What types of woodworking tools are there? Let's highlight the main types

The range of carpentry tools today is very large. A novice master can easily get lost in the list. Therefore, in order to choose the optimal set for performing basic and more complex tasks, you should familiarize yourself with the main list of tools, their nuances and features.

Tools for working with wood are divided into:

- mechanical (manual);

- electrical;

- machine tools

Hand tools can be found in literally every house that the owners built with their own hands. They also have power tools and machine tools, since work goes faster with such devices. Manufacturers have long been producing compact and uncomplicated machines that fit in a garage or workshop.

Types of hand tools for woodworking

Every carpenter should have hand tools, regardless of work experience. The standard set includes:

- saw – a large blade with a handle for removing areas of different sizes;

- hacksaw - an analogue of a saw with a narrow blade attached to a wood/plastic frame;

- plane - a block with a blade, which is used to level surfaces;

- ax - like a tangle, it is used to split or chop a large element;

- hammer - a well-known object for hammering, breaking, etc.;

- chisel - a product for creating recesses, chamfers (used together with a mallet - a special hammer);

- A brace is an analogue of a drill, with which holes are made.

Almost everything on the list can be useful in everyday life during renovation/construction. And not only for owners of private houses, but also for residents of apartments.

Sandpaper is a basic item that is needed in almost all cases. An abrasive with a certain grain size gives the finished product a finished look.

Electric woodworking tool

Electric carpentry tools allow you to do the job quickly and efficiently. Therefore, many manual models, which are difficult to work with, are now being replaced with electric analogues:

- plane;

- Grinder;

- chain/circular saw;

- screwdriver;

- other tools.

An electric planer allows you to create the perfect surface in just a few minutes. A drill is an alternative to a brace, which is used to create holes of the desired size. Today it’s difficult to imagine life without this tool, so it’s worth buying a drill even for those who don’t do woodworking.

An electric grinder is a godsend for professional carpenters and beginners. In large industries, belt models are used, which are designed for a large range of works. But for your home, you can buy a grinding machine with a vibration device or a planetary tool.

If a craftsman has to process a lot of large pieces of wood, he will need to buy a saw with a chain or disk mechanism. Modern models are capable of performing a variety of operations. And for cutting small fragments, instead of a jigsaw, you can buy an electric tool. Most electrical appliances are connected to the network, but there are also battery-powered devices.

Auxiliary tools and accessories

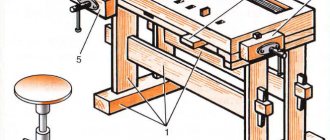

In addition to the basic tools, a woodworker should buy pliers and pliers, a workbench with a vice, as well as measuring tools and pencils for marking the material.

A workbench is like a desktop with an organizer. It has several drawers to keep your tools close at hand. It's worth putting some pliers or pliers there, for example. You can buy a workbench clamp separately.

Variety of instruments

Wood processing refers to a large number of operations, and each of them requires its own tools. Wood can be sawed, drilled, planed, and objects of simple or intricate shapes can be cut out of it. The totality of all tools is divided into two groups:

- manual;

- electric.

In addition, they are divided into professional, amateur and intermediate categories. At home, it is most convenient to perform woodworking with amateur or semi-professional tools. In addition, their price is significantly less than professional ones.

Hand tool

Hand tools are those that require human physical strength to use. Since woodworking was done at a time when no one knew about electricity, all manipulations with wood can be done manually.

The ax is considered one of the most ancient in origin. It is still used at home - in many private households one cannot do without an ax.

There are hand saws, drills, chisels, planes and much more. They need to work carefully and skillfully. You can’t do it without proper practice and skills; you often need considerable physical strength.

Power tools

Electrical devices are easier to use. They allow you to complete the job several times faster and with less effort. Power tools for woodworking at home are available in mains-powered and battery-powered versions. When purchasing such units, you need to pay attention to their power, service guarantee and basic capabilities. Priority should be given to those functions that you plan to use most often.

It is worth noting that power tools can also be hand-held or stationary. Hand-held power tools for woodworking can be carried and performed while holding it in your hands. In the second case, the tool is fixed, human intervention is minimal, it is often a machine that can be a lathe, slotter, milling machine, or planer.

How to use the information we prepare

In principle, everything is completely simple:

- first, go to the section to which the tool you are interested in should belong to;

- secondly, find this tool in the section, based on the fact that all the tools are listed there in alphabetical order. Below the tool name you will find a list of related articles. That is, information that comprehensively describes a specific product.

However, let us clarify that we do not claim that our Olremontopedia covers the entire set of tools existing in the world. We present only those that were mentioned on our website.

Wood sawing tools

You can cut wood or materials made from it using several types of tools:

- hacksaw;

- saw;

- jigsaw

All of them are manual and electric. The hacksaw is ideal for garden work; it is used to saw not too thick branches, boards, and blanks for carpentry.

When constantly sawing wood at home, it is simply necessary to have a circular saw (circular saw). It cannot make shaped cuts, but it cuts through boards, plywood, and some types of plastic as quickly as possible.

If you need to cut down trees or prepare firewood, then in this case you use chain saws. There are also hand saws for logging, which require two people to work with.

Use a jigsaw to cut out shapes of arbitrary shape. It is suitable for cutting out blank models, artistic panels, various crafts, furniture parts, and kitchen appliances.

Assistive devices

For high-quality carpentry work, various standard or home-made devices are used. The most common devices are: clamps, clamps and clamp clamps, clamps for reliable gluing of elements, presses, wooden and metal vices, stops, pads with stops, a miter box to facilitate cutting at different angles, counters for supporting long parts, a bottom to facilitate planing thin bars, a sawing table when using a jigsaw, a bench board, pliers for holding the part.

Axes and splitting axes

From time immemorial, carpentry work has been performed with axes. They trimmed logs, made windows, doors, and built log houses with their help. Axes and cleavers are needed to split logs into firewood. An ax of a certain type is a military weapon.

Note! Splitting tools differ in size, shape of the metal part and handle, which is made of wood or fiberglass.

Today, electric splitters (wood splitters) are produced, which can quickly split logs of a certain length and diameter. Their cost is two orders of magnitude higher than ordinary high-quality axes.

Planers for planing

Wood must be planed with a plane. It removes a thin layer of chips, allowing you to get an even, smooth surface. Neither a joiner nor a carpenter can do without a plane. They are used by craftsmen of musical instruments, furniture, dolls, kitchen utensils and much more.

Advice! When choosing an electric planer, pay attention first of all to its power, blade width and planing depth declared by the manufacturer.

It’s a good idea to have a whole set of planes, or at least one universal one. As you master the work of a carpenter or joiner, you will need other types of planes.

For rough planing, a bearer is used; for finishing, a jointer or semi-jointer is suitable; the removal of tongues and grooves is carried out with a tongue and groove tool. There are also scrapers, moulders, and many other highly specialized tools for planing.

Surface grinder

It is also called vibration.

Used for finishing wood after the belt has been passed over it. Also used for polishing.

What you need to know when choosing

- The “motion amplitude” parameter is responsible for the speed of work, but if it is large, the result of the work will lose its beauty;

- The ability to regulate the oscillation frequency will allow you to select the desired mode for any type of surface;

Grinding and roughening tools

To make wood perfectly smooth, you need a sanding tool. Small figures and wood parts are sanded manually with sandpaper and sandpaper, making monotonous mechanical movements.

To smooth the edges and ends of products, rasps are used. These are special files for wood with a large notch.

For large areas, electric woodworking machines are used, these include:

- grinders with grinding attachments;

- belt sanders;

- eccentric (orbital);

- surface grinding (vibrating).

A belt tool is more suitable for rough sanding, removing thick layers of paint or leveling a surface. Finer grinding is carried out using eccentric and surface grinding units.

Chisels and chisels for chiselling

Tenons and grooves in wood for connecting parts are made with chisels and a chisel. This is a hand tool. To hollow out a deep and wide enough socket or eye, use a chisel. The working part of the chisel is a steel block sharpened on one side.

Using a chisel, shallow holes are hollowed out, the surface of the wood is cleaned, and parts are adjusted. The shape of the chisel blade can be flat or semicircular.

Before starting work, markings are applied to the part, then it is firmly secured in a clamp on the workbench and they begin to hollow out. The fibers are cut at an angle of 45–60°, deepened each time by 4–5 mm, and the shavings are immediately removed.

Woodworking machinery

We can distinguish a category of stationary equipment that simplifies working with large parts and performing serial work. Woodworking machines allow you to achieve greater accuracy and speed in your work.

Planers and planers

For rough processing of boards and flat workpieces, jointing and thicknessing machines are needed. The jointer makes the workpiece even on one side, and the surface planer levels the second side, making it parallel to the first. Using a thicknesser, you can also remove a layer of wood, obtaining blanks of the desired thickness.

Drilling tools

Hand drills, rotary hammers, and augers are necessary for drilling holes. It is much easier to carry out woodworking with an electric drill. It will require special attachments.

There are a large number of types of nozzles, including countersink, center (perk), spiral, screw. A drill can be used to drill holes for bolts, tenons and other types of connections. By selecting a nozzle of the desired shape, you can expand the range of work performed.

Fraser

One of the important power tools for woodworking at home is a hand router. They use it to grind the edge, making it rounded and shaped, cut grooves, and drill holes. They produce various types of milling cutters with a wide and narrow spectrum of action. They differ in power, cutter shank diameter, and maximum rotation speed. In addition to wood, drywall, plastic, and acrylic are processed with a milling cutter.

Workplace and additional equipment

When carrying out woodworking work at home, you cannot do without clamps. They help to fix parts individually and among themselves during cutting, gouging, drilling, and gluing.

Other important tools in woodworking are pliers and nail pullers. They are used to remove nails and other foreign objects from wood.

During the woodworking process, it is important to properly prepare the workplace. For metalworking work you need a workbench. This is, first of all, a table at which it is convenient to perform various manipulations. The workbench also contains useful devices:

- front and rear screw clamps for fixing workpieces;

- holes for wedges into which the workpiece rests;

- tray for storing carpentry tools.

A rack is often installed near the workbench where the necessary equipment, materials, and templates are stored. You will need a comfortable chair. It is also necessary to take care of an outlet for connecting power tools and high-quality lighting.

Additional devices that any craftsman should always have on hand include rulers, protractors, levels, and squares. Most likely, you will need consumables (sandpaper, files, circles). Since a full production cycle is usually established in a home workshop, it is necessary to allocate space for varnish, paints, and brushes.

Any tools must be in good condition. If a breakdown occurs, they are restored as quickly as possible or removed to a place where they will not interfere.

Electric hacksaw

Also known as a reciprocating saw, and colloquially referred to as an "alligator saw"

According to the principle of operation, it completely repeats the classic hand hacksaw, only the reciprocating movement is provided by electrical energy, and not by your hand.

Unlike a circular saw, a reciprocating saw is messier, slower and rougher, but it is safer to work with. However, the alligator also has advantages: the depth of cut, which is limited only by the length of the saw blade (and they are replaceable, so you can always find consumables for any task in the store), and the ability to work in hard-to-reach places.