An indispensable thing for professional work is a stationary jigsaw. To a greater extent, it is used by craftsmen, however, ordinary people may also need this tool for everyday purposes. The main purpose is to accurately saw thin materials (wood, metal, etc.).

The article will discuss the main characteristics of a stationary jigsaw, as well as the model range of the best devices.

Design and principle of operation

The operation of a stationary jigsaw is based on the principle of converting household electrical energy into mechanical energy. The saw blade, fixed in the upper and lower cam mechanisms, performs reciprocating movements. Thanks to this, the workpiece is cut.

The two-position method of fastening the saw blade ensures particularly precise cutting.

Structurally, a jigsaw machine consists of the following elements:

- base . The most massive and critical part of the machine. Serves for fastening the main elements of the jigsaw. It contains an electric motor and a crank mechanism that drive the saw blade;

- bed _ Made from a U-shaped metal profile, this structural element serves to mount a file, a lighting lamp and other auxiliary components of a jigsaw;

- saw blade . It is the main working element of the machine. Used for cutting wood and other workpieces.

- Desktop . Necessary for fixing the saw material in a horizontal position. As a rule, it has the ability to be adjusted in several planes;

- controls. Serve to turn the machine on and off, as well as to adjust the speed and angle of sawing.

Files used

The saw blade is the main working element of the machine, with the help of which the process of sawing workpieces occurs. Their design is radically different from the files mounted on manual electric jigsaws. They have a thinner and more flexible thread-like structure.

Externally, such files are similar to the blades used on manual jigsaws, but they have one difference - special slots are installed on the flat ends for more convenient fixation in the cams of the machine.

In addition, they are classified according to the shape of the teeth. Depending on this they distinguish:

- standard;

- blades with missing teeth;

- files with double teeth;

- blades with reverse teeth;

- spiral;

- saw blades with crown teeth.

Each of them performs its own specific function and allows you to perform different types of cuts. The most commonly used blades are those with standard teeth.

Files for a jigsaw

Files are different. It all depends on what purposes the device will be used for. Files are:

- pin ones have pins at the top and bottom, they are wider (the canvas is 2 mm in size). You won’t be able to make a beautiful pattern with this saw; it’s intended for regular cutting.

- pinless ones do not have pins, the length of the blade is from 0.6 to 1.35 mm, i.e. they are thin. But with the help of such a file, the patterns will be beautiful, high-quality, and you will be able to make even the smallest cut.

Since there are teeth on the base of the file, you need to understand what types of teeth there are and for what purposes each is used:

- standard (the teeth are the same, the cut is high-quality, neat, designed for slow, medium speed work);

- with a missing tooth (necessary for faster cutting, such teeth do not allow the saw to heat up quickly);

- double (the speed slows down compared to the previous type, but the saw works longer, because the tool heats up more slowly);

- with reverse tooth (wood is cut in the opposite direction, which reduces the number of chips);

- American tooth (designed for accurate sawing, ensuring a clean cut, without chips or damage);

- spiral saws (designed for neat carvings, also convenient to use because there is no need to turn the product, the teeth are on both sides).

Characteristics

There are a number of main characteristics that affect the cutting speed and ease of working with a jigsaw. The main ones are:

- power . It is the main parameter affecting the performance of the machine. The higher the power of the electric motor, the thicker and harder workpieces can be cut with its help. The average power of such machines is 90 W;

- depth of cut . A parameter indicating the maximum permissible thickness of the workpiece being cut. As a rule, this indicator is limited by the design features of the machine and is 50 mm. Expensive professional models have the ability to adjust the sawing depth;

- number of moves . Directly affects the speed and cleanliness of the cut. The more reciprocating movements the blade makes, the cleaner the cut is formed. On household machines this figure is 1500 strokes per minute;

- desktop dimensions. Has a direct impact on the ease of use of the machine. The average table size is 0.35 x 0.25 m. This is quite enough for cutting out small parts at home. For professional use, it is recommended to purchase a jigsaw with a larger table.

Before purchasing a stationary jigsaw, first of all, you need to decide on the scope of work that it will perform. Based on this, you can select the optimal combination of parameters.

Popular professional machines

Professional expensive equipment models for performing a wide range of operations with high accuracy.

Proxxon DS 460

The device cuts non-ferrous metals with a thickness of 10-15 mm and wood - up to 60 mm, fiberglass, rubber, plexiglass, cork and leather products. It is characterized by low noise. The body is made of cast iron. The device is intended for finishing sawing without further finishing.

Characteristics:

- used power – 205 W;

- purpose – plastic, wood, metal;

- saw stroke – 1400 strokes/min;

- working surface inclination angle - 50°;

- size (LxWxH) – 580x320x300 mm;

- power supply – 220 V;

- weight – 20 kg;

- number of speeds – 2;

- table dimensions (LxW) – 400x250 mm;

- workpiece thickness – 65 mm;

- the gap between the body and the canvas is 460 mm;

- saw stroke length – 18 mm;

- price – 30511 rub.

Advantages:

- good assembly;

- low noise;

- two-speed motor.

Flaws:

- strong vibration on substrates with low hardness;

- ineffective sawdust blowing.

BISON ZSL-250

A device for processing plastic and wooden products. Additionally, it can perform grinding, drilling and polishing. The cooling system avoids excessive heating of the saw. The blade tilt function makes it possible to make cuts at an angle.

Characteristics:

- used power – 250 W;

- purpose – plastic, wood;

- the gap between the body and the canvas is 457 mm;

- power supply – 220 V;

- weight – 22 kg;

- workpiece thickness – 51 mm;

- saw stroke – 1600 strokes/min;

- number of speeds – 1;

- table dimensions (LxW) – 625x330 mm;

- working blade inclination angle - 45°;

- price – 22250 rub.

Advantages:

- stable;

- rubber feet;

- large work surface;

- possibility of simple modification of saw fasteners.

Flaws:

- price.

Basic and additional functions

To make work easier, many models of jigsaw machines are equipped with a number of additional functions. Among them are:

- speed adjustment. The most common function that allows you to set the required number of reciprocating movements of the jigsaw blade per minute. Thanks to its presence, you can get a fairly clean cut, depending on the type of workpiece being cut. There is a smooth and stepwise adjustment of the frequency of movement of the saw blade;

- desktop tilt. Allows you to cut material at any angle relative to the horizontal plane. Professional models have the ability to adjust the desktop in several planes. For greater convenience, the mechanism is marked with graduations, allowing you to select the appropriate angle;

- work area lighting. Allows spot illumination of the work site. Thanks to this, work can be completed faster and with better quality. In addition, the built-in backlight reduces eye fatigue when sawing;

- dust extraction. An auxiliary function that allows you to instantly remove shavings and sawdust formed during sawing, thereby facilitating the work;

- engraver. The presence of a flexible shaft with an engraver allows you to expand the functionality of the machine. It can be used to polish, drill or grind workpieces. The only drawback is the single drive system, which does not allow you to run the saw blade and the engraver at the same time.

An expanded set of functions makes the jigsaw machine more expensive and is only advisable for professional use.

Selection rules

When choosing a tool for business or professional needs, you should consider a number of basic criteria:

- Material being processed – jigsaw models differ in the level of dust protection, so their use on the wrong type of product can significantly reduce the life of the device.

- Sawing speed – low values are suitable for low-melting parts, high – for brittle or hard ones. For processing a variety of materials, it is preferable to choose machines with continuously variable speed control.

- The thickness of the workpiece is the permissible dimensions of the product that the tool can handle. It is better to choose models with a reserve of this indicator to prevent their rapid wear.

- Weight – the large weight of the device can significantly reduce vibrations and increase the stability of the structure.

- Saw fixation option – quick-release fastener is compatible with pin saws, double-sided clamp with screw is suitable for straight, twisted and round saw attachments. Professional models usually have both options for fastening equipment.

- Power used - as this indicator increases, the potential of the device should increase, but here the type of saw and its speed are of great importance. The most effective output is achieved only with a small number of movements per minute.

- Equipment - the set may contain different blades, light, protective screen, airflow for the saw area, and guides. A wide variety of components facilitates interaction with the unit.

Kinds

Depending on the power of the electric motor, the depth of cut, the number of strokes of the saw blade and the time of continuous operation, the following types of stationary jigsaw machines are distinguished:

- household . The simplest machines, equipped with a minimum set of additional functions. Suitable for artistic cutting with a jigsaw and cutting wooden blanks up to 50 mm thick. The power of their electric motors, as a rule, does not exceed 90 W, and the number of saw blade strokes is up to 1500;

- professional _ Such machines are designed to work with workpieces of large thickness and size. They have the widest range of additional functions for more accurate and faster cutting of workpieces. As a rule, they can work continuously throughout the day.

Classification of tools

There are several variants of jigsaws that have design features and differ in their scope of application:

- Manual - looks like a U-shaped frame with a file attached to it. This option is used for household needs, cutting tasks of plastic panels and plywood. The tool is low cost and easy to use.

- Electric household - distinguished by its high speed of operations, optimally suited for home construction and repair work. Such units have low power, which reduces the scope of their use. Electrical devices process sheet products of small thickness.

- Cordless professional - this type of jigsaw is suitable for quickly completing tasks that require high quality finishing. When manufacturing tools, much attention is paid to build quality and ease of use.

What jigsaw machine do you use?

ManualDesktop

- Tabletop - fixed on a workbench attached to the tabletop. This arrangement ensures safe and efficient operation with increased cutting accuracy. The devices are equipped with powerful motors that allow sawing through thick products.

- Industrial – serial machines for production purposes. Power devices are connected to a 220/380 W power source and can perform long cycles of operations without interruption. Powerful equipment copes with the thickest parts and shows high productivity. Such machines are supplied with a control unit for monitoring and adjusting the units.

Expert opinion

Kokovin Dmitry Vasilievich

Furniture restorer

Jigsaws can work for up to 20 minutes, after which they need time to cool down for 40 minutes; professional battery models can work up to 8-10 hours with short breaks.

How to make a jigsaw from a jigsaw with your own hands

In order not to spend money on purchasing a stationary jigsaw machine, you can make it yourself. This does not require a large amount of material or the use of special tools. The required list of tools and materials includes:

- manual electric jigsaw;

- plywood sheet;

- ball bearings;

- fastening hardware;

- drill with a set of drills;

- glue;

- wrenches and screwdriver.

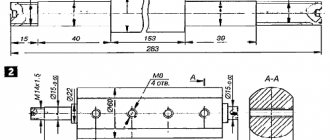

To make a jigsaw machine at home, you need to follow the following algorithm:

- Place wooden blocks on a sheet of plywood to improve the strength properties of the machine and secure them with screws.

- Attach boards to the bars that will serve as the side edges of the future machine. It is also better to secure them with screws.

- Having measured and marked the middle of the work table, secure the supporting surface of the jigsaw to it.

- Having measured the exit point of the saw blade, drill a through hole in the work table.

- Connect the jigsaw to the supporting surface. Then install the saw blade.

- Cut a piece measuring 40x100 mm from a sheet of plywood. Drill holes at one end to install the bearing axles.

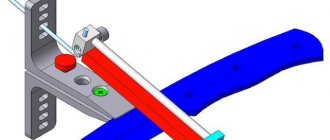

- Using washers as spacers, secure the ball bearings. The distance between them should be equal to the thickness of the saw blade.

- Glue a non-working jigsaw blade between the bearings. This is necessary to fix the working file in a different plane.

- Use two blocks to assemble a stationary jigsaw frame. It is better to fasten them with a metal corner. Then, fix the workpiece with bearings at one of the ends of the boom.

- Place the frame in place, fastening it with screws.

After this, you can connect the machine to the network and start working.

The undoubted advantage of such a machine is the ability to remove the jigsaw and use it for its intended purpose.

After watching the video, you can get acquainted with the nuances of making a homemade stationary machine from a jigsaw and watch it in action.

Review of the most popular models

There is a huge selection of stationary jigsaw machines on the domestic tool market, each of which differs in power, depth of cut, set of additional functions and, of course, cost.

It is sometimes difficult for an unprepared person to choose a model that fully meets his requirements. To make this task easier, we have prepared a review of the 3 most popular models presented today.

JET JSS-16

Stationary jigsaw machine of household class. Used for cutting wood products, fiberboard, chipboard and plastic. The body is made from high quality structural steel, powder coated to protect against corrosion. Small dimensions and weight allow it to be used in confined spaces.

Design features allow the use of saw blades with and without pins. The convenient location of the web tension regulator on the frame allows you to quickly tension it. In addition, the designers provided the possibility of fixing the saw blade in several planes, which greatly facilitates the process of cutting workpieces.

For greater convenience, the machine is equipped with a smooth adjustment of the number of saw blade strokes and a system for cleaning the surface from sawing waste.

Specifications:

- manufacturer – Jet;

- model – JSS-16;

- The homeland of the brand is the USA;

- country of origin – China;

- class - household;

- maximum cutting depth, mm – 50;

- power consumption, kW – 0.09;

- saw blade length, mm – 127;

- saw stroke frequency, stroke/min – 1600;

- maximum workpiece width, mm – 406;

- dimensions, mm – 680x340x385;

- warranty, months – 12;

- weight, kg – 13;

- price, in rubles – 16,500.

| Advantages | Flaws |

| universal saw blade mount | not detected during operation |

| desk tilt adjustment | |

| good performance |

Dremel Moto-Saw (MS20-1/5)

Universal electric jigsaw. Designed for figure cutting of wood blanks and its components. The metal body, coated with powder paint, ensures durability of use. The uniqueness of the tool lies in its small size and the possibility of its use as a stationary machine and as a hand tool.

The light weight and dimensions allow the machine to be conveniently placed on any workbench. The surface of the work table is equipped with graduations for more precise cutting of workpieces. Additional convenience is created thanks to the function of quick replacement and tension of the saw blade.

Main technical characteristics:

- manufacturer – Dremel Moto-Saw;

- model – MS20-1/5;

- The homeland of the brand is the USA;

- country of origin – Taiwan;

- class - household;

- maximum cutting depth, mm – 18;

- power consumption, kW – 0.07;

- saw blade length, mm – 100;

- saw stroke frequency, stroke/min – 2250;

- dimensions, mm – 470x370x130;

- warranty, months – 12;

- weight, kg – 4.6;

- price, in rubles – 9,999.

| Advantages | Flaws |

| small dimensions and weight | small cutting width |

| possibility to use the machine as a hand tool | |

| special cutting precision |

BISON ZSL-90

Household grade desktop jigsaw. Designed for artistic sawing and trimming of wood and plastic workpieces. The body is made of structural steel and coated with powder paint to protect against corrosion and mechanical damage.

Low noise and power consumption combined with good performance make it an optimal choice for home use.

The work table of the machine is made of polished aluminum. This ensures durability and low friction, making the job easier. In addition, it is equipped with the ability to change the angle of inclination.

The height-adjustable transparent protective cover ensures safe work. The flexible pipe of the working surface cleaning system allows you to improve the quality of cutting the material.

Model specifications:

- manufacturer - ZUBR;

- model – ZSL-90;

- The homeland of the brand is Russia;

- country of origin – China;

- class - household;

- maximum cutting depth, mm – 50;

- power consumption, kW – 0.09;

- saw blade length, mm – 133;

- saw stroke frequency, stroke/min – 1450;

- maximum workpiece width, mm – 410;

- dimensions, mm – 580x280x340;

- warranty, months – 12;

- weight, kg – 13.77;

- price, in rubles – 11,170.

| Advantages | Flaws |

| good performance | lack of adjustment of the saw blade stroke |

| ease of setup and operation | |

| Possibility of quickly changing the saw blade |

A stationary jigsaw is a necessary tool for people who are interested in artistic sawing. In addition, it helps to quickly and efficiently cut boards and products made of plastic and wood. We hope that after reading the article, everyone will be able to choose a jigsaw with the parameters they need or make it themselves. Write in the comments if you have a stationary jigsaw and what parameters you used when choosing it. Your experience will be useful to other readers.

The best devices at an average price

Jigsaws, optimally balanced in the ratio of quality and price. Multifunctional models of high quality.

JET JSS-16A

A convenient tool for household use, allowing you to work with products made of wood, plywood, chipboard, fiberboard, and plastic. The saw strokes are adjustable from 550 to 1600. It is connected with a 35 mm pipe to the dust removal system. Thanks to its small size, the machine does not take up much space in the workshop.

Characteristics:

- used power – 90 W;

- the gap between the body and the canvas is 406 mm;

- size (LxWxH) – 620x340x330 mm;

- saw speed – 1600 strokes/min;

- working surface dimensions (LxW) – 415x254 mm;

- table tilt angle - 45°;

- weight – 11.5 kg;

- saw stroke length – 15 mm;

- power supply – 230 V;

- number of speeds – 1;

- purpose – plastic, wood;

- workpiece thickness – 50 mm;

- price – 12,000 rub.

Pros:

- stable work;

- price;

- reliability;

- quiet.

Minuses:

- slow execution of operations;

- noticeable vibrations;

- poor-quality fastening of saws.

Proxxon DS 230/E

A universal device with a low-noise, high-quality motor and electronic speed control. Equipped with a limit bar, a square with a scale, and a set of 5 files with different tooth pitches. The model has three levels of height adjustment, a cast aluminum frame with stiffening ribs.

Characteristics:

- used power – 85 W;

- purpose – plastic, wood, metal;

- number of speeds – 1;

- working surface dimensions (LxW) – 160x160 mm;

- workpiece thickness – 40 mm;

- the gap between the body and the canvas is 300 mm;

- power supply – 220 V;

- price – 17209 rub.

Advantages:

- low noise;

- light weight;

- smooth speed adjustment.

Flaws:

- low power.