Defects in the floor must be eliminated before proceeding with finishing and painting. In this publication, we will look at the most alternative and inexpensive repair options, and also discuss more radical methods than sealing cracks in a wooden floor before painting. Each of you will be able to choose the most rational approach for your individual case.

Gaps in a wooden floor between the boards Source phonoteka.org

Inexpensive methods to help remove gaps between boards

Often, before carrying out repairs, owners discover unwanted defects in the form of gaps between the boards. This usually happens at the most inopportune moment, when funds in the budget are severely limited and there is nothing to allocate for major repairs. In this section we offer several low-cost and very effective options for eliminating defects.

Large gaps between boards are best sealed with products with good viscosity Source phonoteka.org

Installation of rack wedges

You can always turn slats yourself from leftover timber or fresher boards that you have on the farm. They need to be planed so as to obtain a wedge-shaped shape, and the width of the slats should be 0.5 mm larger than the size of the gap between the boards.

Before placing the wooden piece, the gap is thoroughly cleaned, and dust and debris are removed using a vacuum cleaner. Then apply wood glue to the wedge of the slats (PVA will also work). It is also injected into the gap in a small amount. Next, use a rubber mallet to hammer the batten in so that it fits as tightly as possible between the boards. You can use a hammer to hammer in, but you need to put a rubber or thin block under it so as not to make even more holes in the floor.

Sealing according to the warm seam type

Insulation using a “warm seam” sealant for wooden houses is applicable in many cases. First of all, the technology is suitable for inter-crown spaces in houses made of timber. First, the gap is filled with a special cord, because placing such a quantity of sealing mass is expensive and impractical.

At the next stage, the sealant is distributed over the entire joint surface. This must be done with a pistol into which the product is drawn from a bucket. If the composition is purchased in a tube, then it is simply inserted into the gun. A corner is cut off at the tip at an angle of 45° so that the open part is equal in size to the size of the seam.

Sometimes performers put tape around the joint so as not to stain the adjacent parts of the surface. Experienced performers apply the mass from a gun in one step without misses, without using tape.

If the product gets on adjacent areas, they should be immediately wiped off with damp rags of any fabric. A large amount of excess can be obtained from novice installers; in this case, all flaws are removed with a spatula.

Of decisive importance is the thoroughness of the final alignment of the seam, which is carried out with a spatula, brush, sponge, or rag. This should be done soon after applying the product, after no more than two hours. If the finishing is done correctly and on time, the seam acquires a decent appearance.

Complete formation of the seam ends a few days after the polymerization of the mixture is complete. The speed of the final process is determined by the weather in general, air humidity and raw materials in particular. Only after the joint compound has completely hardened does the final color appear on the surface, which will remain for a long time during the operation of the building until scheduled repairs.

Video description

How to seal cracks in a wooden floor

The composition is left for a while and the cracks are prepared in the standard way (small debris and dust are removed). Afterwards, apply the mixture with glue onto a rubber spatula and evenly fill the spaces between the boards. It must be well leveled so that there are no tubercles. The filled cracks are left for two to three days. This time will be enough for quality hardening.

PVA glue and sawdust for preparing a mixture for sealing cracks in a wooden floor Source vodakanazer.ru

On a note! While the adhesive mass is setting in the cracks, it is better not to use the floor, since when walking on it, the boards will inevitably move, which will cause premature ejection of the filling material.

Paint combined with sawdust

In this case, they try to use exactly the paint that will subsequently be used to paint the entire surface of the floor. To prepare the mixture when sealing cracks, use one part paint and one part wood varnish. Four parts of fine sawdust are added to them.

All components are thoroughly mixed together, and then the cracks are sealed with this mixture. One pass will be enough to fill small crevices, but larger defects will have to be filled several times in a row.

Cement with broken glass

This mixture is an excellent protector against rodents that will not be able to penetrate from the underground into the home. To prepare a mixture for eliminating cracks, you will need to do the following:

- Take an unnecessary piece of glass, put it in an old pillowcase (which will no longer be useful. You can additionally cover it with several more layers of thin fabric.

- Then, using a hammer, thoroughly crush the glass into crumbs, then pour the prepared material into a separate, preferably metal container.

- Prepare a cement mortar in water in a bucket and bring it to a uniform consistency. Next add the broken glass and mix thoroughly.

- For a small number of holes between the boards, two tablespoons of cement and half a liter of water, plus 100 grams of broken glass, will be enough.

If it is not possible to use glass chips, then you can replace it with finely chopped wire. An alternative to regular wire will be small fragments of a kitchen scraper.

Preparation of cement mortar with the addition of broken glass to seal cracks in the floor Source egocolor.ru

Varieties

Today, sealants are in great demand. They are intended for different types of work and different materials. Sealants suitable for sealing wooden floors, as well as sealants intended for crown joints, are divided into single-component ones and those that contain two active components.

There are sealants that, in addition to sealing seams, provide additional functions: coloring and antiseptic protection.

- One-component compositions. Since this type of sealant hardens quickly when exposed to air, it requires a very quick approach to work with it when sealing seams;

- Two-component mixtures. Such compositions are obtained by mixing two or more components, which allows you to work with them, having a wide range of possibilities.

If we consider sealants for the materials on which this product is produced, the main ones will be:

- Acrylic-based mixtures (they are produced by the most famous Russian brands - Neomid and Eurotex);

- Composition based on polyurethane;

- Silicone sealants.

The most popular on the market are acrylic and silicone based compounds, which are used in a wide range of tasks.

Based on chemical activity, sealants are usually divided into acidic and neutral.

Acidic sealing compounds . This type should not come into contact with reagents that may react chemically with the aggressive components of its composition.

Neutral sealing compounds . These mixtures can be used on almost any surface and material.

Video description

Securely level old floorboards

Construction foam

This material is most often used to seal joints between the wall and wooden boards on the floor. This option is also suitable for sealing large cracks and damage in the floor. Before using such a product, the surfaces of the gaps are moistened with water so that the liquid foam adheres better to the wood.

It is recommended to apply polyurethane foam in small quantities, as it tends to expand and subsequently the boards may begin to deform, which will negatively affect the plane of the floor.

Acrylic sealant

Sold in special tubes equipped with a syringe. Ideal for filling gaps between laminate and parquet joints, and eliminating spaces between dry boards.

After applying the composition, the boards will stop moving, the creaking will disappear, and it will be comfortable to move on the floor. The acrylic sealant on top can be painted with enamel or special paint for wooden floors.

Acrylic sealant for sealing cracks in wooden floors Source materik-m.ru

The best manufacturers

Some sealants can be purchased without fear: their manufacturers have long established themselves and are respected by professionals.

Soudal

This sealant is prepared on the basis of acrylic; it is elastic, durable, and is well suited for sealing seams between parquet strips, as well as for fastening baseboards and door frames. The sealant cures quickly, is available in a wide range of colors (cherry, beech, ash, oak and other tones), resistant to acids, alkalis, and household chemicals. After drying, the seams can be sanded and varnished.

Soudal parquet sealant color range

Krass

This sealant for parquet boards also has an acrylic base, does not emit odor, and is environmentally friendly. It is a durable grout for wood floors that helps fill potholes and gaps. Advantages of the composition:

- possibility of subsequent sanding, painting, varnishing;

- resistance to temperature changes and moisture;

- high adhesion to all types of wood.

Acrylic composition for wood KRASS Dark oak

The product can withstand wood deformation within 7%, which must be taken into account when purchasing it.

Tytan

Sealants for parquet of this brand are available in various shades: wenge, mahogany, alder, oak and many others. This variety makes it easy to match the composition to any shade of coating. Silicone sealants can withstand severe deformation, are not afraid of mechanical loads, are elastic, and can withstand large temperature changes. They can be used when laying heated floor systems, as they do not contain formaldehyde and other harmful substances. Titan sealants do not deteriorate from water, last for many years and do not crack.

Tytan professional sealants for wood and parquet

Penosil

This sealant is made on the basis of acrylic resins and is available in a rich range of colors. It is used to treat the seams of flooring to protect it during installation or restoration of floors. The grout has high adhesion to wood, can withstand freezing (up to 10 cycles), and can be used in unheated rooms. The composition is resistant to ultraviolet radiation, mechanical factors, and water.

Penosil Premium for parquet

The use of a high-quality sealant guarantees an improvement in the appearance of the floor covering, as well as optimization of its functionality. The parquet will last a long time and will not suffer from moisture and dirt, because the sealing compound will prevent them from getting under the boards. Working with the sealant will not take much time, but its results will become noticeable very quickly.

Factors influencing the appearance of cracks

And finally, to prevent cracks from appearing, you need to know the reasons for their formation. Such knowledge will also help eliminate their consequences. So, the appearance of cracks can occur due to:

- low-quality raw materials (for example, if the boards are damp and laid on the floor, over time they will begin to dry out, forming spaces);

- increased dryness in the room and the prevalence of high temperatures. Optimal indicators: humidity 45-65%, and temperature - no higher than 25 degrees;

- unsuitable material that was used for laying the floor. Ideal raw materials are species of coniferous and tropical trees, as well as oak boards;

- rodent settlements. Only in this case the cracks will be equal and uneven. The best way to eliminate such problems is to completely replace them with a new board.

There are many other reasons why cracks may appear in boards. In any case, it is better to eliminate them while they are small in size.

Overview of wood sealants

Currently, the market offers products from both Russian and foreign manufacturers:

- Acrylic American Perma-Chink sealant is designed for sealing wide joints. It is the absolute leader in elasticity and fits perfectly on wood, creating a durable film. The sealant is not susceptible to UV radiation, humidity, extremely low and high temperatures. The color palette includes ten different shades. Perhaps its only drawback is its high price.

- Another American representative is Energy-Seal sealant, produced for narrow gaps up to 25 mm. The product is fade-resistant and can be used in the most unfavorable weather conditions.

- German sealant Remmers Acryl 100 is designed for wide joints up to 50 mm. It has good adhesion, resistance to UV radiation, and retains its properties for up to 25 years. The color scheme includes eleven tones.

- Wepost Wood sealant comes from Slovenia; it has increased ductility and can withstand several times more tension/compression cycles than other sealants. Prevents the appearance of insects in the tree, tolerates temperature changes from -50 to + 60 degrees.

- Domestic acrylic sealant Eurotex is designed for use in a wide variety of climatic conditions. The material forms an elastic film that reliably and firmly closes the seams of a wooden house and protects the wood from pests. The product is available in four colors and allows you to create beautiful and tight seams.

This is not a complete list of manufacturers. On the shelves of construction supermarkets you can find Polish, Finnish, and Canadian sealants that can be used to caulk the crown joints of a wooden house

When choosing a product, you must first pay attention to the expiration date, composition, recommended conditions of use.

Application technology

The technology essentially consists of 6 main stages:

Laying insulating cord. Its task is to fill the inter-crown space. It makes no sense to use a more expensive sealant for this, and filling the space with it is quite problematic. It is reasonable to use sealant as a top, fixing layer.

Applying sealant using a gun. For this purpose, the tube is inserted into the cavity of the gun (or the sealant is drawn directly from the bucket). After this, the nose is cut off at 45 degrees, to the size of the seam. Next, the sealant is applied as polyurethane foam. Some installers use tape, gluing it as a frame for the borders of the seam. This allows you to avoid staining the timber and collect excess after application. After application, the tape comes off almost immediately. However, after gaining experience, you are unlikely to need such a procedure. Professionals apply the “Warm Seam” without tape to a length of 1.5 to 2 m in one pass and very evenly.

If excess sealant gets on the crowns, immediately remove them with a damp rag.

Wet a small brush and use it to smooth out the seam layer.

If there is a lot of excess, you can use a small spatula to remove it.

Now all that remains is to go over the seam with a slightly damp cloth for final alignment.

Some people use a sponge and spray for these purposes. In this case, the seam becomes glossy.

Corners and cuts

The difficulty, especially with the first experience, is the corners and cuts. In fact, sealing such areas is carried out in the same way as straight seams.

- Measure and cut pieces of cord of the required length in advance;

- Place the cord (you can use a spatula or brush to tuck it in);

- Apply sealant;

- Carry out the alignment procedure described above.

It can be noted that in general, the application process is not particularly difficult. Although, making a warm seam for wooden houses is a very tedious job. So be patient and/or the reliable “Russian way”.

Below in a series of photographs you can see the entire process step by step.

And a video with step-by-step instructions:

Choosing the size and thickness of the floor board

Wooden floors are afraid of moisture, so waterproofing is required when installing them.

If the concrete screed is made in an insulated version, the finishing coating is laid directly on it; If the screed is not insulated, first make a rough wooden floor, then insulate it and then finish the floor on top. To make a wooden floor, edged boards are used, which fit well and do not require additional mechanical processing.

Important!

It is easier to check the edged board for fungus or other damage

For rough coating, boards of grades B and C made from cheap wood species (spruce or pine, and for rooms with high humidity - from larch) are suitable.

Depending on the load that will affect the subfloor, the thickness of the board is selected in the range from 25 to 35 mm. If a tongue and groove floorboard is used, the gaps during installation will be minimal.

For the finished floor, choose a board with a width of 80 to 135 mm (most often 100–105 mm); the thickness of the floorboards is usually 30, 32 or 35 mm. The length of the floor boards can be 3, 4, 4.5 or 6 m; it is selected depending on the size of the largest room in the building, because it is desirable that the board covers the entire length of the room.

Important!

It is not recommended to use lumber with a thickness of less than 22 mm for the floor, because such a board will begin to sag under load and the floor elements will fail.

Conclusion

As you can see, the variety of products for working with the wooden flooring of an apartment or house allows you to select not only by price category, but also to find exactly what is required for certain conditions. As we have already said, the workflow of applying sealant to a surface does not require special skills or abilities; it is only necessary to comply with safety measures: the use of gloves and a protective mask.

In the video presented in this article you will find additional information on this topic.

If you need to buy a hovercraft inexpensively with organized delivery, call or write to us, you will be pleasantly pleased with the quality of our products! In general, if you decide to purchase our products, call or write to us, we will be happy to sell you high-quality products on the best terms! See you in touch!

What are the requirements for floors?

We usually expect the following characteristics from a floor in a room:

- strength and durability;

- ease of operation (simple cleaning);

- protection against leaks (especially in wet areas, in apartment buildings);

- thermal insulation and sound insulation;

- a perfectly flat horizontal (or with a planned slope) floor surface;

- aesthetically attractive appearance.

Depending on the purpose of the room, some requirements may become more or less important.

In accordance with SP 29.13330.2011 “Floors. Updated edition”, floors are divided into the following types:

- floors in public and residential buildings;

- floors in industrial and warehouse buildings;

- floors in industrial premises with fire and explosive technological processes;

- floors with a standardized surface heat absorption rate;

- floors that are made on floors and have noise protection requirements;

- floors in poultry, livestock and fur farming premises and buildings;

- floors that are exposed to aggressive liquids (acids, alkalis, oils and others);

- floors in refrigerated rooms;

- floors in sports facilities;

- floors in the premises of medical organizations.

When designing different types of floors, the requirements established for each category, as well as fire safety, sanitary and process design standards must be taken into account. These standards do not apply to the design of removable floors (raised floors), as well as floors located in buildings on permafrost soils.

The choice of floor design is carried out taking into account the following factors:

- operational reliability and durability;

- optimal use of building materials, as well as soil characteristics;

- optimization of labor costs for installation and operation of the floor;

- environmental Safety;

- safety of people when moving on the floor;

- hygienic conditions;

- fire and explosion safety;

- intensity of mechanical impacts on floors.

According to SP 29.13330.2011, the intensity of mechanical impact on floors can be:

- very significant;

- significant;

- moderate;

- weak.

If the floors in the room are exposed to liquids, a distinction is also made between low, medium and high intensity of its impact.

Important!

With medium and high intensity of exposure to liquids on the floor (periodic or constant strong wetting, during which the floor surface becomes damp or wet), slopes are provided on the floors. The magnitude of the slopes can be from 0.5 to 1% for seamless coatings and slab coatings (except for concrete coatings) or 1–2% for concrete coatings of all types.

Requirements for floors are established at the project development stage.

The type of floor covering is assigned depending on the type of room, as well as the intensity of mechanical, liquid and thermal influences.

The choice of the type of interlayer is made depending on the coating material, as well as the type and intensity of impact on the floors. Adhesive compositions must ensure the strength of the connection (adhesion) of the coating and the monolithic base of the floor.

Floor design

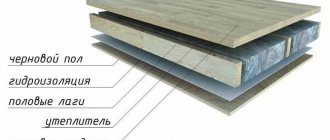

A typical floor structure includes several layers:

- underlying layer (for floors on the ground);

- waterproofing;

- screed;

- leveling layer or finishing screed;

- fine coating.

The final floor covering can be made from various types of materials;

- concrete;

- tiles or porcelain stoneware;

- linoleum or PVC tiles;

- bulk polymer materials;

- laminate;

- piece or panel parquet;

- parquet board;

- wooden edged board.

average price

The average cost in the Russian Federation for the presented types of sealing is determined by product type, quantitative composition, purpose, and have different packaging by volume. For example, the price of any seal in rubles looks like this:

- Mastic (any type, but depends on volume):

- CJSC RASTRO (St. Petersburg) – 390.

- LLC TPK "MasticIzol" (Moscow) - 320.

- “The latest technologies” (Novosibirsk) – 430.

- Sealants:

- Stayer Master – 100-200 rub.

- TYTAN Professional – from 450 rub.

- BISON - on average from 120 rubles.

- Polyurethane foam:

- Penosil – from 350 rub.

- Soudal – from 350 rub.

- Moment - from 150 rubles.

- Tubular seal for 1 running meter. (the price depends on the diameter, the smaller it is, the cheaper the product):

- VILATERM (Moscow) - 30.

- Plant "Stroydetal" (Moscow) - 35.

- LLC “Unified Center for Waterproofing Materials” (Moscow) – 25.

Market prices for building materials are constantly changing and depend on many economic factors, as well as resource ones. It is most expensive to purchase material in the Moscow Region and St. Petersburg, and cheaper in the central zone of the Russian Federation (Vologda, Bryansk regions).