Bow saws have long occupied a place of honor among carpentry tools. And although their design and design have changed significantly over the years, the basic principle of operation of these saws remains the same. What is the advantage of this tool and what makes it stand out from the rest?

What is a bow saw used for?

It is convenient to use a jigsaw to make short, mainly transverse cuts, and a hacksaw to make long, longitudinal cuts. And only with the help of a bow saw can you make a variety of dividing cuts, both with dry and wet wood. In addition, for a bow saw for wood, it does not matter how the wood is cut - along or across the grain. If we add to this the ability to work with one hand (the first “bows” were exclusively two-handed), it turns out that the tool in question can be used for cutting wood:

- in longitudinal;

- in transverse;

- in figured;

- in an angular direction.

The only insurmountable obstacle for bow saws is the transverse dimensions of the workpieces - for thick logs it is still better to use a power tool. However, you have to work much less often with thick logs...

Three circumstances give versatility to bow saws for wood:

- Adjustable tension of the saw blade (in some ways this process is similar to pulling the string of a bow, hence the name of the tool). Testing shows that bow saws can create tension forces of up to 100...120 kg without destroying the saw blade.

- The special shape of the teeth allows for both roughing and finishing cuts.

- The size of the saw is compact, which ensures its use even in cramped environments.

Modern manufacturers of bow saws and accessories for them - trademarks Bahco, Stanley, Intertool, Fiskars and others - complete their products with different types and designs of saw blades, which increases the ease of use of the tool.

What it is?

Unlike conventional wood hacksaws, saws can be used to accurately cut small workpieces at different angles relative to the direction of the grain.

Tool Features:

- Thin cutting line - thanks to a slight tooth set.

- The canvas works when moving both forward and away.

- The bow saw can be held with both hands.

- Suitable for cutting along curves.

If earlier bow saws were made of wood and they looked like large frames, now the main manufacturing material is a thin-walled steel metal pipe and a plastic handle; to improve ergonomics, the surface of the handle is covered with rubber. The mechanism for tensioning the blade is the same as that of conventional hacksaws. The type of blades is varied and differs in the number and size of cutting teeth per inch. Most often, the blade is hardened; in this case, they cannot be sharpened.

Expert opinion

Levin Dmitry Konstantinovich

Some modifications with a length of more than 500 mm can be used by two people, like two-handed saws.

The device of a bow saw for wood

The modern “onion” includes:

- Frame made of rolled profiles. Depending on the size of the saw blade - and they are usually standard: 350 mm, 530 mm or 760 mm, the frame can be made in the form of an oval trapezoid (for longer blades) or an oval triangle (for shorter ones).

- A handle whose profile prevents sudden injury to the worker’s fingers.

- Saw blade.

- Devices for tensioning saw blades.

- Fastening the canvas to the frame.

The frame of a bow saw for wood has special requirements - it must be rigid and at the same time light, so as not to increase physical stress during sawing. A special tubular profile with a very small width satisfies the task. This makes it easy to bend it during the manufacturing process to the required frame configuration without losing the strength of the part, providing the saw with the necessary mobility.

One of the main differences in the design of modern bow saws for wood is the principle of saw blade tension. For example, the Gardena or Proline brands use a handle with an eccentric for tensioning: by using it, changing the angle of inclination of the handle relative to the longitudinal axis of sawing, you can thus adjust the tension force.

Manufacturers of saws from Bahco Stanley have taken a different path: there a special screw mechanism for tensioning the saw blade is mounted in the handle. The choice is determined by ease of use, however, the presence of a screw mechanism provides increased tension accuracy, and does not depend on random movements of the user, when the position of the handle during sawing can randomly change. Therefore, it is recommended to use a rotary tension mechanism if you have some experience working with a bow saw.

To fasten the saw blade to the opposite part of the “string” (frame), removable cotter pins or wing screws are used. The latter are more reliable, since the cotter pin, usually made of mild steel, wears out over time and can spontaneously come out of the mounting hole.

Types of electric and gasoline saws

Gasoline and electric tools have a motor or motor that rotates the tool. Thanks to this, the operator has to put in less effort and the work speed increases. Some versions of the tool are self-contained and suitable for field conditions, others are corded and require a 220 V outlet. Here are the main features of this category of saws.

Chainsaw

The saw operates with an internal combustion engine. Requires gasoline and lubrication of the small cutting part. The tool varies in bar length, which ranges from 35 to 60 inches. This affects the ability to cut a certain diameter of the trunk in one approach from one side.

Device

The cutting element is a chain consisting of links and protruding teeth. It is looped and moves along an oval bus with a guide. The operator holds the unit by the main and auxiliary handles. You can cut horizontally or vertically.

Replacement and tightening of the chain is carried out by a tensioning mechanism on the side. If the working part gets caught in the material, the saw will bounce off. To increase safety, it is equipped with a chain brake that is activated when the plastic safety stop collides with the operator’s hand.

Chainsaw.

Purpose

The presence of exhaust gases allows this type of tool to be used only outdoors. Chainsaws are often used for felling trees and collecting firewood. Thanks to the autonomy of the gasoline engine, they are suitable for long-term use in field conditions.

But the tool is quite universal, so it is used almost everywhere:

- construction of houses and baths from logs;

- cutting firewood in the yard of the cottage;

- cutting down garden trees;

- figured cutting of sculptures from concrete or ice.

Thanks to the powerful engine, the saw copes well with dense materials and withstands heavy loads. But this is an expensive tool that requires proper care.

Electric chain saws

They are similar to gasoline ones in terms of the cutting part and use the same chains. But thanks to an electric rather than a gas engine, they have both their advantages and disadvantages. Within their type, they are divided by tire length and power.

Electric chain saw.

Device

The electric motor is located in front of the main handle and is installed longitudinally or transversely. In the first case, the electric saw has a narrow body, and in the second - with a shorter one. This is worth considering when choosing for use in limited space. All corded chain saws are connected to 220 V. There are 36 V battery versions.

Cordless chain saw.

Electric saws are lighter than chainsaws, so they are less tiring on your hands and are suitable for long-term work throughout the day. They do not emit exhaust gases and are used both indoors and outdoors. Their design is also simpler (only an electric motor, gearbox and equipment), which is why they cost less and repairs are inexpensive.

But the presence of a power cord limits the operator’s maneuverability, and sometimes simply gets in the way (when working at height or frequently walking around a large workpiece). Cordless electric saws are not as powerful and are limited in terms of duration of use by the capacity of the battery.

Purpose

In general, this is a universal tool, but the presence of a power cord allows you to use it only close to an outlet. They are used to cut firewood in the yard, build wooden houses, and cut openings for doors and windows in wooden houses.

Reciprocating saw

It got its name because of its curved cutting element, reminiscent of a saber. Among craftsmen it is also called an electric hacksaw.

Reciprocating saw.

Device

It has an electric motor and gearbox that makes the saw blade move back and forth. Due to such repeated translational movements with high frequency, a cut is made. To protect the operator's hands, there is a stop on the second handle next to the equipment. The main handle is L-shaped or D-shaped. Some models have a step speed switch that helps you set the desired speed for a specific material.

The tool is either corded or cordless. The pros and cons of the type of power supply here are the same as with other saws: a corded one limits mobility and requires an outlet nearby, and versions with a battery remain autonomous only for an hour. For longer use without interruption, you will need a second battery. Then the batteries can be alternated, changing them in the tool and charging them in the base.

Cordless reciprocating saw.

Purpose

The main feature of a reciprocating saw is its compactness and light weight. Thanks to this, it is used at heights or in hard-to-reach places where it is inconvenient to operate a chain saw or a hand-held circular saw.

For example, it is well suited for roofing work. The model cuts not only wood. Special replaceable blades allow you to cut stone, concrete, and metal. There are saw blades that can be used to make neat cuts in combined materials.

Saw alligator

It is a type of reciprocating saw but is intended for larger objects and workpieces. It got its name due to the use of two toothed blades, similar to the double dentition of an alligator. The tool can be battery-powered or corded. The first type is much more expensive.

The alligator saw.

Cordless alligator saw.

Device

It has handles on the motor block and a long guide. Two blades move along the bottom of the tire in opposite directions. The stroke length can be up to 40 mm. This ensures an even cut and minimizes the cutting line moving to the side. When the blade becomes dull, it is replaced with a new one.

Purpose

Most often, the alligator saw is used for cutting aerated concrete and building blocks of similar structure and density. It is lightweight and suitable for sawing bricks perpendicularly or diagonally. But two blades in the composition increase the thickness of the cut, which is important to take into account when calculating the size of materials.

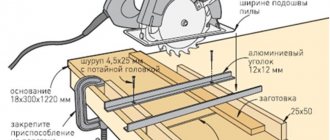

Circular (circular) hand saw

It is held with one hand and can be used for cuts in the downward and vertical positions. It is called disc because of the rotation of the disk as the main cutting element. Thanks to this design, it is compact. There are versions powered by 220 V mains and battery-powered 36 V.

A circular saw.

Cordless circular saw.

Device

It consists of a D-shaped single handle, a transverse motor, to the shaft of which a steel disk with teeth is attached. Rotation of the working part at high speed ensures fast cutting of wood. The circular saw blade is protected by a sliding casing that automatically closes the teeth after the saw is removed from the board. The cutting depth depends on the diameter of the disc and can reach 50-60 mm.

Some models are capable of tilting the blade at an angle to make a bevel cut.

Purpose

The circular saw is used for longitudinal and transverse cutting of boards, beams, etc. Due to its low weight and size, it is convenient for working at heights, for example, trimming pediment boards, frames, rafters, etc.

Circular machines (sawing)

It has a similar cutting element as a hand-held circular saw, but is installed on the floor or table. The user, instead of a tool, holds the workpiece itself in his hands, feeding it at the desired angle to the disk. This simplifies the processing of large parts, but this technique is not used at heights. All types of sawing machines are networked.

Device

All circular saws have a motor and a drive (belt) that transmits torque. There must be a support platform with a slot from which the cutting disc looks out.

Structurally, there are three options for the types of circular saw:

1. Tabletop - has short legs and is installed on a workbench or durable table. The weight of the machine is within 20 kg, so after work it can be put away on a rack or other convenient place. A small disk allows you to cut material with a thickness of 40-80 mm.

Tabletop circular saw.

2. Circular sawing machine with stand - equipped with a table extension, on which it is convenient to place boards or timber with a length of 2-3 m. This ensures an even cut and relieves the operator, because he does not need to hold the weight of the workpiece with his hands.

Circular saw with stand.

There are versions with folding legs, so the machine is suitable for easy transport to the workplace. Depending on the diameter of the disc, the cutting depth is possible up to 80-90 mm.

3. Stationary circular saws - designed for operation in one place, since they weigh 40-50 kg. The heavy bed ensures a stable position even when processing large workpieces. It can be equipped with large discs that cut depths from 70 to 125 mm.

Stationary circular machine.

Purpose

Using circular machines, wide boards and beams are unraveled.

Straight transverse and oblique cuts are possible. Small desktop versions are optimal for working in the garage. Machines with stands are suitable for field activities in order to prepare all the wooden parts on site, rather than transporting them to the workshop. Stationary machines are in demand in enterprises and furniture factories.

Miter saw

It got its name from its ability to cut only ends and perform cross cuts. The material is not used for longitudinal dissolution.

Miter saw.

Device

Consists of a base and a lowering disk with teeth. The electric motor is located on top and transmits torque directly to the saw element. There are no belts or chains in the mechanism. The top of the disk is covered with a metal casing. Lowering is carried out on a bracket with a hinge, and the operator holds on to the handle.

The base of the machine has a stop for placing workpieces and securely fixing them. This promotes cutting accuracy. Some types of miter saws are capable of tilting the cutting blade to the left or right relative to the table to produce a miter cut. The mechanism provides for a tilt of up to 45-55 degrees.

One type of these saws is the broach miter saw. The saw blade of such a tool is mounted on special guides and can move horizontally. This design allows you to cut and trim fairly wide workpieces.

Miter saw with broach.

The saw is installed on a table or workbench. The weight of 10-30 kg makes it easy to rearrange it, put it away for storage and transport it to another place of work.

Purpose

The main area of application for trimming is woodworking. With its help, timber and boards are cut to size for subsequent assembly. Miter saws are designed for miter joining parts. If you replace the disk, then using the device you can cut aluminum, plastic and other non-ferrous metals. The machines are used in framing workshops and furniture production.

Cut-off (mounting) saw

As the name suggests, it is designed for quickly making cuts on parts during installation. Essentially, it is a small cutting machine that sits on a table or even on the floor.

Device

Structurally, the saw is similar to a miter saw: there is a bracket on a hinge, a motor on the axis of which the saw blade is mounted, and a base. The machine is located on the table. Weighs 10-15 kg and can be easily moved from place to place by one person.

The difference from a miter saw is the design of the cutting disc. Here an abrasive wheel is used (similar to wheels for angle grinders, only with a larger diameter and thickness) or a steel disk with teeth and pobeditovy tipped.

The base is equipped with a vice for fixing workpieces. To prevent sparks and abrasives from flying into your eyes, a transparent protective screen is provided. Rotating the vice and tilting the wheel expands the cutting line options.

Assembly saw.

Purpose

The assembly saw is used on construction sites for quick cutting of workpieces. The abrasive wheel allows you to work with metal with a thickness of 1-30 mm. The tool is also used in production for the serial production of parts for welding. It is used to cut: profile and round pipes, fittings, rods.

Stationary band saw

It got its name because of the cutting element in the form of a moving saw blade.

Device

Vertical machine with electric motor and roller system. One node is located at the top of the device, and the other at the bottom. Between them there is a frame with a slot on which the workpiece is located. The cutting depth depends on the height of the workplace between the two rollers and the table, but even for the largest stationary machines this figure does not exceed several tens of centimeters.

Stationary band saw.

Purpose

A stationary band saw is used for straight and curved cuts in wood, metal, and plastic. A thin saw blade allows you to cut figuredly and make cuts with complex configurations. This is in demand for decorative elements or when creating special structural blanks.

Band saw

It also uses a saw blade, only the tool is small and convenient for transportation. There are two types of shape.

Device

The portable tabletop version has a rectangular base and the working part with rollers, belt and motor is lowered by pressing the handle. This saw can be easily placed on the table for convenient manipulation of workpieces. The parts are fixed using a vice built into the base.

Portable band table saw.

The hand-held band saw is made without a base - there are two handles above the rounded edges of the body with rollers. The operator holds the tool suspended, and the part to be cut is placed on the table, floor, or clamped with additional vices or clamps. Carrying the device is even easier.

Hand band saw.

Purpose

Band saws are used by welders and plumbers to make complex cuts where a grinder or other tool is not suitable. With its help, work is carried out on metal, plastic and wood. But the compactness affected the maximum possible size in height of the installed workpiece - often it does not exceed 10 cm.

Combination saw

It is called so because of the possibility of combining two cutting methods. They cannot be carried out at the same time - only one by one. This became possible thanks to the complex design.

Combination saw.

Device

The saw has a base and a hinged bracket. An electric motor and a working disk are attached to the latter. Lowering the rotating wheel helps you make cross cuts quickly - here the saw acts like a miter saw.

An example of using a combination saw as a miter saw.

If the moving part is lowered all the way and fixed, the disk will look out from above (on the back side) and the saw turns into a circular saw. It will allow you to spread boards and beams lengthwise, as well as make cuts at different angles.

An example of using a combination saw as a circular saw.

Purpose

Thanks to the combined cutting methods, the saw is in demand both for trimming boards and timber to size, as well as for preliminary unraveling of wood and reducing the width of the board. But the cost of the equipment is high, so it is used only in professional activities.

Radial console saw

It is called so because of its special shape with radial rotation of the bracket and movement of the cutting part along the console. This is a complex type of equipment for woodworking production.

Device

The machine has an L-shaped bracket mounted on a rectangular base. The stand rotates left and right. A metal disc with teeth is used for cutting. It receives torque from the engine, being directly mounted on the armature shaft.

The saw part moves back and forth under the console, which allows you to make long cuts. Some models are capable of tilting the blade to cut an edge. The cutting depth depends on the diameter of the disk and can be 20-50 mm.

Radial console saw.

Purpose

The movement of the saw blade along the console allows you to make long cuts in sheet material. This is relevant for preliminary cutting of chipboard, MDF, and laminated chipboard sheets. The saw is also suitable for square and rectangular cuts in large panels, since the cutting part has a submersible action and it is not necessary to start the blade from the edge of the material.

Jigsaw

Like a regular jigsaw, it works with a thin toothed blade, only the latter moves due to a gearbox and an electric motor.

Jigsaw.

Device

It has a D-shaped handle, a motor and a metal sole. Suitable for working in downward and vertical positions. The file is submersible and moves up and down in amplitude thanks to a pendulum mechanism.

The jigsaw has a speed controller to select the optimal speed for different materials. The housing has built-in vibration dampers and a bar that protects surrounding objects from accidental contact with the saw blade. Jigsaws can be corded or battery-powered.

Cordless jigsaw.

Purpose

The tool is suitable for straight and curved cuts, cutting out complex shapes. The cut starts from the edge. To cut shapes inside the material, you will need to pre-drill a hole to insert the cutting blade. Used by woodworkers and cabinet manufacturers, kitchen installers.

Jigsaw machine

The machine has a thin saw blade that tightly performs reciprocating movements. The master does not hold a jigsaw in his hands, but a wooden blank and, turning it, makes the necessary cuts.

Device

The device has a base with a supporting surface. There is a hole in the center through which the saw blade moves. The G-shaped frame with a long reach allows for internal cuts in large wood panels.

Since the tool is not supported by weight, but firmly mounted on the table, the cut is cleaner and smoother. Suitable for making critical products. For control, there are start and stop buttons, as well as a speed controller.

Jigsaw machine.

In some versions of the machine, the lower base can be tilted and there is a scale with degrees, so you can cut the edge without preliminary marking exactly at a given angle. Depending on the configuration, the jigsaw can be connected to a construction vacuum cleaner; there is illumination of the work area and air flow to keep the marking lines clean.

Purpose

Curly cutting of complex shapes in sheet materials, boards, production of decorative elements. Used in the production of furniture and wooden doors.

Bow saw blade

The versatility of this tool also determines changes in the design of the saw blade, in particular its teeth. Most often used:

- Saw blades with uniform tooth pitch. They are designed for smooth cutting of wood with a relatively short length.

- Canvases with the so-called “American” tooth, when after 3..4 ordinary teeth there is a double or “Kremlin” tooth. This configuration of the cutting part of the saw blade allows for longer and more complex cuts. The frequency of alternation determines the accuracy of the result: the closer the double teeth are located to each other, the less clean the cutting line will be.

- Spatial teeth with wide spacing. A blade with such teeth is useful for maximum cross-sectional sizes of wood being cut. The cutting force and the amount of waste increase, but sawing productivity becomes the highest possible.

Types of hand saws

Hand tools weigh little, do not require electricity or fuel, are relatively cheap, and have a long service life. But the speed of work depends on the user’s physical fitness. Types of hand saws are divided into universal ones, which are suitable for general purposes, and highly specialized ones, designed for specific processes. Let's take a closer look at them.

Standard saw

Belongs to the classic type. Can be purchased at any hardware store.

Device

It has a high steel blade with teeth, gradually tapering towards the end. The teeth need to be sharpened and set periodically, otherwise the saw will bite into the material. The D-shaped handle was previously made of wood, but is now made of plastic. More expensive versions may have a two-piece handle that is better at resisting slippage.

Hacksaw.

Purpose

Suitable for straight cuts of boards, timber, branches, laminate, MDF, chipboard and other wood materials with a thickness of 2-100 mm. Due to the flexible structure of the blade, which does not have a rigid frame, the cutting line easily moves to the side, so a standard saw is applicable only where strict adherence to dimensional accuracy is not required.

Bow saw

It got its name because of the arc shape of the frame and the tension of the canvas, like the string of a bow.

Device

The U-shaped frame is made of a round steel tube. The ends are provided with a hook-shaped threaded fastening. Using the thumbscrew, the screw is tightened, and the short blade with teeth becomes rigid. There is a rubber-coated handle on one side. When the teeth are ground down, the blade is replaced with a new one. In this, a bow saw has a significant advantage over a standard one.

But when cutting a tall workpiece, there may not be enough depth, since the product will rest against the tool frame. Some manufacturers produce saws with a swivel mount so that the jumper remains on the side and not on top.

Bow saw.

Purpose

Most often, a bow saw is used for sawing metal. This includes profile and round tubes, thresholds for fixing floor coverings, small brackets, etc. But changing the equipment to a blade with higher teeth allows you to saw wooden and plastic blanks.

Garden saw

It is small in size and designed specifically for gardening. Suitable for men and women as it is lightweight and easy to use.

Device

The structure consists of a steel sheet with a height of 40-30 mm. There are teeth at the bottom, and the shape of the saw part is slightly curved in an arc for better cutting into wood. The handle is often L-shaped and molded from plastic. There may be a hole at the end for hanging the tool. The saw blade is not replaceable and requires periodic sharpening and re-wiring.

Garden saw.

Purpose

Using a garden saw, they trim branches, twigs, and shoots on garden trees. You can even cut down a young tree or shrub. But it is not suitable for serious and precise tasks.

Jigsaw

Designed for shape cutting. But working with it is more painstaking and time-consuming than with a jigsaw.

Device

The jigsaw has a U-shaped frame, at the ends of which a cutting blade is attached. This can be a narrow file or a rod with an applied abrasive. The handle on the side is designed to be held with one hand. The large reach allows you to work with wide materials.

Hand jigsaw.

Purpose

A hand jigsaw is used to cut foam, plywood, chipboard, and plastic. Suitable for filing small pieces when there is nothing more suitable at hand. You can perform longitudinal and cross cuts, as well as go along any curved lines. The main purpose is curly cutting in small volumes. Ideal for the DIYer.

Passing saw

A highly specialized tool for precision work.

Device

The pass saw consists of a tall blade and small teeth on one side. Due to the large steel strip with reinforcement on the part opposite to the cutters, it is very rigid and does not bend during the cutting process. Early versions were equipped with a round wooden handle. With a short length they were called passing knives. Longer modern models have a D-shaped handle positioned at a 45-degree angle.

Passing hand saw.

Purpose

Due to the fine teeth and lack of setting, as well as the rigid design, pass saws provide precise and thin cuts. Suitable for fine cutting of wood, soft metals (aluminum, copper), plastic, chipboard. Popular with laminate floor installers and kitchen installers.

Grooving saw

High precision tool for cutting short grooves.

Device

The design is similar to pass saws, only much smaller. A thick rectangular blade with fine teeth is used. The thickening on the upper rib provides rigidity. The handle can be on the side or in the middle of the top butt. The rubber pad on the handle prevents slipping.

Grooving saw.

Purpose

Used for precision cutting of grooves in wood and soft metal. This could be cutting out a groove for a cable or gas hose in a kitchen countertop, cutting an aluminum table edge, or other critical cuts. The saw is not suitable for thick materials over 30 mm. Used only by professional carpenters.

Narrow (circular) saw

Hacksaw for specific tasks with circular cutting. It got its name because of its ability to bend while sawing the workpiece.

Device

A circular saw consists of a saw blade that tapers greatly towards the end. And in the widest part, the hacksaw is also not very large. The work is carried out with one hand. The L-shaped handle with rubber pads promotes a secure grip. There are types with a straight two-component handle.

Circular saw.

Purpose

A hacksaw is used for cutting circular and oval holes in wood and plastic. Due to its narrow shape, the blade can be easily tilted to the side and the cutting line can be rounded. Models with rectangular cutting blades break or bend under such pressure, but here everything is fine.

Plywood saw

Designed specifically for sawing plywood.

Device

The plywood saw is notable for its tall, permanent steel blade and D-shaped handle positioned at a 45-degree angle. Fine teeth without setting contribute to fine cuts and high precision. The large area of the steel sheet prevents deformation of the equipment and the line moving to the side. The end of the saw is rounded.

Plywood saw.

Purpose

Makes straight cuts on plywood without painting the edges or breaking off the edges. Provides dimensional accuracy and minimal waste, which reduces cutting errors. Not suitable for curly cutting.

Folding mini saw

The smallest type of hand saw, which is why it got its name.

Device

The design resembles a folding knife. There is a handle and a saw blade on a hinge. Instead of a blade, the lower edge has slightly set teeth. The end of the handle often has a hole for a lanyard to hang the instrument or wear on the wrist. Non-folding versions are available.

Mini saw.

Purpose

It is convenient to carry a mini-saw with you for camping needs: cutting off an interfering branch, cutting slingshots for hanging a pot on a crossbar, creating a hut, preparing firewood for a fire. They are also convenient to use in hard-to-reach places where a standard hacksaw cannot reach.

Two-handed saw

In common parlance it is called “FRIENDSHIP”, since it requires two people and coordinated actions to use. Use by one person is difficult and not justified in terms of time and results.

Device

A two-handed saw has a tall blade with large teeth. The length of the cutting part is a meter or more. The ends are provided with I- or D-shaped handles. The cut is carried out by alternately pulling the handle towards you. It is considered the largest hand-held non-electric tool.

The saw is two-handed.

Purpose

Designed for sawing tree trunks and large logs, felling forests in conditions where there is no electricity or fuel. For small boards and timber, it is better to choose smaller saws.

Japanese saw

The name of the instrument indicates the birthplace of the invention. It has a specific shape and is suitable for neat jewelry cuts.

Device

The canvas can be rectangular, but more often it is made in the shape of a trapezoid (resembles a long spatula). Sharpening with teeth is provided on one or two longitudinal sides. With a double-sided working part, the tooth pitch is different. The handle is straight or slightly turned down. The teeth are bent in one direction, which provides precise control of the cutting line. Cutting the wood fibers occurs when the user pulls the Japanese hacksaw towards himself.

Japanese saw.

What is it and what is it for?

A bow saw can easily be defined as an outdated device. But even if you have the entire necessary set of power tools stored at home, there may be many situations when you cannot do without a hand-held bow saw. If we consider the main purpose of this tool, it is worth noting that this kind of device is intended for accurate sawing of metal parts, as well as for working with wooden surfaces.

A bow saw can be used to make various parting cuts with any type of wood. We must not forget that for a product intended for cutting wood, the method of cutting it – lengthwise or crosswise – does not matter. There is also the ability to work with only one hand. This tool can be easily selected for cutting wood: in the longitudinal direction, as well as in the transverse and figured, even in the angular direction. True, for thick logs it is better to choose a more serious tool.

If we compare a standard saw with two handles with a bow saw, we should highlight the following positive features over the classic product:

- a bow tool will allow you to make a much more beautiful cut;

- you will spend much less effort - sometimes you can work with a bow and a pair, which will not work when working with a hacksaw saw;

- easy care.

Design features

This kind of saw is called a bow saw for the reason that its structure will be as elastic as that of a combat bow. At its core is a machine made of high-quality racks. There are 3 racks in total - 2 on the sides and 1 placed horizontally. Racks are most often made of hardwood. At the bottom of the vertical posts there are similar holes for attaching handles to them. The horizontal stand is called the mullion.

The working handle can be called a real piece of carpentry art, since the convenience of working and the percentage of its productivity will directly depend on its quality. The handles are most often round in shape; at the end there are cuts and special holes for installing the working blade.

There are several original varieties of bow saws.

- Folding bow saw , which is simply an indispensable accessory on hikes, which involve independently constructing a resting place using trees adjacent to the camp. Most often it is called hiking or tourist. Some manufacturers develop this kind of tool specifically in order to use it in difficult conditions. The main feature of this saw is its folding design. The product will actually quickly fold and unfold, and will not require additional tools or serious effort.

- Hand-held bow saw for wood. Before you start working, you will need to carefully examine the product itself and find out for yourself that there are no defects on those parts of the racks that are made of durable wood, and that the canvas is intact.

- Bow saw for metal. Before purchasing a specific tool, find out exactly what material you will need to process. After this, it will be possible to choose the most convenient shape for the work, as well as the length and width of the teeth, and the speed of movement of the device.

Important! The best option would be to purchase a product made of hardened steel - this is a 100% guarantee of its strength and long service life.

Types of paintings

Since the bow saw is mainly used when working with wooden products, the following blades for the bow saw on wood are distinguished:

- blade having single teeth located at equal distances from each other. Such saws are used for smooth, accurate cutting of material;

- a cutting part that has double teeth (or also called a “Kremlin” tooth). This position of the teeth is designed for more complex and precise cutting. If the tooth pitch is not too frequent, then the cutting of the material will be high-quality and accurate, there will be few chips;

- a saw blade whose teeth are arranged in two rows at a fixed distance. The purpose of such teeth is to work with thick material that is difficult to cut.

The material from which the cutting blade is made is high quality steel. It is advisable that it be hardened, because... this will guarantee a long service life, as well as good, fast work with various types of materials.

It is also worth paying attention to the teeth located on the cutting part of the saw. They are presented in the following types:

- for dry and hard wood, a tool is used whose teeth have the shape of an isosceles triangle, the cut is neat;

- For dry wood, a saw blade is intended, the teeth of which are in the shape of a scalene triangle;

- For raw wood, it is recommended to alternate teeth in the shape of an isosceles triangle, scalene, as well as the presence of double teeth to make cutting much faster.

Rating of the best models

Although they are similar in appearance, bow saws will differ significantly from different brands. For example, there will be differences in almost the entire structure of this instrument - from different bow designs or comfortable handles, to different fixation techniques, as well as different string tension.

- Bow saw from the Proline brand. It is useful for different types of cuts, including figured ones. It has a durable beam with a tightly stretched fabric. The bow will have 2 strong stands, special spacers, and there will also be a tension type bowstring. The length of this product is 760 mm, which will allow it to cut medium-sized logs.

- Product from Stanley Raker Tooth. It is perfect for working with not very large pieces of wood. The oval-shaped cross-section of the steel frame guarantees this product increased durability. There is a lever here with which you can properly tension the fabric and quickly change it if necessary. The saw is made of a special type of steel – hardened. The teeth here will have a shape that is commonly referred to as American - they do not require sharpening or constant care. This tool copes well with dry wood and completely fresh materials.

Subtleties of choice

It is worth paying attention to the main features of choosing a saw blade.

- When selecting or purchasing a bow saw, you need to take a special look at its main parameters - whether you have chosen the right blade size, whether its stability, thickness, and fastening method satisfy you.

- Choosing the most suitable length of the product canvas is quite simple - you just need to know the length of its frame. The parameters of the frame may differ - it can be 350 mm long, and can also have a length of 500 mm or 700 mm or more. The length measurement system that will be used is also important - it can be in inches or centimeters. If the size of your saw is calculated in inches, then you need to select a blade for it, whose length is calculated in the same parameters.

- It is important what material the product is made of. Several types of steel can be selected here. Saw teeth are often coated with a special Teflon coating to prevent corrosion or other negative processes that appear due to the influence of the environment surrounding the tool.

- The shape of the blade teeth is a special characteristic when selecting a product blade. It can have different shapes - trapezoid or triangle, “Kremlin” shape. An important feature of blades for archery woodworking can be considered the fact that it will have a different number of teeth per 1 inch (or centimeter) of blade. This indicator will allow you to get a more accurate cut. The greater the number of teeth per 1 inch of blade, the more beautiful the cut will be, and if there are few teeth, then the cut will be rough.

Safety precautions at work

To make working with a bow product as comfortable and safe as possible, you need to consider the following tips:

- place the blade only in separate slots located in the handle, and secure it in the required holes with special dowels;

- place the product near your chest so that the bowstring practically touches the body itself, and visually inspect the location of the canvas in the most careful way - so that it becomes perpendicular to your line of sight;

- by accurately turning the handle, you can easily achieve an even position of the blade with teeth in special holes;

- after the canvas is adjusted, you should, carefully turning the arrow, tighten the string and stretch the racks in order to secure the canvas more firmly;

- You should not sharpen or straighten blades for this type of product without the help of a specialist if you do not have professional skills; It is best to immediately purchase sharp factory blades;

You should not be distracted when working with such a saw; you should not leave the saw sticking out in the material while resting, so as not to spoil the blade, and it will be extremely difficult to start working again from this position.

To learn how to choose the right bow saw and how to use it, watch the following video.