Plywood is a durable, multi-layer material made from natural wood. The physical and mechanical properties and technical characteristics of plywood are determined by the process of its production itself. Namely, an odd number of sheets of thin wood veneer are glued together using glue.

The veneer sheets are arranged in such a way that the direction of the wood fibers is perpendicular to each other. This makes the plywood very resistant to breaking, stretching and chipping (see table below).

Due to these parameters and affordable cost, plywood flooring is often used in construction.

Plywood for floor

Bending strength of plywood

Bending strength of plywood (birch, coniferous and combined)

Specification for plywood - table

Birch, coniferous, laminated and combined (TU 5512-001-44769167-02 and TU 5512-002-44769167-98).

Specification for softwood plywood

Specification for laminated plywood

Specification for composite plywood

Birch plywood specification

It should be noted that due to the fact that plywood for a long time remained almost the only material available to our compatriots, it was used everywhere. This, in turn, led to the emergence of different types and types of plywood.

How to choose plywood for construction work

In terms of its consumer properties, plywood may be preferable to solid lumber. Since it is glued together from several intersecting layers of veneer, the sheet is stronger than ordinary boards of the same thickness. Some brands of plywood have higher moisture resistance and wear resistance. Due to the large size of the slabs, plywood is convenient for creating all kinds of load-bearing flooring, as well as rough and finishing sheathing. In terms of scope of use, this material has only one competitor - OSB.

This article will tell you how to choose plywood for a construction site.

What can an error in calculations lead to?

What could be the consequences of incorrectly selecting the cross-section of the lags and calculating the distance between them? If the floors are laid on a concrete base, then the most important thing in this case will be the size of the step between the lags, which directly affects the behavior of the floor covering. If you attach a chipboard board to joists that are installed too sparsely, it can sag and even break. If ceramic tiles are placed on top, they will crack or fall out. The boards will simply “walk” and sag. Any of these options will require rework.

It will be much more serious to make a mistake at what distance the floor joists are placed, which at the same time serve as elements of interfloor ceilings. If in this case an insufficient number of such load-bearing elements is installed, the strength of the building structure itself will decrease, which is fraught with the most serious consequences - from irreversible deformations to complete destruction of the floors.

Do you have experience installing joists? Do you do calculations or just use tables? Write about it in the comments.

What species is the veneer for plywood made from?

It should be noted that coniferous or hardwood plywood is called by the type of species its outer layers are made of. That is, the veneer on top can be made from deciduous veneer of birch, linden, poplar, alder... and inside it is possible to use pine needles (pine, spruce, cedar... veneer). Slabs that contain different rocks are called combined.

Based on multiple tests, birch plywood is approximately twenty percent stronger than a homogeneous product glued together from pine/spruce veneer. And it will be almost twice as much as aspen slabs.

Such results are largely explained by the increased density of birch plywood compared to coniferous products. In numbers, we have an average of 700 kg/m3 versus 560 kg/m3, respectively. High density is not only good resistance to bending and stretching. This is also wear resistance, the ability to reliably hold loaded fasteners, etc.

But not all hardwood plywood is created equal; for example, a Chinese product made from poplar has a density of about 500 kg/m3. And sometimes the density drops to 350-400 kilograms per cubic meter. Moreover, even more problems with such sheets are related to environmental safety, since they usually contain many times more harmful substances than the maximum concentration established by regulations. Poplar is softer than birch and is more afraid of water.

Considering its low cost, Chinese poplar plywood (for example, laminated FOF) has a right to exist; it will more than earn its money when creating formwork panels or assembling flooring for scaffolding.

Variety of plywood

Softwood boards are described in GOST 3916.2-96 “General purpose plywood with outer layers of softwood veneer. Technical conditions".

Hardwood boards are described in GOST 3916.1-96 “General purpose plywood with outer layers of hardwood veneer. Technical conditions".

Advantages

Plywood is considered one of the most convenient and practical materials for leveling the floor.

It is known that plywood is a wood processing product, so it has the same basic properties as wooden products, while plywood has a number of advantages over wood due to its structure. For example, thinner than boards, sheets of this building material have the same resistance to mechanical loads as the latest ones. It turns out that a lighter plywood structure can be no less rigid and elastic than a wooden one. In addition, veneer material can provide an absolutely flat surface, which makes it one of the most successful choices when arranging durable ceilings, walls and floors; in addition, plywood can be used to create a reliable base for different types of roofing. However, the main task here is to determine which plywood is best suited for the floor.

It’s worth saying right away that plywood, although inferior (and not always) to some related products in a number of indicators, has one main advantage - high environmental friendliness. And its properties are directly related to the brand, manufacturing technology and grade. It should be noted that the domestic industry produces quite high-quality products that are noticeably superior to Chinese samples, whose manufacturers strive to use cheap binders and defective veneers in their production. It is often very difficult to determine whether the outer layers of products from China have been sanded.

What does the grade of plywood mean?

Labeling is the most important information for selection. The abbreviation letters usually tell us what type of binder was used to glue and impregnate the veneer. The characteristics of the binder have an even greater influence on the overall performance of the board than the type or species of wood used.

In general, in the first and second parts of GOST 3916, only two brands are distinguished:

- FSF

- FC

This plywood, along with laminated FOF models, is mainly presented in domestic retail outlets.

FK brand material is glued together with urea binders. Plates of this type have good strength and excellent appearance. They are absolutely safe. Contrary to popular belief, FC plywood is moisture resistant, but only moderately, so it is preferable to use it indoors.

Deciduous and coniferous FSF sheets are collected using phenol-formaldehyde resins. They are positioned as HIGH MOISTURE RESISTANCE plywood, which can be used indoors and outdoors or in rooms with high humidity. That is, this is, in fact, the only option for cladding the walls of a house from the outside, for assembling a continuous deck on the roof, for creating ceilings and partitions in frame houses, which during construction can be exposed to precipitation for a long time.

Factory marking of plywood pallets

FOF laminated plywood is a type of veneered plywood. In this case, the base is a slab glued using phenol-formaldehyde binder. The outer layer here is sanded and protected with a paper film impregnated with synthetic glue. The cladding can be on only one side or on both; it can be smooth or with a relief mesh structure. Often, FOF plywood has additional paint protection applied to the edges. A dense and durable film acts as the main barrier to moisture and significantly increases the wear resistance of surfaces, which is why laminated plywood models are so often used as reusable formwork. It is also used to assemble used technical decks, truck vans, street furniture, etc.

Bottom line

You can now easily choose plywood taking into account all the necessary parameters for leveling and insulating floors, since you know its advantages and disadvantages, methods of installation on different surfaces and in different rooms. And professional advice will help you avoid common mistakes in choosing material for plywood flooring. Correctly selected simple and affordable finishing material will allow you to enjoy the result for a long time.

A little more attention!

Write in the comments what you think - is wood in the interior a classic, or already a thing of the past?

Prices for FC 4/4 plywood

| Product name | The price of the product |

| Plywood 4 mm birch FC grade 4/4 1525x1525 mm | RUB 510.00 |

| Plywood 6 mm birch FC grade 4/4 1525x1525 mm | RUR 800.00 |

| Plywood 8 mm birch FC grade 4/4 1525x1525 mm | RUB 860.00 |

| Plywood 9 mm birch FC grade 4/4 1525x1525 mm | RUB 1,000.00 |

| Plywood 10 mm birch FK grade 4/4 1525x1525 mm | RUB 1,010.00 |

| Plywood 12 mm birch FK grade 4/4 1525x1525 mm | RUB 1,050.00 |

| Plywood 15 mm birch FK grade 4/4 1525x1525 mm | RUB 1,450.00 |

| Plywood 18 mm birch FC grade 4/4 1525x1525 mm | RUB 1,550.00 |

| Plywood 21 mm birch FC grade 4/4 1525x1525 mm | RUB 2,050.00 |

Prices for FC 3/4 plywood

| Product name | The price of the product |

| Plywood 4 mm birch FC grade 3/4 1525x1525 mm | RUB 750.00 |

| Plywood 6 mm birch FC grade 3/4 1525x1525 mm | RUB 850.00 |

| Plywood 8 mm birch FC grade 3/4 1525x1525 mm | RUB 1,130.00 |

| Plywood 9 mm birch FC grade 3/4 1525x1525 mm | RUB 1,380.00 |

| Plywood 10 mm birch FK grade 3/4 1525x1525 mm | RUB 1,450.00 |

| Plywood 12 mm birch FC grade 3/4 1525x1525 m | RUB 1,530.00 |

| Plywood 15 mm birch FK grade 3/4 1525x1525 mm | RUB 2,000.00 |

| Plywood 18 mm birch FK grade 3/4 1525x1525 mm | RUB 2,350.00 |

| Plywood 21 mm birch FK grade 3/4 1525x1525 mm | RUB 2,730.00 |

Prices for FSF 4/4 plywood

| Product name | The price of the product |

| Plywood 6 mm birch FSF grade 4/4 1220x2440 mm | RUB 1,600.00 |

| Plywood 9 mm birch FSF grade 4/4 1220x2440 mm | RUB 2,150.00 |

| Plywood 12 mm birch FSF grade 4/4 1220x2440 mm | RUB 2,700.00 |

| Plywood 15 mm birch FSF grade 4/4 1220x2440 mm | RUB 3,100.00 |

| Plywood 18 mm birch FSF grade 4/4 1220x2440 mm | RUB 3,500.00 |

| Plywood 21 mm birch FSF grade 4/4 1220x2440 mm | RUB 4,500.00 |

Prices for FOF plywood (laminated) 1500x3000 mm

| Product name | The price of the product |

| Plywood 4 mm laminated FOF 1500x3000 mm | RUB 1,900.00 |

| Plywood 9 mm laminated FOF 1500x3000 mm | RUB 5,300.00 |

| Plywood 12 mm laminated FOF 1500x3000 mm | RUB 3,500.00 |

| Plywood 15 mm laminated FOF 1500x3000 mm | RUR 6,700.00 |

| Plywood 18 mm laminated FOF 1500x3000 mm | RUB 8,000.00 |

| Plywood 21 mm laminated FOF 1500x3000 mm | RUB 8,700.00 |

There are a number of brands of plywood that differ in additional properties (FBA, FB, BS, BV, FSK, FKM...), but they are not particularly widespread in the construction industry.

Installation technology

Do-it-yourself laying of multilayer material along joists is carried out in a certain order.

Preparing the base

Work technology:

- The surface is cleaned of all excess. If there are remnants of the old coating, complete dismantling is carried out.

- Cracks and crevices are sealed with putty.

- Antiseptic treatment is carried out, the base is thoroughly dried.

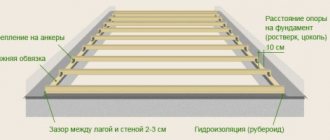

- The surface is waterproofed. This can be done using a special covering material or thick polyethylene film. If the product sheets are joined, then the overlap distance is at least 10 cm. It is mandatory to lay the edges of the waterproofing on the walls.

Waterproofing is laid only on a dry base; if it is impossible to dry the base properly, then a vapor barrier membrane is used instead of polyethylene. A wooden beam is also prepared: it is impregnated with an antiseptic and fire retardant and dried well.

Creating a sheathing

The procedure for setting lags:

- The parts are cut to size. It is taken into account that wooden fragments must be located with a distance of at least 15 mm from the walls.

- The height is formed. To do this, the greatest curvature of the floor is determined.

- To speed up the work, a cord is pulled along both sides of the room. An alternative solution is to use a laser level.

- Laying begins from the edge with a gap of 10–15 cm from the wall. A substrate (pieces of plywood or boards) with a sufficient support area is placed under the exposed timber. The leveling parts are attached directly to the base. If the opportunity and skills are available, a special bolt system is used for the job.

At the amateur level, installing wooden joists on supports is easier and cheaper than installing a base on adjustable metal studs - The pitch is selected individually from 35 to 70 cm. It is recommended to adhere to the rule: there should be three logs per sheet with a width of 1525 mm and a thickness of 10–12 mm. The beam is attached to the substrate using screws, and jumpers are used for additional reinforcement.

- All parts are checked by level, a single plane should be obtained.

Which plywood is safe to use in a room?

For a long time, FC plywood was considered the most environmentally friendly compared to other brands, since it practically did not emit harmful substances into the air. Now it has not become any worse, but in terms of formaldehyde emissions into the air, FSF plywood has noticeably improved. It deservedly receives documents confirming the E1 emission class, and such material is allowed for use in medical institutions and children's rooms. Formally, class E1 includes plywood boards with emissions of up to 8 mg per 100 grams of material. And for class E2 - from 0.8 to 30 mg of formaldehyde per 100 grams of dry board.

Almost all laminated plywood in Moscow corresponds to the E1 emission class, but this usually does not apply to Chinese-made boards. In any case, it is advisable to verify the safety of any plywood based on domestic certificates.

What type of plywood is better to buy

If the brand indicates water resistance and wear resistance, then the grade reflects exclusively the APPEARANCE of the plywood sheet. The physical and chemical characteristics of all grades of FK and FSF plywood remain unchanged and are standardized by current standards.

The determining criteria are visible processing defects and defects in the wood of the slab. In total, 28-30 indicators are taken into account, among which it is necessary to highlight:

- bitches

- cracks,

- Sorry,

- Tars and pockets,

- Rot,

- Foreign colors,

- Edge defects

- Warping,

- bundles,

- Roughness,

- Leaked glue

- Repair inserts.

Defects and flaws are allowed inside the plywood board in addition to the list of 28 or 30 items, but if they do not affect the performance properties or appearance of the board.

Depending on the presence and number of defects, FK/FSF plywood is divided into 5 categories:

- E is an elite type, it has almost no drawbacks (except for “eyes” and roughness), and is used mainly for finishing with a transparent protective and decorative coating.

- I – has single knots and small local color changes.

- II – almost the same defects are allowed as in the first grade, but in slightly larger quantities. All of them can be eliminated by tinting varnish or painting.

- III – in addition to knots, it may contain wormholes and cracks. Well suited for creating closed load-bearing structures and for rough cladding.

- IV – may contain all possible defects, but in limited quantities for some of the items. Mainly used as an inexpensive auxiliary material, for example, if you need to make disposable formwork.

Note that for each grade, GOSTs indicate the maximum number of defects from the list. For 1st grade – 6, for 2nd grade – 9, for 3rd grade – 12, for 4th grade – unlimited. Elite plywood (E) should not have visible defects.

Different sides of a plywood sheet can correspond to different grades. Therefore, the marking is always double: E/1, E/2, E/3, 1/2, 1/3, E/E, 2/2, 3/3, 3/4, 2/3, etc. The obverse side is considered to be the one with a higher grade.

In addition to the domestic digital marking of the grade, sometimes foreign designations can be found on the slab: B (S), BB, CP, C - from the first to the fourth grade, respectively.

Successful examples and options

In this case, the flooring was made on an old wooden floor, maintaining horizontality, using sections of threaded rods covered with PVC corrugated tubes.

The floor is covered with plywood evenly, the seams between the sheets are treated with sealant and putty.

Installation on joists is made in solid sheets with a minimum of cuts, compensation gaps between the sheets are taken into account. Mineral wool is laid between the joists as insulation and sound insulation.

Preparations are being made for flooring along the joists, the concrete floor is leveled, and polyethylene film is laid for waterproofing.

The case when the recommended gap from the wall can be neglected is a narrow section of the floor covered with joists. For metal elements protruding along the edges, cuts were made with minimal loss of load-bearing capacity. Fastening with self-tapping screws. Mineral wool in the space between the joists.

Does plywood need a sanded surface?

Surface grinding allows you to achieve better aesthetics. Plywood Ш1 (processed on one side) and Ш2 (processed on 2 sides) are chosen when high-grade sheet material is needed for finishing and will be opened with transparent impregnation/varnish.

For roughing work, you can use slabs with unpolished outer layers of veneer (NS). In some cases, when something will be glued on top of the plywood flooring, a rougher surface is preferable, as it provides better adhesion.

Plywood for walls

Film laminated plywood

Permissible defects in plywood

Required tools and materials

To install plywood sheets on a wooden base, you may need the following tools:

- screwdriver;

- drill;

- hammer;

- screwdriver;

- level;

- electric jigsaw.

The materials used are self-tapping screws usually 30-50 mm long, nails or glue. The first ones are preferable to use, since they are the easiest to work with.

Self-tapping screws for wood

What you need to know about the sizes of plywood sheets

One of the most important rules: the fewer joints, the better. Therefore, it is almost always better to order the largest sheet of plywood available.

We select the thickness of the plywood depending on the load and the size of the existing spans between the supports. For floors on top of the screed they buy slabs 9-12 mm thick. On average, plywood with a thickness of 22 to 30 mm is most suitable for covering floor beams. Sheets 12-18 mm thick are used for the roof, FC and FSF plywood 12-15 mm thick are sewn on the walls. A material with a thickness of 6-10 mm is suitable for filing the ceiling; to create an arch in an interior partition, it is better to take a sheet of 5-6 mm. The formwork will require plywood with a thickness of 15-25 mm.

If you still have any questions regarding the choice of construction plywood (and not only) - feel free to call our hotline or write to the feedback form. Our experienced specialists will quickly help you decide on suitable materials.

Material calculation

To correctly determine the quantity of products, you must follow the step-by-step instructions:

- The floor surface is measured and all data is transferred to paper. You should get a detailed diagram of the foundation with a lag laying system. This allows you to immediately calculate the order of placement and adjustment of all parts, which is especially important in rooms with ledges and niches.

- The appropriate sheet size is determined and a layout plan is drawn up.

- According to the data obtained, the required number of slabs is calculated.

When installing a floor using joists, first of all it is necessary to draw up an installation diagram for the joists, and then plan the laying of plywood based on it

If the room has the correct shape, it will be easier to calculate the consumption: for this, the size of the object and the dimensions of the sheet are converted into area, and the data in square meters is divided.

On a note! To make the task easier, you can use a table with the exact sheet area provided by the manufacturer.