It is difficult to name areas of life in which trees or products made from them would not be used.

Therefore, the question periodically arises - what to do with various plant and wood waste and products of the woodworking industry, how to get rid of them, because this material, being in an uncontrolled state, poses a serious danger.

In this article we will look at various ways of using or recycling wood and any waste from sawmilling and woodworking, you will find out what is made from wood and its waste, and we will also discuss issues related to them.

What is wood waste?

Wood waste refers to any materials that are obtained as a result of forest maintenance or commercial wood processing, but are not the final product. Therefore, waste can be either whole trees or any fragments that remain after they are cut down or processed.

Most often, waste is classified as:

- tree trunks cut down during site clearing;

- branches cut from trunks;

- stumps left in the ground;

- bark;

- croaker;

- all kinds of trimmings;

- fallen leaves;

- sawdust;

- shavings;

- wood chips

Hazard class according to FKKO

According to the FKKO classification, clean wood waste belongs to hazard classes IV–V, that is, they do not pose a danger to nature , but there are situations in which the level of danger increases sharply.

For example, any waste doused with machine oil or gasoline is classified as hazard class III.

Despite the fact that dead wood, brushwood and fragments of trunks are classified as class V, that is, they are considered non-hazardous, they sharply increase the rate of spread of forest fires. Indeed, unlike living plants, in which sap flow maintains a high level of humidity and also reduces their flammability, these debris quickly lose moisture, which is why they become much more flammable and flammable.

Classification of wood by heartwood and sapwood

- The color of wood depends on the type of tree, age, speed and location of growth.

- The intensity of the color depends on the concentration of tannins, resins, and dyes in the wood.

The heartwood is the dead wood inside the trunk. As a rule, the core of the trunk is darker than the sapwood. This is due to the fact that as living cells inside the trunk die, tannins and dyes are deposited in them, since the water supply pathways are clogged.

It is tannins and dyes, as well as resins and calcium carbonate that contribute to the coloring of the central part of the trunk in darker colors.

The lighter wood around the core is a layer of living cells called sapwood. The wood core is the hardest part of the trunk. It is denser than sapwood and has greater resistance to rotting.

All wood species are divided into three groups:

Heartwood species have dead cells in the center of the trunk, which are darker in color. Sound tree species include trees such as larch, oak, pine, cedar, apple, juniper, ash

Cutting down an apple tree

Sapwood does not have dead cells. Sapwood species include maple, linden, pear, birch

Cutting down a birch

Mature wood is considered to be wood where the color of the sapwood does not differ from the color of dead cells, for example, beech wood

Beech cut down

Who makes them?

Any activity associated with the extraction or processing of wood is also a source of waste, and the type of waste directly depends on the activities of the enterprise or organization.

When logging, waste can be whole trees or individual parts , it depends on the purposes for which the cutting or sawing is carried out.

The purpose of thinning is to free up living space for young growth of certain species, and sawn or felled wood is a by-product.

Sometimes it is recycled, but often it is left in place, where it rots for many decades, gradually turning into driftwood. If the purpose of felling is to extract industrial timber, then after the work, including the removal of the extracted material, sawdust, branches or foliage remain on the ground. You can read more about the reasons for cutting down trees, as well as methods for performing this work, in the Trees section.

The trunks, which are also called canes or logs, are cut down and cleared of branches, and delivered to sawmills, where they are cut into boards, timber or other lumber. The main product at this stage is lumber, and the waste is slab and sawdust.

Another consumer of logs is wood processing enterprises that produce building materials, as well as various chemical products.

At such enterprises, the waste consists of bark and various trimmings.

Finished boards are supplied to construction sites, as well as various processing enterprises, including furniture ones. At construction sites, the main type of waste is all kinds of trimmings, but processing enterprises, in addition to trimmings, also produce shavings. Many enterprises immediately process waste into wood chips, because it is easier to dispose of or sell.

Equipment for processing wood and other forest resources

All equipment can be divided into 3 types, that is, intended for:

- sawing and uprooting;

- recycling;

- processing.

Sawing and uprooting

The main tool for manually cutting down trees is a chainsaw, which is used to carry out almost all work within the city.

Together with it, it is often necessary to use not only hand tools (an ax and a ladder), but also various mechanisms , including hydraulic lifts and cranes.

For uprooting, excavators are used, including those with uprooting grips, or bulldozers with special knives, as well as all kinds of cutters. In addition, when cutting and uprooting, you have to resort to the help of trucks, because the material dumped or removed from the ground has to be delivered to the place of processing or disposal.

Disposal

The main equipment used for wood recycling are all kinds of shredders and wood chippers, which turn wood into wood chips. Household shredders are small in size and operate on a 220 V network, while industrial devices are equipped with powerful electric (380 V) motors or internal combustion engines (gasoline or diesel fuel).

Some models are manufactured in a mobile version, for which they are equipped with either a trailer or a suspension for installation on a tractor.

Most wood chippers are not well suited for processing grass and leaves, so their own models of wood chippers are being developed for these materials.

However, there are devices that, although not very efficient, can process wood and fallen leaves or grass .

To facilitate the labor-intensive manual collection of fallen leaves, various devices are used that work on different principles, but the most effective and popular are garden vacuum cleaners. Some vacuum cleaners not only collect, but also shred leaf matter, making it take up less space and be better suited for most disposal methods.

Shredded wood residues are converted into any popular product, and are also used for heating or used in the garden.

Recycling

The following types of equipment are used for processing lump and shredded wood:

carpentry machines (circular saw, jointer, surface planer, milling machine, etc.);- presses, including granulators;

- dryers;

- shredders;

- debarking machines;

- complex lines.

Choosing wood: features of different species

Wood is one of the most common building materials in our country. Frame and timber houses are built from it, facades are finished, and roofs are covered. The wood is used in carpentry and is used to make designer interior items and carved sculptures.

Despite the general availability, this material has many secrets, knowing about which, you can make an informed choice rather than buying a “pig in a poke.” To choose the right wood, you need to understand its properties. Therefore, in today’s article we will talk about the characteristics of different types of wood.

So, from our material you will learn:

- What you need to know about wood before buying it.

- How does the wood of the most common species differ from each other?

- What kind of wood is best to build house walls and important structures from?

- Which wood is best suited for carpentry.

- How to choose and store lumber correctly.

Features of wood

Our portal has already talked in detail about the features of laminated veneer lumber, and compared profiled timber with regular timber. Anyone who has read these articles knows that the properties of a material largely determine the scope of its use. Therefore, before going to the market to buy “wood”, you need to ask yourself the question – where will you use it. It’s one thing if you need to lay wooden flooring on your terrace, and quite another if you need wood to make carved items. In the first case, increased strength (hardness) and resistance to weathering and insect pests are required from the wood, and in the second, preference should be given to softer (well-processed) varieties of wood.

The properties of wood largely depend on its structure and the thickness of the layers. Maximum strength and resistance to unfavorable external factors and, therefore, durability, have layers of late formation - the so-called. sapwood. It should be borne in mind that this statement is not true for all types of wood. For example, larch (unlike pine and spruce) has a core that is twice as strong as sapwood.

First of all, those who are going to build a house from rounded logs should remember this property of wood. Indeed, in the process of processing a solid tree trunk on a special machine, the outer, and therefore the most durable, part of the wood is usually cut off.

Rule: wood from different tree species has different physical and mechanical properties and characteristics. It is a mistake to divide wood into “good” and “bad”, because Often it is the wrong choice or use of wood that negates all its advantages and significantly reduces the service life of the product.

Wood species can be divided into two large groups:

- Conifers.

- Deciduous.

Having studied these groups and understood the properties of wood, we will understand for which jobs and structures this or that material is best suited.

Softwood

Traditionally, coniferous wood, which includes pine and spruce, is widely represented on any construction market. Less common are larch and cedar. Let's take a closer look at each breed.

Pine. We can say that this is a general construction material from which many people prefer to build houses. The prevalence of this type of wood and ease of processing are reflected. Due to its structure, pine is resistant to decay. In addition, due to the open cell structure, pine has high breathability. Therefore, walls built from this material “breathe.”

If we consider pine as wood for carpentry, it is often used in the manufacture of furniture, doors and window frames. Well-dried pine wood is excellent for sawing, cutting, planing, gluing and painting. Pine wood has a distinct texture, which makes it attractive for carvings and mosaics.

Spruce. The wood of this species is knotty and the texture is less pronounced than that of pine. These features impose restrictions on the use of spruce in carpentry, as well as in the manufacture of furniture. In addition, dried spruce wood is susceptible to splitting, so they try not to use it as a floor covering. Spruce is also more susceptible to rotting than pine.

Hermes-szFORUMHOUSE user

During drying, the cell structure of pine sapwood remains “open”; only the structure of the heartwood is closed. The cell structure of spruce is the same from sapwood to heartwood and “closes” when dried.

Due to differences in the cellular structure, spruce wood is less susceptible to moisture accumulation than pine wood. With seasonal fluctuations in humidity, the spruce practically does not change its volume.

Spruce, due to its loose structure and lower density, has a lower degree of thermal conductivity than pine wood. Therefore, walls made of spruce are warmer than those built from pine. Spruce wood is more flexible than pine and does not warp or burst under load. This affects the scope of its use.

In construction, spruce is in demand in the manufacture of floor beams, rafter systems, rafter purlins and slightly horizontal, intermediate supports for rafters.

In addition, spruce wood has a high resonating ability - a quality valued in the manufacture of musical instruments. Spruce easily splits and peels, so it is used to produce shingles and shingles.

Hermes-sz

In terms of deformation resistance and the ability to hold fasteners, spruce is almost equivalent to pine.

It should also be taken into account that the properties of wood are influenced by the place where it grows. For example, the density and resin content of pine and spruce wood is influenced by where the trees grew - in a mixed forest, on the edge, in a lowland, near a swamp, etc.

Larch. This material, due to its high strength, density (1/3 higher than that of pine and spruce), oiliness and resistance to biological damage and insect pests, is indispensable for the construction of log houses. Larch is used for the bottom backing board and crowns, i.e. — places located close to the ground and subject to the greatest influence of adverse weather factors.

Larch is indispensable in the manufacture of pile structures that remain in water for a long time. During the construction of St. Petersburg and Venice, larch piles were used, because When kept in water for a long time, this wood does not rot, but “petrifies.” Due to their dense structure and density, walls made of larch are less warm than those made of spruce or pine. In addition, larch is heavier.

Hermes-sz

If we take the “thermal protection” of walls made of logs or pine beams as 100%, then the same walls made of spruce or cedar will be approximately 10% “warmer” than those made of pine, and those made of larch will be 25-30% “cooler” than pine ones.

Among the features of larch, it can be noted that this material “breathes” poorly, but is difficult to ignite. Thanks to its beautiful texture, larch wood is in demand in furniture production. Despite the complexity of processing, larch is also used for carving and mosaic work.

Cedar. Cedar has soft wood that is easy to cut and saw. Cedar blanks are easily processed on lathes, and the wood has a beautiful texture. In addition, cedar is resistant to rot. Products made from this wood can be placed outdoors.

Hardwood

If he talks about “carpentry,” then deciduous wood is traditionally in demand in this business. First of all, we can highlight oak.

Oak. Everyone knows the high strength, hardness and durability of oak wood. Oak is resistant to rotting, and due to the abundance of tannins, this wood pickles well. Oak wood is tough, can be easily processed with cutting tools, and can be bent. The texture of the wood fibers is clearly expressed. Furniture made from oak cannot be confused with any other.

NatovichUser FORUMHOUSE

I have been working in furniture carpentry for a long time. I had to work with pine. Didn't like it - boring material. Oak is a completely different matter! This is a tree with character. He exudes positive energy. The products are durable and beautiful. As they say, “forever.”

When processing oak wood, you should remember the dangers and carcinogenicity of fine dust. Therefore, we work with oak in a well-ventilated area. We use respiratory protection - a respirator.

Ash. Ash wood is similar to oak. This can be seen in the similarity of the fibers, but the texture of ash wood is lighter than that of oak. Ash has high strength and toughness, but under unfavorable conditions (high humidity and dampness), ash wood begins to rot. Ash must be antisepticized with protective agents.

After steaming, ash bends easily. This wood also finishes well. Due to the tendency to form growths (like all hardwoods) - thickenings on the trunk - the so-called. burls, which have a higher hardness than the mother wood, ash is often used in applied arts. The burl is well suited for creating artistic products that have an unusual “stone” texture similar to “malachite” or “marble”.

The similarity with oak will determine the main area of use of ash - furniture production, the manufacture of sports equipment, and stair railings.

Beech. Beech wood is comparable in strength to oak. Just like ash, beech can be sawed well, bent after steaming, drilled, and processed with a cutting tool. But, due to its susceptibility to moisture accumulation, beech wood can begin to rot. It is worth remembering this if you plan to use beech products in damp rooms. To protect beech wood, antiseptics and special paints should be used.

Although beech does not have a pronounced texture, when cut tangentially and radially, the tree, as they say, begins to “play.” Therefore, veneer is planed from beech, which is then used for veneering furniture. Beech is also used in the manufacture of bent furniture elements and parts of musical instruments.

Selection and storage of wood

In addition to knowledge about the types of wood and its properties, it is equally important to know how to choose it when purchasing and then store it. Regardless of what you need wood for - building a house or carpentry work, the first assistant when choosing is a tape measure. The selection algorithm is as follows: we determine the required dimensions of wood (thickness, length and width of the board). In order not to count manually, we use a special table to find the number of boards (pieces) contained in 1 cubic meter of wood of a given size.

For example, you need a board 150x50x6000 mm. There are 22 boards in 1 m³. Armed with this knowledge, he goes shopping.

We select wood without visible damage from insect pests and signs of rotting. Boards (depending on the grade and type - edged or unedged) must be without wane, cracks, chips, or delaminations. We select boards by measuring their geometric dimensions - width, length and thickness. The dimensions of the board must correspond to the stated ones, and not “walk” from board to board.

When purchasing boards, we personally control the selection and loading process! This will help minimize the amount of defective material and will guarantee that unscrupulous sellers will not “accidentally” load you with rotten or substandard boards.

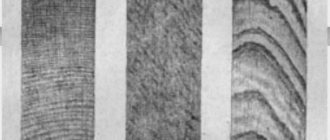

We also look at the ends of the boards. Based on the curvature of the growth rings, you can “estimate” the size of the cut trunk. You can also understand from which section of the trunk the board was cut. This point is worth paying attention to, because... After cutting the trunk, when dry, the boards may warp. Depending on which area the boards were cut from, the direction of the deflections and convexities changes.

For clarity, you can use the following figure.

If possible, purchase a dry board. If this is impossible for a number of reasons (including economic ones), we bring the boards to the required condition, i.e. We dry them ourselves.

To do this, we put the purchased boards in a stack, not forgetting to lay spacers (bars) between the boards, which will ensure free flow of air between the boards. The stack must be raised above the ground, blown (ventilated) from all sides, and closed from above from direct exposure to adverse atmospheric phenomena.

From our material you can learn how to properly dry wood and how to choose material for building a wooden house. Our experts will also talk about all the nuances of choosing boards for building a frame house and the principles of constructing the correct stack for atmospheric drying of wood. The next topic will be of interest to those who want to independently master the secrets of making oak furniture.

Our videos tell about the features of a log house and show the secrets of creating a log bathhouse “Fairy Tales”.

Profitable business in processing wood waste

Despite the fact that waste wood and other forest resources, under many conditions, can be burned or disposed of in a landfill, they are a valuable resource with great potential for subsequent processing.

The recycling business can be very profitable if the costs of purchasing and delivering the material are low. In addition, the demand for finished products and the transportation costs associated with their delivery to the buyer are of great importance.

If these conditions are met, any of the processing methods described in the article can become a very successful business, because such products are in steady demand, and wood is a renewable resource, so there will always be waste.

more detailed information about various types of profitable wood processing business in these articles :

- Business in the production of wood chips for smoking: selection of equipment, search for raw materials, wholesale and retail sales, calculations of possible profits.

- How to organize a business for the production of OSB boards: technological, organizational and economic aspects.

- Wood concrete production - enterprise overview and business plan.

- Sawdust processing as a business - removal and disposal for profit.

- Charcoal production as a promising business.

- Wood waste recycling as a profitable business.

Prospects for processing and disposal

Since wood is a renewable resource, there will always be waste, which means that its processing and disposal of wood waste will always be necessary.

Wood processing products will also always be in demand , because they are made from natural and environmentally friendly materials, unlike their plastic counterparts.

In addition, recycling wood waste allows it to be used again, and also reduces the amount of greenhouse gas emissions into the atmosphere, one of which (carbon dioxide) is released when wood is burned. Therefore, any use of wood waste for the manufacture of other products benefits the Earth's ecology, and in many cases, is also a profitable business.

Also, the use of waste to produce energy or various popular products reduces the number of trees cut down , because many materials that are made from wood can be made from trimmings and other types of waste.

For this reason, processing wood waste and obtaining some other product from it will be in demand until humanity moves to a new level of development and stops cutting down forests in order to then make various necessary products from wood.

Pros and cons of wooden houses

In Russia, according to Rosstat, approximately 10-15% of houses are made of wood. This figure cannot be called very high compared to other countries, but this indicates some undoubted advantages of this material.

To select the right home builder for your desired low-rise housing construction technology, use the Building Companion directory search. Examples of work and reviews are visible in the contractors' profiles; you can request an estimate of the cost of their work. Find a company to build a box house » First of all, this:

- Appearance. The aesthetics and variety of wooden houses allow you to implement almost any architectural solution - from a cheap log house to a luxurious Swiss-style chalet.

- Environmental friendliness. Natural materials bring a person closer to nature, smell wonderful and delight the eye with the naturalness of their colors. Wood also helps maintain normal humidity levels in rooms.

- Heat and sound insulation. Wooden buildings, in addition to the fact that they breathe, also perfectly retain heat inside themselves and also do not allow sound to pass through. But, of course, in cool regions they will still have to be insulated.

- Ease. Logs or parts of a frame house are much easier to transport to the construction site than, for example, bricks.

- Durability. The service life of a building depends on many conditions - the type of foundation, the specific type of material, operating conditions, but with proper care, good wooden houses can easily stand for 100 years, or even more.

- Possibility of not having to deal with additional interior finishing. The wood itself has a pleasant texture and color, so it is not at all necessary to paint it or cover it with wallpaper.

- Compliance of the material. Wood is easy to process; it is easier to hammer a nail or screw a screw into it than other materials. This makes interior finishing significantly easier.

- It is easier to make a wooden house with your own hands. This is especially true for frame structures, which can be erected without the help of a construction team in just a few months.

Almost all the disadvantages of wood are associated with the same feature - it is a completely natural material that can be subject to:

- Rotting. The accumulation of moisture leads to softening of the material, the appearance of an unpleasant odor, and the proliferation of bacteria.

- Fires. A gas leak or careless handling of fire can lead to a fire, but untreated wood burns well and spreads fire.

- Natural changes in the structure of wood as a result of exposure to temperature and time. Shrinkage, swelling, shrinkage - all this may vary depending on the specific type of wood, but must be taken into account.

- Exposure to small parasites. Bark beetles, woodworms, termites - this is just a small list of insects that are not averse to feasting on wood. Small holes in the walls are sure signs that the wood structure needs urgent treatment.

Another disadvantage is some limitations in architectural solutions associated with the initially “given” shape of lumber. For radius, semicircular structural elements of a building, or some other complex architectural solutions, you will have to choose a different material. In wooden buildings, angles and straight lines always predominate.

At the same time, many of the disadvantages of wood can be neutralized by proper care of the material.