The vast majority of floors in both private and apartment buildings are made of wood. The support for a multi-layer, pie-like wood structure is most often logs. Logs are long bars made of wood (less often metal and reinforced concrete) laid transversely to the finishing flooring, serving as its solid foundation. This structure is installed both on a monolithic concrete floor and on supporting posts and beams. Installing floors on wooden joists is very profitable due to the relatively low price of materials and ease of installation.

How to lay an array with your own hands

The solid board is laid on plywood sheets. The base can be either a concrete floor or a wooden floor on joists.

- It is necessary to measure 15 mm from the walls to create a ventilation gap and in case of seasonal deformations.

- The finished floor boards must be laid so that they are located across the subfloor boards. The first row is placed with a tenon to the wall and screwed with self-tapping screws. It is necessary to tighten the screws so that they are covered by the baseboard near the wall. On the second side, the screws are screwed into the groove at an angle of 45°.

- A wooden spacer is placed in the gap between the board and the wall. If the size of the room is greater than the length of the floorboards, then the boards are laid “staggered”. This will make the floor more durable.

- The second and subsequent rows of boards are laid with a tenon in the groove of the previous row, compacted with a mallet and fastened with self-tapping screws on the other side into the groove. If you want your wooden floor to last as long as possible, you need to lay the boards in such a way that the growth rings are located opposite each other.

The parquet board is laid "staggered". Solid parquet boards can also be used as a finished floor. In essence, this is the same tongue-and-groove solid board, only shorter. Its installation is slightly different:

- Can be fixed with self-tapping screws only from the tenon side.

- Installation is carried out only “staggered”.

- If the base is made of plywood, then it is better to glue the parquet board first and then additionally secure it with self-tapping screws.

- If you lay the board diagonally, the room will visually look larger.

Fixation to concrete pillars

This method involves fixing beams to concrete pillars, using similar fasteners, but designed specifically for pillars.

- The pillars must be covered in advance with a waterproofing layer (bitumen or mastic is used). Their upper part can be protected from moisture with roofing felt. You need to pre-drill holes in the posts and beams.

- Next, you need to drive dowels or anchor spacers into them.

- Then the beam is attached to the post with self-tapping screws 2-3 times longer than the width of the spacer.

- The timber is attached to the posts using iron plates with screws. They are fixed to the posts with dowels-nails, and to the beams with screws.

Thanks to the study of all these fastening methods, the question of how to install joists on a concrete floor disappears by itself.

Floors, soils and foundations

Ground floors are not connected to the foundation and rest directly on the ground under the house. If the soil on the site is heaving, then the floor in winter and spring can “go on a spree” under the influence of the forces of frost heaving of the soil. To prevent this from happening, the heaving soil under the house must be made not to heave. The easiest way to do this is to insulate the base and underground part of the strip foundation.

The design of pile foundations on bored (including TISE) and screw piles involves the installation of a cold base. Insulating the soil under a house with such foundations is a rather problematic and expensive task. Floors on the ground in a house on a pile foundation can only be recommended for non-heaving or slightly heaving soils on the site.

When building a house on heaving soils, it is necessary to insulate the base and underground part of the foundation to a depth of 0.5 - 1 m.

In a house with external multilayer walls with insulation on the outside, a cold bridge is formed through the base and load-bearing part of the wall, bypassing the insulation of the wall and floor.

In addition, insulating the base will help eliminate the cold bridge, and will also reduce the thickness of the floor insulation. You can find out how to determine the required thickness of vertical thermal insulation of the base and underground part of the foundation here.

How to make a wooden floor on joists warm, with water heating, read here.

Dear reader!

Please rate the usefulness of the article in the comments. on the topic of the article, supplement, clarify or object to the author. Tell us about how you do it. The comment will be published some time after approval. Thanks for leaving a comment!

Location rules

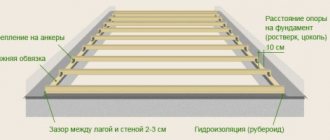

The first and last lags from the wall should be at a distance of no more than 20 cm. If, while observing the calculated step, the outermost lags are located further, their number is increased and the step is reduced.

They are placed either along the wall in which the door is located, or perpendicular to it. If one wall is much longer than the other, then it is along this long wall that the logs are placed. If the room is square or similar in shape, then the location of the window may influence the choice: floorboards look best if they are located along the flow of light. That is, in this case, the logs are placed along the wall in which there is a window.

Wood selection

Choosing a floorboard

Here are the basic principles according to which you should approach the choice of material:

- wooden boards must be well dried, not damp. Otherwise, the wooden floor will deform over time;

- the boards should be free of scratches, cracks and dents;

- the optimal length of wooden floorboards is 2 meters;

- give preference to edged or tongue-and-groove boards, as they no longer require sanding;

- when choosing wood, take into account the characteristics of the rooms in which it will be placed (for the bathroom or kitchen, purchase only moisture-resistant wood species).

Floor board, thermobook

If you have already thought about everything and are starting the purchasing process itself, then purchase 15% more wood than the planned quantity. It will be used to cover the trimmed footage on ledges, corners and other recesses of the floor. The third, most important stage begins - laying the wooden floor.

Wooden floor in the kitchen

What should the cross section of the log be?

The strength of this part of the floor depends on the material of manufacture and the accuracy of load calculations. When choosing the size of the timber, the maximum permissible load on the floor is taken as a basis. For living rooms, this figure is 300 kg per 1 m2. For non-residential premises it is individual in each specific case, so before purchasing the material you need to calculate this indicator.

Basically, timber with a profile aspect ratio of 1.5 x 2 is laid under the floorboard.

The height of the beams must also be selected taking into account the thickness of the insulation. If iron and concrete elements are installed, their cross-section may be smaller. This is due to the fact that these materials are able to withstand high loads for a long time.

What to putty and paint with?

After the floor is mounted on the joists, it needs final processing. Having finished fastening, you need to saturate the boards with fire and bioprotective compounds and dry thoroughly.

If cracks appear during installation, they need to be filled with putty, as well as the screw heads must be hidden. Acrylic putty is preferred for this, as it is more fluid and fills all small irregularities. You can also use oil-glue or oil putty, but you need to take into account that it takes a little longer to dry and after drying it becomes a little more fragile than acrylic.

After puttying, the new floor needs to be painted. The final coating, in addition to aesthetics, also performs two practical functions - it increases abrasion resistance and increases the moisture resistance of wood.

Today, the choice of flooring compositions is quite wide, each has its own application features, advantages and disadvantages.

They can be roughly divided into three categories – paints, enamels and varnishes.

- Enamel is presented on the market in the greatest variety of colors and shades. It lays on the wood in an even thin layer and dries quickly enough. Due to its rather liquid consistency, it is very fluid and in some cases requires three layers.

- Varnish – alkyd or water-soluble. It has the lowest wear resistance and low hiding power. At the same time, it can advantageously emphasize the natural beauty of natural wood.

In each case, you need to take into account that even paints from the same manufacturer from different batches may differ in shades, so it is best to mix the coating from different cans in one container. Depending on the color composition, mineral-based color additives can be used.

This completes the arrangement of the wooden floor on the joists.

For information on the features of laying a wooden floor on joists, see the following video.

Video description

How to install logs for a wooden floor, watch the video:

Preparing the boards

Even kiln-dried lumber needs acclimatization to the conditions in which it will be used. Therefore, it is advisable to bring the floorboard into the house in advance and let it lie for several days. But this can only be done after all wet work has been completed - installing screeds, plastering walls, so that the wood does not absorb moisture evaporating from the solutions.

Then the boards are sorted, putting the deformed ones aside and choosing the smoothest and cleanest ones. Products that are not of the best quality can be used for wooden flooring in less significant rooms or for laying along walls where they will be hidden by furniture.

For reference! If the boards are of different widths, then narrow floorboards will deform less when drying.

After sorting, the lumber is treated with an antiseptic and left to dry. It is enough to carry out such processing only for the back side and ends, since the finished flooring will be subjected to sanding and protective and decorative finishing.

Antiseptic treatment of lumber Source myosu.ru

Branded formulations

They are divided into fire-protective and bioprotective agents, as well as non-washable antiseptics.

Fire-retardant substances

This method of protection is one of the most effective, since it allows you to protect wooden materials not only from microorganisms and putrefactive processes, but also protects against fire. The latter quality, due to the fire hazard of wood, is of considerable importance.

Fire-retardant substances preserve the structure of the logs for many years: fire protection is provided for 3 years, and biological protection of the material is provided for 25 years. Although, if a wooden product is not used under extreme conditions, the actual lifespan of the drugs will be longer.

Fire-retardant compounds are environmentally friendly, lack unpleasant odors and are completely safe to use. The environmental friendliness of the drugs is ensured by their composition: there are no components dangerous to humans, including allergens.

Any legally sold drug must have a conclusion from a sanitary-epidemiological station, fire regulations and a quality certificate.

Bioprotective compounds

Preparations in this group improve only the bioprotective qualities of wooden materials. Bioprotective compounds protect wood from blueing, mold, rotting, fungi and wood-boring beetles that destroy the material. The drugs provide bioprotection for 25-30 years.

Most often, antiseptic drugs are sold in the form of concentrates. In some cases, pigmenting substances are added to the formulations. The pigment allows you to visually control the quality of the coating on a wooden surface.

Bioprotective products have a low odor, are environmentally friendly, and do not contain allergens. They are easy to prepare - just dilute them in water. Surface treatment can be done in a variety of ways, including roller, brush, spray, and dipping.

Used to protect structures operated in conditions of high humidity. For example, non-washable antiseptics are relevant at high levels of precipitation, temperature changes, as well as in buildings where wood is often moistened due to operating conditions (baths, saunas).

Working with non-washable antiseptics is not difficult, but it is time consuming. The approximate consumption of the substance per square meter is 350-400 grams. Surface application is achieved after 3-4 layers. If we are talking about dipping, you will need to soak the material for 20-30 minutes.

This group of antiseptics gains adhesive properties after final drying. The color of the wood usually becomes pistachio due to pigments added to the composition.

Installation of columns under logs

After the soil is compacted and leveled, they begin to install columns under the logs. But first you need to mark the installation locations of the supporting pillars. In practice, cords are used for this, which determine the location of the lags. At the intersection of these cords, places are designated for the foundation for the columns, which are laid out from ceramic bricks or concrete blocks. The cords are then removed, and the locations of the posts are fixed with wooden pegs driven into the ground.

Next, at the locations of the pegs, holes are dug for the foundation for the posts. The depth of the holes depends on the density of the soil and the depth of groundwater. If the soil is sandy or rocky, a depth of 25–30 cm will be sufficient, however, and if the soil is clayey, then the depth of the foundation should be 40–50 cm, since crushed stone will have to be poured into the bottom, which must be thoroughly compacted.

Pouring concrete for the foundation must be taken very seriously, observing the required proportions of concrete, sand and water. You should not skimp on cement, but prepare the mixture in the following proportions: one part cement + three parts sand + three parts fine crushed stone (10–15 mm). Before pouring the solution, it is recommended to lay plastic film at the bottom of the hole so that the “milk” does not go into the ground. And one more thing: below the level of the middle of the pit it would be more rational to attach a metal mesh made of wire Ø 4–5 mm, which will act as reinforcement for the concrete.

After the concrete has hardened, the surface under the brickwork of the columns must be protected with waterproofing made of roofing felt or other material with an allowance of 10–15 cm on each side. Then you can begin laying brick columns, which, for reliability, it is advisable to lay from two rows of bricks. The height of the brick columns must be calculated so that the top bricks are perpendicular to the laid logs.

Concrete floor in a wooden house

A concrete foundation for a timber house is erected in the following cases:

- When installing a monolithic slab on unstable ground. Plank flooring can be made with a rough underlay or laid directly on concrete. In the absence of an earthen subfloor, it is not necessary to make a three-dimensional structure.

- When constructing a strip foundation, where the floor of the first floor is the ceiling for the basement or cellar. Such slabs are thinner and can freeze from the cold coming from the ground. They can be used for any type of wood flooring.

The advantage of a concrete base is its strength and durability, provided it is properly constructed. There is no need to erect support columns or install a ventilation system. The stove reliably protects the living space from dampness, plants and insects.

Preparatory work

Regardless of how you decide to lay a wooden floor, mandatory preparatory work is carried out before laying it.

The following activities are carried out:

- arrangement of vents in the walls;

- leveling the top of the basement level or the edge of the slab;

- removing bark from the boards, under which there may be parasites;

- sorting of lumber, treating wood with anti-rot and fungus agents;

- leveling the earthen base, clearing plant roots;

- covering the soil with geotextile fabric to prevent the growth of grass and bushes.

Waterproofing

Waterproofing is designed to protect concrete from moisture, salts contained in the soil and other aggressive compounds. To create an insulating layer, thick cellophane or roofing felt is used. Strips of material are laid out on the ground with an overlay of 10-15 cm. The joints are glued with aluminum tape, which is resistant to dampness and mechanical stress. The edges of the material are brought out beyond the edges of the pit in such a way that they can be wrapped onto the surface of the finished slab. This technique will protect its edges from contact with the ground, melt and storm water.

Pouring the subfloor

To fill the base, a solution is prepared from a mixture of cement, sand and crushed stone of the middle fraction in a ratio of 1: 3: 3. If the volume is small, this work can be done manually. If the slab is bulky, it is better to use a concrete mixer.

Filling consists of the following steps:

- Filling the cushion with a mixture of sand and crushed stone.

- Production of formwork. The panels are assembled from boards, plywood, chipboard or slate. The walls of the formwork are treated with machine oil or covered with cellophane.

- Installation of a steel frame made of reinforcement, 10-12 mm in diameter. It is better to connect the rods with wire or plastic ties.

- Pouring concrete. Removing air bubbles with a steel rod. Leveling the surface.

It takes 28 days for concrete to gain full strength.

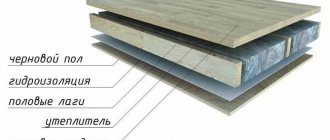

Vapor barrier and insulation

A vapor barrier is necessary to remove moisture from the room and block dampness that forms in the subfloor. To create such a barrier, a fabric membrane is used that allows steam to pass in only one direction.

Depending on the floor design, a heat-insulating layer is laid before laying the front covering.

You can use materials such as:

- Styrofoam;

- ecowool;

- polyurethane foam;

- basalt wool;

- expanded clay

Final screed

The final floor screed is done to completely level the surface before laying the finishing coating. For this purpose, a cement mortar is prepared to which plasticizers are added. These substances make the coating stronger, more resistant to moisture, and prevent the formation of cracks during hardening. The solution is applied with a spatula in a layer of 2-3 cm, after which it is carefully leveled.

Vapor and thermal insulation with penofol

| Attach penofol with a stapler to the sides of the sheathing bars or joists. |

Instead of the top layer of insulation and vapor barrier film, it is more profitable to lay penofol - a foamed polymer covered with aluminum foil, 10 mm thick.

(also available under other trade names).

Penofol must be laid with the aluminized side up, towards the ventilated gap, across the sheathing bars and lowered on both sides of each bar. After this, penofol is nailed with a stapler to each side of all the bars so that a gap of 3-4 cm is formed between the aluminized surface and the floor covering slabs. The joints of the penofol panels are sealed with aluminized adhesive tape. The penofol layer will provide heat transfer resistance equivalent to a 40 mm thick layer of mineral wool and the necessary vapor permeability.

Subfloor boards are attached to the sheathing bars on top of a vapor-proof film or penofol. Instead of boards, slabs are more often used: cement-bonded particle boards (> 22 mm thick), plywood (> 18 mm), etc. Sheets and slabs are placed with the long side on the sheathing bars. Spacers are secured under the short side between the sheathing bars. All edges of the laid sheet must be supported - a block or spacer.

The use of polystyrene foam and polystyrene foam boards as insulation is not recommended. Such slabs serve as a barrier to moisture, which is always contained in the wood of the floor. By preventing moisture from escaping from the wood, foam insulation shortens the service life of the wooden floor parts. In addition, mineral wool insulation, due to its better elasticity, adheres more tightly to the joists than polystyrene foam.

To protect the underground space from ground moisture, it is advisable to cover the entire surface of the soil with a waterproofing film (and not just under the posts, as in the figure). The joints of the covering panels are sealed. The junction of the film to the walls must be connected to the waterproofing of the walls and also sealed. The floor posts lie directly on the film.

As a result, we obtain a ventilated underground space, limited by sealed shells - on top (vapor barrier) and below (waterproofing).

Household products

⇆

Such an underground space protects the house not only from moisture and cold, but also from the penetration of radioactive soil gas radon

.

Construction of a standard bath floor

In the steam room, the floor should rise slightly compared to the zero level. You can make it higher by only 8-10 cm, and the desired effect will already be achieved - maintaining a high temperature in the room is ensured. In the washing department the floor is made below the finishing level. This improvement will help prevent excess water from entering the remaining compartments of the bath.

Installation of plank floors

The most common floor design in a bathhouse (layers from top to bottom).

- Finish coating.

- Wood or concrete (final row).

- Small air space.

- Lining (small layer).

- Insulating layers (hydro- and thermal insulation is required, sometimes noise insulation is added separately if there are industries, clubs, or other establishments that are a source of noise near the bathhouse).

- Lathing.

- Insulating layers (in cold winters to protect the floor structure from cold or moisture).

- Rough floor.

- Wooden beams for sheathing.

- Waterproofing (laid on the ground).

Step width between joists

The pitch between the joists is selected taking into account the thickness of the floorboard. The thicker it is, the larger the step between the bars is allowed. In addition, a thick board sag less under loads.

The table below allows you to quickly select the distances between the bars.

You can also resort to the following rule: when the width of the logs increases by 5 mm, their pitch increases by 10 cm.

When installing plywood, the cross-section of the joist is calculated differently. This is due to the fact that it has great bending strength. With a thickness of sheet material of 1.5-1.8 cm, it is fashionable to place logs against each other at a distance of up to 40 cm. It is necessary to install the beams so that the sheets are fixed at the edges and in the middle. Moreover, the edges of the sheets should fit half the width of the beam.

Laying floorboards

Before laying, the floorboard should lie in the room where it will be laid for one to two weeks. This is necessary so that the moisture content of the wood matches the microclimate of the room. At the same time, wet finishing work (plaster, putty, wallpapering) should not be carried out during this period.

There are three ways to attach a tongue and groove board:

- In the face - not the most aesthetic method, in which the fasteners are driven (screwed) into the front part of the board.

- When fastening a tongue-and-groove board into a groove, a self-tapping screw is screwed into the bottom of the groove at an angle of 45-50°. The cap should fit well into the material so as not to interfere with the installation of the next board.

- When fastening a tongue-and-groove board into a tongue and groove, a self-tapping screw is screwed into the base of the tenon (tongue).

Laying the floorboard

The first floorboard must be attached to each joist with two self-tapping screws. Self-tapping screws must be selected so that 2/3 of their length is in the body of the joist. The first self-tapping screw is screwed in at a distance of 30-40 mm from the wall. Its cap is recessed into the board and later covered with a plinth. The second self-tapping screw is screwed into the groove or tenon of the board (depending on the chosen fastening method) at an angle of 45°. If the board is overdried, it chips easily. In this case, it is better to pre-drill a hole (in a groove or tenon) with a thin drill for each screw.

Subsequent boards are joined and screwed with self-tapping screws. If it is necessary to join boards, the joint should be in the middle of the joist, and the boards should be sawn at right angles to the long edge of the board. Also, when laying the flooring, it is necessary to provide a gap of 7 - 10 mm from the walls around the perimeter.

Screeding floor boards along joists

To tie a tongue and groove board (if necessary), you can use the following devices:

- A support bar and several wedges nailed at some distance from the board.

- Clamps, special staples and other specialized devices.

Basic rules for installing joists

When installing logs yourself, you should strictly follow the following rules:

- Before installing the log, the surface must be cleaned and primed;

- all wooden elements of the pie structure are thoroughly dried and treated with antiseptic antifungal drugs;

- sand or fiberboard can be used as a soundproofing material;

- adjustable floors with your own hands must be fixed well, and then use a long construction level to make sure that the logs are installed straight horizontally; To control the horizontality of the structure, you must use a level

- Under no circumstances should you begin installing the floor without checking the horizontalness and evenness of the joists;

- floor boards are attached to each and every joist;

- In order not to spoil the board, the slots for fastenings must be made in advance; when using self-tapping screws, the holes are made with a thin drill.

Application

As already mentioned, the installation of wooden logs is possible in buildings of any type. However, in reinforced concrete buildings they are used relatively rarely, since it is easier to arrange a rough screed. This installation option is most convenient in:

- wooden houses (wild or rounded logs, beams, boards). In this case, the logs are laid on top of wooden (less often metal) floor beams, forming a strong support for the floor. When covering the ceiling in the lower room, it is appropriate to fill the gaps between the floor beams and joists with insulating and soundproofing material;

- frame buildings. It is permissible to install wooden logs on top of metal or wooden floor beams. Typically, wooden joists are used in houses with a timber frame;

- buildings of any design made of “heavy” building materials (brick, concrete, reinforced concrete, stone) for the purpose of leveling and insulating the floor. This option is optimal if it is undesirable to increase the load on the floors and load-bearing walls (columns) that the concrete screed provides.

If the building does not have basements and there is soil under the finished floor, laying wooden logs is the best option to ensure warmth and dryness in the room.

Each option for using floors on joists has its own installation and further use nuances.

Advantages of installing floors on joists

Logs installed as a support on a wooden floor are very functional. In addition to their direct responsibilities, they also:

- create a uniform load on the ground in a private house and the floor (if the floor is laid in an apartment building);

- level the surface under the covering (adjustable floors can be raised or lowered with your own hands to create a perfectly flat surface, regardless of the initial parameters of the room);

- create a free, ventilated space between the ceiling and the floor in which communications that are undesirable for public viewing can be hidden;

- increase the sound insulation of the room;

- facilitate the procedure of floor insulation.

In addition, individual joist bars can be easily replaced if necessary, without spending money on large-scale renovations in the house.

Detailed step-by-step instructions

Few people know that before assembling the lower flooring, you need to take care of the ventilation of the subfloor. To do this, experts recommend drilling several large holes in the corners of the building. They can then be covered with a grill. Then the entire subfloor is treated with an antiseptic.

Stage No. 1 – preparing the logs

What are lags? These are bars that are used to assemble the finished floor in a wooden house. Wood of the second and even third grade can be used as them. Since such logs often do not have a very smooth surface, it is worth modifying them a little. To do this, the side on which the floor covering will be attached is leveled with an ax.

You don’t need to try too hard, but you will have to try to make the log even in this area. The horizontality of the future floor will depend on this. After engraving, the logs are completely covered with an antiseptic. They can be installed in two ways - on the ceiling and on the base.

By overlap

Long logs must be properly installed and secured. To do this on the ceiling, you must first make grooves in the lower frame of the walls, the depth of which is equal to the width of the bars. Planed logs should lie flat in them. But first, it is advisable to put a rubber gasket on the ends. It will dampen unnecessary noise.

A heavy beam will not be supported on some grooves, so it needs to be supported with reliable support. Brick pillars will serve as it. They are assembled as follows. At the same distance from each other along the line of the logs, holes are dug (20x20x40). A layer of gravel is poured onto their bottom and compacted. The next layer is made of sand, which also needs to be compacted well. A square of reinforcing mesh is laid out on the bottom.

The pit is filled with cement-sand mortar. To prepare it you will need cement, sand and water (proportions 1x3x0.5 liters). After the concrete has dried, a layer of roofing material is laid on top, and only then a brick pillar is built on it.

The distance between the joists depends on what boards are used for the finishing flooring. The principle of arrangement is this: the thinner the board, the more often the logs are installed. It is impossible to lay the timber directly on the erected supports; waterproofing material must be laid again between them.

Based on

Construction of rough floors

It is also possible to construct a subfloor on joists along the base. To do this, the top loose layer of soil is cut off, leveled and covered with crushed stone. The fine-grained material is carefully compacted. And only then the location of the logs is marked. You can’t put them on crushed stone; you need reliable supports. They most often use a grillage wrapped in roofing material or bottom trim beams.

In this case, the support pillars are also installed on the foundation. It is built using the same technology as for brick supports. A layer of waterproofing is laid on top of it, and only then the logs are installed. It is attached to the post with dowels, corners and self-tapping screws. You can lay logs in this way in a brick house.

Stage No. 3 – fasten the timber

After installing the logs, installation of the lower flooring begins. To do this, the support is first assembled. It uses timber with a section of 50×40. It is attached to the bottom of the joists on both sides. For these purposes, experts recommend purchasing not ready-made bars, but a board (150×40), which can then be cut into three parts. This will save you a lot of money when assembling subfloors. Three shards will be obtained from one such board.

Next, you need to decide what to make the floors of the house from, what to use as a subfloor. It is much easier for a beginner to work with ready-made sheet materials - plywood, OSB sheets or chipboard. It is better to choose 12 mm thick sheets for these purposes and lay them in two layers.

To securely fasten them, a sheathing is assembled, which is formed from additional transverse bars and attached to the lower base of the support beam. The joints of the sheets in this case should lie on the central axis of the transverse jumpers.

Experienced craftsmen recommend using low-quality material to assemble a rough foundation in a private home. A waste board, slab or picket fence is best suited for these purposes. Why? The lower base actively reacts to changes in temperature and humidity. The listed material easily changes its shape, so it performs very well in such aggressive environments.

Having completed the described work, you can begin laying the insulation. But first, a layer of waterproofing is laid on the lower base. This can be an ordinary polyethylene film, which covers the entire base, forming niches for laying the heat-insulating layer.

Fixation methods

Basically, four fastening methods are used to fix joists on a concrete floor. Therefore, if you do not know how to attach joists to a concrete floor, then after studying all these methods you will understand this issue.

Fixation with self-tapping screws

This method is considered simple, but it is not suitable for all cases.

- First you need to prepare the concrete surface. To do this, it is cleared of debris (it is allowed to use a vacuum cleaner). Then they repair cracks, chips and other defects with cement mortar or polyurethane foam.

- Next, in the logs (treated with antiseptics) you need to drill holes with a drill to install plastic dowels. Then you need to drill counter holes in the concrete using a hammer drill.

- Then the dowels are driven into the concrete with hammer blows, and then self-tapping screws are screwed into them with a screwdriver. Moreover, the head of the screw is driven into the hole 2-3 cm.

Fixation with anchors

Anchors securely fix the beams to the concrete, so this method is the most reliable. In addition, such fasteners help to restrain the deformation of wooden logs if they are not dried well. But the boards laid on them can sag, so it is necessary to install spacers more often.

- First, you also need to prepare the concrete floor (remove debris from it and repair all defects with mortar).

- After which it is necessary to make through holes in the timber (treated with antiseptics) with an electric drill.

- Next, you need to drill holes in the concrete opposite each hole with a hammer drill.

- Then the anchors are mounted on a concrete base and tightened with keys. The main thing here is not to overtighten the bolt, because this will cause the beam to bend. This is especially true for those places where there is a gap.

Before installing the anchors, trenches (small recesses) are made in the joists to hide the bolt heads.

Anchors need to be installed every 600-1000 mm. This distance is selected taking into account the partial immersion of the anchors in concrete (approximately 60 mm). Many people fix the beams to the concrete with 4-5 anchors ⌀ 10 mm.

How to independently calculate the required distance between lags?

When you install a floor on logs, use the rule: the thicker the floor board, the wider the installation and the farther apart the logs are located.

For example, for a board whose size is 5 cm, you can make a step (the distance between the lags) of one and a half meters.

If you use thin boards, you can take small steps so that the board does not sag. The most common step length between joists is 50-70 cm.

Also keep in mind that you will need additional space to make it convenient to lay the insulation inside. If the size of the base does not correspond to the values in the table, then it is calculated upward.

Technology for self-production of logs and selection of wood

Logs can be purchased at the store, or you can make them yourself. The second option will be relatively cheaper. Wood with a moisture content of no more than 15-17%, 2nd or 3rd grade, is best suited for these purposes. Logs can be made from pine, fir, spruce, aspen and larch.

If you make the logs yourself, keep in mind that the cross-section of the beam should be rectangular. The height is approximately twice the width . The required size is determined based on the parameters of the room, to be more precise: based on the exact distance between the links of the timber frame.

The size of the bars depends on the distance between the strapping links

In addition, it is necessary to take into account the thickness of the insulating layer and the size of the spans. In the illustration you can see approximate calculations with laying lags at a distance of 70 cm from each other.

If your room has an intermediate size between the indicated values, you should take a larger value as a basis. This way you will have a certain supply of material, which will allow you to lay it without gaps and make the structure more durable.

To make a wooden floor with your own hands, you can use both edged and tongue-and-groove boards. The second option is much preferable, because its design involves a groove and a tenon, therefore, installing a fine finishing coating is no longer so relevant.

It is preferable to use tongue and groove boards due to the tongue-and-groove system

You can use floorboards made of cedar, larch, spruce, aspen and pine. The most expensive and durable materials are solid oak and pine: provided that the installation is carried out correctly, they will last for several decades. In turn, larch is excellent for rooms with high humidity, because it is not susceptible to rotting, and healthy aspen and alder boards are great for sleeping areas.

Oak and pine boards will last a long time

If you purchase first-grade floorboards, you don’t have to spend money on the final flooring, and at the final stage simply sand the boards and varnish them.

The main thing is that before laying, be sure to treat the boards with antiseptic antifungal preparations and impregnate them with a water-repellent composition..

If you are installing a wooden floor with your own hands, be careful when choosing wood: the boards should be dry, but not overdried. Wet wood, after drying and under the pressure of furniture, can become deformed. Always buy boards with a margin of 15-20% in case of need for trimming, mistakes and defects.

Wooden flooring material - features

Wooden floors are the oldest, time-tested and many generations, reliable, practical and aesthetically attractive structures. Modern manufacturers offer a wide range of wooden floors to suit every taste, color and budget. Modern material for finishing coating can be made entirely of wood or contain it in one percentage or another. Undoubtedly, a floor made from solid wood is reliable and durable; it looks luxurious and noble, especially if the natural pattern on its surface is correctly emphasized.

Parquet board in the living room interior

Benefits of wooden floors

Natural wood on the floor transforms the premises of the apartment and speaks of its owner’s taste and wealth. The natural shade creates a warm, cozy atmosphere. The advantages of a wooden floor include the following:

- The natural origin of the material and its unique structure have a positive effect on the creation of optimal microclimatic parameters in a residential area. Wood is able to absorb and release moisture, thereby regulating the humidity in the room.

- Wood does not cause allergic reactions, it is environmentally friendly, does not contain or release chemical compounds and toxins into the environment.

- Thanks to its heterogeneous structure, wood provides excellent sound and heat insulation for a room.

- A wide selection of textures, natural patterns and shades allows you to choose a wooden floor for any interior.

- Plank floors are resistant to mechanical stress and can last for decades if the installation technology is followed.

No artificial material can compare with the rich, natural texture of natural wood.

Such disadvantages as creaking and gaps between boards are not observed if the technology for preparing the base and laying the boards is followed. And when using a tongue and groove board, the junction of individual elements is as tight as possible, eliminating the formation of gaps.

Varnishing the surface will ensure moisture resistance and durability of the wooden covering.

How important is the type of wood?

When choosing a wooden floor, not only the external characteristics of the material are taken into account, but also the type of wood from which it is made. The ability to resist environmental influences is influenced by the density of the wood - the denser it is, the more stable it is. Depending on the operating conditions, materials of different qualities are suitable:

- In the bedroom, traffic is low and the risk of dropping something heavy on the floor is minimal, so you can safely choose soft wood.

- The living room is a common room with a high level of traffic - guests are received here and the whole family gathers, sometimes holidays are held, so the floor surface must be stable and aesthetically attractive. In this case, a coating made of walnut, ash or oak is suitable.

- The kitchen and hallway are special rooms with serious operating loads, so the floor material must be resistant to dirt, moisture, mechanical stress and temperature changes.

- The subfloor structure is made from coniferous wood - this material is least susceptible to rotting, as it contains natural antiseptic substances.

- Larch, linden and aspen are used for flooring in bathrooms, baths and saunas. These types of wood are not afraid of moisture, do not deform due to temperature changes and do not release resin when heated.

Oak floor in the kitchen

An unusual floor covering can be obtained by using exotic wood species that have an original appearance and useful properties. This wood is resistant to moisture, very hard and durable. Teak, rosewood, lapacho, morado, merbau, and jatoba are used to make flooring.

Rosewood board

Types of floors

Diagram of a single and double plank floor

Before starting work, you should decide what design the main covering will have.

Among the most popular types, it is necessary to highlight the following types of floors:

- single;

- double;

- concrete.

The choice of each of them is determined by the design features of the building in which future installation is planned, and the conditions of further operation.

Preparatory work

When choosing materials and methods of floor installation, you should first pay attention to the average soil moisture under the house. In some residential areas, logs are laid on the ground, with cut-off waterproofing laid under them. Such floors reliably last for several decades, but such dehydrated soils are quite rare.

Below we will consider a method of preparing the foundation, which is used almost everywhere in our area. The whole point of this method is to install a concrete screed on a waterproofing pad. In a country house, a concrete screed will serve two functions at once: to insulate the floor from moisture and to serve as a rigid foundation for a wooden floor.

When starting to lay out a concrete base for a wooden floor, you must make a small pit in the house and carefully compact its bottom. A layer of sand 20 mm thick or more must be poured into the hole. You can also add an additional layer of crushed stone under the sand, but this step is often skipped. After you have made the sand cushion, cover it with a cut-off waterproofing material, which can be used as cellophane film or roofing felt. It makes no sense to use vapor-permeable waterproofing, because its properties are not needed at this stage, and the overpayment will be significant.

Decoration

The floorboards in the house should be in harmony with the interior, so it is rarely left without a finishing coating, which also protects the wood from damage, discoloration, moisture and dirt. To do this, use various tinting compounds that do not hide the texture of the wood, or covering paints.

Tinting allows you to imitate any type of wood. You can change the tone using stains, impregnations, oils, wax, varnish.

Paints provide even more scope for designers. You just need to discard stereotypes and forget that a wooden floor can only be brown.

- White, light gray, beige and other light shades of the floor make the interior light, airy, and clean.

- Black color fits many modern styles, but you need to keep in mind that dust on it is much more noticeable than on a light-colored coating.

- Bright floor shades look great with light walls in minimalist interiors.

You can also paint the floorboards in different colors, create simple patterns on the floor using masking tape or patterns using a stencil.

Non-standard floor design Source systemautepleniya.com

In short, there are many options for decorating plank flooring. During the next repair, you can cycle it and change the decor.

Installation of adjustable subfloors

When installing a subfloor, you also need to take into account several features

Be sure to pay attention to whether your screed requires repair. Assess what kind of repairs need to be made

If the soil under the screed has subsided and it is skewed, it is accordingly necessary to install logs that will be adjustable.

You can also make a plywood floor as a rough flooring, which can also be used to adjust the level. These methods are used in old buildings where it is not possible to pour a screed, since the floors are not reliable and may not withstand heavy loads.