These days, frame house construction is at the peak of its popularity. This happens due to the extremely low cost of construction, because building a house from other materials is at least 30 percent more expensive. Calculating the material that will be spent on a frame house is not very difficult, this is what we will do in this article.

How does the choice of material affect the calculation?

Of course, materials for building a frame house take up the lion's share of the total estimate. Their use during construction “eats up” most of the budget allocated for the construction of the house.

First, we will need to calculate the lumber consumed for a frame house. Thus we will need:

- Beams of various sizes;

- Edged boards with a cross-section of at least five centimeters;

- Similar material, but with a cross-section of two centimeters;

- Tongue board 2.5 centimeters.

To calculate the price for timber racks, as well as transverse elements, you will need to take into account the size of the house and its area, as well as the insulation used.

To calculate the costs of roofing, you must first decide on the roofing material, which has a significant impact on the final estimate. The amount of roofing material itself is not so difficult to calculate.

In addition to calculating how much lumber is needed for a frame house, you also need to make an estimate for:

- Foundation;

- Thermal and waterproofing;

- Roofing;

- Finishing inside and outside the building;

- Communication networks.

In addition to all of the above, calculations should be made only after the owner of the house has decided on the choice of materials that will be used for the “box” of the house and the roof. A lot depends on them.

Of course, if the budget is not limited, calculations can be made less scrupulously. However, frame house construction involves savings. Therefore, we recommend you our calculator, which will help you calculate the material that will be spent on a frame house, frame house, online. You can enter the data and get the result below:

General information

All the material was ordered in parts - there were 10 deliveries in total, and it turned out that the transportation of the material alone cost 5,000 rubles.

- For the bottom trim, 35 boards with a size of 5*15*0.5 cm were required. One board of this size cost 565 rubles, a total of 19,775 rubles.

- Boards measuring 5*10*0.6 were used for all walls, rafters and top trim, and 98 pieces were required for a 6*8 meter frame. One board in this size cost 380 rubles, and a total of 36,480 rubles were spent.

- The boards, whose size is 2.5 * 10 * 0.6 meters, were used to create jibs, roofing sheathing, subfloor and ceiling. 200 pieces were used, and if you convert the quantity into cubes, then 3 cubic meters. One board cost 195 rubles, and in total they cost 39,000 rubles.

If you add up all the expenses, it turns out that almost 7.5 cubic meters of boards were spent on the house, and money - 100,255 rubles. Compared to other Russian regions, timber in Crimea is the most expensive. But similar material on the mainland will cost you much less. In general, this is a house that you can build all with your own hands. Almost the entire board was used here, and a little later we covered the rough ceiling and floor from this number of boards.

Climatic factor in calculations

The level of heat in the house also depends on the climate of the area where construction is taking place, which is well known. The only exception exists only when it is planned to build a country house that is not designed for year-round use.

In order to make an accurate calculation of the required material for a frame house, you will need to study the thermal resistance coefficient of each of them. Moreover, it is necessary to make calculations separately for the walls of the building and the roof pie, otherwise the heat will escape through the attic.

Based on the data obtained, it is possible to establish the optimal thickness for the walls and roof, sufficient to retain heat inside the house (according to the thermal resistance coefficients).

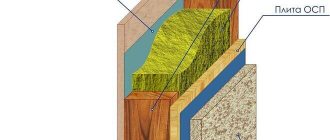

In addition, it is much easier to calculate the materials required for the construction of a frame house if SIP panels or OSB are used to build the walls, since the dimensions and weight of the finished structures are known in advance.

Such factory-made houses are supplied as house kits, so it is not difficult to find out the necessary data, since they are indicated in the technical documents that are always included in the delivery set.

At the same time, these houses, built from sandwich panels, allow significant savings on materials. Insulation is already installed inside the walls, most often mineral wool is used. Thanks to this, there is no need to install thermal insulation on the outside of the house, and therefore reduce costs.

Floor installation

The logs were pre-cut to size and then laid taking into account the irregular geometry of the lumber. Next, the logs were secured with spacers. When laying the joists and struts, defects made during the installation of the piles appeared. Izospan D insulation to block soil evaporation was laid on the ground and pressed with a layer of crushed stone.

aligned the joists on one side

on the other side we measured the length

installed lag

lags

made spacers to stiffen the platform

Calculation method for various house designs

Before starting construction, it is necessary to draw up an estimate for the materials used to construct the roof and foundation.

The process of thermal insulation outside and inside the building is also very important in frame construction. The exception is the construction of houses using the so-called “Canadian” technology, which involves construction from ready-made panels.

Thermal insulation of a frame structure will cost up to 20 percent of the entire construction of the house (if there is no insulation installed at the factory, if it is available - up to 10 percent).

Calculating how much lumber you need to buy for a frame house is even more important for the roof than for the walls. For example, beams used to build an attic can, in some cases, cost almost half the cost of the entire building.

We discussed above how to calculate the required lumber for a frame house, so we need to pay more attention to the roof.

Window

Before installing Veka Softline 5-chamber windows, the opening was thoroughly waterproofed with Niconband roofing tape and pieces of membrane film. After cladding, flashing, slopes and platbands were installed. The cracks are sealed with sealant to match the painted trim.

roofing tape Niconband

gluing the window opening with roofing

taped the entire opening

gap at the bottom

gap at the bottom

gap at the bottom

low tide metal mesh

Roof

When calculating the roof structure, it is necessary to take into account not only its total weight, as well as the loads exerted on the attic floors and beams, but also the weight and properties of the roofing material.

It is also worth paying attention to the roof structure, during the construction of which it is necessary to take into account the wind rose prevailing at the construction site. The side from which the wind blows more often will experience the greatest load. The material required for construction is selected based on this criterion.

If you do not take into account the wind rose, then the roof on one side of the building may begin to leak, become leaky, and the roofing material without the required fasteners and reinforcement may be damaged by strong wind gusts, not to mention a hurricane or other natural disasters.

When building a roof for a frame structure, you need to consider the following nuances:

- You should not build high or sharp roofs in areas where strong winds prevail. Or you will need to significantly strengthen the structure, which will undoubtedly affect the final cost of construction;

- When installing the sheathing, you can reduce the distance between the posts, which will strengthen the structure;

- To construct rafters, you should use only strong timber with a large cross-section, which will make it possible to increase the strength of the roof;

- You should give preference to a more rigid roofing material, for example, use slate instead of metal tiles or corrugated sheets;

- In areas where strong winds blow, it is better to use a rigid roofing material such as slate.

Insulation

Insulation was chosen based on the optimal price-quality ratio. Most of all, Rockwool Light Butts Scandic (60x80 cm), Scandic XL (60x120 cm) for interior spaces and Technolight for external insulation met this criterion. The thickness of the slabs was chosen to be 100 and 50 mm in order to maximally close all openings in the walls and ceilings. The most suitable pitch between frame elements for laying Rockwool is 57-58 cm. To keep the insulation in the ceiling opening, plywood sheets were used. The sheathing for external insulation was made in increments of 59 cm. After laying Technolight, a Tyvek membrane was stretched over it. Foam plastic was used to insulate the windows.

insulation Rockwool Light Butts Scandic

floor insulation

internal insulation

external insulation

windproof membrane

Foundation

For frame construction, “light” foundations are used. Most often you can find a shallow shallow foundation, a foundation on piles or pillars. However, the latter is suitable only for small buildings, for example country houses.

As for the foundation on piles, the easiest way is to use screw structures. When determining how to calculate the material used for a pile foundation, you need to determine what load will be exerted on the support points on which the frame house is supported, as well as its entire mass.

It is also necessary to take into account the soil of the site where the house is being built. You should pay attention to the heaving of the soil and how deep the groundwater is. And if the foundation piles are not installed deep enough, then during freezing the foundation of the house will lift its frame and walls, which will lead to the appearance of numerous cracks and destruction of the building structure.

The most common mistake that people make when doing their own calculations is taking into account the purely weight of the house when designing the foundation. But there are other very important criteria that need to be paid attention to, as mentioned above. That is why if you are not confident in your professional skills, it is better to seek help from specialists.

So you have learned how to calculate the amount of material spent on a frame house. A correctly drawn up estimate will help rationally distribute funds during construction.

Facade

The decision to use imitation larch timber as cladding for a 6x6 frame house was made due to environmental friendliness, relatively low cost and the ability to change color. A ventilation gap should be provided under such cladding and a sheathing with protection from insects and mice made of mounting mesh should be installed. Galvanized nails of 50 mm were chosen as fasteners.

Tikkurila products were chosen for the finishing because the primer and paint preserve the wood structure and have significant durability. A total of 10 man-days were spent on cladding and painting.

metal mesh against rodents

lathing for imitation timber

installation of imitation timber from scaffolding

imitation timber

coat the joints

window bypass

sheathing completed

facade painting

final view of the 6 by 6 house

Gable.

Vertical frame posts. Step 0.5m 6m (side) x2=12m.p - 1.2m.(window opening width) x2 (on each side)=9.6m.p 9.6/0.5=20pcs (19.2) Height racks (board 100mmx50mm) changes with each step proportionally to the middle: 0.5m+1m+1.5m+2m+2.5m=7.5m window opening 2.5m+2m+1.5m+1m+0.5m= 7.5m

Central post 3m (ridge height) - 1.2m (window height) = 1.6m . Total (7.5+7.5+1.6)x2(pediment)=33.2m.p

cross beams (board 100mmx50mm) are fastened in two strips 4m.p. (lower) and 1.6m.p. (upper) (4+1.6) x 2 (gable) = 11.2m.p. 33.2+11 ,2= 44.4 m.p. Or 44.4 x 0.1 x 0.05 = 0.222 cubic meters. The pediment in this example of a frame house is sheathed only on the outside with boards (150mmx25mm) and is not insulated.

The area of two triangular gables is a multiple of one rectangle 6x3 and is equal to 18 square meters - 1.68x2 (window openings) = 14.64 square meters + 10% (trimming) = 16.1 square meters. Or 16.1 x 0.025 = 0.4 cubic meters. (boards)

Waterproofing and wind protection are carried out with glassine paper before covering the frame with boards, taking into account an overlap of 16.1 square meters.

What types of lumber should I choose for building a frame house?

For frame house construction, these types of softwood lumber are used:

Grade 1 lumber includes a small number of knots and cracks. This wood is used in the construction of the main parts of the structure.

Grade 2 lumber includes a larger number of knots and small flaws in the form of wane (bark). During construction, this type of wood is used for the construction of load-bearing structures.

Grade 3 lumber includes small flaws in the form of wane (bark), a small fungal infection, and may have a wavy surface. This grade is used in non-pressure structures.

Grade 4 lumber includes all the natural defects of wood. This type is most often used for scaffolding and formwork.

It is better to read more detailed information on sorting lumber in GOST 8486-86.

Fire and Bio processing of frame house wood.

In order for your house to last longer, you need to take care of its frame, or rather what it is assembled from, and this is wood. To protect lumber from insects, fungi and even fire, it will need to be treated with an antiseptic or fire retardant. What is an antiseptic (bioprotection) is a chemical composition that protects wood from the biological effects of the environment. What is a fire retardant (fire retardant) is a chemical composition that protects wood from direct fire, i.e. from ignition. Compositions such as Firestop contain both of these compounds, both against biological effects and against ignition. It is worth remembering that fire bioprotection is a composition that is easily washed out by rain. Therefore, you should not leave this material in the open air and erect structures during rainfall, otherwise it will turn out that the money spent on processing is simply thrown away.

There are several ways to treat lumber with fire and bio protection. The easiest way, requiring a minimal investment of money, is to process wood with a brush, the next faster method is spraying from a spray gun, you can easily perform these two methods in your own area. The third method, the most effective, is to immerse the wood in a bath of solution. This method is more problematic to organize on site, so it is easier to order it from a lumber supplier.