiece, and a non-through socket on one side. When performing through chiselling, place a board under the workpiece so as not to damage the workbench cover. Chiseling techniques are shown in Fig. 4. The chisel is selected according to the width of the marked socket, placed vertically near the nearest marking line (with a chamfer inward), retreating from the line at a distance of 1 ... 2 mm, after which the first blow is applied to the chisel with a mallet, and then the second blow is applied to the chisel inclined inside the socket. and cut off the first chip. Next, repeat the same thing and hollow out approximately 2/3 of the length of the nest. Then the chiseling process is continued at the opposite marking line. Then the workpiece is turned over and chiseling is performed on the opposite side in the same sequence. It is undesirable to cut off thick chips when chiselling, since as a result

Fig 2 - Chiselling while sitting Fig 3 - Chiselling while sitting Fig 4 - Sequence of chiselling a through hole; 1- blank; 2- lining; 3- workbench cover; 4- chisel

This deteriorates the quality of the workpiece.

Making a slotting machine with your own hands

To make a homemade slotting machine with your own hands, at a minimum, you need a drawing of it. Any such equipment is, in fact, a vertical planing machine with a manual drive. All structural elements of such a machine are placed on a massive base (350x350x20 mm), which is also its work table.

On the base of such a homemade machine, a stand made of a steel rod with a diameter of 40 mm and a height of 450–500 mm is fixed. A longitudinal groove is cut along the entire height of the rack, and at one of its ends there is a groove, which is necessary for connecting it to the flange. Such a flange, which is a massive washer with one central hole and three fastening holes located around its circumference, is necessary to ensure reliable fastening of the rack to the base. The stand is inserted into the flange with its machined end and securely fixed in it using a welded connection, and the flange itself is attached to the base of the machine using a threaded connection.

Chisel cutting techniques

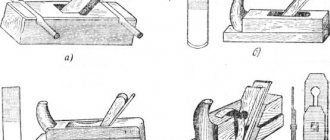

Fig. 5 - Cutting techniques with a chisel

a - cleaning the cutting areas; b - transverse trimming; c - trimming along the sides; d — removal of a fractional chamfer; d - chamfering from the end; c - cleaning the end

When trimming and cleaning surfaces, the chisel is held with the palm of the right hand around the end of the handle, and the palm of the left hand is grasped around the blade of the chisel. With your right hand you press the end of the handle, causing the chisel to cut into the wood and move forward. Use your left hand to adjust the thickness of the chips removed and the direction of cutting. At the same time, to make cutting easier, the cutting edge of the chisel is placed at an acute angle to the wood fibers. Cutting techniques with a chisel are shown in Fig. 5.

Sharpening auger drill and chisel

Slotting auger drills, just like regular auger drills for hand rotating, are sharpened with a small file or needle file. The four cutting edges of a square chisel are sharpened simultaneously using a special tool, similar to a countersink, but with a central guide tip that keeps the tool centered on the chisel. The chisel is sharpened by rotating this sharpening attachment mounted in the rotary chuck. Each chisel requires a corresponding sharpening tool.

Safety

Careless handling of chisels and chisels and failure to follow safety regulations can cause serious injuries. When working with a chisel and chisel, it is forbidden to cut towards yourself, in the air, with the part resting on your chest, or with the part on your knees. When cutting with a chisel, the fingers of your left hand should always be behind the blade. Before starting work, you need to make sure that the chisels and chisels are well and correctly sharpened. A chisel or chisel can be passed next to someone working only with the handle, and not with the blade forward. The wooden handles of chisels and chisels should not have chips, cracks, sharp corners and other defects that could lead to injury to the skin of the worker’s hands. To make it easier to hollow out a nest in the workpiece, you need to moisten the selected area by placing a rag moistened with hot water on it. After the top layer gets wet, it can be easily removed with a chisel. Then the soaking is repeated and hollowed out until the nest reaches the desired size.

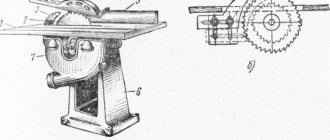

Working principle of a slotting machine

Processing of metal parts on a slotting machine is carried out due to the reciprocating movement performed in a vertical plane by a slider and a cutter fixed in it. The working feed of the workpiece is carried out due to the movement of the table on which it is fixed.

The slotting machine can operate in two main modes: simple and complex. In the simple mode, a metal workpiece is processed point-blank, and the cutter, moving to the required distances, creates a series of holes that do not differ in shape and size. The complex mode involves processing angled holes and hard-to-reach surfaces located in the inside of workpieces. Such operations can only be performed using professional equipment. A machine made by yourself is not suitable for them.

Do-it-yourself slotting machines are optimally suited for equipping small industries and private workshops, where they can be used to process workpieces made of non-ferrous and ferrous metals. Large-scale production requires professional equipment, often equipped with computer numerical control (CNC).

Slotting cutters for corresponding machines:

Milling attachment

The milling attachment includes a horizontally mounted milling head to perform the same operations. This device uses the drive of another machine - in particular, a planer or universal machine - and is installed in a chuck at the end of the knife block. The chuck, similar to the chuck of an electric drill, can accept heads with a diameter of 6 - 16 mm with two cutting edges, one of which is sometimes serrated. The slotting table, on which the workpiece is fixed, is mounted next to the chuck.

The table moves sideways relative to the stationary chuck, as well as forward and backward to set the chiselling depth. The table can also be adjusted in height, and the adjustable height limiters set the limits of its movement. This way the length and depth of the groove are adjusted. The movement of the table to the sides, as well as to the front and back, is controlled by the corresponding levers.

Definition

A chisel is a joiner's or carpenter's tool that is designed for gouging out grooves, nests and other work. This tool has the appearance of an elongated metal bar with a sharply sharpened working end, which is fixed in the handle. At the end of the handle of the chisel there is a crimp ring that protects it from the possibility of splitting from hammer blows. Instead of a shank, carpentry chisels are equipped with a conical tube into which the handle is inserted, as well as a massive blade that slightly tapers to a sharp end. Carpenter's chisels are thicker than carpenter's chisels.

Basic machine models

The most popular and widespread model of a metal slotting machine is the “GD”, which is represented by the 200 and 500 series. A more modern and functional slotting machine is the S315TGI model, which is also very popular among domestic manufacturers. Such a machine, in contrast to simpler models and devices made by hand, allows you to effectively perform a large list of technological operations on metal.

When choosing serial slotting machines, you cannot simply rely on promotional videos; you should take into account a number of important parameters. One of the most important characteristics is the maximum height of the workpiece that can be processed on the machine. Significant parameters of such a machine for metal are also: power, dimensions of the tool and the ability to adjust it, the presence of longitudinal and transverse stroke, permissible angle of inclination and speed parameters of the cutter. When choosing such a machine, you should also pay attention to its dimensions and weight, which affect its stability and ease of maintenance, and whether it is equipped with additional devices that significantly increase the functionality of the device.

Tools for taking measurements and markings

Carpentry work cannot be carried out efficiently without careful markings and appropriate measurements. For measurements, the following basic carpentry tool is used: a square (in the form of perpendicular strips, with a ruler scale on one) - to check perpendicularity; center finder (isosceles triangle); erunok (control of angles 45° and 135°); malka (planks fastened with a hinge) with the installation of any desired angle; carpenter's meter; ruler; calipers; level or spirit level for checking horizontal or vertical surfaces; plumb line; roulette.

The following are used: carpenter's compass with the ability to draw a circle up to 3.5 m; thicknesser - for drawing forming straight lines parallel to the main line and transferring dimensions from the drawing to the part (the thicknesser has the form of a bar with strips equipped with teeth); comb - for forming spikes and corner joints; retraction - drawing lines to ensure good articulation of elements.