Sleepers are used when laying railway tracks as a support for rails. Crushed stone or gravel is poured and leveled onto the earthen platform - the so-called “ballast layer” (ballast), on which sleepers are laid.

Ballast allows you to evenly distribute the load received from the sleepers, and prevents them from moving sideways or longitudinally when a train passes. The thickness of such a layer is at least 0.3 meters. Recently, crushed stone is used less frequently, replacing it with concrete.

In turn, the sleepers take on the load from the rails and maintain their stability, preventing them from shifting under the pressure of moving or braking trains. Sleepers keep the track gauge constant. The rails are attached to the sleepers with special screws or “crutches”. Sleepers and rails act as a kind of shock absorber, preventing the ground from subsiding under the weight of a multi-ton train.

Sleepers can be made of wood, reinforced concrete, or composite. Several years ago, up to 90% of the sleepers on the tracks were wooden. Today, only slightly more than half of all sleepers laid are made of wood. When constructing new railways and repairing old ones, wooden sleepers are replaced with reinforced concrete ones.

Reinforced concrete products - an alternative to wooden sleepers

The weight of a wooden sleeper is significantly less than its reinforced concrete counterpart and installation, replacement, and maintenance are relatively cheaper.

Despite this, reinforced concrete sleepers make up approximately 25% of the total mass of products. Their production is based on the process of concreting on reinforcement - just like conventional reinforced concrete production. Today, reinforced concrete products are most often used to create urban rail connections, including subways and trams. How much a concrete sleeper weighs is more of a question for comparison; the average weight itself reaches 250 kg, and the weight can vary within 20 kg. Due to the weight and size of reinforced concrete sleepers, replacing these products is difficult, but thanks to the development of modern technology, it is becoming easier every day.

The production of reinforced concrete sleepers involves their long-term operation, since they are not subject to rotting and are resistant to moisture and temperature changes. The negative aspect is due to the fact that over time, minor damage is observed at the joints. This is especially evident where there are special holes for fastening rails, and sometimes in other areas found along the entire length of railway sleepers. Therefore, every year from 300 to 500 thousand units of reinforced concrete products of this type are replaced, respectively, all this multi-ton reinforced concrete block requires special disposal. It remains to clarify existing standards and regulations to resolve this issue.

Video - recycling and recycling of reinforced concrete sleepers. In the video you can see that sleepers are turned into reinforced concrete scrap using a special crushing bucket.

Regardless of whether the reinforced concrete sleeper is manufactured in accordance with GOST 32.152-2000 or for installation on crane tracks of the PShP-310 type, disposal takes place based on the degree of wear of the products, as well as in accordance with FKKO.

Disposal of waste railway sleepers 84100000000 is provided for by a document on the basis of which waste of this type is clearly described and each is assigned its own hazard level. This is mainly 3-4th grade. Therefore, for storage, transportation, and disposal, a waste passport is required.

Modern technologies make it possible to process reinforced concrete products, dividing them into fractions: crushed stone and metal reinforcement (see video above). These types of waste can each be reused in their own category. Crushed concrete is used to add to the creation of new reinforced concrete products, as a material with which to sprinkle paths, etc. Metal parts can accordingly be sent for smelting if there is no other area of use.

Rails

Although today it is quite difficult for us to imagine that the rail, of which the railway track actually consists, can be made of anything other than steel, there were times in the history of the rail when it had a slightly different appearance and was made of slightly different material.

Story

It so happened that we mainly associate the railway with the advent of steam locomotives and a whole string of somewhat primitive, but still the same railway cars carrying heavy loads or passengers attached to them. But in this aspect, for complete fairness and clarity in posing the question, we need to slightly clarify such a fundamental moment in the history of the rail, what exactly should be considered the starting point in its history, either the very principle of moving cargo along parallel-laid guides or the moment when these guides began to be made of metal .

After all, it is worth noting the objective circumstance that the transportation of goods, especially heavy and large ones, is much easier and faster when the movement of this cargo occurs not along the ground surface, but along denser guides laid on the same ground. This physical feature, even without theoretical justification, was noticed and applied by the ancient Greeks, who, in their years, dragged their galleys across the Isthmus of Corinth on their “diolki”, roads made of stone slabs with deep grooves. Isn't this a train track in its original form?

Or take a later example from the 16th – 17th centuries. In the coal and iron ore mines of Germany, wooden rail tracks began to be widely used, along which horse-drawn trolleys moved, which already had wheels with so-called “flanges”, protrusions on their inner side, to prevent the trolley from sliding off the wooden rail. This is also a railway track. And even closer to its modern form.

But in a more complete understanding, a railway track can be called only from the middle of the 18th century, when, from an economic point of view, English entrepreneurs in their mines began to replace wooden rails with cast iron ones, as they were more durable and reliable. And although there was a certain “tension” with steam locomotives at that time, since George Stephenson was just designing his famous steam “Rocket”, and James White’s locomotive simply “broke” cast iron rails, the railway track was already “railroad”, albeit horse-drawn .

Well, then the technical idea did not take long to arrive, and cast iron rails began to be replaced with steel ones, and their square profile gave way to an almost modern I-beam-fillet shape. It is worth noting that the I-beam-fillet shape of a steel rail was proposed in 1789 by a certain Steve Jesson from Lowburrow, England, and the dimensions of the “foot” and “head” of the rail he proposed, namely 110 mm. and 35 mm. Accordingly, they are still used today as a narrow gauge railway.

These innovations did not leave the development of metallurgy itself stagnant. So, if the first railway rails were produced by forging, which was also a significant progress, then starting in 1857, rails began to be produced by rolling a steel billet on a three-roll rolling mill. And over time, this led to the fact that the production of railway rails became practically the main product of metallurgical rolling mills. Moreover, today the Russian Federation alone produces railway rails in quantities of more than 6 million tons, which can make a railway track more than 130 thousand kilometers long.

However, it is worth noting here that the railway track cannot be considered only as everything related to the transportation of goods using thermal or electric locomotives. The railway track and, accordingly, railway rails have wider application in our daily life and the country's economy. Here it is enough to recall the same metro, urban electric transport and the naturally necessary rail tracks. But we should not forget that to move almost all lifting mechanisms or, more simply, cranes, rails are also needed, which not only have a slightly different area of application from their railway counterparts. These rails have significant differences, both in their working profile and in the chemical composition of the metal from which they are made. So, despite the somewhat archaic nature of our idea of the same rails, the railway track is quite complex and interesting.

The upper structure of the railway track basically has rails for various purposes. They are steel bars with a special cross-section that serve to ensure the movement of rolling stock. Railways all over the world use wide-foot rails, which are the generally accepted standard.

Material

Modern rail production involves the use of rolled steel ingots only.

The production is based on the Bessemer method, in which the production of this product occurs using converters or open-hearth furnaces. Bessemer steel is produced using oxygen blowing of already molten cast iron for a quarter of an hour ± 3 minutes. When using this process, some part of the impurities and carbon burns out, which allows the metal to become less brittle. Open hearth steel is cooked from scrap steel and cast iron in furnaces with large capacities, ranging from two hundred tons to one and a half thousand tons. This resulting steel has its own advantage, being characterized by greater purity and less cold brittleness compared to Bessemer steel. Rails belonging to the heavy types, considered P75 and P65, are made by rolling steel from open hearth. Rail steel should only be of good quality, which determines its chemical composition, micro and macrostructure. All characteristics of the chemical composition of domestically produced rail steel can be viewed in special tables, which give the percentages of additives used in relation to iron.

The history of rails dates back to the 16th century, when the first, simple wooden structures were created in ore mines to ensure the transportation of mined ore. The development of metallurgy gave impetus to the rapid production of rails. The world learned about the development of a new type of transport - railway. Since wooden rails no longer met the new requirements, two centuries later the production of cast iron rails began. Then came the short era of iron rails. Beginning in the 19th century, railroads required rails to be made from high-strength steel. Our modern railway has switched to the use of wide-foot rails.

Classification

The classification of rails is based on weight criteria, that is, the weight of a rail of one meter. The described products are marked as follows and are used according to their classification purpose.

- Rail P50, weight 1 meter – 51.67 kg;

- rail P43 – 44.65 kg;

- rail P75 – 74.41 kg;

- rail P65 – 64.72 kg;

- R65K rail – products of this classification are used when laying tracks in areas with a certain curvature.

The following rail lengths are adopted as a standard: 12.5 m and 25 m. It should be noted that on Russian territory there are narrow gauge railways, as well as trolley and crane tracks in various companies where P18 rails and P24 rails are used as laying. To ensure the movement of electric trains in the metro, a contact rail is now being specially installed in the metro. This makes it possible to build subway tunnels of smaller diameter. The main advantage is considered to be the reliability of current collection with the existing contact connection with the current collectors of electric locomotives or motor cars. For the functioning of urban transport trams, T58 rail and T62 rail are used as track laying. The construction of crane tracks is carried out using rails KR120, KR100, KR80 and KR70.

The production process for manufacturing all types of rails is carried out through the requirements of GOSTs, which have not been canceled in this segment of Russian production, because we are talking about ensuring the safety of human lives, and therefore the requirements for these products are among the highest. When producing all products for the needs of the railway, everything must be taken into account, from the size range, the location of various parts, their quantity and ending with compliance, according to documentation requirements, with the dimensions of the diameters of the bolt holes on all parts.

Quality control

With the advent of the twenty-first century, experts came to the conclusion that the values of ultrasonic control of rails using sensors do not provide the necessary objective picture due to existing surface roughness, the presence of high temperature of the metal itself, scale and other defects that invariably appear during the rolling process. Today, on the territory of the Russian Federation, to ensure rail flaw detection, the issue of creating a domestic non-contact ultrasonic flaw detector, which can use electromagnetic-acoustic transducers with the abbreviation EMA, is under control to receive and emit ultrasound. The required gap between the rail and the EMA transducer is 4 mm, which ensures the passage of the required signal level. In foreign countries, the quality of rails is assessed through the use of installations and flaw detectors, whose operation is ensured by the use of magnetographic and ultrasonic methods.

Bridge beams: specifics of standardization

So, we looked at what the standards are that regulate the size of wooden sleepers (WW) and the timber that complements it in the structure of railway tracks. But there is another important component of the corresponding highways. We are talking about bridge beams. Just as the size of railway sleepers is regulated, this indicator for the component of railway tracks in question is also fixed in state standards. Let's study this specificity in more detail.

The material used to make bridge beams is wood. Their size correlates with one parameter - the size of the cross section, as well as permissible deviations. The main requirement for the bars is a rectangular shape. The corresponding elements of railway lines come with the following cross-section:

— 220 by 240 mm;

— 220 by 260 mm.

Both types of bridge beams, however, must have the same length - 3250 mm. But in terms of standardization of maximum deviations, indicators may vary. So, for beams with a cross section of 220 by 240 mm, the maximum deviation can be: minus 2 mm (in thickness), 15 mm (in length). Regarding the second type of railway elements, the indicators are different. Thus, adjustments in thickness for beams with a cross-section of 220 by 260 mm are not provided, as well as in length, but in width the corresponding value, which is established in the standard, is 3 mm.

It can be noted that, by agreement with the customer, beams with other sections can be manufactured - 220 by 280 and 240 by 300 mm, with a length of 4.2 m.

As is the case with the standards governing the size of wooden (railroad) sleepers, the lengths of bridge beams are established for products within a certain moisture level. In this case - 20%. If the bridge beams have higher humidity, then it is necessary to consider the size requirements taking into account the necessary allowances for shrinkage - in accordance with GOST 6782.1-75.

This is interesting

Reinforced concrete sleepers in Russia. Today, there is a certain upward trend in the market for the production and sales of reinforced concrete sleepers, even despite the global economic crisis. According to marketers, positive dynamics in demand for concrete sleepers is expected in the future. Competition between enterprises will also increase – competition for new orders and new customers. This competition forces us to pay the utmost attention to proposals for the supply of reinforced concrete sleepers. We do not pursue excessive profits, therefore, by contacting our company you will receive the most advantageous offer that corresponds to the present time. Our prices become most relevant when supplying reinforced concrete sleepers to the central regions of the Russian Federation.

Sleeper Ш 1

These reinforced concrete sleepers are intended for the construction of a general network of 1520 mm gauge railways and are produced in accordance with GOST 10629-88. Reinforced concrete sleeper Ш1 (1Ш 27-ВР1500-КБшз) - used with rails of type Р75, Р65, Р50 with rail fastening type KB (separate clamp-bolt type) with bolted attachment of the gasket to the sleeper (separate type Ш1). The sleepers are reinforced with BP II wire, 3 mm in cross section.

Technical characteristics of reinforced concrete sleepers type 1Sh 27-VR1500-KBshz:

- Product weight - 0.270 tons.

- Concrete volume - 0.108 cubic meters.

- Concrete class - B40

- Concrete grade for frost resistance - F200

- Length - 2,700 mm, width - 300 mm, height - 230 mm.

Manufacturers of sleepers: a modern factory of reinforced concrete sleepers offers supplies of its products!

The modern plant of reinforced concrete sleepers offers supplies of its products at competitive prices. Sleeper manufacturers ship these products by rail; the loading rate for one gondola car is 240 pcs and 256 pcs.

Successful production of reinforced concrete sleepers 1Sh 27-BP1500-KBshz is achieved through the use of modern high-tech equipment and the use of high-quality raw materials. The maximum production capacity corresponds to 30,000 reinforced concrete sleepers per month.

The manufactured products are certified and meet the highest quality!

Cost of sleepers: reinforced concrete sleeper Ш1 – price from the manufacturer!

The main advantages of our products are the low cost of sleepers. excellent quality, high production capacity.

Our offer, reinforced concrete sleepers, compares favorably with prices for similar products from other companies. We are confident in the quality and reliability of the reinforced concrete sleepers we supply; the price list for reinforced concrete sleepers can be found in a special section on our website.

For questions related to the purchase of reinforced concrete sleepers, please contact the sales department of SBT LLC by tel/fax; 960-14-40.

Wooden sleepers. Characteristics, technical requirements

Simply put, sleepers are supports for rails. Their purpose is to receive, elastically process and transmit stress from the rails directly to the ballast prism. In this article we will look at wooden sleepers in detail.

The material used is coniferous tree species. It can be pine, larch, spruce, fir, cedar. The use of birch is allowed for access roads.

The service life of wooden sleepers varies from 7 to 40 years, depending on what kind of wood was used and how intensively they were used; from external conditions. The average service life is about 16 years.

According to GOST, the division occurs into 3 types:

- edged (hewn on all four sides)

- semi-edged (hewn only on three sides)

- unedged (hewn only on top and bottom)

By type, sleepers are divided into 1st and 2nd types.

Impregnation.

When treated with protective agents, wooden sleepers can be either impregnated or unimpregnated. Impregnation methods and materials also have subtypes.

The priority method of impregnation is the “vacuum-pressure-vacuum” method, which is standardized by GOST in Russia.

· Impregnation of wood using the “vacuum-pressure-vacuum” method ensures the deepest penetration of the protective agent and is used for impregnation of wood used in difficult conditions: sleepers, power transmission line supports, piles, bridges, etc. The wood must be dry or dried immediately before impregnation in the same autoclave.

Impregnation of sleepers is carried out with coal oils, creosote, or ZhTK antiseptics for impregnation of railway sleepers.

To impregnate sleepers, manufacturers use a range of equipment: autoclaves, drying chambers, steam generator boilers, etc.

Wooden sleepers consume a lot of wood, but they, unlike reinforced concrete sleepers, soften shaking better.

Wooden sleepers are often used for tram tracks.

Characteristics.

1. The length of the sleepers depends on the track width. In Russia, wooden sleepers with a length of 275, 280 or 300 centimeters are used.

2. Diagram of laying sleepers - this term refers to the number of sleepers per kilometer of railway track. In different countries, this parameter ranges from 1000 to 2200 sleepers. In Russia, according to the standard, there are 3 options: 2000, 1840, 1600 or 1440 sleepers/kilometer. Often a diagram of 1840 pieces/km (46 sleepers per 25 meters) is used on straight sections and 2000 pieces/km on curves.

Main types and sizes

(according to GOST 78-2004).

1. The cross-sectional shape of sleepers is shown in Figures 1-3.

| Picture 1 | Figure 2 | Figure 3 |

2. According to cross-sectional dimensions, sleepers are made of three types, depending on their purpose:

I – for main tracks of the 1st and 2nd classes, as well as for tracks of the 3rd class with a freight load of more than 50 million tons gross km/km per year at train speeds of more than 100 km/h;

II – for main tracks of the 3rd and 4th classes, access tracks with intensive work, receiving and sorting tracks at stations;

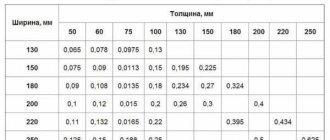

3. The dimensions of the sleepers, depending on the type, must correspond to those indicated in Table 1 (see GOST 78-2004).

top face of the sleeper:

The sawn longitudinal surface of the sleeper, which has a smaller width.

bottom face of the sleeper:

The sawn longitudinal surface of the sleeper, which has a large width.

Wane areas of sleepers must be cleared of bark and bast

sleeper side:

Sawed longitudinal side surface of the sleeper.

wane part of the sleeper:

Unsawed areas of the sleeper surface along the top surface and side.

Extending the service life of sleepers.

AAR estimates show that the number of sleeper replacements on Class 1 railroads in the United States has been steadily declining over the past five years. The noticeable increase in the service life of sleepers in recent years is primarily a consequence of the increasingly widespread pre-impregnation of sleepers on roads, as well as a consequence of previously carried out impregnation, the results of which are now affecting a decrease in the annual output of sleepers. Although some railways, in difficult financial conditions for them, in some years temporarily abandoned the accepted practice of laying only impregnated sleepers, most roads used exclusively impregnated sleepers. As a result, the number of unimpregnated sleepers laid annually on the track is continuously decreasing, and at present it is small. For example, on Class 1 roads, only about 1.7% of unimpregnated sleepers were laid out of the total number of sleepers laid on the road this year. The number of replaced transfer bars, although it fluctuates within noticeable limits in some years, also shows a downward trend. Over a ten-year period, this decrease was about 30%. Undoubtedly, this should also be attributed to the increased use of pre-impregnation.

Impregnated wooden sleepers - an easy task

Impregnated wooden sleepers

Over the last century, in the field of railway construction, the technology of laying specially impregnated wooden sleepers into the railway track has been actively used. Wood was not chosen as a raw material by chance, since this material is easy to process and is an affordable raw material for large-scale industrial production.

When laying the first railway tracks, ordinary sleepers were used without any preliminary treatment. Their service life was short, so soon the wood began to be treated with impregnation. The construction of modern railway tracks is carried out from high-quality impregnated wood. Coal oils or various types of products with antiseptic properties are used as an impregnating agent.

The sleeper impregnated with these agents in the overall railway structure represents the main support for the rail laying and is an important element in the upper layer of the track. Its installation is allowed in a variety of climatic zones, on unstable soil bases, and in areas in the permafrost zone. It is not afraid of laying in areas where there is a fairly large cargo flow. By the way, on steep or curved lines with a radius of curvature reaching 350 m or more, laying technology requires the use of exclusively impregnated wooden sleepers.

In Russia, only coniferous trees are used in the production of wooden sleepers. Most of them are pine (70%), less often spruce and other types of coniferous trees are used. The most popular is the pine tree, since it differs from others in its high and even trunk, and the quality of its wood is much more reliable. Fir, spruce and cedar, in comparison with pine, are more often subject to mechanical damage, deformation and cracking. In addition, their wood is considered weak, although it is much more difficult to treat and impregnate it with antiseptics than pine material.

Larch is also a material from which sleepers can be made. True, this wood is also weak and capable of cracking even during the drying period. It also cannot withstand very low temperatures, so it is not suitable for laying tracks in areas with harsh climates. Its use is possible only after additional processing. Birch wood is considered more durable than pine, but is subject to a faster rotting process, and therefore requires deeper and more thorough antiseptic impregnation.

Foreign railways are built using sleepers made from hardwood. Such products are characterized by high resistance to spontaneous loosening and pulling out. The use of sleepers made of hardwood guarantees a service life of about 40 years. Railways laid in tropical areas are built using metal sleepers, since wooden ones are quickly destroyed by termites.

The peculiarities of Russian climatic conditions, on the contrary, do not allow the use of metal sleepers, since climate humidity promotes metal corrosion. Also, such metal structures are a source of increased noise and are dangerous because they have high electrical conductivity.

- Within industrial production, this is the most technologically advanced and cheapest raw material.

- They have high resistance to longitudinal and transverse displacements of the main supports at the level of the ballast layer.

- This is a wear-resistant, durable, strong material that is resistant to physical and climatic influences.

- They are characterized by high elasticity and dielectricity.

The quality of the wood used is determined by the grade (first or second) of the sleepers; defects are unacceptable in their production. We are talking about their possible bending and accidental damage. To prevent cracking of the sleepers during the installation of the railway track, holes for their future fastening are drilled in advance at the factory.

https://www.chtz-parts.ru

Application

Wooden sleepers can be used in any laying areas: link tracks with wider gauges, narrow gauge tracks, curves with a small radius (up to 300 meters), on swampy soils, in permafrost zones, on unstable soils, on tracks with high freight traffic.

The use of wooden sleepers is more effective than reinforced concrete sleepers on continuous continuous tracks that are intensive in cargo transportation.

Construction of the foundation

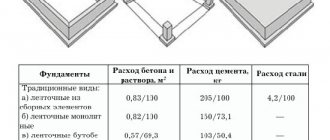

A foundation made of reinforced concrete materials takes on the load from the building pressing on it and distributes it evenly over the entire soil surface. To create a support product, the following materials are required:

- Sleepers.

- Crushed stone and sand.

- Concrete.

- Metal staples, pins.

- Special equipment.

- Mastic, roofing felt.

- Shovels, tape measure, level.

- Pins.

The most popular type of foundation is strip foundation. It involves carrying out excavation work: clearing the area, which includes removing the turf layer and marking the future structure. After preparing the site, they begin digging trenches. Their depth should be 80-100 centimeters. And for a stronger foundation, they dig a width sufficient for three sleepers.

Next comes pouring the concrete. Before starting the procedure, a special formwork is made from the boards, which acts as a form. Reinforcing bars are installed inside this formwork and secured with wire. After the reinforcement layer is ready, it is poured with concrete. Then the entire structure is left alone for two weeks.

After this period, a layer of roofing material is laid on top of the concrete. Reinforced concrete sleepers are placed on it. Next, a reinforcing layer follows throughout the entire volume, and then everything is filled with concrete again.

Features of installation, repair and disposal of reinforced concrete sleepers

The photo shows the operation of a mobile sleeper

Laying railway tracks using reinforced concrete sleepers has a number of characteristic features.

Rails and concrete sleepers, during the construction of railways, are mounted on an initially prepared roadbed based on earth soil, sand and crushed stone backfill. In order to prevent damage to the sleepers during the passage of trains and ensure the safety of the roadbed, special preparation is required, which consists of installing sand strips .

Laying is carried out using mechanized systems that minimize the use of physical labor. As a result, the cost of the installation process is reduced, and in addition, the implementation time for laying the track as a whole is reduced.

As previously mentioned, the service life of reinforced concrete sleepers is limited to 30-60 years. But such durability parameters are only possible if the condition of the tracks is regularly inspected for breakages and partial deformations.

For example, the operational condition of reinforced concrete products is influenced by the condition of the screws securing the lining to the sleeper. If the screw is broken and the problem is not detected in a timely manner, there is a high probability that the lining will hit the concrete as it passes through, causing fatigue stresses in it. (See also the article Hardening of concrete: features.)

If the problem is not eliminated after the screw head comes off, in a relatively short period of time microcracks appear in the thickness of the concrete, which lead to partial or complete destruction of the sleeper.

The photo shows the work of a mechanized complex for recycling solid construction waste

At the end of their service life or due to natural destruction, sleepers must be replaced. At the same time, unusable concrete products must be disposed of.

Since cutting reinforced concrete with diamond wheels for the purpose of grinding seems to be an unreasonably expensive process, processing is carried out using special mechanized complexes. The main working element of the complex is a jaw crusher, which crushes reinforced concrete products to the consistency of medium or small-sized crushed stone. (See also the article Strengthening concrete: how to do it.)

Recycled sleepers can subsequently be used as materials for backfilling pits or for forming embankments.

Ballast layer

During the construction of railways, two types of railway tracks are used, which have a fundamental difference. This is how a ballast-free or ballast layer is constructed. The construction of a ballast-free layer is mainly used in the construction of overpasses, large tunnels, and metal bridges. The ballast layer of the track is designed to create horizontal and vertical stability and gratings to ensure the operational process, which allows for uniform distribution of the pressure arising on the sleepers, which is transferred to a larger area of the roadbed. This type of layer allows for rapid drainage of water directly from the entire area of the subgrade and ballast prism. This function allows you to create optimal elasticity in the under-rail base, especially when using reinforced concrete sleepers.

The main requirements for ballast material are as follows: the materials used must have strength, elasticity and resistance to atmospheric influences and various loads that arise during the operational period. This material should not grow into the grass cover, be eroded by rain, generate dust during the passage of trains, and should not be sprayed in windy weather. The ideal drainage material for the ballast layer is shell rock, sand, gravel, and crushed stone. One of the best materials for creating such a layer is crushed stone, created from pebbles, boulders and natural stone.

Dimensions of railway sleepers according to GOST

Geometric characteristics (sizes of sleepers) and classification are given based on the requirements established by the state standard. For example, GOST 78-2004 wooden sleepers for broad gauge railways combines all the characteristics of finished products. For special routes, their own standards have been developed. GOST 22830-77 wooden sleepers for the subway specifies the individual parameters necessary for their operation in these specific conditions. Each standard is consistent with other guidance documents consistent with the operating rules of the various tracks. GOST imposes certain restrictions on wooden sleepers regarding their area of application

Particular attention is paid to the choice of coating that is applied to the surface to improve their technical characteristics

Reinforced concrete sleepers

After the Second World War, reinforced concrete sleepers began to be intensively introduced in many countries, especially in the USSR, East Germany, Germany, France, England, Hungary, Czechoslovakia and Belgium.

Reinforced concrete sleepers have the following advantages: they save wood; do not rot; withstand greater compressive stresses than wood; have greater resistance to movement; have a longer service life. However, the disadvantages include greater rigidity compared to wood, which requires the use of elastic pads

Reinforced concrete sleepers have greater electrical conductivity and require the use of insulating elements; increased fragility requires caution during transportation and tamping, and the large mass creates inconvenience in working with them

In the Russian Federation, preference is given to pre-stressed concrete beam (shaped) sleepers. We began mass laying of standard reinforced concrete sleepers in 1959. Russia ranks first in the world in laying reinforced concrete sleepers.

The design of a modern reinforced concrete sleeper is shown in (Fig. 3). The sleepers are reinforced with periodic wire with a diameter of 3 mm (44 pcs.); the tension force of one wire is 8.1 kN. For the manufacture of sleepers, concrete of grade no lower than 500 is used. The weight of the sleeper is about 265 kg.

Rice. 3 – Reinforced concrete sleepers: a – type ShS-1; b – ShS-ly type; c, d – location of reinforcement

Reinforced concrete sleepers of the ShS-1 and ShS-lu types (erase Fig. 3) are used for fastening KB, and sleepers ShS-2 and ShS-2u are used for unlined fastenings of BP and ZhBR. Sleepers ShS-2 and ShS-2u have the same shape and all dimensions, except for the distances between the holes for embedded bolts, as those for ShS-1 and ShS-ly. The design of the sleeper allows it to be used on rails P50, P65 and P75. The depth of the under-rail grooves for these sleepers is 25 mm.

In addition to string concrete sleepers, in some countries they use block reinforced concrete sleepers with rod reinforcement with a diameter of up to 22 mm. Most often, reinforcement consists of two rods; their stressed state is maintained by nuts screwed onto the ends of the rods. The disadvantages of this design are greater metal consumption than for reinforced concrete sleepers; concentrated arrangement of reinforcement and the associated stronger opening of cracks than with dispersed reinforcement.

Reinforced concrete sleepers make the track more stable, which reduces the cost of its ongoing maintenance. According to V. Ya. Shulga, it is more than 25% cheaper than maintaining a track with wooden sleepers with an average length of 600 m.

The durability of reinforced concrete sleepers for the road network has not yet been determined. Operating experience on the Oktyabrskaya Road (since 1954) and an analysis of their output, carried out by LIIZhT, showed that with a healthy roadbed and ballast layer that meet the technical conditions, the service life depends on the design of the sleeper, the type of rails and fastenings, load intensity, and speed of movement. and loads from wheel pairs on rails. Based on this, a critical tonnage has been established (see table below), after which the reinforced concrete sleepers are affected by defects, and the volume of the annual single shift reaches 30–40 pcs/km.

| Type of fastener and rail | Average load of a wheel pair, kN (tf) | Critical tonnage, million tons gross |

| KB; P65 | 151,9 (15,4) | 1400 |

| KB; P65 | 113,5 (12,6) | 1650 |

| reinforced concrete; P65 | 151,9 (15,4) | 750 |

| reinforced concrete; P65 | 113,5 (12,6) | 840 |

| K2; P65 | 151,9 (15,4) | 1200 |

| K2; P65 | 113,5 (12,6) | 1250 |

| K2; P50 | 149,9 (15,3) | 850 |

During the operation of a track with reinforced concrete sleepers, the rail fastenings wear out greatly. This encourages replacing the rail and sleeper grid, laying the old one on less active lines, and then on station and non-public tracks. Such a system of repeated relaying of track grids with reinforced concrete sleepers will ensure their service life is significantly more than 50 years.

The technical policy assumes a further increase in the range of tracks with reinforced concrete sleepers. In the near future it is planned to increase it to 64–65 thousand km.

Reinforced concrete sleepers

During many years of operation, the wooden sleeper showed numerous shortcomings. The main one was susceptibility to rotting. Yes, such products are lubricated with special compounds to protect against corrosion and eating insects, such as termites. But even regularly treated wood fails.

Modern technological solutions have brought reinforced concrete products into the world. Reinforced concrete sleepers do not rot, firmly hold the rails in a parallel state, and withstand the multi-ton load of passing trains. Installation is somewhat more complicated and requires the use of mechanisms, but is cheaper. And in subsequent operation, such paths also save the budget. After all, there is no need to purchase those same antiseptic compounds and pay a salary to the person who will regularly process the wood on the tracks.

This allows you to reduce the subsequent budget for maintaining the tracks in a suitable and safe form. The number of emergency situations on the tracks associated with a malfunction of the road itself will be reduced precisely due to the use of more reliable and durable materials. Perhaps it is the weight of the concrete sleeper that remains the last factor why track builders choose obsolete wood. The weight of the finished product affects the principles of installation. Therefore, you need to carefully consider the dimensions of the concrete structure before making a decision. Read about the disadvantages and advantages in the previous article.

Reinforced concrete sleepers

Reinforced concrete sleepers after removal from the mold.

In some cases, instead of sleepers, solid block foundations in the form of slabs or frames made of reinforced concrete or metal are used. Since the 1970s, sleepers made of prestressed reinforced concrete have gained popularity in the USSR; their use has been especially successful on continuous-joint tracks.

Reinforced concrete sleepers are reinforced concrete beams of variable cross-section. On such beams there are platforms for installing rails, as well as holes for rail and sleeper fastening bolts (when driving wooden plugs into the holes, crutches and screw connections are also used). Reinforced concrete sleepers are made with pre-tensioned reinforcement. The manufacturing technology of reinforced concrete sleepers is as follows: reinforcement strings are placed in a special mold, tension is applied to them (depending on the purpose of the sleeper, usually 180 atm), the mold is filled with concrete and compacted by vibration. Then the form is disassembled and sent to a steaming chamber, where the concrete hardens, after which the tension from the strings is transferred to the concrete and the form is turned over (turned over). This method of making sleepers gives them elasticity and protects the sleeper from splitting under the rolling stock.

Advantages of reinforced concrete sleepers: practically unlimited service life due to high mechanical strength and resistance to rotting, which makes it possible to reuse sleepers, as well as use them on heavily loaded sections of the track. Disadvantages: insufficient rigidity, high cost and weight, possibility of fatigue failure of concrete.

Recently, anchor connections have been increasingly used to fasten rails and reinforced concrete sleepers [ source not specified 1685 days

Installation and use

Essentially, these are just concrete beams that have special places for installing rails. Technical holes are also created for the installation of rail and sleeper fastenings. As a main advantage over alternative options, concrete offers a colossal service life. With the right choice of concrete class, this period becomes almost unlimited. The class also forms resistance to mechanical load. In simple terms, the weight of a passing train transmitted through the rails will not cause it to crack or crumble. This is suitable for laying tracks where loaded freight trains are planned to run. And there’s no need to talk about passenger traffic.

If we highlight the negative aspects of use, then the complexity of installation comes first. The weight of the structure does not allow it to be handled by hand, without the use of mechanical lifts. Also electrical conductivity. If a wooden sleeper extinguishes any currents, then spacers must be used. However, today's standards for railway construction are such that wood is already an obsolete material.

Add to this the negative public opinion about the use of trees. Now in Europe there is a clear trend towards replacing wooden structures with reinforced concrete ones. The prospects are also good because the subsequent costs of operating and maintaining the road in working and safe condition are reduced for the reasons described above. Such factors form an excellent future for reinforced concrete products and this niche is actively developing.

Installation, repair and disposal of sleepers

During the installation of railway tracks using reinforced concrete sleepers, there are some features:

- Before installing supports and rails, preliminary surface preparation is required. In order to maintain the integrity of the sleepers during operation, sand strips are poured onto the top layer of soil.

- For installation, special equipment is used (taking into account how much the structure weighs) to reduce physical costs and reduce the cost of work.

- In order for supports to last longer, it is necessary to perform path diagnostics to detect deformations and defects. Checking fasteners prevents breakdowns.

- As a result of untimely detection of a violation of the integrity of fasteners, cracks and breakage of sleepers (not only partial, but also complete) may occur.

- After the service life has expired, or as a result of destruction of the supports, their disposal is required. In such cases, a jaw crusher is used to crush the products. After processing, they fill holes (small volume) and use them to form embankments.

Sleeper repair involves identifying defects and eliminating them in a timely manner. Cracks, cavities, potholes and chips that arise during operation are repaired.

The following types of repairs exist:

- capital (after preliminary drafting);

- medium (with replacement of defective sleepers);

- lifting (the most common type);

- reconstruction (individual elements are often replaced).

During repairs, a signal sign is placed on this section; train traffic is not stopped. Major repairs are carried out between repairs and consist of replacing sleepers. To perform repair work, track machine stations are used.

Wooden sleepers

Used wooden sleepers The type of wood for sleepers can be different (for example, red maple or eucalyptus), in some countries oak is preferred, and in some, for economic reasons, softwood, mainly pine, although such sleepers are more susceptible to wear.

To prevent rotting, sleepers are impregnated with antiseptics, most often creosote. Wooden sleepers have many advantages: elasticity, ease of processing, high dielectric properties, good adhesion to crushed stone ballast, low sensitivity to temperature fluctuations. The most important property is the ability to widen the rail gauge in curves with a radius of less than 350 m.

The service life of wooden sleepers (depending on the type of wood, external conditions and intensity of use) ranges from seven to forty years. Wooden sleepers in Russia are made primarily from pine, as well as from spruce, fir, and Siberian cedar, although earlier experiments were conducted on making sleepers from oak and larch. The main problem of wooden sleepers is the tendency for them to rot in the places where rails are attached to them, and the problem with their further disposal.

Wooden sleepers are manufactured in accordance with GOST 78-2004.

- Type 1 sleeper, impregnated - used for main tracks

- Sleeper type 2, impregnated - used for access and station tracks

Wooden sleepers are divided into three types:

- edged (hewn on all four sides)

- semi-edged (hewn only on three sides)

- unedged (hewn only on top and bottom)

Previously, a dexel ax (adze) was used to cut sleepers.

Impregnation of wooden sleepers

See also: Sleeper impregnation plant

Impregnation of sleepers is carried out with coal oils, creosote, or ZhTK antiseptics for impregnation of railway sleepers. Currently in Russia, impregnation is carried out using the “vacuum-pressure-vacuum” method; this method is standardized by GOST.

- Sleepers before impregnation

- Autoclave lid

- Impregnated sleepers

- Car loaded with impregnated sleepers

To impregnate sleepers, manufacturers use a range of equipment: autoclaves, drying chambers, steam generator boilers, etc.

Impregnation of wood using the “vacuum-pressure-vacuum” method ensures the deepest penetration of the protective agent and is used for impregnation of wood used in difficult conditions: sleepers, power transmission line supports, piles, bridges, etc. The wood must be dry or dried immediately before impregnation, including or autoclave.

Rail fastenings. Anti-theft

By using intermediate fastening, the rails are fastened to the sleepers. There are three types of fastenings: separate, mixed and non-separate. Separate fastening involves the process of fastening the rail to the pads using terminal bolts, rigid and elastic terminals. The liner is attached to the sleepers using screws or bolts. Mixed fastening requires connecting the linings to the sleepers using additional crutches. Inseparable fastening of rails and linings requires fastening to sleepers with the same screws or crutches. During a long descent or sudden braking of a train, forces arise that, as a rule, may cause the rail bed to shift in the longitudinal plane. This displacement can occur together with the sleepers or directly along the sleepers.

To prevent such displacement of the rail track, it is mandatory to install so-called anti-theft devices. Their design is a standard spring clip, which is clamped onto the rail base of the rail and rests on the sleeper. On a rail link 25 meters long, a minimum of 18 pairs of anti-theft devices must be installed, and a maximum of 44 anti-theft devices must be installed. In areas where there is an automatic block installed at the border of block sections, insulating joints are used that do not allow the passage of electric current from connected adjacent rails. To do this, a textolite or tricope gasket is placed in the joint gap, which exactly follows the rail contour. Today, glue-bolt joints have already found widespread use; they are equipped with butt plates made of metal. For the same purposes, it is possible to use insulating gaskets made of fiberglass, and it is also necessary to use bolts with insulating sleeves to make a connection using epoxy glue with the end part of the rail, creating a monolithic structure.

The rail track has a close relationship with the wheelsets of rolling stock, their sizes and design features. The steel axle is tightly connected to the wheelset, which has special ridges that prevent it from leaving the rail bed.

Types

Taking into account the length, width of products, resistance to cracking, the following types exist:

- 1st grade sleepers;

- sleepers of 2 grades (less stringent requirements are imposed on geometric dimensions, the degree of resistance to cracking is low).

Products of grade 2 are used for laying on access, station and non-active tracks. Their delivery is carried out only with the consent of the consumer.

Based on the type of rail fastening, products are divided into types:

- Ш-1 (separate clamp-and-bolt connection, attached to the support with a bolt and gasket);

- Ш-2 (indivisible mount);

- Sh-3 (similar to Sh-2 supports, differ in the method of fastening).

Reinforced concrete products differ in class, type of reinforcement used, and the presence of electrical insulation (non-insulated or insulated). The requirements for the parameters of reinforced concrete sleepers are strict.

Standard reinforced concrete sleepers have the following dimensions (W-1 - dimensions LxWxH in mm): 2700x300x230, 250 kg weight.

Depending on the features of use and installation, reinforced concrete rail supports are:

- pavements (laid on bridges);

- shuttle (for bridges and tunnels);

- intended for curved sections (with a radius of less than 350°);

- transformer (differ in rectangular cross-section along the length);

- for turnouts;

- for children's railways (wheel width 750 mm, rails R-43);

- half sleepers (for tracks along which overhead cranes move).

Introduction

In our modern times, increasing capacity for passenger and freight transportation using railway transport is a pressing issue, which requires the government of the Russian Federation and the management of Russian Railways to quickly solve new tasks. When implementing this issue, it is necessary to increase the speed of trains, increase the weight characteristics of the formed trains, and also continue to engage in large-scale electrification of railway tracks. Today, the volume of work related to strengthening the railway track is increasing. For this purpose, heavy rails P75 and P65 are laid, rail bases made of reinforced concrete are used, and seamless tracks are created. The rail track also changes directly. All this is achieved by laying a series of circular curves, lengthening the transition curves and increasing the elevation of the outer surface of the rail.

Russian railways operate about two hundred thousand switches of various types, each of which is a complex and expensive element of railways. Ensuring the safety of cargo and passenger trains, the uninterrupted transportation process and improving the economic indicators of the entire track facilities is achieved by the reliable operation of the designated units.

In recent years, increased attention has been paid to the switch industry on the Russian railway. Technologies and designs of switch drives are currently being improved. Current maintenance and laying technologies are under constant control.

The priority areas of the switch industry are: developing new conditions in various operating conditions, ensuring constant monitoring by assessing their reliability and strength of all components. It is imperative to carry out new developments in the design of pointer drives, their mathematical and theoretical basis.

When choosing the structure of a railway track, its design features and type, technical, economic and technical calculations must be taken into account and form the basis, taking into account operational experience, analysis, careful design and scientific research.

Production technology

Figure 3. Production of reinforced concrete sleepers

Depending on how much the sleeper will weigh and how much work is expected, a certain technology for manufacturing the product is selected. There are only 4 of them:

| Technology | Description |

| Carousel | A special feature of the method is the delay in removing the mold. The concrete mixture is poured into the prepared form. The solution must be well compacted so that no air bubbles remain in it. In this work, special forms of 6 elements are used. I remove them only after the sleepers have reached their maximum strength parameters. In order for the reinforcement to have good adhesion to the concrete mixture, it is necessary to ensure tension in the steel rods using special tension mechanisms |

| Linear | It involves the use of a conveyor on which forms are installed. Its length sometimes reaches 100 m. At the ends of the molds there are special devices with the help of which pre-stress is transferred to the steel rods. As soon as the concrete mixture hardens well, force is applied to it |

| Removal of the mold followed by transfer of stress | In this case, the forms are installed in templates, the location of the reinforcement in which is precisely defined. After pouring the concrete solution, it is thoroughly compacted by vibration. While the mixture is hardening, metal rods are inserted into it and pressure is applied to it. After hardening, the mold is dismantled and the template is removed. The advantage of the technology is continuity and the presence of a small number of forms |

| Dismantling the pre-stressed mold | This method is similar to the previous one, but frames are used instead of rods |

The choice of technology for the production of concrete sleepers depends on what technical characteristics are required.