Making spikes and lugs

When making tenons and eyes, the following operations are performed: mark the tenons and eyes, saw down, cut out the shoulders and hollow out the eyes.

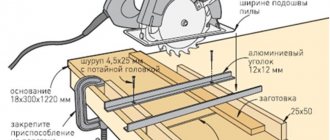

In accordance with the working drawing, the dimensions of the connections are determined, after which they begin marking. The marking of the corner end connection on the open through single tenon UK-1 for bars 42 mm thick and 65 mm wide is shown in Fig. 56. For compound UK-1 Sl = 0.4S0; S2 = 0.5(S0 – S1), where S0 is the thickness of the block, equal to 42 mm. Hence the thickness of the spike S1 = 0.4S0 = 0.4 42 = 16.8 mm (rounded to equal 16 mm), S2 = 0.5(42 – 16) = 13 mm. In accordance with these data, the spikes are marked. Both tenons and eyes can be marked using templates, with the help of which marks are applied to the ends of the bar.

The tenons and lugs are sawed down with a bow saw very carefully, since a distortion of the tenon will lead to a distortion of the sash. If the tenon is thicker than the design size, then when seated in the eye it can split the block, and if it is thinner, the connection will be weak, since it will not fit tightly.

When sawing, make sure that the saw passes near the mark; only in this case will you get the exact size of the tenon or eye. When making tenons, the marks are sawed only from the outside, and when making eyes - from the inside.

Rice. 56. Marking of studs and lugs: a – marking of the linear height of the stud; b – marking the length of the tenon with a square and a pencil; c – marking the thickness of the tenon with a ruler; d – applying the mark with a surface planer; d – marking of the end connection; e – eye; g – thorn; 1 – risk; 2 – cut line; 3 – marking line; 4 – shoulder; 5 – part of wood to be removed

When starting sawing, to quickly deepen the saw, place the saw on the edge at an angle of 15–20° and, after making several movements towards yourself, deepen the saw without pressure, after which they saw evenly without pressure or jerking. After washing, the hangers are cut off. After cutting, the eyelet is hollowed out with a chisel and mallet and cleaned with a chisel.

Marking and making eyelets

The production of elements begins with cutting out a groove into which the tenon will be inserted. The quality of each of them largely depends on the accuracy of the markings and the level of the tool used. For its manufacture, a milling cutter can be used, which allows you to speed up the process of obtaining the eye. In home workshops you can make a groove with your own hands. The manufacturing sequence depends on the type of tenon joint. The basic sequence is as follows. Marking begins by dividing the workpiece into three equal parts. Next, cuts are made using a thin hand saw. Then, using a chisel of the required width, the inner part of the cut is removed, obtaining a groove element. The final processing of the walls of the resulting groove is carried out using sandpaper.

Connections of elements on dowels, nails, screws

Pins are wooden or metal rods of a cylindrical or cross shape. They are used as additional fastening in corner and middle tenon joints to protect the tenon from eversion. The parts are connected with dowels according to calculations, marking the installation locations in accordance with the drawing and using templates.

Holes for dowels are selected using drills. The locations of the holes are marked according to a template before drilling begins. You need to drill holes so that the drill goes without deviation in the given direction.

The dowel is placed in such a way that it is perpendicular to the side edges of the tenon and passes through both bars being connected, i.e., through the tenon and the eye. It is not allowed to replace wooden dowels with ordinary nails in a tenon joint, since nails spoil the joint and do not provide the same strength as a dowel. Wooden dowels in a tenon joint are placed on glue.

Nail connections are determined by calculation, and in some cases the number of nails is determined constructively, for example, when laying floors, installing built-in equipment, installing partitions, filing ceilings, etc.

In nail joints of structures made from larch and hardwood (birch), nails with a diameter of more than 6 mm should be driven into pre-drilled sockets, and the diameter of the socket should be 0.9d (d is the diameter of the nail being driven in), and the depth should be 0. 6 nail lengths.

When connecting elements made of coniferous and soft hardwood boards, nails, regardless of diameter, are driven in without first drilling out the sockets.

The distance between the axes of nails (along the fibers) for knocking together wooden elements (boards) should be 15d when the thickness of the punched element is greater than 10d and 25d when the thickness of the punched element is equal to 4d. The same distance between the axes of the nails for elements that are not pierced through by nails must be equal to or greater than 15d.

The distance between the axes of the nails (across the fibers), provided the nails are placed straight, should be 4d, and when driving nails in a checkerboard pattern or at an angle of less than 45°, the distance between the longitudinal rows of nails is reduced to 3d.

The distance from the longitudinal edge of the element to the outermost nail must be at least 4d. The diameter of the nails should not be more than 0.25 times the thickness of the thinnest board being punched.

Nails should be driven into wooden structures according to a template, a jig, in which the places where the nails are driven must exactly correspond to the drawings. Templates are made from plywood or roofing steel.

In structures in which nails are pulled out, the length of the pinched part of the nail must be at least twice the thickness of the wooden element being pierced and at least 10 nail diameters.

When driving backwards, the nails should not penetrate through all the boards (parquet). When hammering through, the ends of the nails should be bent across the grain. The permissible deviation in the distance between the centers of the nails on the side from which they are hammered is ±2 mm.

If the nail becomes bent while driving, it must be pulled out and replaced with a new one. It is not recommended to hammer nails into frozen and damp wood, as they corrode (rust), which reduces the strength of the connection. Nails must be driven into a healthy part of the wood. They should not be driven into knots and cracks.

When attaching platbands, baseboards, and floor boards, the heads of the nails are recessed and puttied before painting to cover possible dents.

Screws in carpentry are used for fastening flashings, devices - hinges, handles, screws, locks, etc. In this case, screws with a countersunk head are mainly used. Connections with screws are used when assembling built-in furniture, when the elements being connected are difficult to glue together, as well as in the case when individual elements need to be made dismountable (repair of appliances, covers, ebbs, etc.).

The screw is driven into the wood using a brace with a screwdriver or an electric screwdriver, rather than driven into it. When driving a screw into wood with a hammer, the screw connection turns out to be fragile, since the thread is crushed and the wood is broken at the point where the screw passes. In this case, the connection loses up to 40% of the force holding the screw in the wood.

When a screw is driven, a natural nut is formed in the wood, due to which the elements being connected are firmly pulled together.

The strength of the connection with screws depends on the density of the wood, the size and number of screws, the depth of their driving (the screw must be screwed in completely), and the direction of the fibers.

In hardwood, screws should be driven into pre-drilled holes. The diameter of the hole should be 0.9 times the diameter of the unthreaded part of the screw, and the length of the hole should be from 1/2 to 3/4 of the length of the screw. When driving screws into oak wood, they are first lubricated with grease to prevent corrosion. It is not recommended to drive screws into damp wood, as they will quickly corrode (rust). When connecting building elements with screws, the distance between the axes along the fibers should be 10d, between the axes across the fibers and from the longitudinal edge - 5d (d is the diameter of the screw).

Joiner's tenon joint (tenon and groove)

When creating any structure, fastening methods are always developed that can ensure reliability, the possibility of long-term operation and a neat appearance. To solve these problems, so-called tenon joints are used in wooden products. The basic principle of fastening two parts is to create spikes in one part and grooves (eyes) in the other into which they are inserted. Using carpentry tools, both parts are processed with precise adherence to geometric dimensions. This ensures reliable grip, especially if plywood is used as the material. After this, the product can be used without the use of additional fastening elements. However, to increase reliability, wood glue or additional fasteners are used.

Basic information

One of the most proven methods of connecting two parts is considered to be a tongue-and-groove connection. This method of fastening wood products is the most widespread. It is used to fasten parts of window frames, doorways, various furniture elements, and the walls of wooden boxes. Each element of such products has a specially made tenon (or several pieces) or a groove (several grooves).

The types of main connections of parts made of wood are defined in GOST 9330-76. This document defines the following characteristics of such fastening of wooden parts:

- rules for abbreviation (abbreviation) of various compounds;

- drawings showing the appearance;

- permissible dimensions of each element;

- the procedure and rules for determining the size of each element;

- expressions for calculating the dimensions of the required cutting tool;

- formula for calculating the strength of assembled elements;

- inspection procedure and strength testing.

GOST 9330-76 Basic connections of parts made of wood and wood materials. Types and sizes

According to this standard, all connections are divided into the following categories:

- corner (end and middle);

- box (mainly belongs to the corner category);

- along the edge;

- the so-called “on the mustache” length.

For each of these categories, the standard has its own abbreviation (short designation). This marking consists of two capital letters of the Cyrillic alphabet and one number. For example, UK-2 means that we are talking about a connection with a double open end-to-end tenon, UK-9 is a “mental” connection with a plug-in non-through round tenon. The entire list is set out in more detail in the text of the adopted standard.

Any type is accompanied by a detailed drawing. Each of them shows frontal and profile projections indicating dimensions, formulas for calculating each element, and finished results. To obtain a strong connection, the standard defines tolerances that must be observed in the manufacture of each element. The parameters of the corner tenon (its length, pitch and bluntness) are given in detail. Based on the results presented, the guest developed recommendations for choosing the necessary cutting tools. Separate references are made to other documents (standards) that determine by what means each of the listed products must be secured.

Types of finger joints

Today, a wide variety of such methods for fastening wooden parts has been developed. All types of tenon joints are classified according to the following criteria:

- number of spines;

- their form;

- eye depth (through or not);

According to the first sign, tenon joints are: single, double, multiple. It determines the number of fasteners produced. The main forms of the spike are:

- rectangular (has different lengths, pitch and apex angle);

- round;

- triangular;

- so-called “dovetail” (one-sided or two-sided);

- gear (with different angles of inclination);

- angular.

The choice of shape and size depends on the material used and the level of load that the entire structure must withstand. A tenon joint with many rectangular tenons has become widespread. Its main advantage is considered to be ease of manufacture and the ability to use it for any wood.

Marking and making a tenon

To ensure the reliability of the structure, the manufacture of a tenon must begin with careful markings. At the first stage, it is determined what type this element will be manufactured and where it should be located. According to its location, positions are distinguished: corner end, middle and box. In addition, you need to decide how many of them will be in the connection. One of the factors influencing the quantity is the thickness of the workpiece. If the part has a thickness that does not exceed forty millimeters, choose a connection with one tenon. If the width is in the range from forty to eighty millimeters, two or three are made. For thicker workpieces, a triple or multiple connection is cut. The experience of professionals shows that the tenon should have a thickness equal to one third of the total size of the part, and the length should be equal to the thickness of the elements being fastened.

The main stages of making a spike are:

- marking the future spike (horizontal and vertical);

- tool preparation;

- sawing;

- cleaning the walls;

- fit.

Marking the locations of the required cuts is done using measuring tools in both planes. The choice of cutting tool depends on the capabilities of the manufacturer. At woodworking enterprises, this operation is performed on special machines. If you plan to make a tenon with your own hands, use ordinary saws. The most suitable are: a bow saw or a hacksaw. After making the spike, its surface is cleaned. This is done using files and sandpaper. Next, the insert tenon is adjusted to fit the prepared groove. After completion of this operation, its final fixation is performed.