There is a wide variety of accessories that increase the functionality of a milling machine. Among them are:

The design of the rip fence for a router table is the simplest of all types of holding systems. Making it yourself will not be difficult if you first understand the principle of its operation.

For normal movement of the cutter using the workpiece guide, a control groove is first made in it and the distance from the edge to the zero mark is measured. As a result, it is easy to move the stop along the bar, setting any acceptable distance, but it is important to remember that when working with two bars, they need to be fixed at the same time.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

Now you can, without rushing, mill just such a miracle jolana with an implanted stool in the center of the body and a edging made of marijuana mixed in epoxy. If you want to clarify something, please contact me!

How to make a jig for a dovetail box joint with your own hands

Copy sleeve

Having learned how to use a copying sleeve for a router, craftsmen receive a good assistant in processing various wooden parts.

Many craftsmen use templates, especially when it comes to creating a series of wooden parts. It rarely happens that a template is used to cut out one part, but such cases do occur, for example, during restoration.

In most cases, such a device is used in production:

- figured platbands;

- identical parts for further assembly of furniture;

- tenons necessary for joining wooden products;

- recesses for hinges or door locks;

- paneled surfaces on the door.

When making a template, it is important to initially select high-quality and durable material. Even taking into account the minimal contact of the machine router and the edge of the template, it is erased over time, and the drawings lose their original accuracy. Such problems can be easily avoided if you initially use durable materials:

Naturally, it will be difficult to prepare a metal template, but it will last for many years without deforming and maintaining the original dimensions and strokes of the design. It is better not to experiment with such a device and make a template specifically for the required part of the wooden product. There are no high-quality universal devices.

The tongue-and-groove box corner joint is neat and reliable. But it can also be made more powerful if you prepare the grooves with a dovetail router. To do this, you will need to assemble a special conductor.

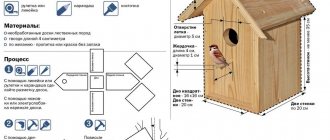

From thin plywood or laminate we cut out the sole of the conductor measuring 15x25 cm. We screw slats to it along the edges.

Mark a transverse line in the center of the workpiece. Then we glue V-shaped stops on it from thick plywood or MDF. They consist of 2 segments with ends sawn at 45 degrees. On the reverse side, the workpieces are additionally strengthened with self-tapping screws.

Which is better: heated floors or radiators?

Warm floorBatteries

To ensure rigidity, the supports need to be strengthened by installing gussets made of the same material. The connections are similarly tightened with self-tapping screws, the heads of which must be recessed.

The conductor will additionally need 2 bar attachments, equal in length to its sole. A quarter is chosen from them. Then we mill a wide groove in the sole of the jig.

To make a corner box joint, you need to saw the workpieces at 45 degrees.

After the glue has set, we apply a jig with a dovetail cutter to them, and mill the groove.

If you use attachments from a block, then it can be made narrower.

Next, we open the rail on the circular saw to get a tenon for the selected width of the groove on the box.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

Now you can, without rushing, mill just such a miracle jolana with an implanted stool in the center of the body and a edging made of marijuana mixed in epoxy. If you want to clarify something, please contact me!

Guide rail

When it comes to straight lines, a guide rail is a good alternative to the rip fence. It is fixed at an arbitrary distance from the edge and at any angle to it. Instead of a stop, a special shoe is installed on the rods - it slides along the tire and sets the position of the router. Due to the support on the guide, a height difference may occur as the machine is raised above the workpiece. To avoid holding it suspended, extend the support leg (if provided).

In a special configuration, such guides also serve for precise milling of holes, which is especially important when making furniture (the ruler has holes with a standard pitch, the machine has a stopper; all you have to do is select the desired positions and drill).

Important note: a set of parts for working along the guide is not purchased in all cases; it must be included in the manufacturer's list of accessories and be suitable for the specific router. The tire is fixed relative to the workpiece

The router is positioned along it using a “shoe” similar to a side stop, and can be placed at different distances from it. Since only part of the platform rests on the tire, an additional “leg” is extended

The tire is fixed relative to the workpiece. The router is positioned along it using a “shoe” similar to a side stop, and can be placed at different distances from it. Since only part of the platform rests on the tire, an additional “leg” is extended.

Boring template making for a router: mux22 – LJ

Actually acrylic (I don’t remember the thickness, in my opinion it’s something like 4-5 mm):

I apply the heel of the neck, trace it with a marker without much precision, because at this stage there is no need for it, and moreover, there is a danger of cutting off something unnecessary with a rough tool. So I make a small margin in all measurements.

By the way, the groove in the template will be significantly longer than the heel of the neck

- at least a couple of centimeters. This is necessary in order to work calmly with the router and have support for it even when processing the edge of the body.

I fix the template on the workbench and start sawing the acrylic with my Japanese wood hacksaw. This does not spoil the canvas, but I still add a little oil, primarily to reduce the heat.

Yes, before sawing, you should outline the marker lines with a sharp awl, drawing a deep groove along them

. This will make your work much easier, because the marker can be accidentally erased, and most importantly, it is highly reflective and difficult to see from some angles. Scratches are always clearly visible.

When the reach of the saw ends (or it reaches the corner, it all depends on the design of the saw), you need to switch to a jigsaw with a larger reach.

The cutting line of the jigsaw MUST be moistened with oil.

, because it heats up the acrylic very much: while the file is moving, everything is fine and without lubrication, but if the jigsaw stops even for a moment, the melted plastic will immediately harden around the file and bite it. The first time I sawed a pattern like this, I broke five files in a row before I realized I needed to add oil.

When the cutting is finished, a magical oscillating spindle-grinding machine comes into play, reminiscent of some kind of creepy device for torturing witches.

Since even the smallest sanding drum does not fit into the corners of the template, I remove the machine and level them with a regular round file:

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

To carve wood with your own hands, you will need quite a lot of tools, and each master has his own special ones that are more convenient and practical for work. If you want to clarify something, please contact me!

Accessories for a wood router: DIY production, instructions and assembly

Copy rings are a round plate with a protruding edge that slides along the base surface along the template. This device provides an accurate path for the cutter to move. Basically, this element is installed on the base of the workbench. There are several methods for attaching it:

Using a template also allows you to achieve more efficient and accurate work. It is attached directly to the workpiece with double-sided tape, and then both parts of the device are pressed to the machine with clamps. Moreover, experienced milling operators advise checking how tightly the ring is pressed to the edge of the template.

In addition, with such a device you can not process the entire edge, but only the corners. Therefore, the procedure for processing material using a template is an excellent option for cutting grooves for a product.

Device for a wood milling machine: list of auxiliary devices, how to assemble it yourself

When the reach of the saw ends (or it reaches the corner, it all depends on the design of the saw), you need to switch to a jigsaw with a larger reach.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

Step-by-step master classes with photos and descriptions, technologies, life hacks - everything a real master or just a craftsman needs for needlework. If you want to clarify something, please contact me!

Special kits

There are also special devices for hand routers designed to perform certain tasks. On sale you can find entire sets of such equipment, the use of which is especially important for professional craftsmen.

Basically, the kits perform a narrow-profile task

Hinge cutters

At home, you can do without using special templates to insert loops. It is necessary to install a second parallel stop on the rods, which will allow the tool to be securely fixed to the end of the door. This equipment is perfect for doing one-time work.

Binding cutter set

There are universal sets of nozzles that can only be used together, as they complement each other. These include a binding kit. In this case, you need to connect the nozzles without gaps. And in order to increase the versatility of the set, it is necessary to provide for the possibility of using typesetting cutters. In this case, several attachments should be fixed on one axis, the arrangement of which can be combined.

Attention! Only experienced craftsmen can make a homemade binding kit. Such work will require a lot of effort and time, which is not always justified.

Working with a hand router on wood: photos, videos

- Profile - to create a shaped configuration of the edges of the product.

- Conical - used to remove chamfers from poses at an angle of 45 degrees Celsius.

- A disc or rebate cutter is designed to create a groove in an edge.

- Galtein - designed for cutting round grooves on the edge of a figured product.

- Edge - used to form spikes and grooves.

Obtaining a figured and curved edge

If you need not a straight edge, but a rounded one or any other shape of the edge, you need to look at the condition of the existing edge. If the workpiece is more or less flat, take the required edge cutter, install it and process the surface as described above. If the surface is too curved, it is first brought to normal condition and then milled.

This is necessary because the bearing roller rolls over the surface and if there are flaws, they will be copied. Therefore, act sequentially - first level it, then add curvature.

If a curved surface is at all boring, a template is cut out. The design is applied to plywood 8-12 mm thick; first it can be cut out with a jigsaw, so the edge can be brought to perfection with a router.

In this case, you will also have to work with a router, but without a template for now. When the surface is perfect, the template is fixed to the workpiece and then the work already described above with a manual wood router. Just one thing: if you need to remove a large amount of material in some places, it is better to do it with a jigsaw, for example. Otherwise, the cutter will quickly become dull.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

There are many different types of milling machines, but for the home craftsman or semi-professional use, universal ones are more suitable. If you want to clarify something, please contact me!

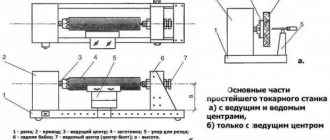

How are bodies of revolution processed?

The factory kit does not include a device for a router that allows you to cut grooves in cylindrical and conical workpieces. But home craftsmen have learned to make them themselves.

The product consists of the following parts:

- Cases.

- Movable milling carriage.

- Disk for adjusting the angle of rotation.

- Clamp for fastening the workpiece.

- Set screw.

The mechanism can be turned into a lathe by connecting an electric drill or screwdriver to it.

What is a router and why is it needed?

- Edges. Serve for processing the side surfaces of workpieces. With their help, you can make smooth or shaped edges, you can form recesses and spikes for joining parts. It is this type of cutter that comes with a bearing at the end - it rests on the part, setting the distance from the edge of the workpiece to the cutter.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials