The marking of jigsaw files serves to accurately characterize the equipment according to the manufacturing method and the features of use. On packaging, the product manufacturer, as a rule, indicates a more complete description. On the blade itself, the markings are more concise and include alphabetic and digital coding.

In fact, there is no single standard for marking saws, but most manufacturers try to adhere to the Bosch classification.

Shank type

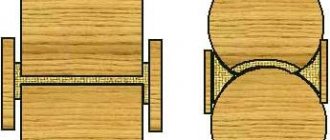

The shape of the part of the file inserted into the jigsaw - the shank - determines the way it is clamped in the tool.

Saws with a T-shaped tail are ubiquitous. They are suitable for most modern models of jigsaws for wood, such as those developed by BOSCH, a trendsetter in this area. In jargon they are called "European type".

American models (DeWalt, Black&Decker) use saws whose tail end ends in a semicircular cutout resembling the letter U. Such shanks fit all clamps with a block or screw. In the jargon - “American type”.

There are still special Makita shanks and T-shaped “Bosh” shanks, but with two stops. They are suitable only for old models of jigsaws from these companies and, rather, are rarities.

Top 5 Quality Universal Electric Jigsaw Kits

Recognized leaders in the production of saw blades have not changed since 2022. The high quality and product characteristics of popular models are checked daily on construction sites, furniture production and home repairs. The rating of universal configurations, based on customer opinions, will tell you which consumables are best to buy.

5th place. Stayer Station wagon 159488-Н5

Average price: 132 rubles.

The manufacturer produces a wide range of hand and power tools. In Russia since 1999. Many buyers recognize the quality and reliability of the product and vote for it with increasing demand.

Saw consumables are made from resistant carbon steel, which ensures flexibility and long service life; a special protective coating on the cutting edge allows you to maintain the sharpness of the blade.

Stayer Station wagon 159488-Н5

Advantages:

- main types of cutting: clean, fast, figured;

- processes chipboard, metal, wood, plywood, fiberboard;

- 5 pieces included;

- T-shank;

- budget brand.

Flaws:

- not found.

4th place. "DeWALT"DT 2294

Average price: 739 rubles.

The company's 90-year history is an example of the reliability of the designed equipment. Powerful, durable and precise power tools are complemented by high-performance accessories. Carbon and bimetallic types of steel are used for it. The recognizable yellow and black colors have become a symbol of Swiss quality.

"DeWALT"DT 2294

Advantages:

- for wood and metal blanks;

- 3 types of cuts: clean, fast, figured;

- universal tail section;

- 10 pieces included.

Flaws:

- high price;

- confusing markings.

3rd place. Set “Gross”78295

Average price: 738 rubles.

German quality has been repeatedly confirmed by numerous customers. The company produces tools for professional processing of all types of wood, fiberboard, chipboard, PVC up to 60 mm, laminate boards and high-quality blades for it. Durable steel cutting surfaces made of chrome and vanadium have a long service life. Wear-resistant, with increased hardness.

"Gross"78295

Advantages:

- perform basic types of cuts: rough, fast, clean;

- for metal and wooden surfaces;

- T-shaped European shank;

- 10 pieces per pack.

Flaws:

- high price.

2nd place. Set “Bosch” Mixed Wood and Metall 2609256746

Average price: 599 rubles.

occupies a strong place among the leaders in manufacturers of consumables for power tools. The widest range allows you to select both a single item and a specific set. Modern alloys extend the service life of the product.

The company has introduced its own labeling, which is also used by other manufacturers. Components are produced in Switzerland or the UK, the T-shank is compatible with power tools from Makita, Hitachi, AEG, Metabo, etc.

Set “Bosch” Mixed Wood and Metall 2609256746

Advantages:

- various files for metal, aluminum, several types of wood;

- information packaging;

- 10 pieces per set, 2 of each type;

- universal shank;

- average price category.

Flaws:

- one type of cut is fast.

1 place. Set “Makita” А-86899

Average price: 350 rubles.

A Japanese brand that produces power tools and high-quality equipment for work in professional fields and private use. Durable steel compounds make the files resistant to mechanical wear, bending and creases.

Set “Makita” А-86899

Advantages:

- for wood, metal, plastic;

- T-shank;

- type of cut: rough, clean, fast;

- 5 pieces per pack.

Flaws:

- unclear markings;

- high price.

Tooth shape

The width and cleanliness of the cut, as well as the suitability of the saw for cutting specific materials, depend on the method of sharpening and setting the teeth of a jigsaw on wood. There are 4 categories.

The first category includes milled files with a regular set. The classic set-up involves alternating bending of the teeth in different directions. A regular saw or hacksaw has such a problem. It produces a wide kerf and high cutting speed, but does not provide cleanliness. The best results are obtained when quickly cutting any type of wood, plastic and even metal.

The second category is milled with a “wave” type pattern. The teeth are not set one by one, but in groups of several pieces. The amount of spread is different for each tooth in the group, so the cutting edge looks like a wave. This file provides good cutting quality and is used for different materials when it is necessary to obtain an even and smooth cut without chips.

Next come files with ground teeth and a classic alternating set. They are characterized by high cutting speed and a wide kerf, the cleanliness of which is better than that of the milled version. Their purpose is fast but high-quality cutting of wood and wood-based materials (chipboard, fiberboard).

Finally comes the category of jigsaw files for wood without cutting with conical grinding of the teeth. The absence of a mark gives a clean and thin cut, but is not suitable for fast and rough cutting. Used for finishing wood and polymers.

The thickness of the blades affects the deflection of the nozzle

Another factor that influences the quality of the cut is the thickness of the saw attachment. They come in two types - thick and thin. Each type has its own advantages and disadvantages, as well as a corresponding purpose.

- Thin blades provide an even and accurate cut, but during the sawing process they vibrate strongly, which depends on the hardness of the material being processed. In addition, their advantage is the low load on the tool, and the disadvantage is that they cannot be used for corner cuts.

- Thick files provide an even perpendicular cut and can be used for angular cutting of materials. Their disadvantage is that due to their size they increase the load on the engine and gearbox of the tool, so they cannot be used on low-power jigsaws

Even thick attachments are not suitable for the quick-clamping mechanism of the saw holder, so it is necessary to choose medium and small blades in thickness.

Canvas dimensions

The capabilities of jigsaw blades are determined not only by the size and shape of the cutting edge. The geometric characteristics of the canvas itself also affect the speed and quality of work. Plus, its dimensions must be selected based on the type and dimensions of the material being processed.

Length

The lengths of jigsaw blades are in the range of 40–250 mm. When choosing a specific length of a jigsaw file, you need to take into account the thickness of the material in the work. It is clear that to cut thick wooden workpieces you need a long saw blade for a wood jigsaw. But if you cut thin sheet materials with a long blade, then due to the possible bending of the metal, it is difficult to obtain an even cut.

Note! When working with long blades, you should understand that the working depth of the cut is affected by the power of the jigsaw.

Width

You need to select the width of the saw blade based on the type of work to be done. For simple sawing, where a straight and even edge is required, wide files are taken. A narrow blade may move during operation, and a straight cutting line will not work.

But when cutting out shapes of varying degrees of complexity, you need to choose narrow jigsaw blades. It is easier to direct them to the side, drawing curved lines.

Thickness

For sawing thin sheet materials, the thickness of the file does not matter much. But when working with thick workpieces, this size affects the quality of the sawn surface. Thin blades will deviate from the perpendicular line during operation, and the cut will be uneven. The thicker the blade, the more even the cut it provides. But there is one caveat - too thick a blade is not suitable for all models of jigsaws. Jigsaws equipped with quick-release devices may not be suitable for thick blades.

How to choose the best and most reliable jigsaw blades?

A review of popular brand models allows you to find the best option for your wallet and the amount of work to be done.

Simple recommendations and convenient markings will help you make the right choice. Retail stores and many specialized online construction sites will help you decide where to buy cutting consumables. Study reviews from real customers, compare products by price and order jigsaw accessories online from the online store.

Very often, abandoning cheap counterfeit products in favor of branded products pays off. Additional costs when purchasing consumables will be paid off by the high quality of the cut, the absence of additional processing, the speed of the process and the absence of injuries during the work.

What do the markings on files mean?

Even knowing all the intricacies of choosing a suitable jigsaw file and having determined the required parameter values for yourself, you can get confused among the many products offered. Don’t go to the store with a ruler and calipers, measuring the dimensions of each blade and the pitch of the teeth!

Files from well-known manufacturers are necessarily marked with various markings that provide approximate information about the parameters of this product. Of course, if you want to know the exact values, you can measure them with a ruler. But it is better to do this not with every canvas, but only with one - pre-selected by marking.

There is no mandatory labeling standard. Most manufacturers of jigsaw files adhere to the rules adopted by BOSCH. It is rare, but you can find markings that differ from these rules.

According to BOSCH standards, alphanumeric markings are applied to the shank of the jigsaw file. The first letter of the marking indicates the type of shank: T-shaped or U-shaped.

The number following the letter refers to the length of the canvas. But this is not the length itself, but the number of the corresponding length range.

1 – short files with a length of up to 75 mm;

2 – average length: 75–90 mm;

3 – long: 90–150 mm;

4 – very long, more than 150 mm.

The next two numbers encrypt the purpose of the file (according to the manufacturers). The same information is usually present in other places on the saw blade in a form that is more understandable to the consumer.

The first letter following the numbers indicates the tooth size:

- A – small;

- B – average;

- C and D – big.

The second letter (if there is one) gives additional information about files that are somewhat different from ordinary ones.

F – especially durable material, bimetal.

O - small width, for figured cutting.

P – large thickness.

R – reverse direction of teeth.

X – teeth of variable size.

Important information about the purpose is duplicated by the markings twice: by the color of the shank and the words on the canvas itself.

For wood – gray; the words Wood (plain wood) and HardWood (hard wood and laminate).

For metal – blue color; the words Metal (metal), Alu (aluminum), Inox (stainless steel). Universal tool for wood and metal – white.

For polymeric materials – red color; the words Acrylic and Fiber&Plaster (fiberglass).

For other materials – black; for example Soft-material (soft materials - rubber, foam).

For ceramics – Ceramics.

Elsewhere on the canvas there may be verbal information about the method of application and special properties (usually in smaller letters than about the material of use):

- basic – standard type of canvas;

- speed – for fast cutting;

- flexible – with a “wave” type connection;

- clean - without streaks, clean cut;

- progressor – variable tooth size;

- special – for highly specialized applications (ceramics, durable plastic, etc.)

A letter marking of the type of metal from which it is made is applied to the neck of the file (between the shank and the blade itself):

- HM – hard alloy;

- CV – chrome vanadium alloy;

- HSS – high-speed steel;

- HCS – high carbon steel;

- VM or ViM is a particularly strong alloy.

Thus, by studying the markings on a jigsaw file, you can obtain comprehensive information about it.

Beware - fake!

Modern manufacturers offer a huge range of replacement materials for power tools and mechanical jigsaws. The average cost for a set of products from well-known brands or new ones can differ tens of times.

It should be remembered that trusted companies value their reputation and monitor the quality of the consumables they produce. Large manufacturers offer a range for amateurs and professionals. But even budget options have excellent performance characteristics.

Care when purchasing will reduce the likelihood of making the mistake of choosing counterfeit files from well-known brands:

- a counterfeit blade made from low-quality raw materials may have chips, minor damage or traces of rust;

- clear edges of the blade are possible with high quality production; the rounded end part indicates a violation of the process during underground stamping;

- blurry, distorted inscriptions are easily erased;

- no branded packaging;

- low price compared to the original product.

The fake quickly wears out and breaks. A counterfeit accessory can damage the workpiece or cause injury to the craftsman. Therefore, how much the product costs is not decisive when choosing equipment.

Types of files according to purpose

The word jigsaw still evokes associations with wood. And although modern jigsaws are widely used for sawing plastics and metals, the main material for work is still wood and plywood. You also have to think most often about which blades to choose for a jigsaw on wood.

On wood

For general work on wood and its derivatives (plywood, chipboard, MDF), standard saw blades with a gray shank for simple or hard wood are chosen. The dimensions of the blade, the spread and the size of the teeth are selected individually. But sometimes it is necessary to perform work that differs from ordinary sawing.

If speed is important, even at the expense of the quality of the cut, then you need to choose long saws with large teeth and a large pitch. Divorce is also desirable more.

If you need to get an even and smooth cut without chips, then take blades with a small mark or without it at all. Teeth – medium or fine. Materials that have a finishing side (laminate, chipboard) have to be cut upside down. If you want to see the cut from the front side, then you need to choose files with the teeth in the opposite direction (the last letter of the marking is R).

For artistic cutting there should be a narrow blade no wider than 4 mm, small teeth and short length. Compliance with these conditions will allow figure cutting to be carried out at small turning radii.

For metal

An electric jigsaw is still not the most suitable tool for cutting metal. But if necessary, he can handle it if you choose the right file. The teeth of such files are very small and wavy; the blades are made of especially strong alloys, but they also quickly become dull. It is advisable to select files marked specifically for the type of metal you will be working with.

For polymer materials

The file markings contain designations specifically for working with such materials. Ordinary plastic and PVC products can also be sawed with wood blades. In this case, the teeth must be chosen larger and with a larger spread. A small tooth will not only cut, but also melt the material. For plexiglass, it is better to choose a metal fabric with a wavy pattern.

For special materials

These options have their own designation. First of all, it is ceramics. The files for it are made of special alloys, and the teeth are made with a special durable coating.

Also, especially strong coated teeth are required for cutting drywall.

But for soft materials, files without teeth are produced at all. Their cutting edge is a smooth blade, sharpened in a wave-like manner.

Shape cutting technologies

Jigsaw

As we noted above, a jigsaw will come in handy if we are looking for how to cut a word out of plywood or make other parts of complex shapes:

We transfer pre-printed drawings or templates onto the workpiece using carbon paper.

Figured carving with a jigsaw: photo of the finished product

- If the structure has through sections, we make starting holes with a thin drill.

- Insert a file or jigsaw blade into the hole. Secure the free end of the file with a fastening screw or clamp.

- We make a cut along the intended line, pressing the workpiece to the workbench. The saw moves either automatically (for electric jigsaws) or manually.

After all the arc elements have been sawn, we remove unnecessary areas and process the finished part with a file or sandpaper.

Finished hole

Fraser

A furniture router is great for cutting out thick plywood. Of course, you can’t make a complex shape with it, but cutting an arc or circle is easy:

- We fix the standard ruler included in the router in the center of the circle using a self-tapping screw.

- If the length of the ruler is not enough, you can assemble a simple bracket from a metal profile or wooden planks.

- By rotating the cutter along a fixed radius, we select a groove along the circumference, resulting in an almost perfect hole.

Bracket for router: with it you can cut a disc of almost any diameter

In this way, you can cut not only circles, but also individual arcs - for example, in order to make grooves for furniture brackets.

Using improvised means

For shaped elements, it is advisable to have special devices, but any craftsman may need to make a round hole in a slab of laminated veneer. Below we will tell you how to cut a circle from plywood when you have nothing at hand. Well, almost nothing:

- To cut plywood, use a wooden strip with two nails.

- One nail is driven through the strip into the workpiece, exactly in the center of the hole being made.

- We drive the second nail into the bar so that the point protrudes on the wrong side by at least 5-10 mm. The distance from the first nail should be equal to the radius of the hole being made.

- Rotating the bar, use the tip to draw a groove on the plywood, deepening it with each turn.

- Instead of a stick, you can use a strong cord. The operating principle remains unchanged.

Diagram of "threading" using nails. The sharper the nail used, the faster the hole will be made. It should be noted that although the price of such a device is low, it is worth using it only when other methods are not available: the edges still turn out to be far from ideal.