Joinery tenon joints

In the production of joinery, the main type of joint is tenon, consisting of two elements: a tenon and a socket or eye.

The pieces of joinery are connected to each other by a tenon joint, consisting of two elements - a tenon and a socket , or eye .

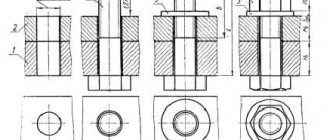

A tenon is a protrusion at the end of a bar that fits into the corresponding socket or eye of another bar. The spikes can be single (Fig. 47, a), double (Fig. 47, b), multiple (Fig. 47, c), i.e. more than two.

A solid tenon is a tenon that is integral with the bar. An insert tenon is a tenon made separately from the bar.

The tenon is made from a separate piece of wood of the same species as the bars being joined, or from more durable wood. In both cases, the direction of the fibers of the tenon wood should be proportional.

A tenon with a cross-section in the form of a circle is called round (Fig. 47, d).

The dovetail tenon (Fig. 47, e) has a profile in the form of an isosceles trapezoid with a large base on the end face of the type; one-sided dovetail tenon - in the form of a rectangular trapezoid on the end face of the tenon (Fig. 47, e).

The serrated tenon has a profile in the form of a triangle or trapezoid, the smaller base of which is the end face of the tenon (Fig. 47, g), the double-oblique toothed tenon (Fig. 47, h) is an isosceles triangle.

Single and double tenons are used in the manufacture of windows, frame doors, and furniture; dovetail spike - in the manufacture of drawers and boxes; jagged tenons - for adhesive joining of parts (splicing) along the length.

In order to form a tenon, an eye, a socket, the processed bars, planed on four sides to the required size, are pre-marked (Fig. 47, i, j, l, m).

Rice. 47. Types of spikes: a – single; b – double: c – multiple; g – round; d – “dovetail”; e – one-sided “dovetail”; g, h – jagged; and – nest; k, l – eyes; m – blind thorn; n - thorn in the dark; o - thorn in semi-darkness.

Spikes in the dark (Fig. 47, n) and semi-dark (Fig. 47, o) are used in the manufacture of frames, furniture, etc.

A tenon in the dark is made not only at the end connection, but also in cases where it is required that the edges of the nest are invisible , since it is not always possible to obtain smooth edges of the nest. To hide this defect, darkness , i.e. remove part of the tenon along the width from one or both sides.

The spikes are flat , round , rectangular and trapezoidal .

A tenon that passes through a block is called through . A thorn that does not pass through is called hidden .

A spike, the side edges of which widen towards the end, is called a “swallowtail” or “nagrat” . If only one side edge of a tenon expands, it is called a one-sided “burst.”

The side edges of the spine are called cheeks ; the cut end parts of the bar, forming a tenon, are shoulders ; the end part of the tenon is the end . The length of the tenon is the distance from the shoulder to its end (end), the width is the transverse size of the cheek, the thickness is the size between the shoulders of the tenon (Fig. 11).

Rice. 11. Elements of a tenon connection: 1 - tenon; 2 - shoulders; 3 - cheeks; 4 - eye; 5 - nest.

The types of tenon joints, depending on the thickness of the parts being connected, are given in table.

Table

Joinery tenon joints

The tenon connection must be made with interference and clearance values in the range of 0.1–0.3 mm, i.e., almost tight.

The main disadvantages in a tenon joint are: inconsistent dimensions of the tenon in length, thickness, non-parallelism of the surfaces of the tenon or eye, chips, tears, leaks in the tenon joint, etc.

The strength of a tenon joint largely depends on the correct choice of tenon sizes.

The main dimensions of the studs are determined by GOST 9330.

So,

— thickness of a single spike S = 0.4 S0;

— thickness of the double spike S1 = S3 = 0.2 S0;

— triple S1 = S3 = 0.14 S0,

where S0 is the thickness of the part (Fig. 12).

The calculated thickness is rounded to the nearest larger nominal size: 6, 8, 10, 12, 16, 20 and 25 mm.

The length of the through tenon should be equal to the width of the bar, the length of the blind tenon should be half the width of the bar.

The depth of the socket is made 2-3 mm greater than the length of the spike.

It is recommended to bevel the end faces of the tenon on both sides at an angle of 25-30 ° so that the tenon fits better into the socket and the glue is less likely to run off the cheeks of the tenon.

In double and triple tenons, the gluing area increases by 2-3 times and the strength of the connection increases.

The dovetail tenon is strongest at an angle of 10° . At a larger angle, the cheeks of the tenon chip off, and the connection becomes less strong.

Making spikes and lugs

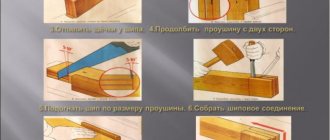

When making tenons and eyes, the following operations are performed: mark the tenons and eyes, saw down, cut out the shoulders and hollow out the eyes. In accordance with the working drawing, the dimensions of the connections are determined, after which they begin marking.

The marking of the corner end connection on the open through single tenon UK-1 for bars 42 mm thick and 65 mm wide is shown in Fig. 56. For compound UK-1 Sl = 0.4S0; S2 = 0.5(S0 – S1), where S0 is the thickness of the block, equal to 42 mm. Hence the thickness of the tenon S1 = 0.4 S0 = 0.4 42 = 16.8 mm (rounded to equal 16 mm), S2 = 0.5 (42 – 16) = 13 mm. In accordance with these data, the spikes are marked. Both tenons and eyes can be marked using templates, which are used to mark the ends of the bar.

Rice. 56. Marking of studs and lugs: a – marking of the linear height of the stud; b – marking the length of the tenon with a square and a pencil; c – marking the thickness of the tenon with a ruler; d – applying the mark with a surface planer; d – marking of the end connection; e – eye; g – thorn; 1 – risk; 2 – cut line; 3 – marking line; 4 – shoulder; 5 – part of wood to be removed

The tenons and lugs are sawed down a bow saw very carefully, since a distortion of the tenon will lead to a distortion of the sash. If the tenon is thicker than the design size, then when seated in the eye it can split the block, and if it is thinner, the connection will be weak, since it will not fit tightly.

When sawing, make sure that the saw passes near the mark; only in this case will you get the exact size of the tenon or eye. When making tenons, the marks are sawed only from the outside, and when making eyes - from the inside.

When starting sawing, to quickly deepen the saw, place the saw on the edge at an angle of 15–20° and, after making several movements towards yourself, deepen the saw without pressure, after which they saw evenly without pressure or jerking. After washing, the hangers are cut off. After cutting, the eyelet is hollowed out with a chisel and mallet and cleaned with a chisel.

Figure - Scheme of marking and processing of tenon joint elements

Depending on the thickness of the products and the required strength, the bars are connected with one, two or more tenons. Increasing the number of spikes increases the bonding area.

The tenon joints of the bars are angular end, middle and box.

The angular end connections of the bars are made with tenons: open end-to-end single UK-1.

Figure - Dimensions of the open end-to-end single end connection of UK-1 bars

Open end-to-end double UK-2

Figure - Dimensions of the open end-to-end double end connection of bars UK-2

Open end-to-end triple UK-3

Figure - Dimensions of the open end-to-end triple end connection of UK-3 bars

Non-through with semi-darkness UK-4

Figure - Dimensions of a closed blind corner end connection of bars with semi-darkness UK-4

Through with semi-darkness UK-5

Figure - Dimensions of the open end-to-end corner connection of bars with semi-darkness UK-5

Not through with darkness UK-6

Figure - Dimensions of the non-through corner end connection of the bars with darkness UK-6

Through the darkness UK-7

Figure - Dimensions of the through corner end connection of the bars with darkness UK-7

(dowels) are increasingly being used . The main advantage of joints on such spikes is the simplicity and strength of corner ties. The use of dowels makes it possible to mechanize and automate production processes.

The strength of the dowel connection depends on the following factors: the amount of interference (clearance) in the connection; the depth of pressing of the dowel into the end of the bar and into the edge of the paired bar (for example, connecting the drawer of a chair with the leg); method of applying glue: only on the walls of the hole or dowel or on both surfaces to be connected; the type of wood from which the dowel is made; dowel diameter.

According to GOST 9330, the total length of the dowel is L = 2.5-6d, where d is the diameter of the dowel .

Non-through and through round insert tenons UK-8

Figure - Dimensions of the non-through corner end connection of the bars on the round insert tenons UK-8

On the “mustache” with an insertable non-through round tenon UK-9

Figure - Dimensions of the non-through angular end connection of the bars on the miter with plug-in round plug-in tenons UK-9

On the “mustache” with an insertable non-through flat tenon UK-10

Figure - Dimensions of the non-through angular end connection of the bars on the “mustache” with the insertion non-through flat tenon UK-10

On the "mustache" with an inserted through flat tenon UK-11

Figure - Dimensions of the angular end connection of the bars on the "mustache" with an inserted through flat tenon UK-10

The dimensions of tenons and other elements of corner end tenon joints are given in Table 5.

Table 5

Dimensions of tenons and other elements of corner end connections

What and how to adjust spikes and lugs

How to make a tenon so that such a connection is of high quality and lasts a long time. The appearance of the tenon is considered one of the key moments in the history of the development of carpentry. They say that a real master must be able to make such compounds. Call them, if you like, a measure of the level of carpentry skill. How to make a tenon correctly and accurately fit to the eyes, through tenons, reinforced with dowels, will be clear evidence of the quality of the product, which is unattainable when using screws or time-saving lamellas. As the name suggests, this joint consists of a tenon passing through the hole (eye) of the adjacent part, and often the tenon is made to protrude slightly on the other side. If you're ready to learn how to make these joints, try using them instead of slats.

Preparation of the project description

3) Assessment and self-assessment of the project

4) Protection of the project

A47: Each machine consists of three mechanisms:

- Motor, cutting mechanism, transmission mechanism

- Motor, transmission mechanism, actuator

- Motor, transmission mechanism, rotating mechanism

A48: What tools are used to control the quality of the manufactured product:

- Jigsaw, center punch, scriber

For cutting external threads

A40:

What is called design documentation: 1) List of documents required for the manufacture of the product

2) A set of graphic and text documents that set out all the information about the design of the product

3) List of materials required for the manufacture of products

4) Instructions for use of product

A41: Processing defects are not:

- knot

Scale for measuring whole fractions of a millimeter

A56: What is not an electrical installation tool:

- Pliers

- Wire cutters

- Screwdriver

- Metal scissors

A57: There are no hinges and locks:

- Mortgages

- door

- Invoices

- Mortise

A58: The tailstock of a woodworking lathe is used for:

- Fastening the left end of the workpiece

- Fastening the right end of the workpiece

- Tool mounts

A59: Product finishing is:

- Intermediate operation in the manufacture of a product

- The final operation in the manufacture of a product

- No such operation

A60: Property not related to metals:

- strength