In modern wooden house construction, it is simply impossible to do without additional fasteners for various elements of the house’s structure. For each wooden part - be it a beam, a log used to construct the main frame of the house, or floor beams of various thicknesses, rafters, etc. - There are different types of fasteners. Depending on the application, timber fasteners can provide a more reliable connection of wooden parts, as well as minimize deformations during the natural shrinkage of the house.

Read on to learn about the types of fasteners for wooden beams and options for their use.

- Perforated timber fasteners

- Simple corners for attaching beams

- Reinforced perforated corners

- Beam holders

- Open and closed beam supports

- Sliding support for rafters in a wooden house

- Perforated plates

- Height adjustable lift for timber

- conclusions

Perforated timber fasteners

Such fasteners are most often used in the construction of wooden objects .

They are needed in order to strengthen connections in the most vulnerable places of the structure and, therefore, extend the life of the house. In particular, such timber fasteners are suitable for fixing consoles.

Perforated fasteners are presented in the construction market in many variations. For each type of work there is a different type of fastener.

As a rule, they are made of high-strength galvanized steel, which is resistant to corrosion processes.

On average, the thickness of the parts ranges from 2-2.5 millimeters.

Certain types of perforated fasteners for timber can be thicker - from 3 to 6 millimeters, depending on the intended purpose and the expected load on them.

Simple corners for attaching beams

This fastener element is a curved galvanized steel plate with holes of different diameters (from 14 to 55 mm).

Due to the presence of holes, they are very convenient to use for strengthening corner joints of beams, using bolts and screws of different sections.

Separately, it is worth noting the material from which the corners are made . Galvanized steel has the characteristics of strength and at the same time elasticity. In addition, thanks to hot-dip galvanizing technology, such parts do not rust or oxidize.

Perforated corners can be used not only as additional fasteners for timber, but also when assembling furniture or installing a wooden staircase. This is the most versatile and inexpensive fastener in the line.

Advantages of using a perforated corner:

- It is very easy to install the corners. Firstly, you don’t need any special tool, and secondly, it can be fixed simply with bolts without making a tap. This not only reduces installation time, but also makes the process less labor-intensive.

- Although the perforated angle is a simple device, it provides a very reliable connection, while ensuring the strength of the entire structure of the wooden structure.

Wood screws

Connections made with screws are more durable and stronger than nails. The spiral thread adheres perfectly to the material and prevents the fastener from slipping out.

For the construction of houses, wood screws with a length of 40 to 320 mm and a diameter of 0.5 to 6 mm are most often chosen.

As for the types of this construction fastener, a wide variety of screws can be used. The most popular among developers are self-drilling screws , since they do not require any preparatory work: you just need to take them out of the package and screw them into the wood with a screwdriver. This is possible thanks to a specially designed Spitz.

Traditional, regular-shaped screws are cheaper, but when choosing them, keep in mind that you will have to drill a hole before you start screwing them into the wood. It should be slightly smaller in diameter than the diameter of the screw.

There are also partially threaded construction screws . In them, as a rule, the thread is located only on a small surface and at a certain angle. These fasteners are useful if you plan to fasten wood to other materials, as they have up to 67% more tensile strength than traditional screws.

Many developers prefer to fasten rafters, beams and other wooden elements of the house with screws. However, keep in mind that this is a more labor-intensive task compared to nails. To make it easier to secure the screw in hard wood, its threads can be pre-lubricated with clear oil, stearin, or rubbed with soap.

However, unlike nails, fastening with wood screws often looks more aesthetically pleasing. In addition, they hardly rust, as they are protected from corrosion by chrome or brass plating. Of course, this does not provide a 100% guarantee.

If you want to completely avoid rust, you should choose stainless steel screws. Of course, they will cost more. However, such fasteners will come in handy if you plan to work with wooden structures that may be frequently exposed to water or located in conditions of high salinity (houses built in coastal areas).

How to tighten screws correctly?

The tightening technology depends on the shape of the screw. The easiest way, of course, is to work with self-tightening screws with traditional threads. It is somewhat more difficult with fasteners in which the threads are only partially applied or with so-called screws with a threadless section.

When working with the latter, you will need to drill holes in the wood. This is done in two stages. First, a hole is made with a narrow drill, and then with a drill with a diameter similar to the threaded part of the screw. The principle of double drilling does not apply to screws whose threaded part is wider than that of a non-threaded part.

Do we need to pre-drill holes if we are dealing with traditional screws, with full-length threads? There are no special rules here: if they are twisted like this, then there is no need to drill the wood. However, if you are dealing with hardwood boards, be prepared to drill every time.

Additionally, if you plan to install a screw near the edges of the board, experts strongly recommend pre-drilling the hole to avoid damaging the wood. Remember that the hole for the screw should always be not only narrower than its diameter, including threads, but also about 1/3 shorter than it.

Reinforced perforated corners

Reinforced corners are used for fastening load-bearing wooden structures. And not only inside, but also outside the house. These corners differ from the previous version not only in the composition of the alloy from which they are made, but also in the thickness of the plate itself. It reaches 3 millimeters. Such a corner is reinforced with an element such as a stiffener . Thanks to it, the connections are stronger and more reliable. As a rule, it is used to attach a beam to a certain plane at a right angle.

What it is?

During repair work and construction, there is often a need to install wooden structures with high load-bearing loads. To ensure that the fasteners are carried out correctly, craftsmen recommend using self-tapping screws, which may have a square or hexagon-shaped head. This product is made from high-quality stainless steel with galvanized coating.

A plumbing bolt can have different shaft lengths and head shapes. This self-tapping screw has a stamp with information about the manufacturer and characteristics of the product. The rod consists of 2 parts:

- smooth, cylindrical;

- with external thread.

The end of the self-tapping screw is represented by a sharp tip, thanks to which the hardware easily enters the wood. Capercaillie have found their application when it is necessary to fasten wooden structures with high load-bearing capabilities. These hardware are used to fasten slats, boards, and bars to a brick and concrete base. It is difficult to do without hexagons when installing plumbing fixtures on a wall or concrete floor. In addition, this fastening connection is used in mechanical engineering, when working with rails and concrete pillars.

Beam holders

Like other perforated parts, the beam holders are made of galvanized steel.

They have high anti-corrosion characteristics.

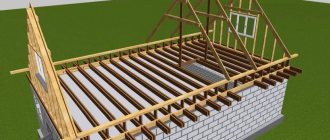

They are used as fasteners for cross surfaces . For example, for fixing ceilings, floors and floors.

As well as the roof truss system. Beam holders are also needed to connect the rafters to the supporting beams.

The thickness of the parts, as well as the reinforced corners, reaches 2.5-3 millimeters.

The holders also have holes for screws, which greatly simplify the installation process and reduce time.

Open and closed beam supports

These perforated parts are considered the most popular in wooden house construction. Their main application is fastening the console of a load-bearing floor beam .

Both types of beam supports are also used in the nodal connections of rafters, for attaching beams to various surfaces, including brick.

An open beam support differs from a closed one only in price and appearance. Also, a closed part is easier to work with and is considered a more reliable fastener .

This fastener for timber has holes of different diameters - from 5 to 11 millimeters. This allows you to use not only nails and bolts, but also anchors.

When using a closed support to connect two load-bearing beams, it is important to accurately calculate the load on the beam. Depending on this, use nails, screws or anchors for installation. The advantage of using a closed-shaped support is also the ability to change the angle of the fastener - not only at a right angle, but also at an acute angle.

Nails

Of course, the first thing a developer of a private house should take care of is to purchase a sufficient number of nails. This is the main type of fastener that is useful for connecting wooden structures to each other.

Of course, nails will not fit everywhere. Using them, you can nail simple flat boards to each other, but it is better to screw more complex structural elements with screws. Long screws with a special thread and a small head are ideal for mounting massive beams and rafters. For even more complex work, special construction fittings will be useful.

Nails are considered the most primitive fastening element. They are also the cheapest. They are quite easy to hammer into wood and also pull out. Another undoubted advantage of nails is the possibility of their reusable use. They are easy enough to pull out of the wood using pliers or the back of a hammer head and use again.

However, when working with this seemingly simple fastener, you also need to have some experience. An improperly driven nail can damage the wood or protrude, ruining its appearance. In addition, it is worth considering that it is better to buy stainless steel nails. Yes, of course, they are more expensive than conventional steel ones, but the latter quickly rust, which will ruin the appearance of the structure and can even lead to a change in the color of the wood.

Types of wood nails

Today, most often for rafter and carpentry work, they use:

- Smooth galvanized hardened steel nails , with a round cross-section and flat heads. As a rule, their length ranges from 2.5 to 30 cm, and thickness: from 2 to 9 mm. Smaller nails are practically not used in construction; as a rule, they are bought only for some auxiliary tasks;

- Hidden nails (no head) . They are called hidden because after driving they are practically invisible;

- Corrugated nails are a cross between a screw and a traditional nail. They wedge into the wood better, but are more difficult to pull out. It is recommended to choose such fasteners for fastening floor boards so that over time the seams do not weaken and the floor does not begin to creak.

In addition, nails are selected based on the thickness of the wood. The optimal ratio of nail thickness to material thickness should be 1 to 5. For dry or hard wood, you can choose 1 to 10.

How to hammer nails correctly?

The head of the nail should be completely sunk into the wood, but not too deep (so that you can feel it by running your hand over it). When working on particularly hard parts of wood, you can use a drill bit to make a thin hole before driving the nail.

Keep in mind that driving a nail into existing seams may weaken them. It is better to use a screw or bolt in this place. Also keep in mind that the nail holds best when it is driven perpendicularly into the plane of the wood along which the grain runs (along the trunk). If it is not possible to drive a nail in this way, to further strengthen the joint, you can drive the nails at a slight angle - up to 15 degrees.

There is also another rule among carpenters: there must be a minimum of 4 nails for each connection. This does not apply to structures made from elements with a small cross-section. If the nail goes through such a piece, you can bend it with a hammer, cut off the protruding part with a metal saw, or sand it down. Of course, in this case a bend may appear, but this way the fastening will be more reliable.

Sliding support for rafters in a wooden house

Such fasteners for timber are important because they help minimize the impact of timber shrinkage on the roof rafter system. As you know, after putting a house into operation, the timber still needs a lot of time to shrink. During the process, the wood dries and changes its geometry . And with it the whole box at home. Naturally, this can also affect the integrity of the nodal connections of the roof system beams. To minimize negative consequences, sliding supports for rafters are used. This is a closed perforated part made of galvanized steel (resistant to corrosion and does not require additional treatment with protective substances). Thickness 2 or 2.5 millimeters. It is used to attach the rafters to the lower support beam - the so-called Mauerlat.

Besides:

- The sliding support, used as a fastener in the rafter system, balances the entire structure.

- It can be used when there is a need to fasten several rafters at once .

- The use of this part greatly simplifies the installation process, since you can get by with a regular screwdriver, special screws and nails for wood.

Height adjustable lift for timber

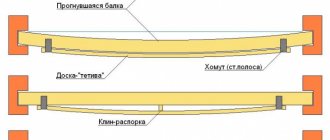

This part looks like a screw support.

Consists of two thick (6 mm) galvanized steel plates.

The plates are connected to each other by a screw support and a nut as a retainer.

Such fasteners for timber are necessary so that during the shrinkage of the house the horizontal level of the structure remains the same.

Roughly speaking, this lift is designed to compensate for shrinkage.

Installation technology

Fastening hexagons consists of several main steps:

- first of all, prepare a hole suitable for the diameter of the screw;

- carefully remove debris generated after drilling;

- insert a dowel into the resulting hole (they are often sold together with screws);

- secure the screw using a special key (since the wood grouse has a hexagonal head, a simple screwdriver will not work);

- After installation, the product begins to be screwed in a clockwise direction. To protect the base from damage and increase the strength of the structure, it is recommended to place larger washers under the screw head. Also, hardware can be covered with decorative caps.

When installing a wood grouse screw in soft wood, you can do without drilling; the pointed end will easily fit into the base

However, it is very important to insert the head nut evenly and screw it in carefully, otherwise the bolt may go in crookedly and damage the fragile wood.

conclusions

Fasteners for timber have become simply an indispensable element in the construction of wooden objects. They are used both to create nodal connections and as an additional fastener (for example, for corner connections of timber or logs). The use of these parts at various stages of construction work also makes it possible to minimize the effects of natural shrinkage of the timber on the geometry of the main frame of the house and the roof truss system . In addition, they significantly simplify the process of installing wooden structural elements of a house and make it less labor-intensive.

Read about what other fasteners for timber are available and how they are used in the following publications on our website.