A hand plane is a tool designed for processing wooden products (but not only). As a rule, it is used for planing, and this process involves removing thin layers from the top of the workpiece to a specified thickness. In this case, the mentioned thickness is determined by the characteristics of the plane. The result of the work should be that the product acquires the necessary shapes while creating the specified conditions of straightness and evenness. Also, the tool in question can be used to make quarters and grooves, i.e. deep recesses of various shapes.

Features of planer designs

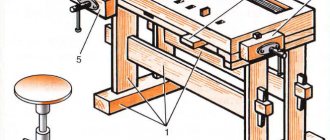

The traditional model of the instrument is made in a wooden case, in which the cutting blade is securely fastened. At the bottom there is a sole with a slot through which the cutting blade passes. For comfortable work, a so-called horn (handle) is installed on the front of the plane, thanks to the pressure on which the lower base fits tightly to the surface being processed, and at the same time the necessary direction for the knife is given. Throughout the history of use, the planer, as well as other carpentry tools, has received many improvements. The wooden case subsequently began to be increasingly replaced with metal (for greater strength) or plastic (to reduce the overall weight). Further, manual planing with the application of muscular effort on the part of the operator was replaced by the use of automatic electric models. Thus, the main parts of the tool in question will always include:

- Housing – all the main components and elements of the device are fixed in it;

- Cutting knife - it is sharpened at a certain angle and is responsible for removing the wood layer;

- Clamp – provides a tight and motionless fixation of the knife in the body (can be made in the form of a metal plate or a massive wooden block);

- Chip breaker - located just above the knife and ensures a break in the emerging chips so that they do not clog the structural elements of the device;

- Adjustment screw - this part is responsible for changing the position of the knife relative to the plane being processed.

All classic woodworking models have the above design. However, some design elements may be missing in new designs or specialized varieties.

How to use

Hand planes for wood are simple in design and quite easy to use. The main thing is to do the work smoothly, without jerking. This is especially true for very long workpieces. If this condition is met, the surface of the finished product will be very neat and smooth. When planing, you should stand to the side of the workpiece, with one foot forward.

The top and bottom surfaces of the products are very easy to process. It is somewhat more difficult to do work on the edges. In this case, it is important to secure the knife very firmly. Under no circumstances should it vibrate in the block. Edges should be planed exclusively in the direction of the grain.

There is also a technique that allows high-quality processing of very wide workpieces. In this case, the product is first planed diagonally, adhering to the direction of the fibers. Next, the plane is checked for evenness using a special ruler. At the final stage, finishing is carried out. In this case, a thin layer of chips is removed from the workpiece parallel to the edge.

How a traditional hand plane works

The main working elements of the device are its base with a guide handle and a knife. From here it is clear that the essence of their work is to comply with two parameters - the accuracy of setting the angle at which the knife is located, as well as ensuring a tight fit of the sole to the plane being processed.

The tightness of the working base to the surface, in most cases, will depend on the material from which the tool is made. The main condition is its perfect smoothness and evenness of the sole. The wood from which the body of the device is made will wear out and deform over time. This process can even proceed at an accelerated rate if work is carried out on hardwood on an ongoing basis. In turn, a metal tool will maintain the flatness of the sole for a long time, but its body may be subject to corrosion processes. Thus, when choosing a housing, it is worth relying on the conditions in which most of the work will take place.

Choosing between professional and household electric planer

Modern technologies are increasingly replacing manual labor. This is what happens in carpentry too. Today, power tools are used for large volumes of work. The same applies to the plane. On the market you can find many types and brands of similar electric tools.

The main working element of an electric planer is a drum with knives mounted on it. The latter can be from one to four pieces. The drum rotates and the knives process the surface. The higher the speed of such rotation, the faster and better the work will be done. For most household electric planers, this figure is 10-15 thousand revolutions per minute.

When choosing such a tool, first of all you should pay attention to its purpose. Here, manufacturers offer two options - a household and a professional electric planer. In addition to their cost, these tools differ in other important characteristics.

Firstly : this is their power. If the household version has from 600 to 1000 W, then for the professional one the minimum value is 1.2 kW.

Very often, manufacturers indicate two values for this parameter in the instrument documentation. The first, largest, indicates maximum power. It is to this concept that the values of 600-1000 W are tied - for household tools. The second value represents the effective power. When choosing, you should pay attention to this parameter; it should be more than 350W.

The effective power of the electric planer must be at least 350W

Secondly: a professional electric planer has more adjustment options. For example, the planing depth of a household tool can be set from 0 to 2.5 millimeters. If you take a professional plane, then this value can be increased to 4 mm. Also, pay attention to the adjustment step. The lower this value, the better the quality of the material can be processed.

A professional plane is more powerful, which means that its weight is significantly greater than the household version. In the first case, we are talking about a minimum of 4 kilograms. Sometimes the weight of a professional electric planer reaches 9 kg. For the household version this value is less. The weight of the simplest plane is 2.5 kg, and a more powerful one can reach up to 4.

In addition, a professional tool can have many different additions. For example, many electric planers are equipped with an electronic system for maintaining a certain, predetermined number of revolutions. The household version of the tool does not have such an addition.

When choosing between a professional and a household tool, you should clearly know what you will use it for. If you need a plane not so often, to perform simple tasks, then there is no point in purchasing expensive equipment. But if you practice professionally, then the instrument must match.

Types of hand planes

The design of the carpentry fixture in question has several standard varieties. Even a classic manual model for professional use, with standard sizes, can be classified in terms of design features:

- Double planer - the comfort of working with it lies in the fact that it is necessarily equipped with a chip breaker, which ensures clean processing (more useful when finishing the product);

- A single plane is more suitable for roughing and initial surface treatment, because its knife blade is straight and single. Such a knife has a cutting edge with the smallest radius of curvature and therefore does not leave large marks behind.

During their historical development, planes acquired many highly specialized modifications adapted to perform a specific type of task, for example:

- Jointer - this manual type device is intended for finishing an object. The long block is its main difference from the classic plane model. It is possible to install one or two knives in such a block, which will make the work of leveling the surface more comfortable.

- Sherhebel - visually similar to the classic version, however, it has a narrower body and is necessary for making recesses. It is worth noting that with a narrow body, the instrument itself has considerable mass, and its knife is very small in width and its blade is rounded and located at an angle of 45 degrees to the surface. This feature allows you to plan wood across or along the grain, leaving behind deep grooves. Sherhebel is used more for the initial processing of wood and is designed to remove the rough top layer.

What types are there?

Hand planes come in several different types. They may differ from each other in the shape of the blades, design and other parameters on which the purpose and scope of application of the tool depends. Depending on the design features and scope of use, planes are of the following types:

- Medvedka. Has a long sole. As a rule, this tool is often used in cases where large pieces of wood need to be leveled. In addition, they are best suited for large volumes of work.

- Planers. Equipped with double cutter. Used for finishing wood surfaces. This tool has a longer sole than the Scherhebel, which makes it possible to process large volumes of wooden parts and workpieces.

- Half jointers. They are a shortened, trimmed version of the standard, simple jointer. It is equipped with a double knife and is mainly used in cases where there is a need for fine planing of workpieces.

- Solid. For such devices, the sole consists of 3 planes. Their main purpose is trimming, processing sharp corners that are present directly on the very edges of wooden parts or blanks.

- Roughing. Used for rough planing of wooden parts. In addition, they are often used for cutting edges on drywall, which ensures smooth sloping cuts.

- Grinding pads. This hand tool is designed for high-quality, fine finishing of wooden surfaces. As a rule, it is used in cases where it is necessary to process the product in the area of knots, at the ends.

For domestic use, as a rule, one model of plane is used (for the initial, rough finishing). However, in carpentry workshops, tools are used for both rough and finishing processing of products. In addition, for the manufacture of wooden parts or products of complex geometric shapes, carpentry workshops also use so-called planers for figure cutting.

Flat planing

Working with flat surfaces, such as bars or boards with the correct geometry, must be done with a high degree of precision. Deviation from the standards for straight lines can radically change the dimensions and dimensions of the material. For this type of work, the following devices with a special design are used:

- Semi-jointer - unlike the classic jointer, it has a small knife and sole. This feature allows you to work with both large and small workpieces, while maintaining the evenness and straightness of the surface, without losing the quality of accuracy;

- Tsinubel - this tool gives the surface a roughness effect, which is necessary for better adhesion between objects when connecting them with glue. The device is equipped with a blade with teeth and can be used to plan even twisted wood and the ends of objects.

How to store it correctly

Experienced craftsmen believe that a knife for a hand plane becomes dull, for the most part, not even during operation, but because of improper storage. After finishing planing the workpieces, this tool should be cleaned of chips and placed in a box specially designed for it. In this case, the position of the tool should be such that the knife blade protruding from the body is not at the bottom, but at the side.

If the hand plane is going to be stored for a very long time, it must be disassembled and thoroughly cleaned before putting it in the box. Knives and other metal parts should be wiped with an oiled rag.

Figure planing

Figure planing on wood is an art. To create unique products with a profile section, it is necessary to use a special material - wood of the highest quality, which must have a minimum number of knots, and it itself must be straight-grained. At the same time, such high-quality material must be processed with a special-purpose tool. Such tools may include:

- Kalevka - this type of plane is used for shaped processing of objects. It has a multi-level sole and special edges on the knife. Perfect for making carved door/window trims, baguettes and cornices.

- Tongue and groove - used for making grooves, holes in boards and tongue and groove joints, as well as other tongue-and-groove joints. Consists of securing and guiding blocks held in place by screws.

- Primer – it is designed for cleaning grooves in the form of a trapezoid along the grain of the wood.

- Zenzubel - it is used for making grooves and quarters and then cleaning them. The knives of this device are shaped like blades, and the body is equipped with a special hole for discharging chips.

- Falzgebel - used for stripping and selecting quarters, has a stepped sole.

- Humpback - its plantar base has a convex shape, which is very convenient for working with cylindrical, semicircular or concave surfaces.

How does a wooden and metal sherhebel work?

The carpentry sherhebel in question is characterized by a fairly large number of different design features. These include the following points:

- The block is the main part of the structure, so the dimensions are quite large. Wood and metal can be used in production.

- Depending on the type of material used, Sherhebel can have different sizes.

- According to established standards, the sherhebel is represented by a combination of a rectangular body, a special horn for resting the hands, a knife, a sole, a cork, and a clamping wedge.

- The surface of the wooden element of the product is coated with a special varnish, which greatly simplifies the movement of the sherhebel on the surface.

Like the Scherhebel knife, other elements of the tool can be made using certain materials. In this case, the standards specified in GOST must be taken into account. Let's take the following as an example:

- The block is made of hard wood. They can last for a long period.

- The purpose of the sole is direct contact with the surface being treated. That is why maple, beech, ash and other similar dense materials are used in production.

- The pad of the block is made of birch and elm. The sherhebel's skin should be smooth and free of significant defects.

- Today, a two-layer blade is installed. In most cases, tool steel is used, as well as some alloying alloys. In some cases, other alloys characterized by increased wear resistance are used.

The Scherhebel is adjusted depending on the operating conditions. You can often encounter a situation where a version with a metal body, which is made in cast form, is used. A special handle is required to support your hands while working. Unlike common wooden versions, metal ones are characterized by increased wear resistance. This is due to the fact that wood reacts to changes in humidity and temperature.

Adjusting and sharpening the knife blade

Proper adjustment of the position of the cutting knife will reduce the time and muscle costs for processing the object. The rib, which is the working surface of the blade edge, has a slight radial rounding. In order to reduce it, you need to sharpen the blade in several steps using a sharpening wheel or a fine-grained sanding block. The sharpening angle of 30 degrees is considered universal and ideal for working with both soft and hard materials.

In turn, if the blade simply slides across the surface, this means that it does not protrude enough. If the blade is extended far from the block, it will remove too thick a layer and tear the wood fibers. It is clear from this that the working part of the knife should protrude from the body to a length of no more than 0.2 to 0.3 millimeters, and this will ensure the proper requirements for uniformity and parallelism. Such an adjustment can be carried out either “by eye” or using a ruler, adjusting the length of the knife extension with a hammer or a retractable screw.

Naturally, a hand plane, like any other carpentry tool, requires constant care. No matter how excellent the quality of steel is used to make a knife, sooner or later it will become dull and will need to be sharpened. As a rule, sharpening is performed on a special stone called a whetstone. To do this, the surface of the stone is moistened with water; you will also have to spray the blade itself during sharpening. To get the best effect possible, the blade should be pressed as tightly as possible against the stone. You can choose the sharpening angle yourself, but 30 degrees is considered the best option. Before starting the process, you should pay attention to how the blade was originally sharpened and it is advisable to repeat this procedure. For example, some professionals prefer to sharpen a knife not on a whetstone, but on a sharpening wheel. If a similar procedure was used, then when using a whetstone, the blade should be applied to the side surface, and not to the edge. Sharpening with a wheel will have maximum results only if its abrasive surface is fine-grained. Otherwise, finishing will be necessary using fine sandpaper or a sharpening stone. The quality of the work done can even be assessed “by eye” - if the blade does not shine, then the knife is sharpened with high quality and can be used.

Reviews of plane brands

Carpentry tools of this type are sold on the modern market from different manufacturers. Many brands are of very good quality. For example, planes from companies such as Bailey and Handyman have earned good reviews from craftsmen. Bailey tools are valued primarily for the excellent quality of their knives and long service life. Sharpening the knife of a hand plane of this brand is done quite rarely. Sometimes there are comments that mention the build quality is not very good. But even if any shortcomings are found in the purchased tool, they can usually be easily and quickly eliminated, and on your own. Handyman planes, judging by the reviews, are also convenient and reliable. Their only drawback is their not very neat design.

Experienced craftsmen do not advise purchasing Groz brand products (India). Despite the fact that the products of this brand are classified as expensive, judging by the reviews, they are not of particularly good quality. Their build quality is simply disgusting, and at the same time it is inconvenient to work with them.

Basic rules for working with a hand plane

This tool should be used exclusively in accordance with its design features. During planing, muscular force is transmitted to the front of the body by the user's left hand, while the back is held by the right hand. It is important to move the plane along the fibers with measured and progressive movements. The main point in finishing is that you should not reduce the force applied to the plane and do not remove it from the product without completing a single pass. But for roughing, small and frequent movements are quite suitable. The main sign of high-quality processing will be a continuous ribbon of wood shavings emerging from under the blade of the tool. Although it may seem that the planing process is quite simple, extra training will not hurt. So, when performing the final processing of a product, it is worth first practicing on substandard materials (trimmings and stumps), because there is a risk of damage to the workpiece due to deep, unnecessary cuts or snags. The basic safety rules can be reduced to several provisions:

- Before starting work, you need to check the serviceability and accuracy of the plane settings;

- The device must be stored in a special place with the necessary conditions;

- During operation, the user's body must maintain a stable position and hands must be safe;

- Upon completion of work, clean the device from chips.

Rules for stripping ends

When cleaning the ends of the product, the plane moves in the direction “away from itself”, in short jerks. This processing method will allow you to cut wood fibers crosswise with less muscular effort. To avoid chipping the edge, you must first remove the chamfer. In general, it is even better to process one end to the middle, then process the end from the other end, also to the middle.

Possible mistakes when working with a hand plane

- Before starting work, you should carefully consider the direction of the wood grain on the board. They should be directed according to the distance of the device from the user’s body. In cases where this requirement is not met and the work is carried out with a plane towards the grain, the result can be a much rougher and less accurate result.

- It is also possible that the material being processed is poorly dried and twisted with a “screw”. Such spiral winging and screw warping are eliminated by planing the raised corners on all sides. The final alignment can be done during finishing.

- The most important problem when working with ends is the creation of so-called “flakes”. Their occurrence can be avoided by planing from the edges to the middle, alternately alternating the side of processing.

- An unpleasant situation is possible when, after planing is completed, the surface of the product remains convex. This can happen if, starting to plan from the edge, the plane is involuntarily held almost by weight and at an angle. Avoiding this problem is very simple - you need to constantly monitor whether the plane is held correctly in the desired position;

- When finishing the product, you should press a little harder on the body, while moving the tool exclusively with your right hand. The left one will guide him forward. From this it can be seen that great efforts must be made to that part of the device that is currently located directly on the workpiece. And the pressure on the part that is in the air needs to be reduced, on the contrary. Following this rule will allow you to obtain a smooth and clearly finished surface.

Tools

0 votes

+

Vote for!

—

Vote against!

If you have ever been lucky enough to “finish” unplaned wood, then you know how labor-intensive and tedious this task is, especially if you use an old hand plane. Armed with such a tool and putting in a lot of effort, you can level the surface of wooden products, reduce their thickness and create a whole variety of extended recesses. High productivity, excellent results and significant savings in labor costs will be provided by an electric plane - an indispensable tool for carpentry work.

Content:

- Hand plane: main purpose and principle of operation

- Choosing an electric planer: what to look for

- Choosing what you need: review of the world's leading brands

- Some tips for beginners

Hand plane: main purpose and principle of operation

Unlike its mechanical counterpart, an electric plane is much more functional and convenient to use. Which is not surprising, since most of the load falls on the electric motor, and all you have to do is easily guide the plane in the desired direction.

The basic list of operations performed by an electric planer includes: preliminary planing, careful processing to size, fitting, beveling the edge, cutting out quarters. And the use of cutting tools and additional accessories significantly increases the functionality of the tool.

Of course, at first you may end up with sloppy “steps” that are very difficult to level. So pick out a few unwanted boards and learn how to plan. In addition, it is enough to install the electric plane motionlessly, and instead of a hand tool you will receive a reliable planing machine.

Like any other power tool, all models of electric planes can be classified into household and professional, differing only in the set of functions, power and permissible duration of continuous operation.

The main elements of a manual electric plane:

Therefore, we will not focus on the classification of electric planes, but will focus on those main points that will allow us to answer the question “how to choose a hand plane.”

So, the fundamental part of any electric planer is a rotating drum on which the knives are securely fastened. In order for the processed surface of the wood, which by its nature is heterogeneous, to turn out smooth, the electric motor rotating the drum must have sufficient power - from 580 to 900 W, as well as a rotation speed reaching 1000 rpm.

By means of a toothed drive belt, the rotational motion is transmitted from the electric motor to the drum, and since it periodically wears out and requires replacement, it is placed under a removable side casing. The second removable cover, located above the motor, hides the carbon electric brushes. Thanks to the smooth increase in motor rotation speed when turning on the tool and automatically maintaining it at a given level, the possibility of overloading the electric motor is almost completely eliminated.

The soleplate of the electric planer, made of high-quality aluminum, is divided into two parts: one part is located in front of the drum, the second is located at the back.

Being stationary, the rear part of the tool sole slides over the processed wood, while the front part still moves over an uneven surface and is adjustable in height, setting the required cutting depth and chip thickness. This adjustment is made using a handle or a button with divisions, which often acts as a second handle. When working with an electric planer, you should move it at a constant speed, which is determined by the thickness of the chips being removed.

Some models are equipped with a drum that is accessible from one side. This allows you to select a quarter at a 90 degree angle along the entire length of the board. Using the side stop, which is often included with the tool, you can, without much effort, select a quarter of the width you need.

In addition, such models are additionally equipped with a protective folding cover, which is located on the side of the drum during the classic operation of an electric planer and rises to the upper plane at the moment when you select a quarter.

More details about the design features of electric planes in the YouTube video.

Choosing an electric planer: what to look for

When choosing a suitable electric planer model, you need to pay attention to certain points.

Sole

The sole of the plane largely determines the final result of the processed wood surface: a smooth sole guarantees a perfectly even planed wood.

The air cushion formed during the work process usually creates obstacles to obtaining a cut of the same thickness. However, this problem is completely solvable; you just need to use a sole with grooves. Several grooves located on the front section of the sole are V-shaped and are designed to eliminate chamfers from the corners of the processed products.

Adjusting the height of the front section of the sole of the electric planer involves moving it in the vertical and diagonal directions. In this case, the sole of the tool is always equidistant relative to the knives, which ensures a thin, even cut. It should be noted that the length and thickness of the sole of the electric planer determines its stability during operation.

Electric planer handles

It is always easier to move such a heavy tool as an electric planer across the surface being processed using two handles rather than one.

Using the rear handle, you can push the tool, while the front handle allows you to adjust the direction of movement of the electric planer and provides the opportunity to work “in a big way.” It is enough to press hard on the front handle, and the chips removed will be thicker.

Possibility of adjusting the thickness of the removed chips

Since the adjustment knob on a power tool sometimes acts as a second handle, it can be seen with internal notches that protect against accidental or unwanted switching of the set chip thickness.

Typically, the switching step is 0.1 mm, but each tool model may have its own characteristics: for example, some models of electric planes continue to remove chips. It is preferable to choose those models whose scale starts from “0”, for example, a tool from MAKITA.

Electric planer knives

All models of electric planers are equipped with two removable removable knives made of tungsten and carbide. However, there are manufacturers offering knives made of hardened steel, sharpened using a holder, which will provide the required sharpening angle.

Thanks to the centering groove, straight carbide knives easily fit into place in the knife holders located in the grooves of the drum. But hardened steel knives require more careful alignment relative to each other.

Knife protection

All models of electric planers are equipped with two types of protective devices, interconnected and located on the side and bottom. They completely eliminate contact of fingers and the surface being processed with the knives of the equipment. A protective plate on the side of the power planer allows you to cover the edge of the drum and rises as far as the power tool goes deeper into the wood being processed when selecting a quarter.

Chip ejection

Thanks to the direct ejection of chips, the tool is reliably protected from clogging, but they can scatter throughout the room. The direction of the ejection mouth will make cleaning much easier.

Depth gauge and side stop

Using the side stop and depth gauge in the electric planer, which must be included in the tool, you can set the exact depth and width of the chips to be removed.

In order to cut corners, some stops must be tilted 45˚. The side stop is essential for creating fine edges: it gives the power tool balance

Accessories for electric planer

An electric hand planer can be equipped with various accessories, for example, wavy knives made of hardened steel, which are effective for rough processing of wood. By equipping an electric planer with equipment for a fixed installation, you will turn it into a planer and an automatic jointer at the same time. Of course, this is very convenient, but it requires special attention to ensure safe operation of the equipment.

Ergonomics of an electric planer

The large dimensions and heavy weight of the electric planer give good balance, but can become a hindrance when processing a large volume of wood and when working in a big way.

Choosing what you need: review of the world's leading brands

Today, the construction tools market represents a huge range of household and professional hand planes, the price of which depends on the functional load and configuration, appearance and technical characteristics. Let's look at products from leading brands, including Skil, Metabo, Makita, Bosch, Black&Decker, DeWalt and Atlas Copco

Electric planer Skil

The Skil hand metal planer is equipped with ultra-sharp knives and a durable knife drum with electronic balancing. From the Skil line of electrical equipment, models 1506V and 1510V stand out, which differ in power: 1506V consumes 450 W, while the planing depth and width reaches 0.6 mm and 82 mm, respectively. The consumption of the 1510V model is 500W, but the planing depth increases to 1.0 mm.

Metabo electric planers

In the Metabo product line, the title of favorite deservedly belongs to the HO 0882 model. And all because its power of 800 W does not overload the network of a private home or country house. In one pass, the planing depth will be 3.0 mm. The compact tool features a comfortable handle with push-button start and a durable front handle with depth adjustment.

The drum rotates at a speed of 12,000 rpm, which allows you to do the same amount of work in a minute that you would do after 24,000 strokes with a regular hand plane. The model is equipped with a set of additional knives for decorative wood processing.

Makita electric planers

A powerful and reliable Makita plane can satisfy all the needs of the most demanding users. If you require fine finishing and adjustment of the thickness of the cut as you work, then you cannot do without an electric planer model 1902 or 1923H. The rotation speed reaches 16,000 rpm, the planing depth is 1.6 mm, while the power is 750 W and 850 W, respectively.

Bosch electric planers

Bosch electric planers are the perfect combination of price and quality. Among household models, a special place is occupied by electric planers PHO 25-82 and PHO 16-82, which differ from each other in terms of power consumption - 750 W and 500 W, respectively. The practically silent model PHO 16-82 is equipped not with two knives, but with one, due to which the number of revolutions per minute reaches 18,000, and the planing depth is 1.6 mm.

Among the professional products, we can highlight the GHO 31-82 and GHO 36-82C models with an increased planing depth of 3.6 mm and a power consumption of 750 W and 850 W, respectively.

Electric planers Black&Decker

Powerful and high-precision household electric planers Black & Decker are equipped with excellent carbide double-sided knives and are equipped with a chip removal device. The most preferred model is KW715 with a power consumption of 550 W and a planing depth of 1.6 mm. The drum rotates at a speed of 15,000 rpm. The KW725E electric planer is slightly more powerful than the previous model: the power is 900 W, and the planing depth is 2.5 mm. Modern control electronics make it possible to precisely regulate the rotation speed.

Professional electric planers from DeWalt are equipped with a front handle, which also allows you to adjust the depth of planing. A powerful motor increases the service life of the tool, and the support block protects the surface being processed from possible damage. Modern electronics allow you to maintain a constant speed under load, and a unique spiral knife will provide better wood processing.

Some tips for beginners

1. When finishing untreated, rough wood, first set the plane to the maximum cutting depth, and only on the next pass significantly reduce it. While working, do not put too much pressure on the tool, because the edge of the wood being processed is rounded.

2. Armed with an electric or manual plane, always plan in the direction of the wood grain. If the surface to be treated consists of several bars or boards, then it is recommended to plan at an angle to the adhesive seams and in the direction of the fibers. Since the sharp edges of wood will splinter over time, it is better to provide a chamfer. The sole of most modern models of electric planers has a triangular groove, which makes chamfering easier.

3. Often, even the most thorough treatment of the wood surface with an electric planer requires the elimination of barely noticeable marks using a hand scraper, the edge of which must be sharp and even. By moving it at a slight angle in the direction of the grain, you will cut off excess protrusions and level the surface. Finally, sand the surface - this will give it a particularly smooth finish.

4. If your tool gets stuck or produces shaggy chips, sharpen the cutter. To do this, use a sharpening machine with clamps that will allow you to fix the desired angle of inclination - usually 25°. This angle is suitable for a blade thickness of 6.7-7mm. Sharpen evenly, otherwise you will significantly complicate further work with the electric planer.

5. You can use a soft pottery wheel to sharpen the cutter. Make sure that the metal does not burn or overheat; to do this, lightly touch the sharpening wheel with the blade, cooling it from time to time. The sharpening wheel must rotate constantly against the blade. If burrs occur during sharpening, remove them by fine sanding using Belgian stone, wheel oil, or leather sanding belts. Sand until you are sure the edge of the blade is completely smooth.

6. And finally, remember that an electric planer is considered a very dangerous tool, even despite the fact that all the cutting elements are hidden, so be very careful and careful. Good luck!

Difficulty of choice

When purchasing a planer, you should first of all pay attention to the quality of the knife - the efficiency and productivity of future work will depend on it. This element must be made of high-quality steel, and it must work for a significant period of time without the need for sharpening. Naturally, it is quite difficult to visually determine the quality of a knife’s material. Thus, it is worth paying attention to the manufacturer’s brand reputation. The next step of the test is to determine the stability of the blade in the body - it should not wobble under any circumstances. The handle should also be given special attention - its position must be stable, and it must be firmly attached to the body. Additionally, it would be a good idea to check the following parameters:

- The sharpening angle is one of the main criteria that will determine the quality of wood processing and the speed of work. An excellent bonus will be the option, thanks to which the body design includes a mechanism responsible for adjusting the sharpening angle.

- The sole – it can also influence the final result of the work. The sole must be as smooth as possible in order to ensure proper evenness of the surface of the workpiece.

- The thickness of the removed chips - this parameter can be adjusted with a special screw on the tool, which is responsible for the depth of the blade extension. Sometimes, next to such a screw, there is a marking strip that clearly shows the specified thickness.

Top 10 rating according to KP

Editor's Choice

End plane STANLEY 60 1/2 1-12-060

End plane STANLEY 60 12 1-12-060.

Photo: market.yandex.ru Our rating opens with a device from the world famous manufacturer Stanley . This plane can be used when processing different types of wood, including very hard species. For the most precise adjustment, the device is equipped with a special angle adjustment mechanism. All parts of the plane are made of metal. This feature significantly increases the service life of the tool. In addition, the stylish design of the plane should be noted.

Main characteristics:

| View: | end |

| Processing material: | tree |

| Case material: | metal |

| Knife width: | 35 mm |

| Knife installation angle: | 13° |

| Outsole length: | 150 mm |

| Weight: | 720 g |

| Designed for: | for processing the end surfaces of wooden workpieces and laminated plastics |

Advantages and disadvantages

High quality materials, interesting design

The body geometry is not maintained

show more

Planer Kraftool 18527-35

Planer Kraftool 18527-35.

Photo: market.yandex.ru Next on the list is the Kraftool 18527-35 . It is intended for primary processing of soft wood. Also ideal for working with fiberboard, chipboard, plastic and plasterboard. High productivity is achieved thanks to multiple cutting edges and chip evacuation. However, the device does not withstand shocks and falls well, as the alloy can easily crack.

Main characteristics:

| Processing material: | tree |

| Case material: | metal |

| Handle material: | tree |

| Knife width: | 50 mm |

| Outsole length: | 350 mm |

| Outsole width: | 50 mm |

| Weight: | 2930 g |

Advantages and disadvantages

Stylish design. The handle is made of wood, good knife sharpening

High price, small errors in geometry

show more

Additional planer Sparta 210795

Additional planer Sparta 210795. Photo: market.yandex.ru

This plane is perfect for cutting out excess wood to obtain smooth planes on small, hard-to-reach parts. The high-strength housing does not deform even under significant operating loads. The design also provides a customizable automatic centering function for the cutting knife. In addition, the plane is equipped with a small chipbreaker for final processing of the wood plane.

Main characteristics:

| Processing material: | tree |

| Case material: | metal |

| Handle material: | tree |

| Knife width: | 58 mm |

| Outsole length: | 245 mm |

Advantages and disadvantages

Low price, light weight

Low quality materials, dull knives

show more

Instead of an epilogue

An analysis of the market for the instruments under consideration has established that the majority of positions on it are occupied by foreign-made goods. Rare models from domestic brands are able to penetrate only into the middle price segment, and that is thanks to high-quality manufacturing technology that has been established since Soviet times. However, foreign brands (even from the budget segment) can boast of quality workmanship and the ability to be effectively used for most typical carpentry tasks. As for the premium class, it presents extremely expensive and reliable devices that, although they cost a lot, are fully capable of earning their price. A striking example is the fact that in the premium class there are practically no models made of low-quality steel or those in which the knife requires frequent sharpening.

The best manufacturers

Constant competition and the struggle for the position of leader in the power tool market force manufacturers to constantly improve their products and release new models to the market.

Taking into account the technical characteristics of specific models and user reviews, the best manufacturers of electric planers today are:

- Interskol;

- Makita;

- Bosh.

Types of knives for electric planers

Knives on an electric planer are consumables. With their help, wood surfaces are processed.

Electric planer knives are classified according to the following criteria:

- opportunities for practical reuse;

- blade shape;

- knife blade sizes;

- cost.

When buying an electric planer, in addition to checking its performance and configuration, you should pay attention to the quality of the knives installed on the drum and their sharpening. Blades should be sharp, with a straight edge and no kinks or gouges.

Spare knives should also be checked. The final quality of lumber processing depends on the correct selection of cutting attachments.

Disposable knives

Knives intended for disposable use are made of steel-based hard alloys in the form of plates sharp on both sides. Such cutting parts cannot be sharpened. After the edge being used is completely worn out, the blade is turned over and placed on the drum with the other side. At the same time, the tool continues to work. If the second cutting edge becomes dull, then the blade is simply thrown away.

Disposable knives are intended only for performing work that does not require high precision and quality of workpiece processing. But they are convenient for practical use: during installation they do not need to be precisely adjusted and balanced.

The shapes of disposable products are:

- straight;

- wavy;

- straight, but rounded at the ends.

The first type of product has a straight cutting part. It is convenient to use such consumables to process parts that have a smaller width than the length of the installed blade, and to select quarters. Wavy knives are used when it is necessary to carry out rough processing of lumber. With their help, you can give a wooden surface a different texture, for example, to simulate “aging.” Straight cutting edges, rounded at the edges, are good because they do not leave marks (grooves, steps) on the surface of the wood being processed. This is a suitable option if you need to work with wide wooden pieces.

Reusable cutting attachments

Products that are intended for reusable use differ in both their shape and size from disposable cutting attachments. They are made using high quality steel, which ensures ease and quality of processing of wooden surfaces.

Using reusable knives, you can achieve such a smooth surface of the workpiece that grinding is not required. They are marked HSS (fully High-Speed Steel, which translates as high-speed steel). These blades are considered professional. Their installation is accompanied by high-precision balancing and adjustment. The sharpening must also be of excellent quality. In this case, tool high-speed steel can be sharpened so that it is very sharp.

The working drums of most models of electric planes can be equipped with both disposable and reusable cutting attachments. But there are also devices that can only be equipped with blades that are not intended for sharpening. For this reason, when purchasing an electric planer, it is recommended to give preference to universal power tools.

Classification by size

Knives for electric planers can be standard or non-standard sizes. Products of the first type, called “plates,” have a length of 82 mm, a width of 5.5 mm, and a thickness of 1.2 mm. Such cutting attachments are suitable for most models of electric planes from foreign companies Makita, Skil, Bosch, Black&Dekker.

Straight knives for electric planers Bosch, SKIL

Non-standard cutting attachments with larger blade widths and thicknesses are typical for electric planers from Baikal and Interskol. Due to their parameters, they are stronger and better than standard plates. When they come into contact with metal, such knives do not break. They can be sharpened using sandpaper. The width of the nozzles is about 1 cm. The length can be 82 mm, 102 mm, and for products from the Rebir company it reaches 110 mm.

Straight knives for electric planer Rebir IE-5709

The price of the cutting attachment depends on the manufacturer. Also, this factor often determines the quality of the product. If you purchase knives from well-known companies (for example, Bosch), you can count on their long service life.