Today we will talk about what kind of plywood is used in furniture production. We'll tell you how to choose plywood sheets for making various types of furniture and structures.

Plywood is more expensive than MDF and chipboard, often used in the manufacture of cabinet furniture. But this drawback is covered by two more important advantages: increased strength and the ability to produce bent elements. Therefore, plywood is just as in demand in furniture production as MDF and chipboard panels. We will tell you which plywood is suitable for making various pieces of furniture and its individual elements.

Plywood as a universal material

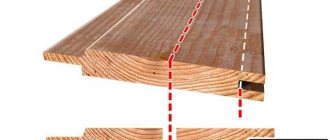

Plywood is a multilayer building material that is made by gluing together several layers of veneer. Veneer is very thin layers of wood, which are presented in a plywood sheet in odd quantities (3 or more). In order to increase the strength of the material, the veneer is applied in such a way that the wood fibers run strictly perpendicular to the fibers of the previous sheet.

Application of plywood sheets

Plywood is used in the following industries:

- In the aviation industry.

- In shipbuilding, including making boats with your own hands.

- In furniture production.

- In electrical engineering for the manufacture of various insulating products.

A few words on material classification

Choosing a wood species

Coniferous or hardwood veneer can be used as the top layer. To reduce the cost, sometimes the front side is made from more expensive raw materials, the inner layers from cheap ones.

Softwood plywood

It is made from spruce or pine veneer, less commonly larch and fir. The cost of this material is lower than that of hardwood, which explains its wide distribution. The material is more resistant to moisture and can be used in wet rooms without special impregnations. The presence of resins in the composition protects plywood from bacteria, mold and microorganisms.

The main disadvantage of coniferous plywood is its insufficient strength. For this reason, the material is not used in products where this is a key factor. When heated, the process of releasing resinous substances starts, which must be taken into account when using finished products.

Hardwood plywood

The most commonly used hardwood is birch veneer. There is less of it on open sale and the cost is much higher than coniferous. The main advantage of hardwood plywood is its strength and wear resistance.

Features of furniture plywood

Advice! For the production of kitchen furniture, only plywood with a high level of moisture resistance should be used. The best option is FSF sheets. Otherwise, such pieces of furniture will quickly lose their attractive appearance under the influence of moisture and frequent temperature changes.

Advantages and disadvantages of plywood sheets compared to wood

Materials such as furniture board or plywood are successfully used in furniture production, and today, much more often than natural wood. As mentioned above, the main reason for this is the low price of plywood sheets.

However, in practice this material has a significant number of advantages.

Let's look at some of them:

- It consists of wood, only from thin layers (about 1 mm), and its price is an order of magnitude cheaper.

- Even large plywood sheets are shaped stable. This is achieved due to a special production technology - crossing veneer fibers.

- True freedom of choice regarding sizes.

- High lateral strength when compared with a wooden panel of the same thickness.

Unfortunately, this material has in addition to its advantages.

It also has some disadvantages:

- The mass of a plywood sheet will be greater than that of a wooden sheet of similar thickness.

- The ends have stripes, which affects the aesthetic perception of the product, since many have a negative attitude towards plywood as a material.

Lining the ends of plywood.

Advice! If you don't want the veneer layers to be visible on the ends, they can be sealed or coated with several layers of dark varnish.

- This material gives you less freedom in surface treatment, since the front layers are about 1 mm thick, so they can be “removed” with a tool if you are careless.

- Some manufacturers save on adhesives by using adhesives that are harmful to human health. Thus, purchasing plywood from an irresponsible manufacturer can have unpleasant consequences, which cannot be the case with the purchase of natural wood, even of the lowest quality.

Area of use

This type of plywood is usually used for the underlay when laying parquet floors.

Very often this type of plywood is used as a substrate when laying parquet. Inexpensive coniferous plywood FK, size 1525 x 1525, is suitable for this. The sheet is cut into squares of the required size and attached to the screed using self-tapping screws, leaving gaps between the squares of 3-4 mm.

The same sheets are used to create disposable formwork. They are suitable for filling walls with aerated concrete as a primary finish.

For those who provide foundation pouring services to the public, laminated plywood is suitable for reusable use, the dimensions of which depend on the height of the base.

Interior wall cladding will look good with FC birch sheets. They do not contain phenol, and increased moisture resistance indoors is not needed.

The production of packaging products is another area of use of plywood sheets. When making boxes for different purposes, they use rejects, which have the lowest price. Sheet 18 mm FC has high mechanical strength, is safe for health and is suitable for packaging food and non-food products.

Laminated plywood sheets are commonly used to make various home furnishings.

For the construction of children's playgrounds, where various attractions are often installed, street benches use FSF plywood, made of birch veneer. The construction of temporary buildings requires following the rule when choosing sheets: take FSF for street work, and FC for interior decoration.

18 plywood sheets, laminated, are used for the manufacture of interior items. Kitchen sets, dining corners, bookshelves and partitions are made from this material. A wide range of top films will help bring almost any design idea to life. Handcrafted pieces of furniture will look like they are made from a single piece of wood. To achieve this effect, you can choose the ones you need from the many different shades and textures offered.

Features of making furniture from plywood

Knowing about the flexibility of plywood in work, many home craftsmen have probably thought about making their own furniture. And in reality there is nothing particularly complicated here - you just need to follow simple recommendations in your work.

The instructions for working with plywood provide several tips:

- This rule applies to working with sheets of different thicknesses:

- The thickness of which is no more than 1.5 mm. In this case, the material should be cut exclusively with a knife.

Cutting a sheet using a stationery knife.

- If the thickness is more than one and a half millimeters, but less than six, then you should use a jigsaw.

- If the sheet is more than 6 mm thick, it will have to be cut with a circular saw.

- Never cut plywood boards across the grain, as this will cause the material to crack. To prevent this, loosening cuts should be made. They are made using a knife, applied parallel to the sawing line.

- Before joining sheets with screws or nails, it is necessary to pre-drill holes, otherwise cracks will form in the material.

Advice! If you are connecting building materials made of soft wood with screws, then you should place small washers under their heads.

- To bend the panel, you must first moisten it with water and then fix it. The sheet should be kept in this position for about 12 hours.

Caring for plywood furniture

Products made from plywood are quite unpretentious. They do not require special conditions for normal operation. To prevent surfaces from becoming dusty, they are regularly wiped with a damp, well-wrung out cotton cloth. If necessary, wash the furniture with a cleaning solution, which is then thoroughly washed and the product is allowed to dry. To reduce dust accumulation, furniture is treated with an antistatic agent.

To make your products last longer, you should follow these tips:

- maintain normal humidity in the room (about 60%) - this will prevent the plywood from drying out;

- do not place hot objects on furniture surfaces;

- periodically treat products with polish or wood oil.

Plywood furniture is a real find for those who value practicality and environmental friendliness in their furnishings. It will fit perfectly into the interior, will not cause unnecessary expenses and will allow you to admire the natural beauty for many years!

Furniture plywood

Currently, there are many building materials that are used for repair and finishing work. One such material that is very popular is furniture plywood . It is a durable product with a long service life. In terms of cost, plywood is much cheaper than natural wood. This material is used to make furniture.

First, you should understand what a material such as furniture plywood is.

How it is made

Plywood is often used in furniture production. Typically, sheets with a thickness of 3 to 30 mm are used. The advantage of plywood over natural wood is that it is cheaper and has the same dimensions.

Production begins with the production of thin layers of wood, so-called veneers, which are subsequently glued together. Their number is always odd and starts from three.

The best plywood is made from birch. This is a strong and durable natural material. It can be made entirely from one breed, or from several. With equal thickness, it is approximately 20% stronger than coniferous wood and does not release natural resins in hot weather. Its cost is higher than that of coniferous samples.

To increase strength and add moisture resistance, the plywood sheet goes through a lamination process. The presence of such a film makes it easy to clean. In addition, this is a big plus from a design point of view. The film can be of different colors and textures: walnut, beech, oak or even mahogany.

Which brand is best to use?

When creating furniture, moisture resistance does not play an important role. In most products it is only 6-11%. Safety, environmental friendliness and aesthetic appearance are more important.

FSF brand plywood is least suitable for this category, as it contains a high level of toxic phenol-formaldehyde resins. They take a very long time to erode, and using them indoors is generally hazardous to health.

Another option is the FC brand. Its strength indicators are higher, it is non-toxic due to the use of urea glue. Can withstand heavy loads, is easy to process and easy to sand. Therefore, it is recommended to use this type to create furniture.

What is furniture plywood?

Plywood is a building material made by gluing together several layers of veneer. Veneer is a thin-layered wood. To make a plywood board, an odd number of layers of veneer are used, ranging from 3 or more. To increase the strength of the product, the veneer layer is glued so that each subsequent layer is located perpendicular to the previous one.

To create furniture, plywood sheets with a thickness of 3-30 mm are used. As a rule, 3-layer plywood is used to make cabinet walls and furniture bottoms and has low strength. The five-layer material is characterized by high strength and is used in furniture production for the manufacture of tabletops.

To make the front surfaces of high-quality furniture, expensive decorative plywood is purchased.

Since plywood furniture should not only be durable and strong, but also attractive in appearance, its production is carried out in special factories, where special attention is paid to the choice of glue and details of the products.

Design

Plywood board is sheets of wood veneer glued together into a monolithic whole using special equipment using formaldehyde resins. For the outer layer the thickness should not be higher than 3.5 mm, and in the inner layers it should not exceed 4 mm. Plywood can be assembled using various technologies, using veneer from one type of wood or from several types of wood. According to these indicators, it is divided into homogeneous and combined, which may include various types of deciduous or coniferous cuts. The arrangement of fibers in sheets can be parallel or mutually perpendicular, and also differ in symmetry.

Pros and cons of furniture plywood

Today, plywood is more popular in furniture production than its natural counterpart - wood. This is due to the fact that plywood sheets are much cheaper than natural wood. In addition, this building material has a number of advantages:

First of all, it should be noted that plywood is made from natural material, only in this case thin layers of wood are used. With all this, the cost of a sheet of plywood is much lower.

Despite the size of the plywood board, we can talk about the stability of its shape, which is achieved using a special technological process, namely cross-layering of veneer layers.

Another advantage is the wide choice of material sizes.

High strength of plywood sheet compared to wood of the same thickness.

In addition to the advantages, this building material also has some disadvantages:

These include the greater mass of one sheet compared to a wooden slab of the same thickness.

There are stripes at the ends of the product, which subsequently spoil the appearance of the surface being treated. Because of this, the frequency of its use is somewhat reduced.

The choice of material for processing plywood sheets is limited. Since, if necessary, remove the old coating and apply a new one, you can also remove the top layer of the material itself. And this will affect its quality and durability.

Separation of plywood by surface

A number of manufacturers, in addition to the grade, additionally indicate the method of processing the surface layer when marking plywood. Plywood is divided into 4 categories based on surface type:

- Laminated. The sheet is covered with a special film for additional protection and increased strength.

- Ш2. Plywood, sanded on both sides.

- Ш1. Plywood, sanded on one side.

- NS. Plywood that has not been sanded.

Furniture production using plywood

Furniture plywood has good flexibility. It is this feature of this material that often pushes craftsmen to make some kind of furniture with their own hands. In fact, there is nothing difficult about this if you follow certain instructions.

Regarding the thickness of the material, it should be noted that for different thicknesses of sheets, different cutting methods are used. So, if the thickness of the plywood is no more than 1.5 mm, then you only need to cut it with a knife, but if it is more than 1.5 mm, up to 6 mm, then you will need a jigsaw for the job. If the product thickness is over 6 mm, you will need to use a circular saw to cut plywood.

It is not recommended to cut a sheet of plywood across the grain of the veneer, otherwise the material will begin to crack. To avoid this, make small cuts with a knife parallel to the sawing line.

Before fastening the sheets with screws or nails, you must first make holes in the slab so that the sheet does not crack.

In places where furniture plywood is bent, it must be moistened with water and only then mounted.

There is a special sequence for gluing plywood sheets. The surface on which the plywood board is supposed to be glued should be cleaned with sandpaper. The glue must be applied in a thin layer. After this, the material is compressed until it hardens completely.

Furniture plywood is considered a good material for making furniture. Even though plywood products are not as good in quality, they are often superior to natural wood due to their technical performance. With the right choice of material, you can get good furniture at a low cost, which will last a long time and have a pleasant appearance.

Characteristics of plywood

Technical characteristics of various brands of plywood.

Source: mosfanera.ru

Price and material calculation

The cost of plywood depends on the size of the sheet, its thickness and grade. The latter is determined by the presence of defects on the surface of the material:

- Grade E - the sheet does not have any visible damage, defects or irregularities;

- I – minor flaws without knots or rot are acceptable;

- II – small healthy knots are possible;

- III – knots and holes not exceeding 6 mm in size are acceptable;

- IV - this type of product can have any damage up to 40 mm.

Table of average cost of different types of plywood per sheet.

| Brand and thickness in mm | Variety | Size | Cost per sheet in rubles |

| FC 3 | 4 | 1525x1525 | 220 |

| FC 10 | 4 | 1525x1525 | 555 |

| FC 16 | 4 | 1525x1525 | 850 |

| FC 20 | 4 | 1525x1525 | 1090 |

| FSF 10 | 3 | 1525x1525 | 840 |

| FSF 15 | 3 | 1525x1525 | 1000 |

| FSF 27 | 3 | 1525x1525 | 2300 |

| FOF 9 | 1 | 2440x1220 | 1700 |

| FOF 18 | 3 | 2440x1220 | 1700 |

| FOF 30 (with mesh) | — | 2440x1220 | 5380 |

| Baked 10 | — | 2500x1250 | 3910 |

The most accurate way to calculate the number of sheets is to make a visual layout on paper. This way you can determine what size plywood is best to purchase so that there is no waste left. When choosing dimensions, it is necessary to take into account the possibilities of transportation and transfer into the room: the height of the openings, the difficulty of climbing to the floor, the presence of a freight elevator.

Scheme of laying the first and second layers of plywood on the floor

A simple method to calculate the amount of plywood for a floor, rectangular or square room:

- Calculate the area of the sheet;

- Measure the area of the room;

- Divide the second value by the first and round to the nearest whole number. The resulting number is the required number of plywood sheets.

It is also recommended to provide a small reserve in case of damage during cutting or installation.

Plywood is a universal building material and raw material for furniture production. It is stronger than solid wood, but their cost is approximately the same. Thanks to the variety of overall dimensions, you can choose sheets or plates that are convenient to work and transport, suitable for different purposes and mechanical loads.

Plywood for furniture. Types and grades of plywood. Materials Science.

| [td] Wooden kitchen is a very vague concept. The materials for it include both expensive solid wood glued together from natural wood beams and budget slabs pressed from sawdust and various binding resins (including formaldehyde). But if you’re going to make a kitchen with your own hands, you should choose the golden mean – plywood. It is quite affordable, easy to process and more environmentally friendly compared to the same chipboard What does a furniture maker need to know about plywood? Plywood is a kind of “pie” made from thin sections (from 0.1 to 1.18 mm) of solid wood - veneer. There is always an odd number of layers, and they are laid perpendicular to the direction of the wood fibers. The sections are joined using high-pressure adhesive, resulting in a durable, wear-resistant material. Composition - for the manufacture of plywood, veneer is used from coniferous (pine, spruce, fir, larch, cedar) or deciduous (most often birch, linden, oak) tree species. Based on the number of layers, it is divided into three-, five- and multi-layer. |

Acceptance, quality control

Each batch of wooden plywood is accepted according to the following criteria:

Plywood comes in 1-4 grades.

- each batch must be documented in only one document including all necessary data;

- sheets of general purpose products are checked selectively with control of strength, size and number of layers;

- the concentration of formaldehyde in plywood must be within sanitary and environmental standards;

- General purpose plywood should not contain veneer delamination or bubbles;

- humidity must comply with GOST 9621;

- the roughness of the outer surface must comply with the requirements of GOST 15612;

- The sound absorption coefficient must comply with GOST 16297, the factory hardness should not deviate from GOST 9627.1, and the thermal conductivity GOST 7076.

The product must be transported in closed transport. Transportation is carried out taking into account all transportation rules applicable to each type of transport separately. Storage is carried out on pallets only in a horizontal position in closed warehouses at temperatures from -40C to +50C and humidity not more than 85%. The warranty period is within 3-6 years.

In summing up, I would like to note that if there are high requirements for the durability of this material, it is recommended to use high-strength laminated plywood.

Types of plywood.

There are several main types of plywood, depending on the material used.

Apart from the finishing methods used to process finished material, it is the base from which this or that type of plywood is produced that determines its performance characteristics in the future. Each type of wood has its own individual characteristics and properties, which means that a product made from trees of a particular species will be endowed with such properties to a certain extent. Let's look at the characteristics of the main types of plywood:

Birch plywood . Birch plywood, due to the properties of the wood from which it is made, is distinguished by its highest strength. Of course, this is precisely the quality that determines to the highest degree the demand for this material. The most common type of birch plywood used for interior decoration and furniture making is FC plywood , which is also characterized by an average level of moisture resistance and environmental friendliness. Among other things, this plywood has a pleasant color scheme and pleasant texture, and is easy to process. birch plywood is best suited for outdoor work, since it is a more moisture-resistant material and is actively used in construction, formwork, mechanical engineering, etc.

Coniferous plywood . The main characteristic of plywood, which is made from pine wood, is high strength with relatively low weight, which makes it the best option for use in house construction. This plywood also looks great. Work such as creating bases for floors, cladding walls, erecting partitions, covering roofs - in low-rise housing construction is often carried out using coniferous plywood. In addition, coniferous plywood best meets the needs of the furniture industry, packaging manufacturers, interior designers, etc.

Combined plywood (birch/coniferous). Combined and birch plywood are similar in appearance, however, due to the fact that the birch and coniferous veneer in combined plywood are glued together in layers that alternate, the cost of this material is somewhat lower. If we talk about strength, then combined plywood is not as strong as birch plywood, however, it is stronger than coniferous. This set of characteristics has made this wood-based panel material in demand for performing the same work as birch plywood, and interior decoration is also one of the main areas for using combined plywood.

Unidirectional plywood . This type of plywood is fundamentally different from other varieties in that almost all veneer layers in it are directed in the same direction - which is why unidirectional plywood is a very elastic wood-based panel material. The specificity of such plywood has made it in demand in the manufacture of upholstered furniture, and, for example, hockey sticks are made exclusively from plywood of this type.

Laminated plywood . The lamination effect is achieved by covering the plywood with a special film (based on phenol-formaldehyde resins). This coating significantly increases the wear resistance and moisture resistance of ordinary plywood, having a key effect on density and strength. The layers of wood veneer in such plywood are also glued together with glue based on phenol-formaldehyde resins. Such plywood is used for purposes in which wear resistance plays a key role - formwork, floors, various types of cladding, up to the construction of bridges (large format plywood is used).

Bakelite plywood . This type of plywood has its own special characteristics - it is indispensable for use in aggressive environmental conditions - sea salt water or, for example, a hot tropical climate does not subject it to destruction. This plywood is made from birch veneer using bakelite varnish as an impregnation.

Class “E” plywood is considered the best - during its production the presence of knots, cracks, chips and wormholes is not allowed. It is used in finishing work and in the manufacture of furniture, since the smooth surface is ideal for any finishing treatment and looks beautiful when opened with varnish, paint, wax or oil impregnation. The remaining grades (from 1 to 4) allow an increasing number of defects, and if with grades 1 and 2 you can still try to save money, then with grades 3-4 I should experiment - the large amount of waste and low quality of products are not worth it.

Main dimensions

The veneer layers from which plywood is made are connected with various adhesives and kept under pressure until they fully adhere. These layers are laid on top of each other so that the direction of the wood fibers in the previous layer does not coincide with the direction of the next layer. This method improves the strength of the material to bending and other mechanical damage. The minimum number of veneer layers in a plywood sheet is made at least 3 - in this case, the size of the sheet thickness is marked as 3 mm. The largest number of them is 21 sheets, but the thickness of the finished material can be in the range of 30-40 mm.

Plywood dimensions may vary in width and length; each parameter is measured in millimeters. According to their size range, plywood sheets can be large, for example, 2000x3000 or 2000x3500 mm, and small, for example, squares 1220x1220 mm. The standard size of the thickness of the material directly depends on the number of veneer sheets glued together. The greater the thickness of the slab or sheet, the stronger the material.

Standard

Small errors in the dimensional parameters of a plywood sheet are also regulated by the state standard. GOST, adopted in our country, allows the production of these woodworking products in any size, according to the consumer’s order.

The most common width dimensions for plywood are 1220 and 1525 mm. The length of the product can be limited to 1525 or 2440 mm. Such parameters are in demand among consumers, since they are easier to use during work, and they can be transported by light-duty vehicles. Plywood materials with large format or non-standard parameters have a length of 3500 or 3660 mm and a width of 1500 or 1525 mm. Sheet materials with similar cutting are often used for finishing work when finishing large areas or for production needs.

Non-standard

Small-format wood-based sheet materials are also popular. On sale you can see products with the following dimensions: 1220 by 1220, 1220 by 1525 or 1525 by 1525 mm. Such minimal cutting is convenient because one person can handle a sheet of plywood without the involvement of third-party assistants. On the other hand, when facing with such sheets, there are too many joining seams, which sometimes is not a good solution.

With large formats, sheets are most often in demand, the dimensions of which are: 1525x1830, 1220x2440, 2500x1250, 1500x3000 or 1525x3050 mm. Such product parameters are not found by every manufacturer - some produce only part of the listed formats or are guided by their own dimensional standards.

Based on the GOST standards adopted in 1975, the dimensions of the sheet material are as follows:

- The length of the sheet is made from 1000 to 1525 mm, the interval for increasing the dimension is 25 mm;

- The width of the sheet is made from 800 to 1525 mm, the interval for increasing the dimension is also 25 mm.

Due to the fact that plywood is not subject to particularly precise requirements for compliance with dimensions, typical values can deviate from the standard requirements by up to 0.5-4 mm in length and width, and by 0.5 mm in thickness.

Types of plywood.

Sorting - changing the grade depends on the defects of the wood, which has 28 points.

Marking - depending on the adhesive composition, plywood is distinguished:

- FC (urea glue),

- FKM (melamine resins),

- FBA (albumin casein glue),

- FSF (phenoformaldehyde),

- FB (bakelite varnish),

- BS (alcohol-soluble bakelite glue).

Of course, not a single composition reaches absolute environmental friendliness (after all, it is a product of the chemical industry), but FBA plywood, the glue for which is made on the basis of protein, is considered the safest for health.

Plywood based on formaldehyde glue has emission class indicators for harmful substances (like chipboard). For residential use, it is recommended to purchase materials marked E0 or E1.

Surface treatment - unsanded plywood is designated “NSh”, with one sanded side - “Sh1”, with both sides - “Sh2”.

Dimensions - standard plywood sheets can be either square or rectangular. The minimum length is about 1.5 m, the maximum is a little more than 3 m. And the thickness varies from 3 to 30 mm.

Source: www.makuha.ru

Indicators of water resistance of plywood sheets depending on the adhesive connection

Among the main characteristics of plywood sheets, manufacturers distinguish the type of veneer used in the base and the structure of the adhesive joint.

FSF. Robust, highly water-resistant products suitable for indoor and outdoor use. High-quality phenol-formaldehyde resins are used as the basis for the adhesive joint. The disadvantage of the material is the increased toxicity of plywood due to the increased content of phenolic toxins in the base.

FC. Reliable and waterproof plywood sheets with the addition of urea glue to the base. The product is suitable for indoor use and does not emit any foreign odors or toxic compounds. Plywood is in demand for finishing rooms, making furniture, and interior items.

FB. A building material based on bakelite varnish. The sheets are durable under mechanical loads and are protected from deformation due to changes in temperature and humidity. The structure is protected from damage due to prolonged contact with water.