Wood has not lost its popularity for many centuries, but the material has a significant drawback: its decorative properties and reliability are lost due to external factors. You can increase the durability of a wooden product by using special solutions that can create a protective barrier from external factors. Often for this purpose they choose to cover the wood with stain or varnish. The features of each product, advantages and rules for their use will be discussed in detail below.

Color spectrum

Beitz is a unique product that helps give wood a noble shade.

The structure of the wood is heterogeneous, different areas are impregnated unevenly, therefore, after the composition dries, an original pattern is created on the surface. The most popular shades of stains are included in the wood range; their names correspond to different types of wood. When purchasing, you should carefully consider the samples on which the stains are applied, because the shade on the label and in reality may not match. The finished color will depend on the following factors:

- original wood shade;

- degree of porosity of the material;

- density;

- breed;

- amount of resin.

Deciduous wood is impregnated much better than coniferous wood, so the tone will be as close as possible to the stated one. To give a light shade, you can purchase a lightening impregnation, which also tends to emphasize the wood grain. There are even colorless stains on sale that do not change the color of the wood, but still have full protective properties.

How to choose the right stain

Stain or, as it is also called, stain is a finishing coating for wood, which, without painting, favorably emphasizes its structure. It consists of a pigment and a base, which can be water, alcohol, or oil. Recently, water-based stains based on acrylic resins have become very popular. In addition to being decorative, they have the properties of a good antiseptic.

Another type of stain is wax. The thin film of wax that forms when covering the surface with stain gives not only the decorative effect of natural wood, but also reliably protects it from water.

When choosing a stain, you must be guided by the following criteria:

- Operating environment (external or internal work). Exterior stains contain pigments that are resistant to ultraviolet rays.

- Composition safety. In children's rooms or children's household items, stains without harmful compounds are used. These include water-, oil- or wax-based stains.

- Powdered or ready-made stain. Water and alcohol stains are also available in dry form. They must be bred at home. If there is any doubt that the desired result will be obtained, then it is better to give preference to ready-made stain.

- Method of applying stain to a surface. It is better to apply alcohol stains with a spray gun, as they dry very quickly and it is difficult to achieve an even coating. Small objects and surfaces are covered with brushes, foam rubber or fabric swabs. For a large finishing area, use a sprayer.

- Design solution for interior or exterior. It is important to know that the sample presented in the store often differs in color from what is obtained during finishing. The reason for this may be different species and structure of the tree, lighting. Even different batches of the same type of stain have differences in shades when coating.

Making an antique effect

An interesting effect of aged boards can be achieved by using, for example, white water stain as the main tone. After drying this layer, apply a layer of gray or black thick wax stain, which will emphasize the texture of the wood. In this way you can combine stains of different colors.

The appearance of worn, erased boards is achieved by applying a water-based stain to the surface as a background. Without letting it dry, you need to wipe off part of the stain in the right places, imitating abrasion. After complete drying, cover the surface of the product with a second layer.

The stained surface of the wood is lightly burned with a gas burner to reveal the texture. Firing can be done only after the stain has dried. Next, the surface is cleaned with a shoe brush.

A beautiful effect with a pronounced wood structure is obtained by applying the first layer of white water-based stain. After drying, an oil stain with the addition of melted wax is applied to the main background.

Not all stains have antiseptic properties and can protect wood from the influence of the external environment, so it is better to varnish the treated wood to extend its service life.

rmnt.ru

20.04.16

Antique doors highlight the design solutions in the room. To update the interior of the house in this way, an “antique” wooden door is created. Several technologies are used for this:

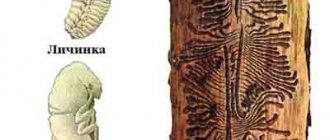

- Brushing is a simple technique that is used by many craftsmen. The work is done with an iron brush, with which the top layer of wood is removed (until the annual rings appear). But this technique of giving the door an antique look requires a large amount of varnish;

When brushing, the top layer is removed with a metal brush. Patina is a special paint that is often used to create the effect in question. The technology for applying the mixture consists of choosing the desired color and applying 1 main layer, which is subsequently covered with paints or varnishes, but of a lighter shade.

Patching gives the wood the effect of multiple paintings

- aging with wax - to perform this technology, you will need to follow a certain sequence: applying wax - painting in a lighter tone. After complete drying, the paraffin is removed. A spatula is used for this. Then the base is sanded. Varnish or stain is applied. The door is treated with wax. It is this technology that allows you to create a “antique” appearance that is as close to the truth as possible.

If you have old doors, then it’s easier to update or restore them a little.

Popular manufacturers

Today there are a large number of stains from different manufacturers on the market. It is difficult to choose the best: many products are of excellent quality and have a reasonable price. You can buy stains at any hardware store: IKEA, Maxidom, Leroy Merlin and others. The selection of a good stain for woodwork can be done from the following list:

- "Novbytkhim" (NBH). Water-based, odorless stain that forms an abrasion-resistant coating. Helps to tint doors, baseboards, railings, trim, boards and other products. It has a rich palette of shades and can be used in decoupage.

- Coswick Wood Stain. Alcohol stain for tinting and protecting wooden bases. Helps to repair minor scratches, chips, and finish edges when installing parquet. Combines perfectly with varnishes.

- "Rainbow 21". Acrylic stain contains special substances to protect against mold and wood-destroying fungi. Has a high degree of adhesion to all types of wood.

- Zar. A quick-drying composition for interior and exterior work, with a self-leveling structure. Apply to wood without stains or streaks.

- Tikkurila Pirtti (Tikkurila Pirtti). A colorless stain that can be tinted according to the Tikkurila pigment catalog in absolutely any color: mocha, antique, villa and others (36 glaze shades).

- Liberon. It is used for the restoration and protection of wooden surfaces, suitable for indoor and outdoor work. The product is resistant to UV radiation.

- Varathane (“Varatan”). Oil stain made from transparent soybean oil, has pure natural shades, and is characterized by deep penetration into the wood.

- Zerwood. Stain is water-based and comes in many colors to match noble types of wood.

- Minwax (“Minwax”). Oil impregnation, which gives beautiful shades to wood and protects products from water and ultraviolet radiation.

- Pinotex Interior (“Pinotex Interior”). Water-based decorative impregnation is widely used for finishing work and protecting wood from external factors.

- "Krafor". The product is used on products used inside and outside buildings. The finished coating is highly polished and does not require varnish.

- "Biotex Universal". Antiseptic impregnation, highlights the wood structure, gives a beautiful shade, extends service life.

- "Vertex". A popular inexpensive water stain that comes in a wide range of shades: rosewood, ebony, beech, walnut and many others.

- Tury. A wood-protective stain that produces an attractive matte finish. Emphasizes the structure of wood, protects against microorganisms.

- Renner. Concentrated product with an emphasizing effect, water-soluble, has 17 basic shades.

- "Latek". Used to highlight wood fibers. Does not fade under the influence of light, is applied evenly, and has high moisture resistance.

- "Belinka". A wax-based wood coating designed for long-term protection of wood from any external factors.

- Herlac. A line of environmentally friendly stains without harmful components. Can be used for any joinery, chipboard, lining, veneer.

How to paint a wooden door?

The paint for the door leaf must meet high performance characteristics and be safe for human health. Conventionally, paint and varnish materials are divided into two groups:

- It is better to paint new wooden interior or entrance doors with transparent varnishes and impregnations. The applied layer is a decorative glaze that does not hide surface defects. A transparent coating can highlight the interesting structure of new wood.

- Opaque paints or enamels for windows and doors are made from solvents with added pigments. Under a new layer it is easy to hide wood defects, uncleaned areas of old paint, or simply give the door block a new original look.

Most often, when restoring a wooden door, preference is given to opaque paints.

From a wide variety of interior work, it is best to choose safe water-based paint or varnish. From the street, a wooden canvas can even be coated with nitro paint.

We suggest you read: What is penoplex glued to?

Alkyd paint

It is advisable to use alkyd paint during major renovations when no one lives in the apartment. During this period, all toxic odors will have time to disappear. The dried surface can be matte or glossy, but in any case it repels moisture well.

Alkyd quick-drying enamel is characterized by the presence of a pungent odor. Its popularity is justified by the variety of colors, low cost, and resistance to aggressive environmental influences.

Alkyd varnish

Due to their transparent structure, it is better to cover a new wooden interior or entrance door. The disadvantage is the strong odor and long drying time. A shiny transparent glaze will highlight the beauty of natural wood.

Acrylic paint

The best choice to paint interior wooden doors indoors. The advantage of the coloring composition is the absence of a toxic odor, as well as the ability to preserve the wood texture. A thin layer allows the wood to “breathe”.

Acrylic enamels dry quickly, and after painting there is no toxic odor indoors. Another advantage is the large selection of colors. The disadvantage is the high cost. After drying, the surface becomes matte. Additional opening with acrylic varnish further increases the cost of painting a wooden structure.

Acrylic lacquer

Acrylic varnish is perfect for covering a new, unfinished interior door. The non-flammable composition, harmless to human health, will preserve the color and texture of the wood. The wooden door leaf on the street side is not coated with acrylic varnish.

Thermal enamel

It is unreasonable to use it for an interior door block. The paint is expensive and its main purpose is to protect the painted surface from low and high temperatures. If desired, you can paint a wooden or metal door at the entrance to the house. Thermal enamels differ in their scope of application. For wooden panels, Bosny aerosol paint is suitable; depending on the brand, it can withstand heating up to a temperature of 200°C or 650°C.

Nitropaint

The most durable and durable paint for wooden doors is nitro varnish or nitro enamel, but it is better not to use it for interior door blocks. They are highly toxic and can only be handled in well-ventilated areas. Nitro paint is suitable for the front door. If it needs to be removed in the future, it will not be easy to do.

Polyurethane paints, characterized by good adhesion to wood, are gaining popularity. With proper preparation of the wooden surface, you can not be afraid of the appearance of blisters on the door. The dried layer of paint is completely harmless to humans, retains its bright color over a long period of use, and is also resistant to scratches. The main advantage of the polyurethane layer is elasticity. If the wood is slightly deformed, cracks will not appear in the paint.

Sequence of work

High-quality finishing is obtained only on a surface that is free of dust, dirt and grease, without defects in wood processing. If the surface of the wood has already been painted with something, then the old finish must be completely removed. Coniferous wood needs to be deresined.

The cleaned surface is sanded twice. This is done first with coarser sandpaper (No. 120), then with finer sandpaper (No. 220). Wood sanding is carried out only along the grain. The resulting dust is removed with a damp cloth, and dirt with some solvent or alcohol.

The stain can only be applied to a clean and dry wood surface. In order not to make a mistake with the color of the coating, do a test paint job. You need to take a small sample. First, cover it with one layer of stain, after 2/3 of the sample has completely dried, cover it with a second layer. The third layer should cover 1/3 of the wood piece. This will allow you to choose the finishing option you like.

Application methods

With a brush you can apply almost any stain to the prepared surface. Difficulties arise only with alcohol-based stain due to rapid drying. The vertical surface begins to be covered from below so that smudges are not absorbed by unpainted wood. This significantly improves the uniformity of the coating.

The second and subsequent layers can be applied after the previous one has dried. For oil-based stains, the drying process lasts up to 3 days, for water-based stains - up to 3 hours. The coating is applied along the wood grain. When painting a surface with a brush, it is important not to go into adjacent areas that have already been treated with stain. This way you can avoid unwanted stains.

Water-based stain can lift wood grain. After the first layer, wait for the stain to dry and sand the surface with sandpaper. Then remove the resulting dust and cover the surface with the next layer.

The stain is applied using a swab by rubbing in. This method is only suitable for small surfaces. A tampon can be made from a piece of foam rubber or thick fabric. Wax sealants are applied using this method. It allows you to achieve uniform surface coverage. This is especially true for rocks with a porous structure.

Spraying stain onto a wooden surface is most often used for large areas of coverage. Alcohol-based stains dry quickly and during their application, for example, with a brush or swab, it is difficult to avoid spotting. Spraying with a spray gun allows you to achieve a high decorative quality of finish, regardless of the base of the stain.

How to treat a wooden door?

Wood has a big disadvantage - it absorbs moisture. An expanded sash cannot be closed or opened normally. To prevent a wooden door from swelling from dampness, before painting it must be treated with a protective impregnation and preparatory measures must be carried out.

- The process begins with removing the sash from its hinges and dismantling the protruding fittings. The canvas is laid on a horizontal surface, sanded and thoroughly cleaned from dust.

- When using paint, the clean surface of the wooden door is impregnated with a primer. The first layer is allowed to dry and the second treatment is performed.

- The panel door is painted with a roller, and the panel door with a brush. Depending on the structure of the material, 2 to 4 layers of enamel are applied.

- If stain is used instead of paint, the surface of the wooden door is not primed. The door leaf is simply sanded and cleaned of dust. The stain itself is a protective impregnation that penetrates deeply into the wood.

A wooden entrance door needs to be treated especially well, since outdoors the door is constantly exposed to moisture and temperature changes.

Work technology

The method of applying it depends on the type of stain. Typically, a brush, spray, swab, or sponge are used for painting work. It is better to treat unsmooth and large-sized bases with a spray gun (in the first case, do not use a brush so that there are no fallen bristles left on the wood). To use a sprayer, choose a lighter shade of stain: the layer will be thicker, making it appear darker.

Before the main stage of work, a test painting is always carried out to clarify the required number of layers to obtain the desired shade. The procedure is as follows:

- take a board of the same type as the base material and polish it;

- cover the product with impregnation;

- leave until dry;

- apply another layer to 2/3 of the board;

- after drying, treat another 1/3 of the workpiece with a third layer;

- As it dries completely, evaluate the appearance of all three areas and select the optimal shade.

Dealing with defects

When applying stain, it is very important to avoid smudges, which are quickly absorbed into the wood and significantly worsen the appearance of the finish. A small amount of stain on the brush and a thin layer of coating can avoid this defect.

You can remove unwanted stains from stain using sandpaper, or in more difficult cases, with a plane. You will have to act carefully, gradually removing the darkened area of the wood and smoothing out sharp transitions.

For porous wood species in which the coating is absorbed unevenly, it is better to use wax-based stains or gel stains. They cover the surface with a thin layer and do not penetrate deep into the wood structure. You can also treat the surface of the wood with a special conditioner compound, which will prevent the active absorption of the stain.

The “apple-colored” defect occurs when pigment thinners are of poor quality or there is a lack of skill in spraying stain. Stains form on the surface covered with stain.

When applying stain with a spray gun, in order to avoid coating defects, it is necessary to adjust the material supply torch. It should be oval in shape and the spray angle should be approximately 90°.

Coating defects can arise from poor-quality sanding of the wood surface. In this case, it is necessary to remove the layer and sand it again. Then cover the surface with stain.

Remaining stains of grease and dirt due to poor cleaning will appear when applying stain. Here, too, it is necessary to remove the poor-quality layer by grinding, clean and degrease the surface. Apply a new coat of coating to clean, dry wood.

It happens that the stain is applied to the surface incorrectly. Here are the main ways to eliminate defects:

- For numbness. Immediately after tinting the wood, you need to cover the area with varnish, which will dissolve the stain. Then clean the treated area with a rag. When the drip has already dried, it will have to be softened with white spirit or ground off with sandpaper.

- For stains. If we are talking about plywood, you will have to remove all the veneer using a plane. Solid wood is also processed with this tool, removing the thin top layer.

Advantages and features of using varnish

For wood, stain and varnish not only give a beautiful appearance, but also additionally protect the natural material from aging. A combined coating of two components is often used. The stain penetrates deep into the wood, where, together with tannins, it forms a protective barrier against moisture and preserves the natural color of the wood from fading. The varnish creates a decorative shine on the door and also additionally protects it from moisture.

The varnish gives the canvas a spectacular appearance and enhances the protective functions of the wood. With the help of varnish, wood rotting is prevented, and the apartment or house becomes more comfortable.

To cover interior wooden doors, you can use several types of varnish. In this case, the canvas can be made of pine and other types of wood. Due to this technique, the shade inherent in the door leaf is emphasized. The covering material gives some door parts a rich and deep color.

Varnish - an affordable universal product for coating wood

To varnish wood, it is recommended to choose the right product. Impregnations protect wood from mold and rot. Protective agents do not allow the fabric to swell. They also protect the box from the sun and sudden temperature changes.

In some cases, instead of varnishing, you can paint the doors - this looks very stylish in modern interiors.

Before varnishing wooden doors, let’s get acquainted with the advantages of this finishing method:

- accessibility – the buyer is given the opportunity to buy varnish taking into account the price factor. At the same time, experts advise treating the canvas with a mixture that can improve the external and protective properties, extending the service life of the canvas;

- easy updating - anyone can paint the door, including those new to such work;

- versatility - the varnish is used for different surfaces;

- varnish helps to increase the fabric’s resistance to various negative influences, which include scratches, moisture, and mechanical damage.

Water-based varnishes are odorless

All varnishes are classified into the following types based on composition:

- oil based – they are based on oils that are well absorbed into the surface, changing its color. They are used as a solvent. Such compositions take a long time to dry. They have an unpleasant odor;

- aqueous - colorless and without a pungent odor, matte or glossy type. They dry out quickly. But stain is used first.

Some of the stains are transparent. Such solutions emphasize the beauty of wood and protect it from harmful influences. Brushes must be used for application. Read the instructions carefully: some manufacturers suggest applying one layer, while some recommend applying several layers.

It is advisable to coat a door that has been previously painted with clear varnish. In this case, it will be less susceptible to external negative influences and will retain the shine and color of the coating. If you have coated your door with acrylic varnish and notice that there is a whitish tint left, don't worry - it will become transparent after it dries completely.

By choosing a special cold-curing varnish, you can make the coating of a solid pine door glossy or matte.

Tags: what, stain, cover, after

« Previous entry

Making your own stain

There are a large number of folk recipes for making stain at home. Various shades of brown can be obtained by preparing a solution of ordinary potassium permanganate. It is necessary to experiment a little to achieve the desired result, selecting the concentration of the solution. The surface stained with potassium permanganate must be protected from fading, for example, with varnish.

Another simple way to stain wood is to brew strong tea. It will give the wood a rich brown tint. You can also kill a tree with strong brewed coffee. The natural brown color comes from wood treated with a rich decoction of walnut shells, crushed to a powder.

A decoction of oak bark will give the wood a black tint. The golden color is obtained by treating wood with a decoction of buckthorn fruits. A red-brown tint can be obtained by treating a wooden surface with a concentrated decoction of onion peels.