Most country houses are heated with solid fuel. The task of a prudent owner is to calculate and select the type of efficient fuel with minimal costs for its acquisition. European experience of several decades convinces us of the rationality of using briquettes made from compressed sawdust - Euro-firewood. If you make such fuel briquettes with your own hands, the cost of heating your home will further decrease.

Advantages of Eurowood

Briquettes for combustion are a natural product without additives or binders, with a moisture content of no more than 10% by weight. The product is suitable for use in boilers and furnaces of all types.

In comparison with other classic types of solid fuel (wood, coal), Eurofirewood has the following advantages:

- The burning time is 3.5-4 times longer than firewood. A sawdust briquette burns with an even flame without the formation of sparks, with a small amount of smoke, with minimal smoke formation, and does not “shoot.”

- 1 ton of compressed fuel emits as much heat as a full dump truck of firewood – 7 m3.

- The high calorific value of fuel briquettes, even with low draft, is comparable to that of coal and is 2 times higher than this value for firewood.

- After their combustion, up to 1% pure ash remains. For comparison: burning wood leaves 15-20%, coal – up to 40%.

- The environmental friendliness of Euro firewood is evidenced by the absence of hazardous volatile substances and soot in combustion products. In this case, carbon dioxide is released 15 times less than when burning natural gas and 50 times less than from anthracite.

- When servicing boiler equipment, material and time costs are reduced, and the operating life of heating systems is increased.

- The cost of heating a building with compressed sawdust is significantly reduced.

- Briquettes are stored compactly, do not take up extra space, and are convenient for transportation.

DIY fuel

It would be unrealistic to think that anyone would undertake to buy such a powerful unit for home use. It will not be possible to apply the method for producing lignin at home. But some craftsmen have learned to use other binding materials. In order to start making your own firewood from sawdust with your own hands, you should consider the following:

- Briquettes made in artisanal conditions are significantly inferior in quality to factory briquettes.

- Preparing and pressing sawdust requires a lot of time and physical effort.

- You need a large warm room, which will require a lot of fuel.

- Any improvement in equipment increases the cost of the product.

Thus, after thinking about how much effort, time and finances it will take to produce briquette fuel at home, many will prefer ordinary firewood or coal. To start making sawdust briquettes with your own hands, you don’t have to buy expensive equipment. Home craftsmen came up with the idea of making briquettes for heating from various combustible materials: paper, straw, cardboard, leaves, etc.

To make Euro firewood with your own hands, you need to put sawdust in water, put clay there in a ratio of 1:10, stir, add wallpaper glue or soaked cardboard. This mixture should be poured into the mold and squeezed as tightly as possible with your hands. Then remove the figures from the mold and lay them out in the sun to dry.

For quick briquetting, you can cover each figure with paper or rags. As for homemade pressing machines, they are usually made in three versions:

- with manual drive;

- with jacks;

- with hydraulic drive.

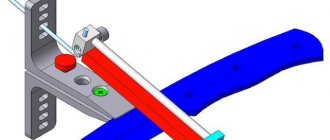

One of the simplest options for the machine: a frame is welded from a metal pipe, which can be attached to the wall of the house. A rectangular shape is attached to the bottom of the frame, and a lever going inside it is attached to the top. The second and third options are that the briquette press is represented by a jack or a hydraulic drive, which are designed in place of the lever.

How to make briquettes from sawdust

Why briquettes? This is explained by the inability of many furnaces to burn natural waste from logging and wood processing - chopped wood (chips) and sawdust. Expensive equipment with the principle of top combustion is adapted for this purpose. The briquettes produced have no restrictions for use in stoves, fireboxes, fireplaces, and boilers .

The fundamental principle of briquette production is the squeezing of small waste wood until lignin is released, a natural substance that glues them together into a monolithic finished product.

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are clear. When a person has his own wood production or the opportunity to cheaply buy sawdust for briquettes, then thoughts about making them at home are quite natural. The fact is that not every heating equipment is suitable for burning sawdust. As a rule, fine wood in a conventional stove or boiler burns quickly and gives off little heat, and even half will spill into the ash pan.

To successfully burn wood waste, you need a special shaft-type or top-burning boiler. It’s quite difficult to make this; the prospect of pressing sawdust into fuel briquettes seems much brighter.

It turns out that not everything is so simple here either, and here’s why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to purchase ready-made European firewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of low quality and will provide little heat, and will take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light.

Point two requires clarification. Due to the impossibility of following the technology, the “bricks” after drying are light due to their low density. Their specific heat of combustion is three times lower than that of wood, which means that for heating they will need three times as much. The whole process will take a lot of time and consume a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Educational video for enthusiasts who want to start manual briquetting of various household waste:

Methods for making briquettes

A machine used for sawdust briquetting must compress the embedded raw material with enormous force. Only in this case will lignin be released and bind individual particles. The process is accompanied by an increase in the temperature of the compressed substance. Therefore, the sawdust and the binder are sintered.

Raw materials

In addition to sawdust, shavings, larger woodworking waste, and agricultural waste that can burn are suitable for making Eurofirewood. You need to start making fuel briquettes after preparing the raw materials: grinding large fractions, drying to a moisture content of 8-10%.

Briquetting

The next stage of production is briquetting - pressing sawdust with pressure until a compact product of the required shape is obtained. The briquetting method is determined by the equipment used at this stage - a hydraulic press or a screw device.

The compressive force of the press reaches 300-650 atmospheres and the principle of its operation is intuitive. The operation of auger equipment is to gradually push raw materials into a tapering conical channel. In this case, a pressure of up to 1000 atm is created in the working part of the channel (with a minimum cross-section). At the exit, the compressed monolith is cut to size.

Manual hydraulic press

Screw press

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Mainly the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from natural wood sawdust with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading container, and then fed through a screw for pressing. Dispensers distribute the mass into molds under pressure.

- Pini kay. In shape they are polyhedra with the number of faces from 4 to 6. During the production process they are subjected to processing at high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust are the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. Its high density and low hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, and straw are used to produce briquettes. The equipment for this has a fairly simple design, and you can make it yourself

If you have the necessary raw materials to form briquettes, you can make them yourself.

Equipment for the production of

Homemade devices for home production of fuel briquettes can be classified into the following groups.

Screw press

The ability to make a screw press is considered a great success and will require professional skills. In addition, considerable costs will be required for the mandatory electric drive, high-strength and complex parts of the working auger, housing, and frame. The result of the work done is the opportunity to obtain homemade products comparable in quality to factory ones.

Manual screw mechanism

A simple homemade press has a screw drive. The manual press consists of a molding container for the initial mixture and a pusher with a screw drive, rigidly mounted on a durable frame. The filled container is placed on the base of the frame and by tightening the screw (a mechanical jack can be used), the mixture is compressed to the required force or size. During the procedure, excess liquid is removed through the holes of the molding container. The removed briquette dries naturally. The user's work will be greatly accelerated and facilitated by the use of a hydraulic jack.

Briquette ejection mechanism

A press for fuel briquettes with manual compression of the embedded raw materials using a long lever is also easy to manufacture. The longer the lever handle, the greater the force that compresses the future briquette. For convenience, a mechanism is provided that pushes out the finished brick, which fits tightly in the mold. To obtain productive equipment, you can make a press with several forming containers.

Heating with pine sawdust

Heating with pine sawdust

Those who have a house outside the city sooner or later think about heating it. There are several types of heating - gas, electric and solid fuel heating. Gas and electricity today are expensive energy sources, and not all settlements have communications for them. Autonomous heating is the most economical and at the same time capable of providing the most comfortable level of living. Of all types of fuel, sawdust is the cheapest. Our country has a huge number of wood processing plants, the lion's share of which are engaged in the processing of coniferous forests. The waste from processing is sawdust. Good news in recent days has been the news about the possibility of heating with pine sawdust

, the alternative name of which is “eco firewood”.

The difference between pine sawdust and other types of fuel. Heating with pine sawdust

compares favorably with alternative combustible materials.

· Thermal conductivity is much higher than that of firewood and some types of coal. · Briquettes made from pine sawdust do not require additional drying before placing them in the firebox. · Pine sawdust requires much less space to store than coal or firewood. · When burned, they emit a stable temperature, and they burn for about 4 hours. Due to this, fuel is added less frequently. · Form incomparably less ash. · And finally, their cost differs significantly from alternative combustible materials. Features of heating with pine sawdust. To heat a house,

they use both pine sawdust itself and briquettes and pallets, which are produced by pressing at high temperatures. For heating, ordinary autonomous solid fuel boilers may be suitable. But there are also special ones that work on sawdust. As a rule, sawdust-fired boilers are used for water heating systems. The advantage is the low price of both the boiler itself and the initial combustible material. It is also worth noting that this fuel is highly environmentally friendly. After all, pine sawdust is a natural material, and even when pressed, no synthetic substances are added to it. Sawdust from softwood contains more resin, due to this they provide greater heat transfer than their hardwood counterparts. In addition, they better maintain a constant temperature in the room.

Pros and cons of heating with pine sawdust.

The advantages are. · The undeniable environmental friendliness of this material. After all, even during combustion they do not emit harmful substances. · Low price of fuel, because sawdust is essentially a waste product from the wood processing industry. · Today there are fully automated boilers that control all work processes. · Maintenance of such a boiler is significantly lower in cost than its analogues. · Today there is a large selection of pressed sawdust that can be sealed in any packaging. The disadvantages are. · Sawdust is a bulk material, making it not very convenient to transport it. On this basis, it can be argued that heating a house

pine sawdust, much more practical and economical than other alternative materials.

(no votes yet)

Stage 3. Preparation of raw materials

This is the most important stage of the process in which you create your own fuel briquettes. But to work you will need not only waste, but also components such as:

- water in a small amount - only to soften the clay;

- the clay itself will serve as a binder; Note that in industry no additives are used, since the binding element is lignin, a substance released by wood at high pressure, but at home you are unlikely to achieve such pressure, so you will use additional components so that the briquettes “keep their shape.”

Let's summarize

Do-it-yourself fuel briquettes are inexpensive and at the same time quite effective!

They can be used for heating not only commercial buildings, but also residential buildings. But does it make any sense to make it yourself if briquettes can be purchased in specialized stores? Of course, it does, as always when it comes to making something with your own hands. After all, with a little effort and desire, you can save a lot in winter!

Warm winters and good luck at work!

Stage 2. Choosing a room - what should it be like?

And the room should be chosen in such a way that it can not only accommodate all the necessary equipment, but also store raw materials and finished products. The area of such a room directly depends on the scale of future production, but, for example, a minimum of 55-60 m2 is required for pressing.

Attention! When arranging the premises, carefully monitor the quality of ventilation of the area where pressing is planned, as well as the fire extinguishing system and the reliability of electrical networks.