One of the most pressing questions that arises during the construction or renovation of a wooden house is: “Is door frames necessary in a wooden house?”

This question is far from idle, since the cost of time and money for framing windows and doors is very significant and, oddly enough, is often not included in the original design of the house.

In our opinion, the answer to this is obvious: it is definitely needed, and the main proof of this is the age of this technology. For hundreds of years in Rus', wooden houses were built without milling cutters, band saws and electric drills, spending many times more time on each operation. And, nevertheless, doors and windows in a wooden house were always installed in a casing frame.

Let's consider what reasons determine the need to install window and door casing, and what designs exist.

Shrinkage and seasonal changes in log dimensions

First of all, let us remind you why the pigtail is needed.

Wood is a good and environmentally friendly building material, but it has one significant drawback - its linear and volumetric dimensions are not stable and depend on the level of humidity.

In turn, the moisture content of wood changes not only over time (due to natural drying), but also depending on climatic conditions.

For a new log house, the total changes in its geometric dimensions can reach 100–150 mm during the initial shrinkage and up to 7–10 mm during the remaining period of operation (due to seasonal humidity fluctuations).

Let us immediately emphasize that humidity changes in size always occur, even after the end of the shrinkage period.

To prevent size fluctuations from being transmitted to those structural elements of the house, the dimensions of which must remain unchanged, they are installed in special casing boxes, also called “casing” or “casing”.

U-shaped casing for the door

The connection between the casing and the rest of the house structure is always sliding. That is, the logs in the log house shift, but the dimensions of the frame remain constant.

The basis for disputes on the topic “is a door frame necessary in a wooden house?” is the assumption that when using modern methods of wood stabilization (special drying modes, oil impregnation, etc.), seasonal fluctuations in size in a wooden house are negligible and in an old house it is possible to install doors and windows without jambs.

To some extent, these judgments are correct. A wooden house built from profiled or laminated timber, specially dried in a factory and treated with water-repellent agents, will indeed maintain stable dimensions in the first 5-10 years.

But will he retain this ability in 12-15-20 years? It’s unlikely, since we have not yet learned how to completely prevent the appearance of cracks, micropores and age-related deformations in wood.

Impregnations and protective coatings also have a certain “shelf life” and even the instructions for their use state that the coating needs to be renewed (every 3-5 years). But in practice, this requirement is rarely met, especially in cases where the log house is sheathed on the outside with clapboard.

Summarizing the above, let's summarize: installing doors in a wooden house without casing can only be done in temporary buildings, and even then, only under certain conditions, but a house for yourself and your family must be reliable and built with casing installed.

Cutting methods

To cut a doorway with your own hands, you will need a tool, but you can choose it correctly after determining the method of work being carried out. The method depends on the wall material. It is not advisable to chisel and sledgehammer, as the integrity of the entire partition will be compromised. You can carefully cut the opening using diamond, laser, waterjet or oxygen cutting.

Diamond cutting

For concrete partitions, the method of diamond cutting of a doorway using a grinder or circular saw is used. The cutting element of the tool is a metal disk coated with diamond.

The diamond cutting method has many advantages:

- low level of vibration eliminates the appearance of cracks even on loose partitions;

- during the cutting process, an accurate thin cut is entrusted along the marked contour and at the desired angle;

- the noise level of a working tool does not exceed the permissible threshold specified in sanitary standards;

- a small amount of debris due to the absence of chips, which is impossible to achieve when using a hammer drill.

Among the shortcomings

highlight the costs of purchasing expensive diamond blades. During work, the concrete wall is moistened with water, but fine dust still spreads into the room.

Laser cutting

Expensive equipment is used for laser cutting of openings. Previously, it was bulky and was used only in production. Modern laser cutting equipment is compact, but its high cost and specific purpose have made it popular only among specialized repair teams. The cutting of a concrete wall is made with a laser cutter due to the gas-discharge action.

Before starting work, the parameters of the wall

:

- thickness;

- the presence of a reinforcing frame;

- passage of communications inside the partition;

- grade of reinforced concrete wall.

Additionally, the floor of the apartment building where cutting is planned is taken into account, as well as the admissibility of wetting the concrete structure with water.

Waterjet cutting

Cold cutting of an opening in a wall refers to the waterjet method. A special installation is used for work. It creates a strong stream of water at a speed of 1 thousand m/s. The liquid in the tank is mixed with abrasive particles with a diameter of about 0.4 mm. The prepared mixture is fed through a nozzle onto the reinforced concrete structure and destroys it at the point of contact. The cutting force depends on the pressure. At the maximum power of the equipment, a reinforcing frame made of steel rods is cut along with the concrete.

The waterjet cutting method has the following advantages:

- precise cutting of concrete according to markings;

- the environment is not polluted due to the absence of chemical impurities and harmful gases;

- the concrete partition is not subject to mechanical and thermal stress;

- no wall vibration;

- low noise level;

- The method allows you to cut out a section of the partition at any angle, as well as make a doorway of complex shape.

Disadvantage

is the formation of dirt, the high cost of consumables, and the large dimensions of the equipment. Waterjet cutting is used on construction sites that have not been put into operation.

Oxygen cutting

The oxygen cutting method is also called spear drilling. To cut out a doorway, a machine with a metal tube is used. Oxygen is supplied through the spear under high pressure. At the same time, the jet is heated inside the tube to a temperature of 1400°C using a gas burner. After the spear has ignited, the external heating source is turned off. When the temperature reaches 2000°C, the tube is leaned against the concrete surface and turned slightly. During cutting, you cannot move the spear away from the concrete, as it cools quickly.

The disadvantage of this method is considered to be a fire hazard, as well as the possibility of getting burned. During cutting, hot slag particles scatter throughout the room.

Types of door frames

Let's consider what types of casing there are for doors in a wooden house in terms of labor costs and cost, since it is from this perspective that most builders who are faced with the need to manufacture a casing consider this issue.

Mortgage beam

The fastest and cheapest way to prepare an installation site for wooden or metal doors is to cut a frame into the embedded beam.

In this case, the load-bearing frame is made from ordinary rectangular timber and placed in grooves punched at the ends of the openings.

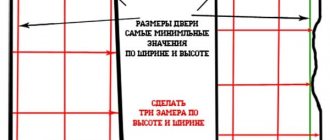

The height of the casing frame under the door jamb should always be less than the opening by the shrinkage height of the frame (that is, by 60-100 mm).

The timber is placed in the groove using a soft fiber seal (jute tape or flax batting). No additional fastening is required - the frame should move freely in the grooves.

This technology is especially convenient in a log house, where logs can be supplied with ready-made grooves at the ends.

But since the door frame should be installed only within the casing frame - and its thickness is only 50-70 mm - this scheme is rarely used for installing external doors. The optimal area of application for casing in embedded timber is the frame of interior doors.

Piglet in a monolithic spike

In practice, to install wooden and metal doors, a T-shaped casing is used in a monolithic tenon. The difference from the previous option is that the end of the opening is covered with a solid board, rigidly connected to the tenon.

The general design of the T-shaped casing frame consists of the same elements: two vertical jambs, an upper crossbar (“top”) and a lower crossbar (“bottom”). All these elements will be connected without rigid fixation, but with the creation of support in the vertical and horizontal directions.

Ideally, the entire vertical post of the T-shaped casing is made from solid timber. But in order to reduce its cost, the use of glued structural elements is allowed.

Please note a common mistake when assembling a socket into a tenon: to reduce its cost, the tenon and frame are made from different boards, and then connected with self-tapping screws. This cannot be done, since such a connection does not provide adequate thermal protection, which after a short time will result in drafts and freezing.

If you still decide to use a prefabricated structure of vertical posts, then it is better to put the tenon on the side of the frame in the groove and glue it, although this is also not a universal solution, since such a design requires special glue and special conditions for its polymerization.

Casing into the deck

Tenon for U-shaped casing

The most expensive and, at the same time, the most reliable way to equip a load-bearing frame when installing doors is to use finishing casing in the deck (“U-shaped casing”).

In this option, a tenon-groove connection is also used, but the end of the log house is turned onto the tenon, and a groove is cut in the vertical jambs.

At the same time, the vertical and horizontal crossbars of the casing are made in such a way that after installing the frame there is no need for finishing operations. A quarter is selected for installing the door frame on the outside of the frame.

You can learn about the advantages and disadvantages of each type of casing from the article “Purpose and design of casing in a wooden house.”

Design selection

The choice of a door for a wooden house is noticeably different from the choice of the entrance door to an apartment, where the access space protects it from the direct influence of external factors and one function remains, namely protection from unauthorized encroachment.

A door in a private house has direct contact with the external environment, that is, exposure to temperature changes, frost, and precipitation should be taken into account.

Installation of a door for a house made of timber.

The front door should not become a source of cold in winter, that is, it should have thermal insulation of the canvas and heat-insulating sealing gaskets at the joints.

Taking into account the requirements, the door of a log house is usually made of solid wood or steel sheet.

In the latter case, additional thermal insulation lining must be provided. In addition, we should not forget about sound insulation.

There is a nuance to installing doors in a private house: they must be installed so that they open inward, otherwise there is a risk of not leaving the house if there is a snowdrift near the door.

Some common features of casing for windows and doors

Method of attaching the door leaf to the casing

The increased popularity of wooden houses has led to the fact that construction teams who do not have practical experience in this area of architecture began to undertake their construction.

The consequence of this were three main mistakes made when installing casing elements for window openings and doors:

- Rigid connection of the frame and logs using self-tapping screws or nails. This absolutely cannot be allowed, since such a connection fundamentally contradicts the basic working principle of the casing frame (the casing must allow vertical displacement of the frame).

- Using polyurethane foam to seal the casing-frame joint. Due to the high strength and good adhesion of polyurethane foam, such a connection is equivalent to a fastening one and will ultimately lead to deformation of the windows.

- The use of additional brackets connecting the door block in the casing with the log house. That is, first, according to all the rules, they install the frame and the door, and then, to create additional rigidity, they connect the casing frame and the frame with brackets.

In general, when designing a wooden house, you should always take into account that the casing is an important strength element of the entire structure of the house, and its manufacture and installation are carried out without nails and screws.

We also recommend that you take into account that any end-to-end connection of wooden elements without a seal (that is, plane to plane) when making casing is unacceptable. Due to drying of wood, such compounds become the main conductors of cold within a year or two.

What tools will be needed for installation?

When deciding how to make a doorway and insert a door, first of all you need to decide on the tools necessary for this work. They must be at hand at all times. This will allow installation to be completed as quickly as possible. To carry out the work you will need:

- chainsaw or electric saw with a bar;

- hammer;

- perforator;

- circular saw or manual milling machine;

- chisel;

- construction measuring instruments: level (preferably laser), tape measure and square.

As a rule, searching for tools will not take much time, because all of them, one way or another, were used during the installation of the log house. Having prepared everything you need and understood how to install the door correctly, you can begin work.

Do you need a frame for arched vaults?

Of course, it is necessary, and this is the most complex and most expensive version of the casing frame. Such doors are often installed in bathhouses and wooden houses, stylized as antique.

The casing for them is made according to the same principles as for rectangular openings: with the possibility of displacement in the vertical direction and with a gap to compensate for shrinkage between the top and the frame.

The design of the vertical posts and the bottom crossbar in it is the same as in a conventional pigtail, but the top is made of several sections that simultaneously perform a strength and decorative role.

Installation of wooden window frames

Wooden window frames are installed in the same way as doors. First of all, the window openings are carefully marked. The distance from the opening to the corner of the house should be more than 1 m, and the distance between the windows should be at least 1.5 m, the height from the ground surface should be at least 90 cm. When marking the window opening, you should not forget about installing the window sill, you need to take into account its thickness. The installation of plastic window frames is not fundamentally different from the installation of wooden structures.

When installing window frames, an additional element (jamb) is usually used, which is a beam with the function of an additional frame. A groove is made in it for installing the top, with the help of which the frame is connected to the beams of the log house. There is no groove made in the window frame itself, and its end is attached to the surface of the frame using screws.

https://www.youtube.com/watch?v=Km0Jh2LacLY

Features of casing for metal doors

Unlike windows and wooden doors, a metal door always has a rigid door frame, which can be used as a load-bearing frame for the casing frame.

If the door frame is made according to a reinforced design, then the top crossbar of the casing can be omitted. However, the benefit of such a solution is questionable, since the upper part of the frame still needs to be decorated in the same way as the side posts.

The second important point that distinguishes the installation of a metal door in a wooden house from a similar process in a stone building is the scheme for fixing the door in the door jamb.

We cannot display this gallery

In a brick or concrete house, anchor bolts or dowels are driven into the wall to the maximum depth. This cannot be done in a wooden house, and the maximum immersion depth of a bolt or self-tapping screw should not exceed the thickness of the casing frame.

It should also be taken into account that large-diameter self-tapping screws installed without preliminary preparation of the holes can split the wooden casing post.

accepts orders for the preparation of wooden houses for the installation of doors of any type. To clarify terms, prices and other terms of cooperation, please contact us by phone or e-mail published in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

How to make a doorway in a brick wall

The steps involved in punching an opening in a brick wall are different from cutting a concrete panel. The masonry consists of rows with bandaged seams. The top of the doorway should line up with the joint. You cannot cut bricks lengthwise. Such actions will weaken the tub and cracks will appear along the partition.

After applying the markings, they begin to strengthen the opening in the brick wall by inserting the upper lintel. A row of bricks is selected above the marked line. A lintel longer than the width of the passage is built into the void.

Further actions are aimed at cutting an opening in a brick wall with the selected tool. If the masonry can be disassembled, then it is wiser to pick out the bricks with a pry bar. The seams are drilled with an electric drill. Uneven protrusions at the ends of the doorway are leveled with a grinder.