Woodworking is a complex process that consists of many stages. Special devices can make work easier, for example, a wood band saw helps to make a straight cut and is suitable for processing boards of various widths.

What is a band saw?

A tool that is designed to work both in a carpentry workshop and in a small garage - a wood band saw for a home workshop, is a metal blade closed in a ring on which teeth are cut; their height, frequency of arrangement, width of the blade determines the type saw and its ability to work with different materials. A wood band saw is capable of processing logs and boards of such width that other types of saws - circular or frame saws - cannot be processed, and can be used to work with other materials:

- metal;

- stone;

- plastic.

Wood band saw device

Band-type sawmills are similar in design. Professional tools differ in size and weight compared to home saws intended for domestic use in small workshops, and hand-held units. Structurally, band saws consist of several units:

- Frame or bed is a body on which all the main elements are fixed.

- A working surface equipped with a ruler and a stop, which helps to regulate the correctness of the cut.

- Engine – powers the saw.

- The wood band saw blade fits onto a pulley and rotates at high speed.

- The control panel, lubrication system, protective casing are additional components that make the operation of the band saw safe and convenient.

The working principle of a wood band saw

There are many types of sawmills that work with wood. Understanding how a wood band saw works is important to using it correctly. The toothed cutting blade rotates thanks to the motor, resulting in sawing of materials that come into contact with it. The performance of the band saw machine depends on the shape and height of the teeth located on the blade and on the engine power. Special sharpening of the teeth is necessary to clean the working blade from sawdust and prevent the saw from jamming.

What to pay attention to

Replacing wear parts can cause a lot of inconvenience, so when purchasing, be sure to find out the service life of carbon brushes, drive belts, guides and feed rubber rollers, bearings, and toothed belts. And also are there any reliable analogues from German or Japanese manufacturers.

The cause of premature failure of band saw machines is mechanical damage due to worker negligence. In addition, reliability is negatively affected by:

- high humidity;

- aggressive environments;

- internal or external contamination of equipment;

- deliberate violation of operating instructions, for example, to increase productivity;

- power surges;

- foreign objects entering the saw frame - for example, sand, stones, insects;

- design changes;

- violation of the rules of lubrication and coolant cooling.

What is a wood band saw used for?

When choosing a tool for smooth sawing of wood, special attention should be paid to household wood band saws. Adjusting the cutting blade speed and direction allows you to use the sawmill for a variety of jobs. The ability to select the tooth size to work with a specific type of material expands the range of capabilities of the saw. A blade with large teeth is suitable for soft wood, and fine teeth for hard wood. Other features of the band saw make it an indispensable assistant for the home craftsman:

- Many band sawing machines have the ability to be precisely adjusted to suit the specific needs of the worker.

- Thin blades can be used to cut out shaped products and various decorative elements.

- A household wood band saw can work in any direction – both along and across the grain.

- Using a saw, you can create identical and mirror parts for furniture.

- The productivity of a band saw is higher than that of other types of tools.

- Band-based sawmills are safe.

Subtleties of choice

The most important consideration when choosing the best band saw machines is the impeccable quality of the resulting boards. Any “dips”, “waves” and so on are categorically unacceptable. Based on power, these devices are divided into:

- professional;

- semi-professional;

- homemade.

This semi-professional product is recommended for small businesses and utility workshops. Such a tool can work for quite a long time, including when cutting strong material. But if you need to process frozen forest of large diameter, only professional devices are suitable. The depth of the cut also plays a big role. It is directly proportional to engine power

You also need to pay attention to the width of the cut. The width of the processed boards depends on this indicator

Machines installed in large industries can cut workpieces up to 61 cm wide. It is necessary to check the degree of sharpening of the teeth, which affects the evenness of the cut. Saws that allow you to change the operating speed are clearly better than the regular versions.

But we must remember that household tools extremely rarely have such a function. The fee for auxiliary options is not very significant, but they immediately affect the ease of use. The ability to quickly tension the canvas reduces time consumption, also reducing the labor intensity of the work. It is advisable to choose versions with millimeter scales. They increase cutting accuracy, especially if there are 2 or more stops.

Types of band saws for wood

A carpentry workshop cannot do without a high-quality band saw from a trusted manufacturer. When choosing a sawmill, you need to understand the differences between the best band saws for wood. By type, sawmills are divided depending on the location of the blade, they are:

- vertical;

- horizontal.

Vertical band saw for wood

Machines for sawing wood of the vertical type are distinguished by the fact that the blade, which is in contact with the surface being cut, is located vertically. This type of wood table saw can be used in small woodworking shops, as well as in home workshops for household needs. Such a tool easily copes with materials of various widths and can work in any trajectory. The sizes of wood band saws of this type may vary. When choosing a vertical band saw, you need to remember the following characteristics:

- moving speed of the web;

- blade length;

- number of speeds;

- possibility of adjusting the angle of the table;

- depth of cut;

- machine weight.

Horizontal band saw for wood

Saws in which the cutting blade is positioned horizontally are widely used by professionals and novice craftsmen for cutting a variety of wooden materials. A horizontal wood band saw works well with both cross-cuts and miter cuts. Machines for industrial use can operate autonomously; electronic control systems in such devices calculate the size of cut surfaces down to the millimeter. The horizontal band saw for wood has the following characteristics:

- possibility of cutting at an angle;

- the ability to save a program for reuse (in electronically controlled machines);

- engine power;

- web speed;

- desktop size.

Specifications

Key parameters to consider when choosing a band saw:

- power: a household unit has enough power of 500 - 750 W, industrial units can be up to 3 kW;

- mains voltage: household models operate from 220 V, industrial models from three-phase 380 V;

- cutting depth: the weakest machines can handle boards up to 15 cm thick, industrial ones - up to 1 meter;

- cutting width: the maximum cutting width is determined by the distance from the tape to the stand. Minimum distance 350 mm, sufficient for working with small parts;

- the speed of movement of the belt or cut is measured in meters per minute and can be from 200 to 1250. The higher the speed, the cleaner the wood is cut. For hard rocks the speed is slightly reduced;

- dimensions of the working surface;

- saw blade length;

- mechanism weight.

How to choose a band saw for wood?

A good woodworking machine is not cheap; purchasing such a tool must be approached responsibly. When thinking about which wood band saw to choose, you need to weigh and correlate the parameters of the tool and your own needs. According to the characteristics, band-type sawmills are divided into several types; you should choose a saw for yourself, taking into account the important characteristics:

- Capacity based on estimated production volumes.

- Characteristics of the working surface.

- Manufacturer of the machine.

Hand band saw for wood

Small-sized tools are not inferior in their properties to professional machines for large-scale production. A mini band saw for wood will serve faithfully a caring craftsman, and will definitely come in handy on the farm; with its help you can easily and simply perform various actions:

- cut down dry branches on trees;

- get rid of old seedlings in the garden;

- prepare firewood for the winter.

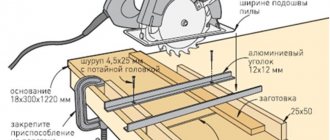

Securing the workpiece

Check that the workpiece, firmly clamped on both sides, is unable to move during the cutting process. If your machine has adjustable clamping force, use the maximum clamping force to maintain consistent pressure without distorting the workpiece geometry. General vibrations occur when the side of the workpiece being cut is not properly clamped. As the band blade approaches the end of the cut, the weight of the workpiece being cut may pull or slightly move the overall workpiece out of the clamp. If you are cutting a rectangular workpiece, then it must be placed vertically and not along a larger plane. This reduces the contact area of the strip blade with the workpiece, resulting in more efficient cutting and less roughness of the cut surface. For better stability of the web in a vertical position, the guides should be located as close as possible to the workpiece. If the distance is too large, the blade may wander when cutting, especially with too high a feed. Modern bandsaw models have carbide guides in addition to rollers to help keep the blade in an accurate vertical position.

Band saw for wood - rating

This tool is widely used in carpentry shops. It is better to choose a band saw for wood based on the rating of the best time-saving, high-performance and reliable units presented below.

- JET JBS-12

. The wood band saw is designed to work with wide boards and beams, copes well with bulky workpieces, is powerful and productive, and has a stable metal frame that does not vibrate during operation. - Way Train UE-330

V. The horizontal type machine copes well with wood of any size, works at an angle, is equipped with a powerful motor and a large work table. - Corvette-35 Enkor

. A wood band saw has high power and blade speed. The high stand on adjustable legs adapts to any worker, and the beveled frame allows you to cut shaped workpieces of any shape.

Examples of choosing machines for small and medium-sized businesses

The Anchor Corvette 422 cantilever machine is designed for small-scale work; it has a rotary vice, but is equipped with a coolant supply system. The console Proma PPS-270THP is capable of sawing at any angle chosen by the operator.

The two-column semi-automatic machine Fmb OLIMPUS 3+VHZ is designed for simultaneous sawing of several rolled products; it can cut large-sized workpieces made of steel of all grades, albeit with low productivity.

What brands are most in demand today:

DIY wood band saw

Making your own band saw is difficult. The wooden frame for the machine is assembled from scrap materials; any craftsman will have the necessary tools for assembly. The process of working on a homemade wood band saw can be divided into the main stages:

- The frame for the machine can be assembled from old furniture; a preliminary drawing will make the work easier and will allow you to assemble the saw to the required dimensions.

- The simplest homemade belt machine rests on a frame assembled from a rod and two supports. The distance between the supports should be thought out in advance; it should not be less than the size of the logs being processed; it is better to make it a little larger.

- You can use an old desk for the work surface; its cabinets can serve as containers in which sawdust will be collected.

- Depending on the engine parameters, it is necessary to calculate the diameter of the pulleys for the belt drive.

- For the lifting mechanism to which the cutting blade is attached, a massive spring is suitable, with the help of which the necessary pressure of the machine will be ensured.

- Guides are necessary to ensure that the cut is carried out along a straight line.

- In order for the machine to be safe, it is better to cover the pulley with a special casing.

- Treating the machine with wood varnish or painting will increase its service life.

Machine Tool Manufacturers

The production of equipment of this type is carried out in several stages. Initially, sketches are made, including components and parts. These are used to subsequently produce units. Closed profiles are used to make the frame. They can have different sizes, which are directly affected by the dimensions of the components and parts. Most often, woodworking machines are made from U-shaped profiles.

The manufacturer initially makes the base of the machine. For this purpose, sheet steel is usually used, the thickness of which is 4 millimeters. The frame must be properly attached to the base. Next, the desktop is processed. To do this, a sleeve is welded for the axes of the support bracket. Ball bearings are characterized by the presence of an axis into which the lower disk is screwed. The upper disk is installed on ball bearings. The axle is fastened with a special bracket, with the help of which the angle of inclination is changed.

The manufacturer attaches the supporting frame with bolts or nuts and guides are placed on it. A guard is attached to the front of the machine. Screws are often used for this purpose. For the highest quality movement of the workpiece on the table, it is made from textolite. The pulley is secured using screws or a pin. Installation of the lower and upper disks is carried out with a divorce.

The production of band saw machines is carried out according to a strictly established scheme. This ensures the long life of the band saw.

The body of the unit is characterized by the presence of a paint and varnish coating, which protects it from corrosion. High-quality materials are used to produce the machine, which guarantees not only excellent performance, but also a long service life.

The main brands found on the market today are Jet, Proma, Altesa, Makita, Metabo, Holzstar and others.

How to use a band saw on wood?

This device helps to quickly and accurately make any cuts on wooden products. Practice and care are required when working with this type of tool, knowing how to use wood band saws will make the results worth the effort.

- Choose the right type of band saw, paying attention to power, speed, blade length, parameters of the working surface of the table, and electrical characteristics.

- The saw blade must be selected individually for each project, taking into account its width, thickness and tooth spread.

- Before work, you should check the movement of the working blade and adjust the guides.

- The working surface must be adjusted to the desired angle of inclination.

- Before work, markings must be made on wooden blanks.

- You can turn on the saw and wait until it picks up speed.

- Guide the workpiece along the guides and make a cut.

Setting up a wood band saw

Any power tool requires daily maintenance. It is necessary to spend a few minutes before work setting up and adjusting the band saw for wood. By performing simple manipulations, you can significantly increase the service life of the tool.

- The saw must be disconnected from the power supply and the working blade removed.

- Clean the guides from debris.

- Remove any dirt from the pulleys and vacuum the inside of the casings.

- Place the canvas in place, adjust the degree of its tension.

- Align the pulleys, they should be parallel and coplanar.

- Check the operation of the working blade and make final adjustments if necessary.

- Check the position of the bearings.

- Make sure that the working surface of the table is installed at the desired angle to the canvas.

The main reasons for premature failure of the belt web.

A)

- Chipping (knockout) of teeth

- The saw pitch is too small.

- Saw pitch too large.

- The workpieces are not securely fastened.

- Saw speed is too low, resulting in excessive penetration.

- Feed pressure is too high, causing the saw to cut into the material too much.

- Weak saw tension causes it to slip.

- Slipping (stopping) of the saw under load, leading to excessive penetration of the saw into the material.

- The saw cleaning brush is missing, does not work, or is worn out.

B)

- Cracks in tooth cavities.

- Difficult movement of the saw in the guides and pulleys due to contamination of the pulleys or reduced clearance in the guides.

- The gap between the guides is too large.

- The guides are too far from the workpiece.

- The side guides clamp the saw in the tooth gullet area.

- Weak side guides cause the saw to tilt

- Incorrect saw tension.

IN)

- Cracks on the back of the saw.

- Wear of the upper support bearing in the guides

- High supply pressure.

- Wear of side guides.

- The blade is pressed against the pulley collar.

G)

- Beating (vibration) of the saw

- Crooked weld.

- The saw pitch is too much.

- Missing teeth (broken).

- Supply pressure too low or high.

D)

- Premature dulling of teeth.

- The saw speed is too high for the material.

- Saw pitch too small or too large

- The saw blade is not parallel to the feed direction.

- Defects on the side guides.

- The guides are poorly secured or worn.

E)

- Non-perpendicular cut.

- The saw blade is not parallel to the feed direction.

- Large gap in guides.

- The table surface is not perpendicular to the saw.

- The vice is not perpendicular to the saw.

- Low saw tension.

- The side guides are poorly secured.

AND)

- Burnt chips.

- Big serve.

- The saw cleaning brush does not work.

- Dull saw.

- No cooling.

Tools and materials

To create the type of saw in question, you will need the following tools and materials:

- a piece of plywood approximately 1.5 centimeters thick;

- timber made of solid wood;

- tapes or attachments that will be used for a screwdriver or grinder;

- a pair of bearings for a drive axle;

- studs, washers, self-tapping screws, nuts, fittings;

- a pair of shafts;

- bolts that will be used to adjust the vertical and horizontal types;

- a pair of brass bushings with internal threads;

- PVA glue;

- upper type axle bearings;

- lamb for tuning screws;

- insulating tape.

Separately, it should be noted that in order to correctly create certain parts of the saw, you must have drawings. To work you will also need the following components:

- pulleys;

- sawing table;

- base;

- cutting blade;

- mechanism responsible for tensioning the tape.

Necessary equipment

Such a tool is needed if there is a need to work with wood. Although some models of band saws also allow you to work with synthetics, metal, and stone. The high density of the described materials requires the use of devices that contain components made of reinforced steel. A standard analogue will not be suitable due to the fact that when processing metal or any other of the mentioned materials, a disk with teeth very quickly becomes unusable.

If we talk about the equipment that will be needed to make a band saw, then this is:

- welding machine;

- welding machine (it is better if it is semi-automatic);

- Bulgarian;

- sharpening machine;

- electric jigsaw;

- Sander;

- screwdriver

By the way, electric tools can be easily replaced with their manual counterparts. However, it is worth keeping in mind that this will significantly increase the assembly process time and require more labor.