Louvered doors not only provide a special appearance to the interior of a living space, but also greatly increase the comfort during its operation. Such products provide natural ventilation of any room, increase the air exchange rate and eliminate the formation of mold. In order to independently install such door leaves in the living rooms of an apartment or private house, you need to study the technological map in detail, and also have the right tool at hand.

Classic louvered door

Characteristics of blinds and their varieties

It is immediately worth noting that blinds are not full-fledged doors, that is, they cannot fully replace them.

This is a type of partition. If you still want to use them as a door with all the functions, then you can combine them with a regular leaf, preferably glass. Now blind structures are offered in various configurations, among which the following stand out:

- Vertical, which are a classic version of the office type. The slats are located vertically; they can be moved to the side using a special mechanism.

- Horizontal is the same familiar design, which has been popular for use on windows for a long time. If the slats are made of metal, then such blinds completely replace the door leaf.

Interior doors with the effect of blinds stand out especially. They represent a frame, inside of which horizontally located lamellas are installed. They look very advantageous and refresh the design. They fit especially harmoniously if the room has cabinets with doors of the same design. Such models are made from various materials, including polymers, wood, metal and others.

DIY shutter doors. Step-by-step instruction

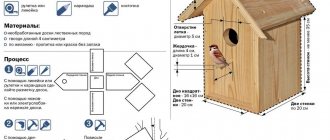

The procedure for making a door with louvered slats is as follows:

- First, the bars from which the frame will be made are cut according to previously determined dimensions.

- The lamellas are made using a thickness planer, and the corners are removed using a router.

- Using a router, fastening grooves for the lamellas are cut out in the side bars. This is a very important operation, on which the quality of the door as a whole depends. The size of each cut and the angle of inclination must be measured as carefully as possible so that there are no problems during assembly.

- All parts must be carefully sanded. First, take medium-grain paper, and then fine-grain paper. After which all elements are painted over.

- In one of the vertical racks, grooves are selected and dowels are placed in each groove.

- The slats are placed in the inclined grooves. When everything is ready, the horizontal crossbars are fixed to dowels. The last element is the second vertical stand.

The assembly procedure is shown in the figure. To make the structure stronger, the dowels are lubricated with PVA glue.

How to paint a louvered door

It is better to paint the door with a spray gun. However, if it is not there, you can take a brush. Ideal quality is obtained if all elements are painted separately. But if the entire door is being painted, you need to carefully work through all the joints with a thin brush.

What are the requirements for automatic sliding doors?

Automatic sliding doors ideally meet the requirements for structures of this type. They allow large groups of people to freely enter and leave the premises, prudently opening when they approach. The doors do not close immediately, but some time after the person leaves the opening - this is convenient for mothers with strollers or small children, as well as when moving luggage in a suitcase or trolley on wheels.

Owners of private households mainly use automatic sliding doors on the street: at the entrance to the territory, to the garage or to the site. Self-opening gates are valued by homeowners and car enthusiasts, because they allow you to enter/exit the property without getting out of your car or fiddling with locks.

Materials for custom shutter doors:

1) Solid wood from economical options made of pine to luxury louvered doors made of solid oak or even teak. These materials are completely environmentally friendly!

2) MDF coated with enamel - this is the most popular version of louvered doors; it is smooth, easy to process and inexpensive to manufacture.

3) MDF covered with veneer - this material completely imitates solid wood at a much lower cost. Veneer gives custom-made louvered doors not only a natural look, but also greater strength.

What types of louvered interior doors can there be?

There are two main characteristics by which structures are divided. To get a complete picture, you should consider them in as much detail as possible:

- Material used for manufacturing. At this stage, it can be divided into three main types - made of wooden material, metal and plastic. Today, of course, wooden ones remain popular, with metal ones in second place. The first and second options can be painted so that they fit perfectly into the interior. A painted door will be much better and will fit, for example, already installed furniture;

- Direct appointment. In this version, the door can be an entrance type, an interior door, or intended for furniture.

Dimensions

Supermarkets like OBI and Leroy Marlene usually have pine louvered doors in stock. They are usually presented in one or two lines in different sizes. Most often the parameters are as follows:

- width - 294 mm, 394 mm, 494 mm, 594 mm;

- height - 606 mm, 720 mm, 993 mm, 1100 mm, 1700 mm, 2013 mm, 2422 mm.

There is a certain set of standard sizes

These standard sizes can be adjusted a little - trim a couple of centimeters in height and width. If you need a completely non-standard option, there are companies or private owners who will make doors to order - according to your dimensions.

Design of louvered doors for a dressing room

Today, in many hardware stores you can easily purchase doors made of wooden blinds of any size.

When choosing wooden structures, you need to pay attention to the ideal geometry of the product, the absence of knots, the canvas should be dense, without cracks and no bending lines

There are many options for processing wooden shutter doors:

- Stain;

- Oil;

- Varnishing;

- Paint (with film or repeating the texture of wood);

- Decoupage;

- Inlay (for professionals, as it is a complex type of finishing that brings uniqueness to each item).

All irregularities must be eliminated before starting painting work yourself. All materials used for finishing wooden shutter doors should preferably be made from water-based compounds. This will allow you to create with your own hands in comfortable conditions, where there are no unpleasant odors and the material itself dries faster.

Without a doubt, louvered wooden doors will always look great and remain in demand as a decoration for an apartment or house for many years

And it doesn’t matter whether it’s dressing room doors, interior partitions, a sliding partition in a niche under the window, folding cabinets in a children’s room or in a closet, these wooden structures will always please the eye of both homeowners and their guests

What to look for when choosing

When choosing shutter doors in a store, you need to pay attention, first, to the quality of the wood. There should be no knots at all, or there should be few of them. They should be dense, brown in color (not black and without cracks).

The second point is geometry. The entire door leaf should lie in the same plane. This is the first thing - no longitudinal bends or “twisting” of the elements and the entire door as a whole. Next, you need to check the length/width/thickness. They must match to within a millimeter.

You need to choose shutter doors carefully

And the last thing is the quality of wood processing. Wooden louvered doors are sold unpainted. You will have to do the painting yourself. But the wood must be well processed. It is desirable that there are no roughness, unevenness and other defects that will then have to be eliminated with your own hands.

What are the benefits of blind designs for a dressing room?

In the modern world, blinds are used in the interior in order to create a unique interior, an extraordinary decoration of the house and at the same time reliable protection of rooms from heat and from prying eyes. Thanks to the fact that you can easily change the area through which light passes, blinds allow you to regulate the amount of light in the room. Doors made of wooden slats (blinds) look aesthetically pleasing, and the unique pattern on them will give the interior a special cozy feel.

Wooden lamella doors owe their success to the following characteristics:

- Special appearance;

- Huge selection of bases and colors;

- Lightweight material (installation is simplified);

- Easily amenable to repair work.

Traditionally, they are made from natural materials such as beech, alder, pine and oak. Modern technology of “merging” wood allows you to install a structure that is durable and resistant to temperature changes and moisture. At the same time, the very design of wooden blinds remains light, flexible and, most importantly, for example, for a cabinet in a utility room, “breathable”.

An undoubted advantage of products made from wooden blinds is the fact that they are double-sided.

This makes it possible to use such structures to create a partition in the room, which will be a wonderful addition to the interior of the room. Blinds are used on windows, as cabinet fronts, and as interior doors. Below we will describe blinds exactly like cabinet or wardrobe doors.

Possible finishing methods

Wooden louvered doors can be decorated in almost a dozen different ways. There are traditional ones and not so traditional ones. You can do the following:

- Cover with stain. The effect and appearance are known to everyone.

- Soak in wood oil. It is usually sold with color, but there are also wooden products that preserve the natural color. These compositions have antiseptic properties, and some can be used in baths and swimming pools. As a result of this treatment, the grain of the wood appears more clearly, and water is not absorbed into it. There may even be puddles. At the same time, there is no film on the surface; it is absolutely “natural” in appearance and touch.

Paint, varnish, wood oil - the most popular finishing options - Cover with varnish. This can be done after treatment with stain or without it. It is better to use water-based varnishes. They are available in glossy, semi-gloss, semi-matte and matte. The difference is in the degree of gloss of the treated surface.

- Paint it. There are a variety of paints for wood, with different effects. There are those that create a durable film, and there are translucent ones that do not paint over the texture.

- Decoupage. Equipment for creative interior.

- Inlay. A complex finishing method that gives the products a unique look.

These are all the ways to finish wooden lattice doors. In any case, it is worth remembering that before finishing it is necessary to fill all uneven areas with wood putty and let them dry. Afterwards, smooth out all the unevenness with sandpaper. And those that remained after putty, and those that were allowed during the production process. After this, we cover all the planks and frame with wood primer. The type of primer is selected for finishing. After drying, you can carry out finishing work - paint, varnish, etc.

Technical use

Due to their high air permeability, iron shutter doors have become very widespread. Wooden structures do not provide sufficient protection against intrusion by criminals. And metal blinds combine the ability to create a good barrier and provide ventilation and maintain temperature conditions. Due to this, they are often used - steel blinds can be seen at substations, blind doors

used where there is equipment that generates a lot of heat.

At home, the property of blinds to allow air to pass through is also conveniently used. Use in the toilet to save from condensation and mold has already been mentioned.

Another popular case is decorative wood louvres.

panels on heating radiators. They allow warm air to flow freely, while at the same time serving as a wonderful decoration and part of the style of room decoration.

Designer design

Metal, wooden, plastic doors with louvred grilles can have a variety of finishes. For example, wood products are coated either with a colorless compound (special varnish) that emphasizes the texture of the wood, or with a special tinting.

Moreover, in the latter case, with the help of a properly selected facing agent, you can “give” the product any type of wood (from cherry to wenge). In addition, by creating louvered doors with your own hands, the structures can be given a patina effect: such products will be a highlight in the interior.

Door systems made from MDF are usually coated with enamels of various shades and topped with a finishing varnish coating. Such products look original.

Plastic and metal door systems are presented on the market in a huge variety (white, yellow, green, etc.) Selecting a product in a particular color is not difficult.

According to designers, it is better to install blind doors in rooms decorated in ethnic or Mediterranean style, as well as eco-style. At the same time, the color design of the design is the main criterion for choosing such a product.

Expert advice

- Professional manufacturers advise: before starting work, make a draft of the future product. This will allow you to avoid making mistakes with the sizes. Every little detail must be taken into account. For example, the width of the material.

- To fill the interior of the closet, you can select special baskets for things, place modern drawers, install nets and organizers for things.

- Choice of material: laminated chipboard is a standard economy class furniture option, it requires covering the edges and does not allow moisture to enter. MDF - made from tightly compressed chips, covered with PVC film, which protects the part from liquids, can be milled and does not require an edge. Plastic (PVC) is the most moisture-resistant option and can be easily cut and processed at home. Any of the materials is suitable for filling the installation.

Subscribe to our Social networks

Advantages of furniture roller shutters

Furniture curtains are ideal for rooms with a small area - bathrooms, toilets, loggias (balconies), toilets and so on, but they also find a place in large rooms. Due to their low cost, practicality and excellent durability, these wonderful devices are gaining increasing popularity. If previously they were used only for garages and road protection mechanisms, now they can be seen in residential areas, for example, as doors for a niche or toilet.

In conditions of lack of space, when it is impossible to do without doors on shelves or on a cabinet, roller shutters for furniture are an excellent alternative to other options. Among the main advantages of such protection mechanisms it is worth highlighting:

- Easy assembly

- Functionality

- Save space

- Elegant appearance

Open and close the shutters shown in the picture by pulling the canopy up or down.

Assembling furniture blinds and curtains for a wardrobe is quite simple and does not require special skills. Before choosing them, you need to think about the type of room in which they will be installed. Caring for it is quite simple, however, in order for the canvas to retain its presentable appearance as much as possible, it is necessary to avoid sudden changes in temperature. Of course, furniture blinds are an excellent solution for a home or apartment and will perfectly decorate any interior.

Installation without drilling

Installation without drilling can be done easily and quickly with your own hands; even a woman and child can hang blinds in this way. The advantages of installation are that there is no need to make holes and spoil the profile of the plastic window. There are two options for attaching the cornice:

- on double-sided tape;

- on clamp brackets, metal or plastic.

Here it is necessary to take precise measurements; the width of the canvas should be from the handle to the hinges minus a gap of 5-10 mm on each side, otherwise the curtain will cling to the fittings and quickly break.

Types of mounting brackets for different surfaces

For clamps

Clips can only be attached to opening sashes:

- assemble the cornice according to the manufacturer's instructions; there is no need to fasten the curtain;

- put the clips on the cornice, be sure to check that they do not touch the moving elements;

- open the sash, try on the cornice in place, mark the installation locations for the fasteners;

- snap the clamps onto the fold, usually they are put on as staples or as clamps;

- hang the curtain rod and put on the canvas.

We invite you to watch a video on how to properly hang blinds with your own hands on an opening sash using special brackets.

With double-sided tape

It just so happens that if not everything, then a lot can be glued to tape, including horizontal blinds, there are 2 types of designs:

- first, brackets with hooks or magnets are installed on the tape and the curtain rod with the canvas is fastened to them;

- The tape is already glued to the cornice and it is simply fixed to the frame or glazing.

Installation steps:

wash the surface thoroughly, wipe with acetone or solvent; make marks on the sides and draw a line with a pencil, be sure to check with a level and a tape measure, the line must be strictly parallel to the surface of the window sill, otherwise there will be an ugly crooked gap at the bottom; if the geometry of a plastic or wooden window is broken, it is important to hang the cornice correctly: make a vertical plumb line from a thread and a bolt, attach it to the upper intended point and make a mark at the bottom, the same must be done on the other side; connect the top and bottom marks; attach a square and connect the 2 upper marks, the angle between the vertical and horizontal lines should be 90°, the canvas should hang strictly parallel to the plumb line, if the cornice skews up or down, the curtain will not work well and will quickly fail; remove the protective film from the tape and carefully glue the cornice along the line; fasten the cloth.

The diagram shows one of the options for fixing the brackets with tape

Installation of louvered doors

Installing louvered doors is not much different from installing regular doors. If you have chosen a double-leaf or single-leaf swing door, then its installation is carried out by analogy with a regular interior door. The same applies to sliding doors and accordion doors. All components and fittings necessary for installation can most often be purchased already complete with the door, or you can select it yourself.

Advice. If you do not have experience in installing doors, then it is better to entrust this work to specialists. This is especially true for sliding doors and accordion doors, because even a slight misalignment can negatively affect the opening of the door.

Louvered doors are now actively used in the interiors of country houses made in the “country” style. But the owners of ordinary apartments also appreciated all the advantages of these doors. Indeed, in addition to external qualities, such a door allows you not only to leave the desired room ventilated, but also to save space, which is so necessary in small apartments, thanks to the variety of designs.

Sliding louvered doors for room zoning

The light weight of louvered doors allows them to be made into screens of various sizes, with which you can zone a room at your discretion without installing additional walls and partitions, which also have high decorative qualities. If you are still in doubt about which louvered door to choose for your home, then look at the photo. Perhaps they will help you with the choice and design of the original interior.

Doors for built-in wardrobes: two available options and an alternative to them

It is considered standard to install compartment doors in a built-in closet, but besides them, there are other options, and some of them are not much inferior in their advantages to this common method of closing the closet. Let's get acquainted with the possibilities of all door manufacturing options available to furniture makers in more detail.

- Sliding doors for built-in wardrobes. This closet closing system has become widespread due to one advantage - when opening, the doors move to the side and do not create any problems when moving around. Simply, the door does not interfere with either the person or the furniture standing nearby. But besides this advantage, sliding doors for a built-in wardrobe also have some disadvantages - for example, no matter how hard you try, you will not be able to open the wardrobe completely. Maximum half. Although this point completely depends on the width of the cabinet - the larger it is, the wider it will be possible to free up space in the cabinet by moving all its doors as far as possible to the sides.

- Hinged doors for built-in wardrobes. This is a classic option that is not in fashion now - it’s no secret that the main disadvantage of such doors is the rather large space required to open them. Let's just say that if the closet is sandwiched between two walls, then problems will definitely arise with opening the hinged doors. Of course, you can put up with them, but why do this if there are better options?

- Furniture roller shutters. Despite the fact that this option can hardly be called a door, you shouldn’t keep silent about it - it combines all the advantages of swing and sliding doors. Essentially, roller shutters are installed in such a way that when opened they do not take up any useful space in the room and allow you to open the closet completely. Among other things, they are quite easy to install with your own hands. If we talk about the disadvantages of such an alternative for cabinet doors, then we can highlight only one disadvantage - the appearance, which not every person likes. If desired, you can diversify it by applying a self-adhesive film with a pattern to the roller shutters.

Roller door models and scope of application

Louvered doors have a wide range of applications. They are installed in bedroom closets, bedside tables, kitchen cabinets, and on windows. They can serve as interior structures and access to a terrace or balcony, and also act as an entrance door to an outbuilding or house, if such use is permissible in the climatic zone. They are often installed in bathrooms and boiler rooms.

Depending on the functional focus, louvered doors can be made from several materials.

- Wooden structures are classic, environmentally friendly and lightweight, but they have quite a few limitations in operation. In addition, often only residents of warm regions install them in their homes.

- Plastic structures have become very popular. They are quite cheap and tolerate changes in humidity and temperature well. But often the slats of a plastic product are made of solid casting, and, as a result, they do not have the ability to replace individual elements in the event of a breakdown.

- Metal (often stainless steel) louvered doors occupy a special place. They are not afraid of moisture and temperature changes. The big advantage of metal structures is that they are very durable, capable of providing security and protecting the premises from intruders. However, the decorative effect of such products is not suitable for housing, so they are installed as an entrance to technical rooms that need good ventilation and maintaining a stable temperature.

Required materials and tools

First of all, to make doors you will need high-quality dried wood. An importance of no more than 12% is allowed. Also, the presence of knots and other defects in the wood is not allowed. You will also need to stock:

- PVA glue.

- Finishing materials: dowels, varnish,

- Tools for assembly: mallet, hammer, screwdriver. Self-tapping screws are usually used as fasteners.

- To process wood you will need a sanding machine. You will need medium to fine grit sandpaper.

- For marking you will need a ruler, tape measure, and pencil. To install the elements correctly, prepare a level (bubble type, construction) and a plumb line.

- To make lamellas quickly you will need a milling cutter and a thickness planer.

As you can see, a fairly wide range of tools and the ability to use them at a good level are required. Therefore, it will often be a better decision not to make the doors yourself, but to turn to manufacturers.

Assembling a cabinet with blinds

If you have read the article to this point, it means that you have some experience working with power tools and you can assemble a cabinet with louvered doors with your own hands. As you understand, the key point in such an assembly is the blind doors, and they can be hinged, sliding or made like shutters. In any case, blinds should not only serve as a beautiful decoration, but also as ventilation for the contents of the closet, which is very convenient in bad weather when you have to leave wet clothes on the hanger.

Closet

I will not tell you how to make the closet itself, since my goal is to explain how to make shutter doors with your own hands. However, I am posting several drawings for assembling cabinets so that you can use them if necessary. If you want to use these drawings, then instead of regular doors (solid or with a mirror), you will need to install a shutter door. In addition, you can use an old cabinet by removing the doors from it and remodeling it to suit your needs. But if you do assemble this furniture yourself from scratch, I recommend using laminated oriented strand board (OSB) for this purpose.

What do you need for work?

For work you will need materials:

- bars and boards (needles):

- any wood glue or PVA;

- wood varnish, clear or stained (to your taste).

Prepare the following tools:

stationary or hand-held circular saw (circular saw);

jigsaw;

thicknesser (may not be needed if the thickness of the workpieces matches the thickness of the parts);

manual frezer;

grinding tool (grinder or grinder with appropriate wheels);

clamps of any type;

tape measure, square, pencil;

conductor (you need to do it yourself).

Conductor

The assembly of the blinds is done according to the drawings, but first you need to make a jig (template) so that all the slats are symmetrical with respect to each other after installation. The top image shows the principle of making a jig, which will allow you to make grooves on two posts at the same time, which will lead to perfect symmetry. Of course, the holes in the form of a stencil can be placed at a different distance from each other, but this does not change the essence.

The photo shows that there are holes for dowels at the bottom. That is, you first arbitrarily cut the first two grooves, and then insert dowels into these holes and, clinging to the groove with them, cut out the next one, and so on until the end of the racks. In the center of the jig (along) there are two more holes for dowels, which allow you to fix a gasket of the required thickness - it will move the posts apart if there is a need for it. If the posts come into contact when cutting the grooves, then you can simply remove the jumper from the jig. Recommended groove length 30 mm and width 8 mm.

Shutter doors

Procedure:

- Take a 50x50 mm sanded block and cut two posts to the height of the doorway in the closet.

- Place the two pieces together and join them together.

- Place the jig randomly on the blocks, using a square to cut out the two bottom grooves, but secure the template with a clamp so that it does not move.

- Then insert the conductor dowels into the cut grooves and continue removing them to the end of the posts.

- Now you need to make lamellas 30 mm wide and 8 mm thick, which will correspond to the selected grooves, and round their edges with a grinder or grinder with a turtle disk.

- Insert the upper and lower slats into the grooves of the racks and temporarily tighten them with clamps. Now you can measure the crossbars for the door frame and cut the block to the required length.

- These jumpers will be fixed with dowels and carpentry or PVA glue.

- Now you can start assembling, but first coat all the grooves and dowel holes with wood glue.

- Insert the slats into the grooves and secure the jumpers (top and bottom) with dowels.

- Tighten the assembled structure in three places with clamps and leave for a day until completely dry.

- Open the product with the varnish that you prepared for this and after drying the doors can be installed on the cabinet.

Photo report on the assembly

First, all profiles are cut exactly to the calculated dimensions. The accuracy must be perfect. The cut is strictly perpendicular, at 90°. Holes are drilled in the handle profiles for installing rollers and fasteners.

The holes are made through two diameters. The exact size depends on the dimensions of the purchased fastener, but basically there are two sizes: 4 mm and 6 mm, as well as 6 mm and 10 mm.

How to drill holes

One such hole is made at the top, the center of which is located at a distance of 7 mm from the edge of the profile, at the bottom there are two holes - the first at a distance of 7 mm from the edge, the second at a distance of 42 mm from the profile cut.

Holes at the bottom of the side profiles

During assembly, all parts of the filling are assembled first. First, if there is glass or a mirror, sealing rubber is installed around the perimeter. It is simply put on the end of the part by pressing a finger. The seal is cut off along the edges and placed end to end, but without overlapping on the next side.

Seal on the mirror

A protective film is glued to the back of the mirrors. You can use regular self-adhesive. This film will prevent fragments from scattering if the mirror breaks.

If the sash is composite, we assemble it using connecting profiles. The filling parts are simply inserted with force into the profile. Sometimes considerable effort may be required. You can tap the end with the back of your hand or use a rubber mallet for this.

Simply insert the filling parts into the grooves of the profile and tap on the end

When the sash is assembled, the corresponding profiles are installed at the top and bottom using the same principle.

Top profile installed

Then it’s time to install the side handle profiles. Everything is the same: push the filling into the groove, make sure that it fits all the way along the entire length without distortion. When the frame is assembled, it is necessary to tighten it with fasteners. Let's start from the top. Take the fasteners and insert them into the previously drilled hole. If the distance was measured accurately, the screw fits into the groove of the upper cross member.

If drilled correctly

Tighten the connection using a hex wrench. Slightly not tightening it all the way, insert the upper rollers between the screw head and the profile jumper, then tighten the screw.

Insert the upper rollers

We repeat the same operation on the other side. Then we move down. Here the fasteners are installed in the upper hole. Just tighten it all the way. We repeat similarly on the other side.

Install the fasteners from below

Next, install the lower rollers. We insert the thrust plate into the groove and press it.

Installing the lower roller - insert the plate into the profile

We press the spring, tucking the roller body inside. We insert a screw into the hole, trying to get into the socket, and tighten it with a hexagon. You may need it in a different size - slightly smaller than the others - since this screw is usually thinner and longer.

Press the roller, insert the screw

There is no need to tighten it all the way. So that it goes into the plate half a centimeter or so. Then, when installing the door and adjusting its travel, this screw adjusts the position of the sash - the angle is raised or lowered.

Tighten the screw that fixes the roller

If you press the roller wheel, it will go into the housing, then return due to the elasticity of the spring. This simple mechanism ensures smooth movement of the sliding wardrobe door.

First screw on the top guide. It is attached either to the ceiling or to the top of the cabinet. The distance from the shelves is at least 100 mm, otherwise the doors will touch shelves, things, and hangers.

Screw on the top guide

We insert bumper springs into the grooves in the lower guide from the sides. They will limit the movement of the door. The number of springs is equal to the number of leaves; they are installed at both ends.

Door stoppers

Insert travel limiter springs

If you don’t have a laser level, so you don’t have to worry about plumb lines, you can start by simply laying the bottom guide without fixing it yet. Then install one blade, placing its upper rollers at the top and installing the lower ones in the desired groove. This way the doors will connect the upper and lower guides.

Having aligned the sash vertically, automatically align the bottom guide

By aligning the canvas strictly vertically, you will automatically align the lower guide. All that remains is to screw it on. Just be careful that the doors do not move.

The last thing left to do is to glue the Schlegel on the sides. This is a fleecy self-adhesive strip that softens the impact of the sash on the walls of the cabinet (or simply on the walls, if the cabinet is frameless).

The final touch is the Schlegel sticker

Here the wardrobe doors are installed and ready to go. You can watch the process again in the video.

Application area

The scope of use of louvered doors is determined by their properties. They are indispensable in rooms that require constant ventilation.

At the same time, the degree of sound insulation should not be important for these rooms. There are several such rooms in our houses and apartments:

- Technical rooms - storage rooms, laundries, wardrobes. In the case of dressing rooms, it is worth thinking about the feasibility of this option. After all, it is advisable to protect clothes from dust. A compromise is possible: make a louvered grille in the upper part, where there is less dust and the warmest air accumulates.

- Bathroom.

In the bathroom, it is desirable to quickly remove excess moisture and louvered doors will help with this. But this option is only good if the bathroom is separate, since a combined bathroom will become a source of not very pleasant sounds and smells. Louvered doors to technical rooms are an excellent option to achieve ventilation without organizing a special air duct - Boiler rooms facing the street. The street door for such a room may have a louvered grille. Only it should be adjustable so as not to make the room too cold in winter. One thing: before installing such doors, check with your local fire department. Just in case.

In addition to serving as doors between rooms, louvered structures can be used in furniture. They are good:

- In kitchen cabinets, both floor and wall mounted. In the dryer and the cupboard with cereals they provide quick ventilation, in the rest - more like decorative ones.

- In cabinets that cover the pipes in the toilet as an enclosing structure.

You can hang them on hinges, or you can put them on magnets. In bathrooms, toilets, kitchen cabinets can be used as cabinet doors - As blinds on windows. The problem of light scattering is solved very well. It does not cut off completely, creating twilight lighting.

- For wardrobes, chests of drawers and other furniture located in living rooms. The advantages in this case outweigh the disadvantages, and the appearance is interesting.

Another area of application is as shading structures with a large glazing area. On terraces, winter gardens, large balconies and loggias with continuous glazing. Why are louvered doors better than regular blinds? The fact that “fixed doors can be opened while leaving shutter doors closed. There will be free air access and there will be no too bright light.

Louvre doors can be used as shading

As a partition that delimits a room. For example, fencing off the sleeping area in a studio apartment. This option is ideal if there is no window in the fenced off area. Such a partition will provide air access, let in sufficient light and create privacy.

A partition made of blinds to separate the sleeping area

In principle, louvered grilles can be used for other purposes than their intended purpose - as a notice board, a screen, covering or separating something.

Wooden louvered doors for wardrobes, bathrooms and toilets, kitchens

All photos from the article

Louvre doors have been used by furniture makers, builders and other specialists in one way or another connected with interior design and building equipment for centuries. They are periodically forgotten, then again, having remembered, they are actively used in the most expanded range of areas. In our article we will describe possible options for using such products.

Doors with horizontal rivers improve ventilation of living spaces

Possible options for the location of wooden shutter doors

Standard wooden shutter doors for cabinets are installed on cabinet furniture as facades. Below you will learn how to apply them directly in this way and “outside the box.”

Bedrooms and living rooms

As you know, the best storage for clothes, linen and other things are wardrobes and chests of drawers.

So, a louvered cabinet facade has several advantages over solid doors:

- Possibility of ventilation (things can “breathe”), which significantly improves the quality of storage.

- As a result of good ventilation, moths will not appear in the closet.

For your information! The moth does not like dry and fresh air; its best habitat and breeding habitat is humid, warm nooks with a stagnant climate.

Two types of furniture are used for the wardrobe:

“Ventilated” furniture allows you to avoid the appearance of unpleasant odors on clothes

Regardless of the design features of the clothing and linen storage, louvered doors can be used, installed in various ways:

- Using furniture hinges for wooden door frames, the leaves of which open and close in the usual way.

- With a set of guides for wardrobes with sliding doors.

Wardrobe rooms

Now it has become fashionable and, I must say, affordable for large apartments to arrange entire dressing rooms. So, on the line between the space of the dressing room and other rooms (usually the bedroom), it is customary to install louvered doors. For dressing rooms, in addition to the two methods of fastening doors described above, the “accordion” option is possible.

These doors fit especially well in wooden rooms, where they blend with the interior

It is possible that wooden shutter doors can be installed inside a room – a wardrobe, or on separate parts of a “storage room”.

Bathrooms and toilet rooms

Doors with slats look very impressive in bathrooms and toilets.

In these rooms, blind doors are used:

In the photo - all unsightly communications under the washbasin are hidden in this way.

- Bathroom screens.

- Panels for decorating niches with pipes, shut-off valves and metering devices.

- Screen for water heating system.

Attention! For covering water supply and wastewater pipelines, as well as for the boiler piping system, ventilated structures with blinds are a priority.

The instructions recommend their use, as this will help avoid condensation on communications.

Kitchens

Following the same principle as in bedrooms, louvered facades are installed on kitchen units, usually made of natural wood. Cabinets for storing groceries, just like clothes, need constant access to fresh air to prevent the appearance of cereal bugs and moths.

In addition, it is worth noting that regardless of the installation location, louvered doors make the interior of the furniture and room extremely attractive and unique.

Design of openings

Separately, we should talk about the equally frequent use of such doors in the design of windows, balconies, and doors. This style “a la Provence” is in great demand today not only among the French.

Louvered wooden painted doors are installed as shutters both indoors and outdoors. In any case, they are not only a decorative element that makes the appearance of the openings from the outside completely complete and quite elegant.

Covered up on a hot summer day they:

- They will protect from the heat without interfering with the free circulation of air.

- They will not provide complete blackout like blind shutters.

Other Applications

The use of louvered doors does not end there.

You can make wonderful decorative elements from them:

- False shutters for openings and street buildings.

Louvered doors can be installed as both entrance and interior doors

- Screens - for dividing space, for small partitions separating, for example, a bedroom from a ladies' corner.

- Ventilation grilles for heating devices.

With the help of blind products, huge radiators will no longer confuse you and your guests

Purchase or self-production

Recently, simple door designs - blinds made of pine - have been sold in domestic stores. Their price is quite affordable, and, what’s even more pleasing, there are a variety of sizes of wooden louvered doors.

Here are some of them:

- Width options - 294, 394, 494, 594 mm for all door heights shown below.

- Heights – 606, 720, 993, 1100, 1700, 2013, 2422 mm.

As you can see, the range of dimensions is presented in abundance; anyone can choose the appropriate option for themselves and do the finishing and hanging on site with their own hands.

You can also purchase more expensive louvered doors made of valuable wood, painted at your discretion.

Without a doubt, there are woodworkers who can make similar cabinet doors to individual sizes on their own. (See also the article Wooden stools: features.)

Conclusion

The use of the above-mentioned products is not limited to generally accepted standards; in this case, only two things serve as the framework: financial capabilities and your ideas. To come up with something unusual, look at non-standard solutions using blind doors on the Internet.

Types: wooden, plastic, metal

A shutter door is a durable frame into which thin slats are inserted. The slats are inserted into the frame at an angle to block the path of light, so the louvered door is impenetrable to prying eyes. But the gap between the slats allows air to pass through the canvas.

Since the lamellas are very thin, they are not able to provide high structural strength. The role of the load-bearing element in a louvered door is played by the frame. A handle, hinges and other fittings are attached to it. If necessary, you can even embed a lock into the frame, but a louvered door, for obvious reasons, cannot be a reliable barrier.

A number of materials are used to make doors of this type:

- Tree. Wooden slats look the most luxurious. This door will serve as a decoration for various interiors. The main disadvantage is the high cost, although the price of a louvered door will be somewhat less than that of the same door made of solid wood. This material is also afraid of high humidity, because... wood tends to warp and swell from water.

- Aluminum alloys. This is the most durable material used in the construction of louvered doors. The strength and durability of the material allows the use of such doors in technical rooms, storage areas, etc. In addition, aluminum is not afraid of moisture. Disadvantages: high price and relatively heavy weight of the structure.

- Polymer profile. This is the most budget option, which is inferior in strength to aluminum, and in aesthetics - to wood. The main advantage of plastic shutter doors is their affordable price for a wide range of people.

When designing doors, blinds can be combined with other elements. For example, doors look good if the two lower quarters are made of solid wooden panels, and the two upper segments are filled with slats.

The design solutions also differ. Blind doors can be hinged (with one or two leaves), sliding or folding like an accordion. Such a variety of design options allows you to fit louvered doors into almost any interior.

Read the series of articles about doors: How to install an accordion doorInterior doorsHow to make sliding doors with your own handsInstalling plastic doorsInstalling entrance doors instructionsDo-it-yourself soundproofing of doorsDo-it-yourself plywood doors

Where to buy

You can even make louvered doors for a home closet with your own hands, according to the algorithm indicated by yours, and it is also possible to buy ready-made products. The main thing is that you know about the best stores and online sites that offer high-quality shutter doors for built-in wardrobes. The price for such canvases can be very different for the same type of product, and therefore, ideally, you should compare prices and models, and then choose the best option. And to make it more convenient to compare, we suggest considering the popular construction hypermarket Leroy Merlin, as well as other less popular manufacturing companies LTK Kedr, Rehouse and Profi&Hobby.

| 1.8*0.494 meters | 1.995*0.394 meters | 2.013*0.594 meters | |

| Rehouse | 1450 rubles | 1290 rubles | 1939 rubles |

| Leroy Merlin | 1100 rubles | 954 rubles | 1560 rubles |

| LTK Kedr | 900 rubles | 790 rubles | – |

| Profi&Hobby | 930 rubles | 840 rubles | – |

The table above shows popular and standard sizes of blinds. The manufacturing materials presented at Rehouse and Leroy Merlin are polished pine needles, while LTK Kedr and Profi&Hobby use pine. By the way, pine and pine needles are environmentally friendly wood materials that have a rather beautiful and unusual texture of natural origin. In the event that the dimensions of the built-in doors in the form of blinds must be non-standard, then the companies described earlier offer the manufacture of canvases to individual sizes. The price for these types of structures varies from company to company. It depends on the material of the products, as well as the fact whether this company is a manufacturer. For this reason, before purchasing, it is worth finding out the price offered by several companies, assessing the quality of the product, and then making an informed choice.

How to install doors

The installation method for louvered doors is determined depending on where they need to be installed. For example, cabinet doors are simply fixed to the walls with hinges, maintaining evenness. If the canvas is mounted as an interior door, then you must first assemble the frame and secure the hinges on the vertical post of the door and frame. The following events are carried out:

- The box is installed in a flat opening, secured with wedges that are secured between the wall and the box posts. By adjusting the wedges, the structure is leveled, and then the cracks are sealed with foam. After this composition has dried, the wedges are removed.

- The canvas is hung on hinges and the levelness is checked using a building level. If necessary, the hinge screws are tightened or loosened.

- Holes for a lock or handle are made in the canvas in advance, and after hanging, the mechanisms are installed.

- Check the quality of installation. If the door touches the frame when closing, you need to adjust it by fixing the screws.

Installation of a louvered door is carried out in the same way as an interior door

At any stage of installation, it is important to control the evenness of fixation of each element. This way you can prevent the box canvas from touching the floor and causing abrasions.

Repair and restoration of wooden doors

Louvered wooden doors have a lower level of strength than other options. Therefore, even minor faults should be corrected in a timely manner, which will prevent more serious breakdowns. In the most common options, the following actions are taken:

Deformation of planks and cracks in wood. Such damage to the slats requires their replacement. If they are not fixed with glue during manufacture, then the structure can be disassembled and the elements replaced. Otherwise, the door is completely replaced, since the panels held together with glue cannot be carefully removed. Broken lock or handle. If the lock or handle is broken, you need to carefully remove the old mechanisms and install new ones in their place, which have the same dimensions. Cracking of varnish or paint. If the paint is cracked, you will need to disassemble the structure, remove the old paint and apply a new coating. Formation of scratches. Small scratches on easily accessible surfaces of the door are repaired with furniture wax or wood-colored putty. Updated appearance

An unpainted but assembled door can be coated with a colored compound using a spray gun, but it is important to carefully treat all hard-to-reach places.

If the lamellas are located freely, then painting is possible already assembled

Repair and restoration of canvases with lamellas require care, because such structures are not solid and consist of thin slats. Therefore, when removing a door, for example, to repair and replace hinges, everything must be done carefully.

Video: painting doors with a spray gun

How to care for louvered doors

Regular care of such doors involves removing dust with a damp cloth, treating them with furniture polishes and other products for wood products. And you also need to carry out an inspection about once a month to identify faults and eliminate them in a timely manner. It should be noted that louvered models are not resistant to strong impacts, loads and mechanical influences. Therefore, they often serve as lightweight partitions.

Any doors require proper care

During operation, the following measures should be taken:

- When squeaking occurs, door hinges are lubricated with grease, door lock products, and WD40, which will ensure the elimination of unpleasant sound and easy movement of the door leaf.

- Regular treatment with furniture polish will prevent the accumulation of dust and dirt. The product should be wax-based; it is applied to a soft cloth and wiped over the surface.

- You cannot remove stubborn stains with hard sponges, as this will lead to deep scratches and loss of the appearance of the structure. Difficult stains can be removed by light sanding with fine-grit sandpaper, painting or thorough washing.

How to finish the opening after installing the enclosing structure

When the door frame and leaf are mounted, it is necessary to modify the opening by installing framing elements - extensions and platbands. This will require the following algorithm:

- The remainder of the opening is measured after installing the box.

- The extension strips are marked with a pencil.

- Elements must be cut in strict accordance with the markings using a circular saw

- The extensions are fixed into the opening using dowel-nails or polyurethane foam.

- The correct installation of accessories is monitored.

- The trim strips are cut in place after the measurements have been taken.

- The finished framing elements are assembled on the wall, in the plane of the opening.

- At the final stage, each mounting hole in which self-tapping screws are installed is closed with decorative plastic caps of the desired color.

- If necessary, an elastic sealing tape made of rubber, polyurethane or soft silicone is placed around the perimeter of the rebate.

Installation of additional equipment

Before installing the trim, experts recommend finishing the walls and floors in advance, as well as installing the baseboard, since the decorative elements must fit together in place, without creating any gaps.

Correctly installed louvered interior door

If all the algorithms described above are strictly followed, the louvered door will be in use for at least 20 - 25 years, without the need to replace it or perform major repairs.

Laminated varieties

As you can see from the reviews, side doors made of laminate are the most budget option. The decorative coating is applied to the MDF strip frame. The film material is created from prepared paper that imitates wood. To make the product stronger and more resistant to moisture, the base is impregnated with resins. It is worth noting that such modifications are not intended for installation in rooms with high humidity levels. In addition, laminated models are not recommended for installation if there is a high risk of external influence (small children, pets).

Manufacturing material

Louvre doors can be made from various materials.

- plastic;

- metal;

- wooden;

- MDF products.

So, for example, wooden products are made from well-dried wood (usually pine is used for this, less often alder, beech and oak), which is divided into separate layers and glued into dies. This technology of wood fusion makes it possible to obtain a unique product: this structure is resistant to adverse external influences, moisture and temperature changes, and therefore can be installed even in rooms with high levels of humidity.

Metal and plastic louvered doors look very stylish and beautiful, so they play a special role in the interior. As a rule, metal and plastic products are either purchased ready-made or made to order. But wooden louvered doors and MDF structures can be made with your own hands if desired.

Installation of louvered doors

If, for example, you made wooden louvered doors for the toilet with your own hands, you will probably be able to install them. It’s another matter if you bought a ready-made kit and decided not to call a specialist.

In this case, you will need some advice:

- First of all, unwrap everything you brought from the store and see what is there. As a rule, these will be sashes, fasteners, a lifting mechanism and instructions. You need to carefully study the installation rules so that everything works the first time.

- The first step is to take measurements. After this, you need to measure the size of the guides and immediately cut them.

- Now install the spiral mount on the drill and make holes for the mounts in the guides.

- The guides must be installed on the base or in the opening, secured, and then latched.

- Next, mark the position of the axis at the upper end of the left blade. You need to make a hole in it. The upper part of the axle should protrude beyond the end. Using the same scheme, you need to install the lower axle.

- Now let's start installing the hinges. Lay out all parts of the door on a flat surface. You need to leave a gap of 2-3 mm between them. Three loops must be distributed at the same interval. Now you should mark where the hinges will be on the sash - holes are drilled to install them. Awnings are attached to the structure.

- Louvre doors are secured into place when folded. The lower axle is placed in the receiving plate, and only then the upper one is installed.

You should check whether the mechanism works and everything is in place. If the sash does not hold well or you have to jerk it open, it means you did something wrong. If everything is holding well, the blinds are secured and can move along the correct trajectory, then the installation has come to an end and you can use the door.

Design features

Louvered doors have a unique design: they consist of a rigid frame and dies. Moreover, the angle of inclination of the horizontal slats is such that one element does not overlap the other. At the same time, this arrangement of the dies allows you to hide everything that happens in the room from prying eyes and at the same time ensures proper air circulation.

It is worth noting that shutter doors of standard sizes on the modern market are represented by a huge range of models, numbering hundreds of varieties of products.

However, if the plastic, metal and wooden structures offered to the buyer’s attention do not meet his needs, he can always order a unique product or make a blind door with his own hands. In most cases, factory-made blind structures are rectangular in shape, but door systems made by hand or to order can be square, polygonal, semicircular, etc.

For fastening, either standard hinges or mechanisms used in compartment systems can be used. Since most blind structures are lightweight, to move the shutters it is enough to install the upper guides.

Advantages and disadvantages

Furniture blinds for cabinets have the following advantages:

- rational distribution of functional space;

- simple, easy installation;

- light weight of the material, good ventilation due to gaps;

- long service life;

- you can perform simple repairs or restore damaged areas;

- neat, attractive appearance.

Blind cabinets also have disadvantages that can help when choosing a design for a home, office, or apartment:

- the finished product has a relatively high cost;

- painting or opening with varnish becomes difficult;

- the contents of the cabinet are not protected from the penetration of odors from the room;

- it is necessary to carefully control the humidity level (the doors may become deformed);

- the coating of the lamellas directly depends on sharp temperature fluctuations.

The main positive and negative qualities of this type of design

An installation that is equipped with louvered grilles is in itself a specific thing. She has peculiarities and negative traits. In order to clearly understand whether you should install blinds yourself, first consider the positive aspects:

Good level of air circulation. This parameter is influenced by the space that exists between the individual slats. In addition, the moisture that will enter the room does not remain on the structure and the service life is extended;

Lamels - close-up view

Installing louvered doors also has disadvantages. And the most significant of them is that such a design will not be able to fully provide the required level of sound insulation. She simply doesn't exist. Therefore, the scope of their application is narrowing. But the second drawback is the cost. Due to the complexity of their design, such doors become more expensive than conventional door leaves.