Learning how to use a circular saw safely and effectively gives you a rewarding and fun hobby. A circular saw is a sophisticated and effective tool that will help you create a range of beautiful projects, from shelves to art. For beginners, the circular saw may seem more complex and less user-friendly compared to the puzzle, but don't worry! We'll help you learn to cut with confidence, safety, and enjoy your skills.

First, let's look at what a circular saw is. It is actually a blade with a guard around it, driven by a motor that creates a circular motion for cutting. Generally speaking, circular saws can be divided into two types: side saws and screw saws. The side mechanism has a compact shape and the motor is located along the blade.

Due to its smaller size, this type of saw is less powerful than larger models. For the same reason, it is less durable, so if you are choosing a tool for heavy use, this is not the type you want. Buy a side mechanism in case you need a light and simple tool for occasional use.

The worm saw is larger and the motor is located behind the blade. This saw can cut through hard materials without overheating. Overheating should be avoided for safety reasons: when the saw slows down during heavy work and gets hot, the blade will quickly dull and the quality of the cut will drop dramatically. Eventually, the sheet can rip and hurt you.

Quick Start Checklist

Is this the first time you are going to do carpentry? If so, it means you still don't have the necessary tools. We recommend trying a tool that is versatile and affordable and feels comfortable in your hands. This will help you gain some experience and then you can choose a specific model or models as per your needs and requirements.

When you are a beginner, it is best to start with simple woodworking projects and move on to more complex tasks when you feel more secure. Once you have a tool at hand and are ready to put it to work, the best way to overcome your fear is to run some tests to get a feel for how it works. After this, you can start your first job.

It's important to follow safety guidelines when using a circular saw, so here's a quick checklist to read:

- There are two important things you should keep in mind: safety and protection. Although modern saws are designed to be compact and safe, this tool still requires your full attention.

- Before each use, check the saw to ensure that it is not damaged. Do a safety check on the blade and replace it if you see broken or chipped teeth.

- Inspect the cable and please be sure to unplug it before performing any operations on the blade such as cleaning or replacement.

- The quality and speed of cutting depend on the condition of the blade. For best results, make sure the sheet size is smaller? Inches beyond the edge of the board. Adjusting the blade too deeply can force the saw joint and push back.

- Never use a rusty or damaged blade! Sheet selection is important, and you'll find more information on how to choose a good sheet for carpentry below.

- Check if the blade is sharp enough and sharpen it if necessary. A sharp blade is safer and works more efficiently. On the other hand, a dull blade could stick to the wood and overheat.

- Make sure the blade fits properly and that the guard moves easily to cover the blade when not in use.

- Be sure to place the saw in a safe position. There are no strict rules regarding cutting direction, but you should keep the saw motor oriented towards the larger part of the board; This will provide better support for the saw plate.

- Make sure the blade is rotated correctly.

- Check your sheet or board to see if there are nails or knots before cutting.

- Remove all cables from the cutting area and ensure they are not damaged.

- Wear a mask or safety glasses to protect your skin and eyes from damage.

- Long sleeves in addition to gloves (gloves are required) will give your hands extra protection.

- There is a risk of inhaling dust, so using a respirator or mask may be helpful.

- Hearing protection may be considered as some jobs may not be as quiet.

Hacksaw - simplicity and safety

A hacksaw is a simple tool that is quite suitable for the job. And although the cutting speed is low and considerable physical effort is required, such a saw is the most acceptable option for home use.

to cut wood correctly The main condition for a high-quality cut of the material is to make the cut correctly. To simplify the task, you can use a regular flat block, which is used as a guide.

The question often arises of how smoothly with a hacksaw at an angle. For this purpose, a special carpentry device is used - a miter box. Moreover, it will help not only to make a cut at the desired angle, but will also allow any beginner to cut the board smoothly.

You can also saw off the timber with a hacksaw. The only problem when working with such a workpiece is that you have to put in a lot of effort.

The last option is to use an angle grinder with a wheel with teeth installed for the work. But since the “grinder” is not intended for cutting wood, this method can only be used as a last resort: attempts to cut a board can result in serious consequences. It’s better to use a hacksaw - it’s labor-intensive, but safe.

The hand saw must be driven, otherwise it will start to “walk”. And this must be understood literally, since wood is a living material whose behavior is unpredictable. But the sawing process itself can be complicated due to knots, cracks, hard growth rings, high humidity and high resin content.

READ Miter Saws Bison With Broach for Wood

It is because of these reasons that there is no universal tool capable of taking into account all the vagaries of wood, but various special saws can be used for these purposes. The shape and order of alternation of their teeth are not determined by the material. from which the saw blade was made, and its purpose. Some of these tools are designed for cutting in a straight line, the other, on the contrary, is better to go in a circle.

Tips and tricks to help you achieve the best results.

Once you have gained some experience and are good enough to move on to more complex and sophisticated work, it is time to start learning the secrets that will help you improve your skills and create masterpieces of wood art. For a safe teacher, a good circular saw can go through any material: foam, plywood, PVC. With a diamond blade you can even cut stone! Circular saws can be configured for compound or bevel cuts and can even replace a table saw in many jobs.

Here are some tips and tricks to keep in mind:

- Start again if the cutting line has been lost. Don't try to get back on the line as it will be difficult, especially if you are new. Remove the blade and start again. After a few tries, you'll be able to cut beautiful, straight lines effortlessly.

- Don't use easels when cutting heavy boards - With heavy pieces, it's easier to cut them while they're in place than to cut them on easels. Place the board on your toe and lean towards it, but make sure you cut more than 10 inches from your foot.

- Avoid pinching When cutting leaves, you need to provide support to avoid the kickback that usually occurs if the saw blade gets stuck in the cut. When cutting on trestles, be sure to position the saw outside a pair of ribs. Position the board or sheet so that the longest part does not fall off when cutting.

- Continue cutting to a safe level and avoid cutting above your chest . Otherwise, you will not be able to hold the saw safely. For tasks that require cutting at a higher level, you should elevate the handsaw.

- Beware of splinters - This can happen on the top surface of the board or sheet and can be a nuisance if you are driving on expensive woods. To avoid this, place the table with the visible surface facing down. So in this case, if fragmentation occurs, it will affect the back. You can also mark the cut line using a utility knife to help you make a smooth cut. For a more pleasing appearance, support the board completely so that it does not allow a falling object to attract a piece of wood.

- Cut the same pieces - If you need to cut multiple pieces of the same size, place the sheets on top of each other and make sure all the edges are aligned. Then hold or secure the stack to prevent it from moving and cut all the sheets at once.

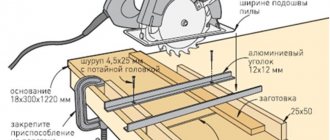

- When you need to cut a straight line, you can use a metal ruler or a wooden strip as a guide

Adhesive cutting tape

To ensure that there are no chips on the material, and the veneer retains its original appearance, you can use adhesive or, in other words, masking tape. It will not leave marks on the wooden board, and will also protect the wood from visible mechanical damage.

The tape is attached in the place where the cut will be made. Next, you should carefully saw the board, after which you can remove the masking tape. It can only be dismantled away from the cut and at a right angle. The main thing is not to pull the tape upward so that the plywood does not delaminate.

Important features when choosing the right blade.

If you are a beginner and don't have the services of a circular saw expert, choosing the right blade can be a little daunting. There are different types of saw blades designed for different materials, types of cutting, and for different power saws. Then one of the most important characteristics when choosing is the diameter and type of blade. You just have to make sure that it is compatible with your circular saw model.

Here's a quick guide to help you find the right sheet:

- Hand saws accept smaller diameter blades, typically 4 to 7 inches;

- the saw will require a diamond blade with a diameter of 7-10 inches;

- table saws require 10 or 12 inches, and table saw blades must have a carbide tip;

- For cutting metal, 14-inch blades are typically used.

Another important feature is the RPM (or revolutions per minute). For example, smaller sheets have higher rotations and larger sheets have lower rotations. The recommended saw speed should be lower than the recommended blade speed. Note that a saw's RPM does not directly indicate its cutting speed, so higher RPM does not mean it will cut faster.

The diameter of the blade will affect the speed because the edge of the larger blade will move faster compared to the edge of the smaller blade as it covers more distance at the same time. On the other hand, don't rush to select a larger blade, as you also have to consider the desired cutting quality. So when looking for a suitable RPM indicator, consider the material you will be working on.

To do this, you must calculate the SFM, which is equal to Surface Foot Per Minute. The formula is as follows:

SFM = (diameter / 12) * O * RPM

Typically, you will need an SFM of 5,000 to 8,000 for wood materials, and less than 1,000 for metals.

Also pay attention to the cut line indicator when selecting a tool. This is so you can see where your sheet is going as you cut. Without this, you will have a harder time cutting a straight line. The cut indicator is usually located on the motherboard and looks like two small notches. However, in some cases you may not be able to see the crop indicator. For such cases, a small window that shows you where the leaf is is helpful, so look for it. Feel free to grab the tool and see if it feels comfortable.

Next, take a look at the motherboard. What material is it made of? Magnesium base plates are more stable, but can break if you drop the saw. On the other hand, an aluminum base plate can flex when you need it most, while plastic base plates are stable and impact-resistant.

Regardless of the material, the base plate must be flat in length and width and have a straight edge. At the end, take a look at the guard. Guards with sharp or rough edges can get stuck on wood surfaces during cutting and make lifting difficult.

When it comes to what you are going to cut, you should also pay attention to the type of blade. Different types of materials work better with different types of blades. For example, there are blades designed for cutting wood, plastic and acrylic, metal and several materials. Here are some types you may need:

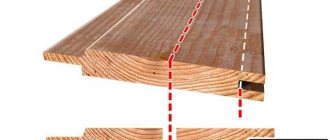

- Rip Cut is wood cutting; Consequently, cutting blades are designed to cut along the grain: these blades have fewer teeth, specifically designed for aggressive cutting;

- The cross-cut blade is designed for cutting grain and has 40 to 80 teeth designed to provide a clean cut;

- Combination blades are used to make both crossed and ripped cuts as they have groups of teeth separated by a throat.

Since the teeth make a cut larger than the disc itself, its shape and quantity must be taken into account. This is another aspect of the blade that will affect your cutting performance. The more teeth, the more accurate the cut will be. Additionally, the shape of your teeth determines the quality of your cut. For example, the alternative top bevel type is suitable for quick cuts in rough wood that are along the grain. Multi-material blades are good for cross-section, and radial arm blades have a negative angle to avoid automatic feed.

Types of circular saws

Types of circular saws.

For household needs, manual options capable of transverse, longitudinal and oblique cuts are quite suitable. They are distinguished by maneuverability, lightness and relatively low price.

A number of models allow you to make cuts not only from the end, but also anywhere thanks to the special immersion function. Thanks to the ability to tilt relative to the slab, such models cut material at different angles.

The base plate of such a tool is made by stamping (suitable for household purposes) or cast (for professional tools).

For large volumes of work, a stationary circular saw with a box-type bed will be required. They have been used before. Modern models are made very compact, which allows them to be placed on work surfaces, such as workbenches.

For professionals, more massive tools are needed that are placed directly on the floor of the room. They are able to influence the depth of cut thanks to a moving work table. The disk remains motionless during operation. Thanks to this, the capabilities of the circular saw are greatly expanded.

If work is often carried out with variable load, then combined options are suitable. They differ from manual ones in that their body has special fastenings that make it possible to work stationary on any horizontal surface. In this case, the saw is secured with the disc facing up.

How to care for your blade

No matter what type of blade you choose, it will require the right attention to give you an accurate result and allow you to work safely. Here are a few rules to follow:

- To protect your teeth from splinters or breakage, you should try to avoid contact while storing the blade.

- Sharpen your blade regularly and ideally have an extra blade on hand to ensure you can replace a dull blade immediately when needed.

- When doing woodworking, always place the saw on a level surface between cuts; Never place it on the ground.

- Never remove the chain saw from the board and never try to reverse it while working. Always stop the blade before lifting it.

Cleaning is very important to keep the blade in good condition and extend its life. Do not use aggressive cleaning materials such as wire brushes or steel scrapers. The blades can withstand tremendous force and the use of such materials can compromise the integrity of the blade. If necessary, use a higher quality plastic cleaner or a brass brush.

Why is cleaning so important? In the case of a saw blade, it's not just a matter of hygiene. When in use, the blade becomes contaminated with bits of sap, resin, dirt and dust that stick to the blade body. If they are not removed, they add more friction, which in turn makes it easier for the blade to heat up during use. Additionally, dirty blades cool more slowly, resulting in faster shutdown and ultimately warped blades.

Keep in mind that even the sharpest blade will be sharp enough to cut human flesh, so take all appropriate precautions when cleaning.

Advantages of electric circular saws

Various types of circular saw blades.

There are models of saws that control the load of the tool during operation, protecting it from overheating, and are able to control the speed of rotation of the mechanism.

Most circular saws are equipped with an overload indicator and their motor brushes. Replacing discs is very safe thanks to the built-in fast braking system and engine blocking of the device.

A number of electronic saws allow you to measure the number of revolutions as the blade moves when cutting. This feature allows you to work not only with wood, but also with plastic and some soft metals.

More advanced models are equipped with an electronic soft start system. Thanks to it, such tools quickly gain speed at a steady speed.

It is very difficult to get injured in this case, since such models have a protective casing against the saw teeth. It moves away from the disk smoothly, without jerking, when starting to work. A number of some tools of this kind are equipped with a pendulum casing and a feed roller.

Many models, used for both professional and domestic work, are equipped with special outlets used to connect a vacuum cleaner. Despite the decrease in maneuverability, such a tool lasts longer, since the number of negative factors is significantly reduced.

Useful cleaning products.

To effectively and safely clean your blade, you may want to consider a special blade cleaner. You can also try household cleaners (non-aggressive), but for severe stains this may not be enough or may require additional cleaning.

For cleaning, use a nylon cleaning cloth. If you are the proud owner of a coated blade, always make sure that your cleaning products and cleaning materials are suitable for the layer of the blade. Whether you use a spray cleaner, a liquid, or just soap and water, it's important to dry the blade after cleaning it. And, of course, the last important parameter of cleanliness is regularity. This will help you keep your blade sharp and safe for longer.

Among the other tools in his workshop, the circular saw isn't the most basic, but it's durable, economical, and can be used for a variety of applications. It will take some time to gain the experience and confidence of a teacher, but eventually the circular saw will become one of your carpentry devotees' assistants. From plywood to stone, any material will be impossible for you. Follow safety rules and carpentry will become your favorite hobby.

SURVIVAL SKILLS

The importance of following safety precautions

When working with a circular saw, you need to be careful. Carefully tuck in the garment by tucking in any overhanging parts and tying the belt and laces.

Hold the instrument well. If it wobbles during operation, such a situation can lead to a number of troubles: damage to equipment, the desktop and cause injury.

Use a saw to cut dry wood. If the rules are not followed, the tool can quickly be damaged. The motor of the circular machine will burn out.

After finishing the work, you can put the saw on the workbench. She must stop completely.

Do not touch the exposed wire or use a damaged tool to avoid injury.

If you follow the rules, working with a hand-held circular saw will be easy and safe.

Main characteristics of equipment

When choosing the right drive for your machine, there are a number of important factors to consider that affect performance. The main technological indicators are:

- Electric motor power. To fit a large diameter saw blade, you need to turn the motor as high as possible. The disadvantage of such devices is their weight. For example, a device with a 1200 W electric motor weighs about 4 kg. The most powerful system with a power of 2000 W already weighs 7 kg.

- Depth. To get a long cut of a certain depth, it is very important to choose the right power.

Disk rotation speed. This parameter is directly proportional to the density of the workpiece. The cut will be clean if the rotation speed is very high.

disc on a miter saw

Adjusting the angle of inclination. Many saw models have this setting. If you often cut at an angle, then you need to take a disk with a thickness of more than 2.5 mm.

Thinner discs will bend when cutting at an angle and it will not be possible to make an accurate cut.