What does a jigsaw consist of?

All variations have the same configuration, and, therefore, a single set of components and what is worth remembering when deciding to make a jigsaw:

- File;

- Tire-connecting rod type assembly;

- Drive unit;

- A special device that allows you to tighten the files;

- Working surface or bed;

- Additional mechanisms (optional).

Device classification

Basically, the classification of jigsaws consists only of the purpose of the tool, so based on this, jigsaws are:

- household - designed to perform small and low-cost work. Machines of this type can have a power of only up to 500 W and run for half an hour, this will be quite enough.

- Professional sawing machines are necessary for work that requires a lot of labor. The power of such a stationary jigsaw is much greater, 700-1500 W, it can be used for 3 hours without a break. It is intended specifically for permanent professional activities.

- The production unit is much larger than previous types; it performs work in the production sector, so the duration increases to 20 hours.

The device can also be classified depending on the cutting material. This is what determines the type of device, as well as the saw used for cutting.

Main characteristics of a jigsaw

Remember that any option must comply with the established parameters:

- The optimal size of a work surface or table should be between 30 and 40 centimeters. The smaller size is not convenient for processing parts, the larger one represents industrial designs;

- The drive power is equal to 150 Watts. This is the most real value that can belong to a structure made at home;

- The rotational force imparted to the saw is transmitted using a special mechanism. It has a complex name - crank mechanism. Its main task is to change the rotation into a special reciprocating motion;

- The file has a certain vibration limit of one minute. This figure should be between 800 and one thousand movements per minute;

- Jigsaw files have a number of features. The file also has a limit on vertical movement - it should not exceed five centimeters;

- Most models have a speed control function, this allows you to perform work more efficiently and adapt to the different technical qualities of the material with which you interact;

- A jigsaw has a limit on the parameters of the material with which it works. So a manual jigsaw should work with plastic and wood, whose parameters do not exceed ten centimeters in thickness, and the length of the product is not more than thirty-five centimeters;

- Each material (be it plastic or wood) has its own saw. The width of the saw on average can vary from two to ten millimeters;

- Smooth operation is ensured by the tension mechanism.

Note!

- DIY induction heater ♨️ - reviews of the best manufacturing options. Varieties of homemade device designs + step-by-step master class (160 photos)

- Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

- DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

While studying all the features of jigsaws, remember that there are exceptions to the rules. These are industrial designs and variants intended for small-sized figurative work. Most often, their first difference is their high cost.

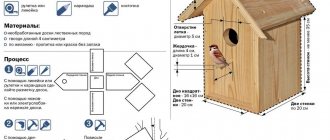

How I made my jigsaw. Blueprints. Part 1

This machine will be 5 years old in the spring. During this time, the machine performed very well.

Initially, I made such a machine according to drawings from the “WOOD” magazine, but after three months of use I discovered a number of shortcomings in it and decided to make my own machine. I started, of course, with a project.

I decided to make the base of the machine on four supports and high, so that I could work while standing. Material pine.

I made the rods of the machine from ash (you can also use plywood), and to attach the rods I made a separate block of pine bars.

The rods were secured between these bars using bearings. Each rod had two bearings installed on both sides. As an axis, I selected a piece of nail of suitable diameter. I also installed bearings in the bars between which I clamped the rods. I tightened everything with threaded rods and nuts.

Next, it was necessary to connect these two parts - the base of the machine and the block with rods - together. I also connected it with threaded rods and nuts. Previously, holes were drilled in the block with rods, fixed it to the base with clamps and ensured that it stood exactly with right angles and in the center.

To tension the file I used a threaded rod.

To secure it in the rods, I drilled holes and cut grooves to place the rod in the center of the rods.

Next we needed to make a pusher for the lower rod. I decided to use a jigsaw as a motor. His file moves progressively up and down - that’s what you need. To transmit this movement, I made a pusher. Later I glued a jigsaw file into it.

The thickness of the central part of the pusher corresponds to the thickness of the rod.

Next, it was necessary to make fastenings for the saws. I developed the same fastening for both the top and the bottom.

I cut the clamping plates from an old hand jigsaw. The hook for fastenings was made from a suitable piece of iron, and more specifically, a U-shaped clamp from a Soviet trellis was used to make it. Such clamps were used to connect mirrors to the trellis cabinet.

Next, I bolted a jigsaw to the base of the machine and adjusted the pusher so that when the jigsaw blade is in the middle position, the lower rod should be parallel to the base table.

The pusher had to be shortened and the slot for the file had to be deepened. Next, I glued the saw blade into the pusher. I cut out a table and a supporting arc for it.

At this stage, all parts of the machine were ready and setup could begin.

Setting up the interaction of all parts of the machine is perhaps the most important part for further comfortable work. I will tell you about setting up the machine in the next part. And now I suggest watching a video with the main points of making the machine.

Drawings of the machine, fixtures and a list of parts for manufacturing can be downloaded from the link.

Setting up the machine will be discussed in the next part.

Thank you for reading.

Alexander.

What is the difference?

Each species has its own nuances and advantages over its neighbors. So options with a lower support are the most popular in everyday life. They are the vast majority. The lower frame has several functions at once - a controller, a motor, a main gear, and a button to turn the device on and off.

Models with two (upper and lower) have their own significant advantage. The top has a rail, which is additional to the design. It copes well with cutting small parts and point work. It is important to remember that for this type the thickness of the material during work cannot be more than eight centimeters.

Variations on the suspension do not fix the frame stably. But their advantage is mobility. In this case, the material being processed is fixed and does not move, and the jigsaw itself moves with the help of an attachment behind the master. This variation makes it possible to create very complex and subtle patterns.

The scale and stops are necessary for carpentry masters who work exclusively from drawings. Markings prevent inaccuracies.

Note!

- Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

- DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

- Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

Modernization process

A manual jigsaw as the main device for a machine has disadvantages. The main problem is the file - it is too wide in manual models. Because of this, fine woodwork is difficult to perform with it - the curvature of the lines is limited.

The previous design is simple and does not have additional parts that make working with wood easier. The direction of modernization is the possibility of replacing the file with a thin one.

Options for improving the design:

- Build a rocker. The structure will be tensioned by springs on one side. The second side of the rocker is fixed to the file.

- Secure the file between two rollers. They serve as guides for the thin file.

- A stationary factory device is used as a drive for a system of two rocker arms. A file is pulled between the latter. The movement is transmitted from the factory device to the lower beam of the saw.

When buying or making it yourself, you have to choose a design based on personal preferences and the desire to tinker with technology. Using guide rollers is a less popular option - its reliability is poor.

Modernization by installing rocker arms is common. It is better that the factory device only serves as a drive for the jigsaw file. To do this, you need to turn off the pendulum stroke in the tool.

How to make a jigsaw with your own hands?

The easiest option is to make a machine. A homemade jigsaw is probably a better solution. There are a great many variations and drawings, they are easy to find on the Internet. This is all a consequence of the desire to create a unique and inimitable instrument. However, the operating principle will always be absolutely the same.

Machine from a sewing machine - giving a second life to old tools!

If you inherited a foot-operated or manual sewing machine from your grandmother or mother, consider yourself the owner of an excellent jigsaw machine! Of course, for this you need to “work a little magic” on the machine. First, remove the thread weaving device, which is usually located at the bottom of the machine. There is nothing complicated about it, just unscrew two bolts. Then we knock out the cotter pin and remove the drive shaft leading to the thread weaving mechanism.

Having unscrewed the top panel that protects the mechanisms, it is necessary to expand the slot in which the needle went. Be guided by the needs and width of the nail file that you will use in your work. Files for a jigsaw machine of this kind also need to be slightly modified, namely, cut to the maximum length of the needle that could be used on this machine. Having ground off the upper teeth and sharpened the lower part to the point, all you have to do is insert the file into the needle holder and test your machine in action!

Step-by-step instruction

To create a jigsaw with your own hands, you don’t need to have superpowers:

- We make a work table that will serve as a support. For this you need a sheet of wood or metal. Lay the size of the base, which will be approximately four times the size of the saw;

- At the bottom of the support we attach the factory device. Cap screws can be used for fastening;

- The structure is mounted on a table.

The trick is that a manual jigsaw is cheaper, but it’s more convenient to work with it on a stand. This will avoid unevenness and shifts when working with the material.

A do-it-yourself jigsaw is a real help for single people who have no one to hold part of the element being cut.

Basic and additional functions

To make work easier, many models of jigsaw machines are equipped with a number of additional functions. Among them are:

- speed adjustment. The most common function that allows you to set the required number of reciprocating movements of the jigsaw blade per minute. Thanks to its presence, you can get a fairly clean cut, depending on the type of workpiece being cut. There is a smooth and stepwise adjustment of the frequency of movement of the saw blade;

- desktop tilt . Allows you to cut material at any angle relative to the horizontal plane. Professional models have the ability to adjust the desktop in several planes. For greater convenience, the mechanism is marked with graduations, allowing you to select the appropriate angle;

- illumination of the working area . Allows spot illumination of the work site. Thanks to this, work can be completed faster and with better quality. In addition, the built-in backlight reduces eye fatigue when sawing;

- dust extraction. An auxiliary function that allows you to instantly remove shavings and sawdust formed during sawing, thereby facilitating the work;

- engraver. The presence of a flexible shaft with an engraver allows you to expand the functionality of the machine. It can be used to polish, drill or grind workpieces. The only drawback is the single drive system, which does not allow you to run the saw blade and the engraver at the same time.

An expanded set of functions makes the jigsaw machine more expensive and is only advisable for professional use.

How to improve the design?

Of course, a manual jigsaw is not perfect, but it can be modified and brought to perfection.

- A rocker is being made. This type of structure will be tensioned using springs on one side and secured to the file on the other.

- We fasten the file between two rollers. Their function is to be guides.

- We use a factory jigsaw as a drive. A file is pulled between it and the rocker.

Note!

- Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

- Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

Homemade jigsaw from hand tools

Home woodworking enthusiasts often look for information on how to make a jigsaw with their own hands without any special skills. You can use a ready-made manual jigsaw as a base. The mechanism does not require careful modification. The factory manual device is a drive. But the crank mechanism will have to be developed independently. Manufacturers are trying to offer consumers platforms for quick remodeling, but personal needs can only be satisfied with their product.

Assembly order:

- A support table is made. A sheet of metal is taken as a material and a hole is made in it. The shape is oblong, 3-4 times wider than the saw blade. Holes for fasteners are made nearby.

- The factory device is fixed at the bottom of the support table. Holes for fasteners are made next to the hole for the saw blade. Countersunk head screws are used as fasteners. This is necessary in order to ensure a perfectly flat plane of the table. Otherwise, the processed products will cling to the caps of the wines, which will cause inconvenience in work.

- The structure is fixed on a wooden table.

The advantage of creating a jigsaw machine with your own hands is that the factory tool can be disconnected at any time. When necessary, you have an ordinary manual jigsaw in your hands. Therefore, it is better to purchase a manual version of the tool that can be used on a homemade machine - it’s cheaper. Stationary devices are expensive.

Comfortable work with wooden products can be ensured by installing guide rails on a homemade support table. Additionally, markings are applied to the table, which makes it easier to measure distances on parts during processing.

How to use a sewing machine?

It's hard to believe, but it can also be converted into a jigsaw. How can this idea be brought to life?

- We remove the part that ensures weaving of threads (the lower part of the machine).

- We remove the cotter pin and drive shaft.

- We remove the upper part, which protects the mechanism from mechanical damage.

- We expand the part for the needle for the file.

- Let's modernize the file. The file should not be longer than the needle.

Such a device perfectly replaces a jigsaw for shaped work on plywood and will become a homemade jigsaw that can surprise all your friends and acquaintances.

It allows you to create even the most complex patterns and turns. However, this design has its drawbacks:

- The leg may get tired from working with the pedal;

- Vibrations may occur that complicate work.

If it is not possible to purchase an expensive design, you can get by with small losses. A jigsaw - a machine made independently can be an excellent solution. The main thing is to follow the instructions exactly when working and conscientiously fasten all the elements together.

Consider a table base so that it becomes a reliable support for the mechanism. It is important that the table does not rock or vibrate when the mechanism is running.

The more static all elements are in the end, the easier it will be to work, avoiding unnecessary movements and mistakes. And mistakes in such a matter are most often not acceptable.

A slight change in the angle or position at which you work, and the part may not fit into place or lose its shape. In any carpentry, the most important thing is the accuracy and measuredness of all actions.

A homemade jigsaw machine with your own hands is not such a complicated story as it might seem at first. After studying the article, understanding the basic elements and how to create your own tool, you can get to work.

It is worth noting that very often such a homemade machine is much more convenient than a purchased one. This saves money, but most importantly, this table is personalized. It will perfectly suit your workplace, your height and weight.

Such a design will fully meet the objectives, because the most convenient mechanism can be created only by the person who will use it in the future. In addition, in case of minor breakdowns, it will be clear how to repair and what can be fixed.

For a purchased sample, you will have to look at the instructions and study forums in search of a specific model and its characteristics. Have fun creating, and let the new jigsaw give you confidence and the desire to start a new renovation!

The structure of a jigsaw machine - what lies inside?

Jigsaw machines are more of a special tool than a device that is needed by both an experienced craftsman and an amateur who runs a garage. Their purpose comes down to a special task, namely cutting out complex curved contours from sheet materials. A special feature of such machines is the execution of cuts without violating the integrity of the external contour. Most often, sawing occurs on wooden and derivative materials (plywood, chipboard, fiberboard), although modern machines equipped with appropriate saws can also work with other materials, for example, plastic or plasterboard.

Such equipment has found application in the music industry (making musical instruments) and, of course, in the furniture industry. Those who like to make things in their own workshop also buy such units. The structure of a traditional jigsaw machine, designed according to all the rules, looks like this: the working surface on which the saw is mounted hides a drive (electric motor) and a crank structure underneath. The tension mechanism can be located either below or above the machine.

To process a part, it must be placed on the workbench. Many models have the ability to rotate it at different angles to make bevel cuts. The stops and guides on the surface, as well as the rotating mechanism, can be marked, which greatly simplifies and speeds up the work. The length of the cut depends on the length of the work table - most models are limited to 30-40 cm. Electric motor power is an important, but still far from the most fundamental factor, since the machine has a huge reserve of unclaimed power . For example, for a home workshop or even a small production, an “engine” of only 150 W is sufficient.

The crank mechanism is a much more important detail, because in this case the quality of transmission of the drive’s rotational moment into the translational and reciprocal movement, directed in the vertical plane by means of a file, depends on it.

Standard jigsaw machines are considered to be devices with an amplitude of movement of around 3-5 cm and a vibration frequency of up to 1000 per minute. Many models provide a change in speed mode for different materials. The jigsaw file itself is usually made up to 35 cm long and is capable of sawing material up to 10 cm thick. The width of the files can vary in a fairly wide range - from very thin two-millimeter to coarser ten-millimeter, with a thickness from 0.6 mm to 1.25 mm.

Photo of a DIY jigsaw

Electrical equipment, light, lighting

0 votes

+

Vote for!

—

Vote against!

A tabletop jigsaw is an indispensable item for any owner who is used to doing household work on his own. Electric jigsaws are especially good for residents of the private sector, lovers of manual labor and country holidays. The desktop electric model has gone quite far from its prototype, an ordinary manual jigsaw. A desktop jigsaw makes it easier and faster to cut, not to mention improving quality.

Concept of a tabletop jigsaw

A jigsaw is a saw, which is characterized by reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving along the surface that is being processed, and makes movements at a frequency of up to 3000 vibrations per minute.

This instrument was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in a sewing machine with a blade. The instrument went on sale already in 1947. A manual jigsaw has a body with a flat platform and a handle. The main difference between an electric jigsaw and a manual one is its greater functionality and cutting quality.

Inside there is an electric motor and a special mechanism that drives the blade. In stationary jigsaws there is no handle, and the platform is located on top. At the front of the mechanism there is a guide, at the bottom there is a retractable blade that moves and makes cuts.

The tool works as follows: a tabletop jigsaw file is securely secured with clamps in the slide. The reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part being cut, so the work is carried out very accurately.

The purpose of a desktop jigsaw

A jigsaw is an integral part of every workshop and every hobbyist. Its thin file can successfully cut plywood, copper, iron, thick boards, brass, and steel. The tools come with motor, foot or hand drive and are more productive. An electric jigsaw is simply indispensable for carpenters, wood workers, furniture decorators, and drywall workers who produce complex parts.

An electric jigsaw can make straight and curved cuts on workpieces with complex shapes and various sheet materials without disturbing the external contour. Most often, tabletop jigsaws are used for cutting wood and wooden boards, figures with complex outlines made of laminate and plasterboard, plastic blanks, and also for cutting sheet metal.

The benchtop electric jigsaw makes clean cuts in complex shapes and works on small parts. Due to the stable and fixed position during operation, high cutting accuracy is achieved. The file has a stable motion thanks to the tension system and guides, which manual jigsaws lack. The large size of the table makes it stable, so the precise sawing direction is maintained.

Types of jigsaws

Today, the power tool market offers a wide variety of jigsaws, which differ in the nature of their application, technical characteristics, type of power supply and design features. In construction stores you can buy a tabletop jigsaw for every taste and budget.

It is difficult to classify by design features, because each manufacturing company strives to provide its products with features that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is a significant parameter.

There are two established types of handles: mushroom-shaped and D-shaped. A jigsaw with a staple handle requires one-handed operation. This increases the possibilities of using a jigsaw, but has a somewhat negative effect on the quality of cutting the material.

Mushroom-shaped handles allow for more accurate cuts when holding the jigsaw with both hands, having previously secured the workpiece to be cut. The choice of a jigsaw with a specific handle shape depends on the financial capabilities and personal preferences of the buyer. You should choose the jigsaw that will be more convenient to work with.

Household jigsaws are not intended for intensive use, but the low price of a desktop jigsaw and the power that is sufficient for household needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of daily long-term (up to 8 hours) use. The significant power of such jigsaws allows processing of materials of large thickness. Expanded equipment and improved characteristics are reflected in the price.

Among professional jigsaws, industrial jigsaws also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

Depending on the type of power supply, there are mains and cordless jigsaws. Network models are powered from a power supply network with standard voltage. If productivity is important to you, then you should choose a corded power tool.

Cordless jigsaws provide independence from the presence of sockets and greater mobility during operation. When purchasing a battery model, you should pay attention to the type of battery. Increased performance characteristics are inherent in lithium-ion batteries. The battery capacity is responsible for the duration of operation without recharging.

Advantages of desktop jigsaws

A tabletop electric jigsaw is a stationary design, so this type of cutting tool has many advantages. Modern models can work with wooden materials with a thickness of 40-50 millimeters. The working body is a narrow saw, which makes vertical translational and reciprocal movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the saw, the material is cut out by moving upward.

A tabletop jigsaw allows you to cut out complex decorative parts, make longitudinal, straight, inclined and transverse cuts. The wide tabletop allows you to process large parts and make cuts inside wide workpieces. Reliable fastening protects the housing from unnecessary vibrations and allows the material to be well positioned, so the motor can operate without overload.

The advantages of desktop jigsaws include good accuracy and clarity of cuts, high safety and ease of use, wide customization options depending on the material and the required detail of the cut workpieces.

If you need to cut small parts, a manual jigsaw will not be very convenient. It is quite heavy, so you will have to hold it with one hand and guide the workpiece with the other. A table jigsaw does not have this drawback. Perhaps the inconveniences are the large size and the difficulty of working with large parts.

A tabletop jigsaw is a kind of mini-machine for cutting workpieces. If you purchase a jigsaw in a store, most likely it will provide the ability to select power and adjust the frequency of saw strokes. However, you can make a simple homemade tabletop jigsaw, and very quickly. You will need a hand jigsaw, a few screws, a small piece of plywood and just an hour of work.

Making a tabletop jigsaw

A carefully made jigsaw will be little inferior to one made in a factory, and in some respects even superior to it. Assembling such a jigsaw is not difficult if you have the necessary materials. Next, we describe a simple scheme for such manipulations.

The design of the jigsaw includes the following components: handle, switch button, insulating washer, power cord, frame, heating filament, screw clamp and earring. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind that the lighter the frame, the more convenient the jigsaw will be to use. Be sure to provide a channel so that you can lay the power cord later. The best frame shape is one with one side tilted at 45 degrees.

Next you need to make an earring. It is made of copper sheet one millimeter thick. After this, it is attached with screws to the frame where it connects to the handle. This way the screw, wing nut and shackle will form a clamp in which the heating filament can be secured. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make pressing cheeks from it, between which there is a switch button.

After this, you need to cut a gap in the plywood that the saw can fit through. It can be done using a drill. To do this, you need to drill holes along the marking line and smooth out the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill mounting holes on the plywood and jigsaw base plate.

Then you need to secure the jigsaw with screws to the plywood base so that the file can fit through the gap. You attach the structure to the table using a clamp so that the file is pointing upward. You can also secure the platform in any way possible. The jigsaw file remains a regular one, but the possibilities for good cutting are expanded by freeing up your hands.

You can use a nichrome spiral from any household heating device (iron, for example) as a heating filament. It must be secured with tension between the ends of the frame bends. In order for the thread to heat up, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome thread. Using a rheostat, you can set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the filament is heated. Before starting work, it is necessary to determine the current strength. But keep in mind that if the force is too high, the material being cut out may be caught in the flame, but if it is insufficient, it will not be taken. A self-made desktop jigsaw will allow you to cut shapes with complex contours from various types of materials.

Rules for using a desktop jigsaw

When working with a table jigsaw, you must adhere to some rules:

- When cutting, do not press too hard on the tool, otherwise the needle will break at best, or you will ruin the work at worst.

- Replace saw blades from time to time. An old saw can damage and destroy the surface of the material.

- If you work with organic glass and non-ferrous alloys, the surface of the product must be moistened with water. This operation will speed up the process and extend the life of the saw.

- If you are cutting a surface with a thickness of less than one millimeter, place a sheet of wood or plywood under the material being processed.

- Before cutting, it is necessary to secure the material. It is better not to make long cuts by hand; the line may turn out to be crooked.

- To cut different materials, appropriate blades are required, with a special pitch and length.

- Rotate the tool by turning only the back of the tool.

- When cutting laminate, tape is applied to the cut line, which protects the material from chipping.

- If there is a need for curved cuts, set the jigsaw pendulum to minimum.

If you have not yet fully understood how to make a tabletop jigsaw, watch a video about this procedure. This tool allows you to cut complex parts from wood and other materials, make longitudinal, inclined, straight and transverse cuts. Using a jigsaw, you can process large parts, wide workpieces and small products, which is not superfluous at home.