To work with wooden, plastic and even metal workpieces at home, a circular hand saw is often used as a more productive analogue of the simplest sawing tool. It has several varieties and application nuances that are important to consider when working.

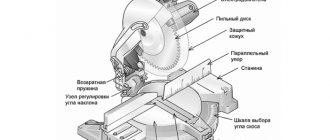

Circular hand saw device

When constructing and repairing both your own home and on a professional basis, a circular hand saw becomes a convenient aid in your work. The tool is very convenient for sawing wood of different thicknesses, thin metal and plastic products, such as baseboards. There are several varieties of this manual circular saw, but the design of each of them is typical. The standard design consists of:

- Protective plastic housing with one or two handles.

- A special casing for the saw blade that performs protective functions during operation.

- Platforms for holding and guiding the disc. It is necessary to adjust the depth and angle of the cut.

- Riving knife. It is needed to free the knife if it gets stuck in the wood.

- Electric motor. A special disk is attached to its shaft using bolts.

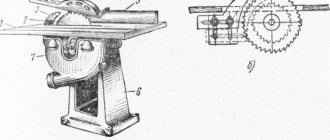

Stationary with jointing

It is better to immediately design a stationary circular saw with a jointing drum. Without it, most of the work on its production will simply lose meaning, except perhaps for the sake of the creation process itself.

The structure of a stationary circular saw with a jointing drum is shown in the figure:

The device of a stationary circular saw with a jointing drum

When designing it, it is necessary to apply additional safety measures and ensure the quality of the machine. Firstly, during sawing, the jointing drum must be covered with a securely fastened protective cover on the pads to the jointing depth or slightly more, pos. And next. rice.:

How to adapt a jointing drum to a stationary circular saw

Loss of cutting depth will be approx. 6-8 mm (jointing depth up to 3-4 mm + 3-4 mm thickness of the lid. For jointing, a working pad of the same thickness (pos. B) is attached to the tabletop along its entire length behind the drum (along the workpiece). . overhang of the finished part behind the drum will lead to its planing onto a wedge; very flat, but due to the accumulation of errors during the construction or finishing work, it may turn out that all the processed material is damaged.

Note : by increasing the thickness of the working pad, you can adjust the jointing depth from maximum to 0.5 mm.

The motor matters

Secondly, the safety of using a homemade circular saw and the quality of sawing with it (especially finishing materials) is largely determined by the external characteristics (VnH) of the machine drive motor. ВнХ is the dependence of the torque on the shaft T on its rotation frequency N; the rotational speed (RPM) depends on the cutting resistance of the material being processed, and this, in turn, depends on the speed and feed force of the workpiece.

The VnH of a sequential excitation commutator motor (grinder, drill, hammer drill) is not monotonic (see figure).

External characteristics of a series-excited and asynchronous commutator electric motor with a squirrel-cage rotor

The maximum torque occurs at a certain rotation speed nр, slightly lower than the idle speed (without load) nхх. This is good: in the area of operating loads on the shaft ΔTр, the harder the material is, the stronger the motor turns the saw. Changing the feed force within these limits has virtually no effect on the quality of the cut, because the disk keeps the speed within the optimal range, and you can work at the highest performance.

The same thing, but without “adjusting” the saw to knots and other irregularities, is observed in a fairly wide range of overloads (ΔT region), i.e. High qualifications and a subtle tactile sense are not required from the operator - a beginner (not armless, of course) applied it once or twice, and that’s it, the work started. But, if you press hard, or something like a nail comes across, a dangerous property of the commutator motor appears in this case - a significant zero torque T0. An engine whose armature is forcibly braked will strive to turn at all costs: the workpiece can turn out and give you a kick in the teeth; the disk will fly apart.

Note : in manual circular machines, parallel-excited collector motors are used and/or with special armature winding circuits that reduce T0, but at the same time the “hump” of VnH is smoothed out. Therefore, in drills and grinders, where the “gnawing” ability of the tool with a small working stroke is important, T0 remains large. That is why it is impossible to put a saw blade larger than the standard one in the grinder - defects in work are inevitable, and the likelihood of injury increases sharply; This applies to abrasive discs to a lesser extent.

The VnH of an asynchronous electric motor with a squirrel-cage rotor is monotonous and quite rigid (in the same figure on the right). In the rotation speed range nmin – nmax that is optimal for a given disk, the feed force must be maintained very precisely, sensitively feeling the resistance of the material, i.e. Quite a high level of working skill is required. “Overfeeding” leads to a drop in both productivity and cut quality - a too slowly rotating disk tears the material. But if the saw suddenly jams, the motor will stop and begin to accelerate until the load is completely removed. If a 3-phase motor with a starting device from a single-phase network is used, then it will have to be turned off and restarted. When sawing long lengths, when the likelihood of awkwardness in work increases greatly, this quality of “asynchronous” VnH becomes valuable - a beginner/amateur can gradually learn to work without risking himself or spoiling a lot of material. Therefore, a homemade circular jointing machine should only be made with an asynchronous AC electric motor with a squirrel-cage rotor.

Motor mount

High-performance industrial circular saws, designed for long-term, round-shift operation, are equipped with large and heavy motors of 3-5 kW or more. Among other things, this reduces the sensitivity of the saw to material inhomogeneities and expands the range of permissible feed forces (see above), which, in turn, reduces the dependence of the quality of work on the qualifications and fatigue of workers. Another feature of circular saws compared to sawmills is that the belt drive from the motor to the disk turns out to be better than a chain drive, since you need to cut cleaner, but the material is of higher quality.

However, the belt tension weakens over time, so the engines of industrial circular saws are placed on supports that slide (and are fixed) in grooves (shown by arrows in position 1 of the figure).

Advantages of a pendulum motor suspension in a homemade circular saw over a sliding one

It is unrealistic to cut a long, even groove in metal without special equipment (a metal milling machine), but a 1-2 kW motor for a household circular is sufficient, and it can be placed on a pendulum suspension (item 2). Belt tension is thus ensured automatically without time-consuming adjustment work. There is more wear on the belt in a pendulum suspension, but you don’t work a full shift on your circular machine every day.

Note : assembly unit for pos. 1 pic. Above is the pendulum saw module of an industrial circular saw, which allows you to quickly install the output of the saw blade above the tabletop. But in the context of this section, this is not significant, and the output of the disk of a homemade circular saw can be changed not so quickly, but it is structurally and technically much simpler, see Fig.:

The mechanism for raising/lowering the saw blade of a homemade circular saw

The suspension hinge (shown by an arrow in position 2) can be quite rough (a steel pipe placed on a pin and filled with grease), but this does not noticeably affect the quality of the cut. You can do without a hinge on a steel sheet s(4...6) with screw support-clamps (shown by the arrow in position 2a). An additional advantage of the pendulum suspension of the motor is that the work table can be made tiltable, pos. 2b. When sawing a large amount of long timber (for example, for a construction site) by a sufficiently experienced worker, this significantly reduces his fatigue and speeds up the work.

Note: video material about building a circular saw with a jointing drum (sawing and jointing machine) on your own, see also the story:

Video: a simple homemade circular saw with a jointer

Rotation unit

The bearing assembly (rotation assembly) is the most complex and loaded part of a circular machine. We will try to make do with a minimum of expensive precision custom turning work.

Drawings of a homemade bearing assembly of a traditional design are shown in Fig.

Drawings of a bearing assembly for a homemade circular saw

Critical dimensions are highlighted in color:

- At pos. 3 D32 – for the installation size of the saw blade (see above). Tolerance –0.05 mm.

- At pos. 4 D40 – for installation of bearings (see below). Tolerance +0.03 mm. Misalignment is no more than 0.01 mm. Finish sharpening in one setting on a high-precision machine.

- At pos. 6 D17 – for bearings. Tolerance –0.03 mm. Misalignment is no more than 0.01 mm. Finish sharpening in one setting on a high-precision machine.

- The pulley (item 7) is machined to size according to the gear ratio, based on the rotation speed of the existing engine, the diameter of the pulley on its shaft and the operating speed of rotation of the saw blade (see above).

Due to more stringent requirements for the cleanliness of the cut than for a sawmill, but the same as on it, or of a comparable length, conventional ball bearings, such as, for example, for a cutting machine, wear out quite quickly in a circular saw, and the saw begins to beat. Therefore, this design uses more durable bearings No. 60203; We will continue to focus on them.

How could it be simpler?

The described design of the bearing assembly is not without serious drawbacks:

- no jointing drum;

- turning the internal diameters clean in one setting is not a task for an amateur turner or even an entry-level specialist;

- from the heat when welding the bearing race 4 to the support plate 5, the race may move, and the bearings will not fit into the sockets, and it is possible to grind them cleanly in the assembly only on a rotary or shaping machine.

Unreliable design of the housing and bearing assembly of a homemade circular saw

With a jointing drum, it looks like it can be solved: cut the frame with the slab in half, and that’s it. But adjusting the machine to verticality and eliminating the misalignment of the saw blade outside of production conditions will cost painful work with no guarantee of success. Or you will have to machine the mounting pin with high precision (for one-time use). But then, so that the setting does not soon float away, you need a strong, rigid body of the machine. Like welded UBDS-1 or UBDN-1. A homemade analogue with threaded connections (see figure on the right) will quickly become loose, and after 2-3 readjustments the bearings will also break.

Unconventional approach

What if we completely abandon the holder with the base plate? Then only the shaft will need to be sharpened with high precision. How to attach it? In wood to wood, this will further simplify and reduce the cost of the machine. Wood is an archaic material, expensive and poorly technological in mass production, but not bad for piece work. In the old days, wooden sailing battleships served for 120-150 years, with periodic upgrades. And modern 40-year-old warships are subject to renewal only if there is no ready-made full replacement.

The method of attaching the bearing assembly of a homemade circular saw in wooden cages to a plywood tabletop is shown in the figure:

Fastening the rotation unit of a homemade circular saw in wooden cages

The frames require dense, fine-grained, fairly elastic hardwood. The best is maple; further – walnut, hornbeam, oak. In this case, a durable rigid body of the machine is also not needed; a simple “bedside table”, like for a table for a manual circular saw, is enough. Modern achievements include furniture screws - confirmed ones; in fine-grained wood they fit tightly and do not come loose from vibrations. The “trick” of the design is that during the adjustment process (see below), the bearings are pressed into the wood and thereby securely fixed.

Assembly of the entire assembly is combined with adjustment:

- A groove for the saw blade is pre-cut in the tabletop and holes are drilled for the heads of the D6 confirms.

- Pioneer (installation) holes for confirmations D4.8x60 are also pre-drilled in the clip blank.

- Empty clips are “baited” so far only with the top confirmations.

- A shaft with bearings is inserted into the cages.

- A saw blade is mounted on the shaft.

- The upper confirms are tightened so that the bearings fit into the cages without play, but not tightly.

- The disk is wedged in the groove symmetrically with 4 pairs of wedges: 2 pairs on top closer to the center, 2 pairs on the bottom closer to the edge.

- By tapping the wedges, align the disc along the slot and vertically.

- The upper confirmations are tightened until the heads are recessed flush with the table top.

- The confirmations are tightened alternately on both clips in 3-4 steps using an “envelope”, i.e. with a diagonal transition.

- Leave the assembly to “settle” overnight or, better, for 2-3 days, so that the bearings are pressed into the wood.

- Take out the wedges and check to see if the disc has moved. If the confirmations were tightened carefully and correctly according to the scheme, it will not work.

- They place and tighten, also with an “envelope,” the lower confirmations.

- Let the tabletop with the bearing assembly “settle” one more time.

- Check the disk installation again. It didn’t lead, did you pull the lower ones correctly? The unit is ready for further assembly and operation.

Shaft drawings for this design are shown in Fig.:

Shaft drawings for a circular saw with a jointing drum

The blank is round timber St45 D60. The finished shaft assembly with jointing knives must (!) be balanced in the centers. During balancing, the material can be selected both from the “raw” surface of the D60 and from the areas under the knives.

Working principle of a circular hand saw

The tool is used for even sawing of surfaces, longitudinally or transversely. Arc cutting is not possible with a circular hand saw. The principle of operation of such a unit is simple:

- Torque is transmitted from the electric motor shaft to the cutting disc.

- The sawing disk rotates around its axis at high speed, making it easy to cut the desired surface.

Depending on the cutting depth, the tool is divided into several categories:

- Mini circular hand saws are capable of cutting material up to 46 mm thick.

- The average tool can handle surfaces up to 55 mm.

- Large equipment can cut workpieces with a thickness of about 70 mm.

- Professional equipment cuts products about 140 mm thick.

Types of Circular Hand Saw

There is a large selection of circular saws on the shelves of construction stores. All variety can be divided into:

- A hand tool that the master moves independently.

- A stationary saw on a special table, designed for placement in work shops and workshops.

The circular hand saw is divided according to power classes into:

- Household appliances with power up to 2.2 kW.

- Semi-professional models that are more powerful than household ones. They have great functionality.

- Professional units with increased power and functionality. Used in production.

Another difference is the method of transmitting torque, so they distinguish:

- Electric models connected to a standard power supply.

- A cordless hand-held circular saw is convenient where you don't need a nearby power outlet.

- Models with manual drive, which are currently practically not used, are becoming a thing of the past.

How to choose a circular hand saw?

When purchasing a tool, you should focus on a number of specific parameters:

- Engine power. The higher it is, the faster and with less effort you can cut. In addition, large-diameter cutting discs can be installed on powerful saws (from 3 kW).

- Cutting depth. There are 4 standard sizes that you need to select based on your needs.

- A hand-held circular saw for wood can have an adjustable cutting angle.

- Stationary chip removal system or the ability to connect a vacuum cleaner. A very convenient option that allows you to work practically without dust and debris in the workshop or at home.

- The start lock is an important safety feature that prevents the tool from being started accidentally.

Functions of a circular hand saw

The main “duty” of a circular saw is to cut large quantities of boards, drywall, laminate, plastic panels, soft metal and more. It is indispensable when building a house or cottage, and is also useful when laying floors in an apartment or covering walls with decorative panels. For speed of work and ease of use, the circular electric hand saw is equipped with a number of additional functions:

- Immersion in the material. This function is very convenient when working with large slabs.

- Adjusting the speed of rotation of the cutting disc. To work with different materials, different rotation speeds are required to obtain an even cut without burrs.

- The soft start function is necessary to increase the service life of the cutting blade. Thanks to it, the saw smoothly picks up speed after starting, rather than immediately spinning the shaft to maximum speed.

- A laser pointer is an optional accessory for a handheld circular saw. However, such a pointer is convenient to use when carrying out quick work.

Circular saw blades

An important consumable in a cutting tool is the cutting disc. Each model has its own characteristics:

- height and number of teeth;

- cutting profile geometry.

Conventionally, all disks for hand-held circular saws are divided into:

- Consumables for soft materials such as wood or plastic. They have a positive sharpening angle, the number of teeth is about 50-100, which ensures an even cut.

- Discs for hard materials are produced with a negative sharpening angle and fewer teeth. They can cut through harder materials, but the edges will be more jagged.

Tool selection criteria

In a market where there are many hand-held circular saws, a comparison of the main indicators will help with your choice. When choosing a device, pay attention to the characteristics:

- Electric motor power. The greater the power, the greater the number of cuts that can be made per unit of time. The larger the disk that you plan to attach to the shaft, the more powerful the tool is needed. Increasing power allows you to work with harder wood species. But the more powerful the device, the heavier it is. A model with a 1200 W motor weighs about four kilograms, and if the motor has a power of 2000 W, then the saw’s weight will already be seven kilograms.

The material from which the body is made. It must be durable and be able to withstand the vibration that occurs during operation. Models can be metal or plastic. The weight of the device also depends on the material of the case.- Minimum and maximum cutting depth. This indicator depends on the engine power. In total, there are four ranges of cut sizes. It is worth paying attention to the presence of a cutting depth regulator.

- Disc rotation speed. The accuracy of cutting a part directly depends on the rotation speed. The higher the speed, the more accurate the cut. You need to know that the rotation speed does not directly depend on the motor power. There are low-power saws that have a high blade rotation speed, and these tools cut fragile material very carefully.

- Tilt angle adjustment. Most often, this function is used when performing professional work. It is not needed for amateur cuts.

- Handle design. Its ergonomics influence productivity, convenience and comfort in work. Before purchasing, it is imperative that the instrument be checked “in hand”. If there are doubts, then another model should be considered.

- Type of equipment. Today, manufacturers offer corded and corded tools. Each type has its own advantages and disadvantages. Cordless saws are heavier, but autonomous. Suitable for any unexpected situation. Corded tools are lighter in weight, but require a constant supply of electrical power.

- Replacing disks. You need to pay attention to how the disk is changed. There are simple replacement methods, and there are models that require the simultaneous participation of two keys.

- The type of blades that are suitable for a specific saw model.

- The presence or absence of built-in electronics.

Rating of circular hand saws

Professional builders and home craftsmen identify certain tool models that have the most optimal characteristics for the job. Among them:

- Makita HS7601

is an excellent device for home use with two branded disks included. Cost – $121. - DeWALT DWE560

is a model with the ability to connect a construction vacuum cleaner. Cost – $140. - Hammer CRP 1500 D

is a high-quality lightweight saw with a convenient carrying case. Cost – $93. - Bosch GKS 190

. The Bosch hand-held circular saw is considered one of the best tools in its price segment. Cost – $128.

Operating principle

The choice in favor of a circular saw is justified by the effectiveness of the tool in cutting wooden workpieces. This is ensured by a powerful electric motor and a cutting disc in a cast or stamped design. If this is a manual model, then the driving element is built into the body of the circular saw. Stationary tools can be equipped with a separate motor, and torque is transmitted to the disk through a belt and pulleys.

Replaceable equipment has large sharpened teeth along the outer diameter, and rotation occurs at high speed. Therefore, the following are important for a circular saw:

- strict alignment of the constituent elements;

- ensuring maximum security measures;

- use of high quality materials.

Thus, manufacturers equip circular saws with various mechanical-electronic systems and devices. They are aimed at protecting the user in operating mode and blocking the tool in the event of certain malfunctions.

The operating principle of a circular saw is based on the transmission of torque from an electric motor to the saw blade. Manual models are moved by the user, stationary ones remain in place. The workpieces being cut must be moved.

Stationary tool model Source sezontruda.ru

Materials are cut in a straight line at one angle or another. The graduation depends on the design of the devices. Budget options are usually designed for 90 and 45 degrees. For professional samples, it is possible to install the platform at almost any degree.

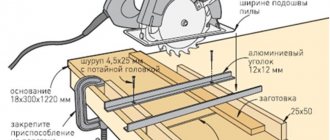

Hand circular saw table

When working with a large volume of sawn material, it is not always comfortable to hold the tool in your hands for a long time. It is much more convenient to secure the tool on a special table, so the cut will be more accurate and faster. All masters prefer to use:

- Factory tables purchased from a store. They can be either stationary or portable.

- Homemade tables, the advantage of which are individual sizes suitable for the workshop area and additional options.

After making your own table, it is important to know how to properly secure your handheld circular saw to your table. There are just a few rules here:

- The instrument is placed inside a prepared compartment that is exactly the right size for the instrument.

- The saw base is securely attached to the table with bolts.

- The disk should fit freely into the slot.

Briefly about the main thing

The main focus of a circular saw is cutting wood material. Options are available for working with plastic and metal.

A circular machine for home can be manual or stationary. The first is powered from an outlet or battery.

Before choosing a particular model, it is important to consider a number of basic and additional characteristics. Among them are power, cutting depth, disc diameter, platform inclination angle, user and tool protection system.

The rating of circular saws is compiled based on demand and feedback from users.

How to use a circular hand saw?

There are standard instructions on how to use a hand-held circular saw, which for different models will differ only in nuances:

- Before starting work, it is important to ensure that the tool is in working order.

- Secure the cutting blade, adjust the position of the guide pin, check the protective cover and the parallelism of the stop with the groove and the pin.

- Set the minimum required cutting depth.

- Set the guide to the size of the material and mark it.

- Make a test cut 3-5 mm long.

- Continue working without stopping along the entire movement of the disk.

- You can use adhesive tape at the cut site to prevent chipping.