Caulking (caulking) is the process of sealing cracks and gaps that form between logs or beams during the construction of a wooden house. This is part of the work that is mandatory during the construction of any wooden building. Refusal to carry it out is guaranteed to cause:

- moisture getting into the gaps between logs or beams; the appearance of drafts in the finished house; loss of control over thermoregulation; the development of mold and fungi in the crown joints and corners.

Needless to say, all this will significantly shorten the life of any wooden house and significantly reduce the comfort of living in it. High-quality caulking will eliminate not only the above problems, but will also help level out the building’s distortion due to its uneven shrinkage.

How to do caulking. Types of insulation.

Caulking of a timber or log house must be carried out outside and inside the building for the best effect. Today, there are several types of thermal insulation materials - classic and modern. The classic ones include:

- moss – has antiseptic properties, is environmentally friendly, but quite expensive; tow – a waste product from the primary processing of flax or hemp. Not the best option for caulking. It is difficult to work with, it attracts pests and tends to absorb moisture, which is extremely undesirable for a log house.

Modern thermal insulation materials include:

- flax wool - made from flax production waste with the addition of synthetic fibers; sealant - a material based on petroleum products. It comes in the form of a gel, paste, in briquettes (rubber sealants) or a rope (polyethylene foam); jute is the most popular natural sealant, which is made from the fibers of the plant of the same name. It does not absorb excess moisture, is durable and inexpensive.

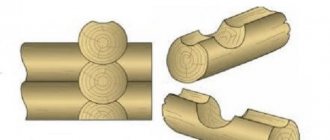

The caulking process is carried out in two stages: Stage 1. Primary caulking. It is carried out at the construction stage during the assembly of the house: before laying the next row of logs or beams, thermal insulation material is laid “in a stretch” or “in a set” on the previous one.

In the first case, the insulation is laid lengthwise, in the second - across the logs. When laying “in a set”, the insulation is laid in sections so that its edges protrude from the seams by 0.5 - 1 cm.

These edges are used in the second stage of caulking. Stage 2. Final (secondary) caulking The procedure is more labor-intensive. It is carried out 8-12 months after the construction of the house.

This is done to ensure that the building settles. The edges of the thermal insulation that remain after the initial caulking “as a set” are rolled up with a roller and driven into the crown joints using a special tool. If the initial caulking was carried out “in a stretched manner,” then additional insulating material is hammered into the gaps.

Execution of work

Caulking of log houses or beams is a labor-intensive task that is performed entirely by hand. There are no devices that mechanize such work. This process is long and quite difficult; the master performs it only with his own hands.

Caulkers are a special specialty in wood construction. The caulking team consists of several physically resilient and strong men who perform caulking exclusively.

Since these masters are not involved in other types of work, they reach the pinnacle of mastery in their specialization and have the highest qualifications. If possible, you should definitely use the services of such a team, since everything is done quickly and with the highest quality.

It is quite clear that a team of caulkers has at its disposal the entire necessary set of tools to carry out caulking of a log house of any complexity:

- in the presence of any material for sealing the seams of the log house;

- different sizes of seams;

- different types of wood for wooden buildings;

- the need to seal seams in complex elements.

Every stage of work is important. It is impossible to neglect caulking, on which the warmth and comfort of living in the house depends. It is impossible to do without it in wooden construction.

When is it necessary to caulk and is it possible to caulk in winter?

To carry out high-quality caulking, the logs (beams) must be dry (wood moisture content should not exceed 20%). Several conditions must also be met:

- Secondary caulking should not be carried out earlier than 8-12 months after the construction of the house; The procedure can only be carried out in dry weather at an air temperature of at least 10 * C; Rain and snow must be avoided, as they can lead to wetting of the insulating material and subsequent entry of moisture into gaps between logs.

It is also worth noting that all external and internal finishing work should be carried out after secondary caulking, because after it is carried out, the height of the building may increase by several centimeters.

Tow

This material is waste generated after the primary processing of natural fibers.

The logs are caulked with jute, hemp and flax tow. The properties and quality of such material are determined by the raw materials, the length of the fibers and the level of their purification. During production, tow is pressed into blocks. To use it, you need to pull a strip of material from the block, twist it into a rope and place it in the seam.

Although, it is easier to use tow sold in rolls.

In general, tow is not very convenient to work with, since it is very difficult to get an even seam. When caulking a log house, due to the high rigidity of the material, it is difficult to obtain a tight seam from the first approach. We have to resort to a repeat process.

If you decide how to properly caulk a bathhouse by choosing between moss and jute tow, then you can confidently say that it is better to choose moss, since it does not harbor fungus and bacteria.

What do we offer?

Considering the complexity and painstakingness of the caulking process, our team is happy to provide caulking services for any wooden structure made of timber and logs: houses, cottages, churches, bathhouses, cafes, restaurants. Our craftsmen perform caulking only by hand and are ready to provide high-quality services using any insulating materials. To estimate the volume and cost of work, you can order a free call to a specialist.

You can request a call by phone or through the form on the website. Our employee will help you assess the general condition of the house, draw up a detailed estimate of the upcoming work, taking into account your wishes, and help you determine the best solution when choosing insulation. Contact us, we are always happy to cooperate!

Houses made of timber are durable, strong, beautiful, warm, and not very expensive.

But they need exterior finishing. During construction, very small gaps remain between the beams. No matter how hard you try to lay them tighter, these gaps will still remain.

They are dangerous because excess moisture penetrates into the house through them and the wind blows. As a result, the building will soon require renovation. To prevent this from happening, the structure must be caulked.

Caulking tool.

Caulking a house made of timber increases the service life of the building, protects it from the negative influence of the external environment, and makes the house warmer. It is necessary regardless of what material it is made of - rounded, glued or profiled timber. The structure is subject to shrinkage, so after some time the gaps between the logs may increase.

Felt, moss, jute, hemp and tow are used for caulking.

Methods for caulking a house made of timber.

All these materials have common properties:

- natural; retain heat in the room; parasites do not like them; allow the house to “breathe”; long service life (more than 20 years); do not absorb moisture.

Felt is a linen material in the form of a ribbon. Moss - sphagnum, grows in a swamp, was previously used in villages and villages, you can collect it yourself.

Jute - made from the jute plant, which grows in tropical climates. Hemp is hemp fiber. Tow is the remains of flax from the production of ropes; it looks like hair.

Materials used for caulking a log house

In order to choose the right material for caulking, you need to know the properties that it should have (or at least most of them).

These are properties such as:

- high thermal insulation performance;

- moisture resistance and resistance to temperature changes (the material works under constant atmospheric influences);

- harmless to the human body;

- resistance to processes such as rotting and mold formation, as well as “uninteresting” for rodents and parasites;

- resistance to mechanical damage;

- no pungent odor;

- relative durability (at least 20 years) while maintaining performance characteristics.

All materials used to insulate a log house are divided into two groups: natural and synthetic.

Caulking stages

You can caulk houses made of timber immediately during construction or after 6-12 months, that is, after the building shrinks, in warm, dry weather. You can plug cracks in 2 ways: by stretching - tapes are made from the material, which are compacted into the spaces between the logs; in a set - they make ribbons, wind them into a ball and collect loops from it, and then use them to seal the gaps.

Caulk at home.

It is necessary to seal cracks not only from the outside, but also from the inside of the building.

First you need to calculate the required amount of material: add up the length of all the seams, and increase the resulting value by 2-3 times. Caulking of timber is done on all walls of the building. There is no point in insulating only one, as this will not protect against external influences.

To insulate the gaps between logs, you will need the following tools:

- tape measure; steel spatulas of different sizes with a wide and narrow flat blade; rubber mallet.

You need to start working from the bottom seam. Moreover, you need to seal it around the entire perimeter of the house, and not just on one wall.

You can choose any method of caulking the building. You need to take a piece of material and compact it into the walls using metal shovels. Where the logs are very close to each other, you need to use a rubber hammer to compact them.

First, the walls are caulked from the outside, and then from the inside. Remember that you need to seal the joints between the beams along the entire length. Be careful and careful, you can accidentally increase the gaps between the logs so that it will be difficult to close them with insulation.

The process of caulking walls made of profiled timber differs from rounded timber. The first type of logs has a rectangular shape: one side is flat, the other is figured (there are grooves).

Many people think that houses made of such material do not need to be caulked, but this is not true. Sometimes cracks are plugged twice: during construction and after shrinkage. Unlike profiled timber, rounded timber has a rounded shape on all sides, but the contact area of the logs is much smaller, so caulking will require more material.

Houses made of timber are durable, strong, beautiful, warm, and not very expensive.

But they need exterior finishing. During construction, very small gaps remain between the beams. No matter how hard you try to lay them tighter, these gaps will still remain.

They are dangerous because excess moisture penetrates into the house through them and the wind blows. As a result, the building will soon require renovation. To prevent this from happening, the structure must be caulked.

Caulking tool.

Caulking a house made of timber increases the service life of the building, protects it from the negative influence of the external environment, and makes the house warmer. It is necessary regardless of what material it is made of - rounded, glued or profiled timber. The structure is subject to shrinkage, so after some time the gaps between the logs may increase.

Felt, moss, jute, hemp and tow are used for caulking.

Methods for caulking a house made of timber.

All these materials have common properties:

- natural; retain heat in the room; parasites do not like them; allow the house to “breathe”; long service life (more than 20 years); do not absorb moisture.

Felt is a linen material in the form of a ribbon. Moss - sphagnum, grows in a swamp, was previously used in villages and villages, you can collect it yourself.

Jute - made from the jute plant, which grows in tropical climates. Hemp is hemp fiber. Tow is the remains of flax from the production of ropes; it looks like hair.

The final stages are sanding and finishing.

After the construction is completed, sanding will help give the log house a beautiful appearance; the log house should already have caulking by then. This is done with a special tool - grinding machines. Their design can be different - tape or disk. Special attachments for hard-to-reach places are also present.

This work is important, as it will remove excess roughness, the pattern of the wood will appear more clearly, and the practical value is also great - wet dirt is removed, which in the future can open the way for bacteria and mold that are pathogenic to the tree.

In order to start sanding, you need to follow the same rules as for caulking - dry and clean. At the same time, try to ensure that not a single piece of material interferes with further work, so going through it again with a spatula will not be superfluous.

You also need to stock up on sandpaper if there are no attachments for corners. But this is for independent use - contracting teams usually have everything they need.

After the sanding is completed, special compounds - varnish, paint and others - will help to fix it. They will not paint over the natural pattern, they will simply make the logs or beams stronger.

Since there will be repeated caulking and the next one after the shrinkage of the house, in 3-5 years, it is carried out without additional sanding - the gloss of the wood will not be lost.

Caulking stages

You can caulk houses made of timber immediately during construction or after 6-12 months, that is, after the building shrinks, in warm, dry weather. You can plug cracks in 2 ways: by stretching - tapes are made from the material, which are compacted into the spaces between the logs; in a set - they make ribbons, wind them into a ball and collect loops from it, and then use them to seal the gaps.

Caulk at home.

It is necessary to seal cracks not only from the outside, but also from the inside of the building.

First you need to calculate the required amount of material: add up the length of all the seams, and increase the resulting value by 2-3 times. Caulking of timber is done on all walls of the building. There is no point in insulating only one, as this will not protect against external influences.

To insulate the gaps between logs, you will need the following tools:

- tape measure; steel spatulas of different sizes with a wide and narrow flat blade; rubber mallet.

You need to start working from the bottom seam. Moreover, you need to seal it around the entire perimeter of the house, and not just on one wall.

You can choose any method of caulking the building. You need to take a piece of material and compact it into the walls using metal shovels. Where the logs are very close to each other, you need to use a rubber hammer to compact them.

First, the walls are caulked from the outside, and then from the inside. Remember that you need to seal the joints between the beams along the entire length. Be careful and careful, you can accidentally increase the gaps between the logs so that it will be difficult to close them with insulation.

The process of caulking walls made of profiled timber differs from rounded timber. The first type of logs has a rectangular shape: one side is flat, the other is figured (there are grooves).

Many people think that houses made of such material do not need to be caulked, but this is not true. Sometimes cracks are plugged twice: during construction and after shrinkage. Unlike profiled timber, rounded timber has a rounded shape on all sides, but the contact area of the logs is much smaller, so caulking will require more material.

The word "caulking" is usually found in construction. It means the procedure for sealing cracks and gaps that form between logs and beams.

In addition, this word means a tool for caulking a log house. Today it can be found in several varieties. The caulking tool is a special wooden device or a metal spatula.

In appearance they can be compared to a handle with a sharpened blade. When caulking walls, other tools are also used - a large hardwood hammer (mallet). It must be used to hit the caulk so that the insulation fits tightly to the logs or beams.

video on how to caulk with a hammer drill, tool and what is better, photo of tow, log house

Thanks to the caulking of a log house, the thermal insulation qualities of the structure can be improved. Log houses are beautiful and very original buildings. They are made from logs and look massive and reliable. At the moment, it is especially popular to make a bathhouse from such material. However, as you yourself understand, the cost of such buildings is high. Therefore, owners are unlikely to insulate walls using classic methods that cover logs. So what should you do, since heat preservation is especially important in a bathhouse? And this is where the centuries-proven method of caulking comes to the rescue. What is it and how to make such insulation - read on.

How to caulk a log bathhouse

Caulking a log house is filling the cracks between the logs with a special material. Due to this, the building is partially sealed and cold air stops entering the room. Since wood is a poor conductor of heat, caulking is sufficient for making log houses.

Despite the fact that the construction industry is moving forward by leaps and bounds, the best material for caulking is considered to be the material that was used by our ancestors three hundred years ago.

Before caulking the cracks of the bathhouse, you need to decide on a material that is suitable for these purposes. The list is not as long as it might seem since not all materials are suitable for a bath.

Material for caulking a log house can be purchased at a hardware store.

What material is better to caulk a bathhouse:

- Linen wool is good because it has high thermal insulation properties, perfectly absorbs and releases moisture. However, such material has a service life of only three years, and is treated with chemical compounds that can evaporate when heated.

- Tow is a very good option for a bathhouse. It is inexpensive, has excellent thermal insulation qualities and is easy to use. However, the service life of tow is only three years, after which the old material is removed and replaced with new one.

- Jute is a moisture-resistant and durable material that has excellent thermal insulation properties. However, it is better not to use flax-jute for a bath. Opt for jute felt or jute tow. Jute caulking is very often used for baths.

- Swamp red and white moss is the best material for caulking baths, which has been used for several centuries. It does not have any disadvantages, except for the difficulty of caulking with moss.

- A house made of timber can be caulked with sealant. This method is reliable and durable, but not environmentally friendly. In addition, the composition applied between the logs hardens into a durable monolithic substance.

From everything described, we can conclude that the best candidates for caulking baths are: moss, jute, and tow. And exactly in the order in which we have now placed them. That is, they wait first. That is why we will analyze caulk using the three presented materials.

Tool for caulking a log house

First of all, to caulk a log house you need a suitable tool. In most cases, caulking a log house cannot be done with what you already have at home.

Sometimes, you can transform a variety of things into the household items you need. Perhaps this way you can replace absolutely all the tools.

So, we come directly to the definition with the tools that you need to caulk a log house. By the way, most of them can be carved from wood with your own hands.

Tool for caulking a log frame:

- To seal the cracks between logs, you need caulking. This is a spatula with a flat blade of 10 cm and a thickness of 0.5.

- A curved blade is needed to hammer insulation into the most inaccessible places of the timber. Its width is 6 cm and length 0.5 cm.

- The road worker helps to insert a decorative tape into the frame, covering the main layer of insulation. This tool is big.

- Breaking caulking is a narrow wedge that helps to widen the narrow gaps between the beams of the bathhouse. Sometimes it is replaced with a hammer drill.

- A wooden hammer is another required attribute when caulking a bathhouse.

When working with tools, you must follow safety regulations

As you can see, most of the necessary tools can be made with your own hands. However, they are freely available at any hardware store.

How to caulk a bathhouse with tow

Tow is one of the cheapest materials for caulking a bathhouse log. At the same time, it is considered truly suitable. This material does not emit harmful compounds and is absolutely environmentally friendly. It is easy to use for caulking and such work can be done very quickly.

In winter, a log bathhouse is not caulked. The best time for this is the warm and dry season, that is, summer. At this time, you will be able to complete all the work quickly, and the material used will last for many years.

We want to warn you in advance that the service life of tow is only three years. Then the material will have to be removed from the cracks between the beams and caulked again.

How to caulk a log house with tow correctly:

- The first step is to treat the tow in a special solution. This is done to prevent moths and other insects from infesting the material. The best solution for these purposes is formalin solution, which can be purchased at a pharmacy. The tow is soaked in this solution for half an hour.

- Treated tow can be used immediately. However, it is better to let it dry a little. In this case, it will be easier for you to carry out all the necessary actions.

- A piece of rolled tow is carefully placed into the gap between the logs using a spatula. Next, using the same tool, a curved spatula, and a wooden hammer, the insulation is driven deeper into the cracks. If the gap is too narrow, then a splitter is used.

The material is collected only one tier at a time. Step by step you must caulk the entire bathhouse. If you caulk each side of the bathhouse separately, the building may become warped.

You should caulk a bathhouse yourself after carefully studying the recommendations of specialists and watching a training video

It's easy to caulk the tow. Especially if you purchased the material in rolls. Such work can be done quite quickly. However, you should not expect that it will take you only one day to caulk the entire building. This is only possible if you have several assistants with their own tools.

Instructions: how to caulk a bathhouse with jute

Jute is quite expensive. You will have to spend a considerable amount on a bathhouse. But such material will last you longer than tow.

As we have already said, jute felt is best suited for caulking a bathhouse. You will have to buy a special resin for it.

It is best to use ready-made jute cord. This material does not require preliminary twisting. It looks great and adds originality to the bathhouse. If you use jute tow, you must first soak it in a formaldehyde solution. After this, the material is dried for half an hour.

The technique for laying tow, regardless of whether it is jute or not, is always the same. Therefore, we will tell you how to caulk a bathhouse using a jute cord in a kit.

How to make caulk in a bathhouse using jute cord:

- The jute rope needs to be folded into loops. Such a cord is pushed with caulking into the gap between the beams. Before this, all gaps are cleared of dust and wood chips.

- Now the jute cords are pushed as firmly as possible along the top and then along the bottom edge. To do this, use a hammer and a curved caulk.

- A strand without loops is placed on top. It is leveled by a road worker. This is done to make the bath decorative.

It is better to caulk a bathhouse with jute in dry weather

Such caulking not only perfectly insulates the log house, but also gives it a decorative effect. That’s why builders like to use it to design a bathhouse.

Step-by-step instructions: how to caulk a log house with moss

Moss is the most expensive, but the most environmentally friendly and durable type of insulation. A bathhouse caulked with such material looks very original. Therefore, if you have the means for this, be sure to use this type of insulation.

Caulking bath with moss:

- Add two hundred grams of liquid soap and half a liter of oil to a bucket of water. Soak the brain in this solution for half an hour.

- Take out the insulation in bunches and twist it into bundles. Each bundle is inserted into the gaps between the logs and compacted using a hammer and caulking.

- Process the bath from bottom to top. Gradually, in rows, all sides at the same time.

The moss caulk in your sauna will serve you for many years. However, you will have to spend a lot of money on this.

Caulking a log house using a hammer drill (video)

Caulking a bathhouse is working with natural insulation. This activity cannot be called difficult, but it is considered lengthy. However, if you do everything right, you will get a beautiful and warm bathhouse with an original appearance!

Examples of tow (photo)

Attention, TODAY only!

oteplicah.ru

Types of tools

Various types of tools are used for caulking. Construction of a house from timber by professionals involves the use of a basic type of caulk.

It has a flattened shape and a blade measuring 10 cm in length and 0.5 cm in width. Its main purpose is to seal seams. When caulking corners, another type of caulk is used - a curved tool.

It is equipped with a blade 0.5 cm thick and 5 cm long.

For caulking in hard-to-reach places, for example, building a house from profiled timber, a broken blade-shaped caulk is used. With its help, you can widen narrow grooves and fill them with insulation. The main caulking tool also has another name - a typesetting tool.

It has an additional classification depending on the area of the surface being treated - large, medium, narrow. Such tools for caulking log houses have a longitudinal groove located opposite the blade. Thanks to this, the insulation penetrates even further into the voids.

What tool is needed for caulking a log house and how it is used is described in more detail in the video:

Mechanical caulking method

We will talk about such work as caulking a log house with a hammer drill. It’s worth mentioning right away that even professionals who are venerable in wood processing do not allow such actions. This is the sin of construction crews, for whom time is money. Therefore, if the owner of a building is offered this method of caulking, it is better to refuse and do everything yourself in six months - then the house will begin to shrink.

What this represents is that the corresponding attachments are put on the hammer drill and, using frequent chiselling, the material for compaction is placed on the intended seams. Plus, and this is the only one - the work is done as quickly as possible.

The downside is that the surface and structure of the wood are damaged by powerful mechanical effects. And this will be followed by cracks and other troubles.

"Tool City"

The building materials store “City of Tools” has been working in the construction market for a long time.

The store unites a professional team consisting of managers with extensive experience and sales specialists. The company offers an individual approach to each client. Advantages of "Tool City":

- A wide range only from leading specialists; Activities are carried out only with official representatives of well-known manufacturers. For this reason, you can have no doubt about the quality of the products; Well-functioning and efficient system for accepting and placing orders; Reliable and fast delivery service.

You can buy caulking tools in this store at an attractive price.

The main office is located at: Moscow, Devyataya Rota street, building 7-A, office 107. For any questions, please call: +7.

How to make a log house correctly

Unfortunately, without this additional procedure it is impossible to achieve a normal microclimate in a wooden house.

Our ancestors came up with an effective way to deal with uninvited “fickle” guests. To do this, write down the rope with your own hands: after the trailer structure in the house, the room is tightly packed with insulating material on a natural basis (for example, moss, hemp, yarn).

Then the wooden cottage was completely protected from the weather, and the thermally insulated seams adequately played the role of a protective “jacket”.

Until now, the ancient technology is still in process, only the tools and materials for the work have been improved.

Builders systematized this process by developing two algorithms for constructing poles.

"Winter House"

Construction offers to purchase tools for caulking both wholesale and retail. There are several types of tools available, so you can choose the one you need. The company cooperates only with trusted manufacturers; products are inspected and tested for quality before being put up for sale.

Thanks to such precautionary measures, you can purchase caulk at an attractive price and of good quality. To purchase products, you can visit the store or call and place an order with the help of a manager.

Fast and reliable delivery is guaranteed. The store is located at the address: Moscow region, Balashikha, Sovetskaya str., 35. If you have any questions, please contact us by phone.

Why do you need to caulk a log house?

The process of caulking is the insulation of a log house by sealing the cracks between adjacent logs. Most often, log houses are used as bathhouses, and so that the steam room warms up faster and you can wash in it even in winter, it needs to be properly caulked.

During caulking, a compactor is placed between the logs Source koon.ru

Here are the main problems that log caulking helps solve:

- Presence of gaps between individual logs

- The appearance of drafts and condensation

- Rotting and premature destruction of wood

In addition, if we talk about a bathhouse, then less fuel will be required to heat a caulked room.

"Caulker"

Caulking is a special tool for caulking a timber house, available in several varieties. All of them have common requirements - their blades should not be sharp, otherwise the insulation used will be damaged. There should be no rough spots on them, as materials could get caught on them and be removed from the groove.

You can purchase high-quality tools for caulking a timber frame, where all these requirements are met, in the Caulker hardware store.

This company has been operating in the construction market for several years. During this time, she worked with many tool manufacturers, and as a result, continues to cooperate only with a few reputable ones that offer several options for purchasing tools:

- Independent purchase by coming to the office; Order via the Internet; Call the manager and purchase with his help.

In any case, you will be able to receive high-quality service and fast receipt of goods. The store is located at: Moscow, st.

Polymernaya, 8; Art. Perovo metro station. To order, please call 6.

Basic recommendations

All types of blades should not be sharp, as a blade that is too sharp will cut tow, jute and other caulking materials. Wooden blades are made from wood that is slightly softer than log wood. A tool that is too hard will leave marks on the logs and crush the caulking material.

The blades of the blades must be perfectly smooth, free from burrs, roughness and other defects. If the shovel is flawed, the caulking material will catch on its irregularities and, instead of being pushed between the logs, will come out again.

"Flax and Jute"

All work on caulking a house made of timber cannot be carried out without the use of a special tool - a caulking machine.

It comes in several varieties, each of which can be purchased at a reasonable cost at the Flax and Jute hardware store. Construction materials are purchased only from a reliable manufacturer. The range includes both metal and hardwood products.

Thanks to the high-quality manufacturing of tools, it is possible to achieve the tightest possible fit of the insulating material to the beams or logs. The store is located at: Novosibirsk region, p.

Baryshevo, st. Lenina, 247. Contact by phone: +7(383)297-62-26.

Do-it-yourself log caulking technology

The technology for caulking a log house with your own hands is quite complex, although you can’t tell it from the outside. As we said earlier, when caulking a log house, the structure becomes 7-10 cm higher, so you need to caulk it evenly and correctly.

You should know that no finishing activities should be carried out before caulking the log house, because... during lifting of the structure they will be immediately damaged.

Proper caulking of a log house involves insulating the inter-crown space in tiers (from lower to upper). First, we caulk the very bottom joint (between the first and second crown). This must be done along the perimeter, starting from one corner and ending with it. As soon as the tier is insulated, you need to move to the overlying crown.

It should be noted that experienced builders can straighten a skewed frame using only caulking.

When caulking a log house, it is necessary to carefully hammer in the insulation at the corners, because These nodes need this the most (due to the presence of locks and complex grooves).

There are two ways to caulk a log house with your own hands: “stretch” and “set”. The first method is used if the gaps between the rims are small, respectively, the second is intended for wide gaps. Let's take a closer look at each of the methods.

Extended log caulk

To caulk a log house "expanded" you will need a strand of insulating material for the length of the entire crack. First, you need to tamp one side of the strand into the gap, then bend the other side (as shown in the picture) and carefully hammer it in with a breaking or type-setting caulk.

Extended log caulk

Log caulking “set”

Log caulking “set”

This method of caulking a log house with your own hands requires much more insulation material, but it insulates the bathhouse from the log house more efficiently. The caulking technology proceeds differently: a strand with a thickness of at least 15 mm is prepared. Next, you need to gather the strands into the loops and hammer each loop into the gap one by one (so that the strand goes across the gap, as shown in the picture). It is necessary to hammer the strand using a breaking caulk, tamping the material from above and then from below. After the strand is completely hammered into the cracks, it is recommended to make a final compaction using a road builder.

You can study the technology of caulking timber in more detail in this video tutorial:

Video lesson on how to caulk a log house with your own hands

As you can see, the technology for caulking timber with your own hands is quite difficult and requires certain work skills!

We also recommend that you read the article: waterproofing a bathhouse with your own hands!

"DrevCos"

Stroitelnaya has been operating in the market for the sale of building materials for more than ten years. The store cooperates only with trusted manufacturers who have the necessary licenses and certificates for the production of tools. The company has several regular customers and a large number of positive reviews.

All products are carefully checked and inspected before they are put up for sale or sent by courier.

Reliable and fast delivery to anywhere in the country is also guaranteed. A close-knit team of workers quickly and efficiently accepts all orders. The store is located at:

Moscow, st. Ugreshskaya, 2с64, metro station Kozhukhovskaya, Technopark "Sintez". Contact by phone.

Video description

This video describes in detail the methods of caulking log houses:

They try to use wooden tools for caulking log houses. They are softer and do not leave damage on the logs.

It is advisable to caulk the log house from the inside and outside. You need to start from the corners, you need to go from bottom to top, caulking each row to the end. If you work on the walls separately, you can warp the entire building.

You need to start caulking the log house from the bottom rows Source psk.baraholka.com.ru

Video description

Watch a video on how to caulk a log house with jute:

And the last thing we will look at is caulking a log house with sealant. A sealing cord is first laid in the gap, and then the entire gap is blown out with foam from a mounting gun. You can also seal large cracks in logs.

Then the seams that have not yet dried are moistened with water and carefully smoothed with a brush or spatula. All excess foam is removed.

The easiest way to caulk a log house with sealant is Source krasiviy-dom.ru

Materials used

The most popular material for caulking is called tow. Adherents of natural materials still use natural moss to fill large gaps and insulate.

Working with tow requires some skill, since laying it out is quite difficult. As a result, the seams may turn out sloppy and blow out in winter. In addition, birds are very fond of tow; because of this, bald spots often appear in the walls, which need to be redone.

Another modern option would be to use natural seals, which can have different sizes: narrower ones are used for subsequent caulking, and wider ones for the initial procedure. When choosing an interventional sealant, attention should be paid to its vapor permeability, thermal insulation, strength and hygroscopicity.

Separately, you need to figure out what material to use to seal the cracks. Taking into account the modern number and variety of their properties, the list can be quite impressive.

Popular materials

1. Jute. This material is used because it has extremely high strength. Moreover, it does not suffer from water and does not absorb it, which is important. Thanks to the use of jute, you can significantly insulate a wooden house and save on heating costs. It is produced in three different forms, which makes jute more convenient to use.

2. Tow. It can be made from both hemp and flax. Thanks to its use, it is also possible to insulate a house well, but its significant disadvantage is that it can rot. Moreover, in order to properly lay it between the cracks, you will have to work hard. The tow lasts for several years, after which the procedure is repeated. The quality of the material matches its low price.

3. Moss. It’s interesting, but even moss can be used for such an important process, however, there are some nuances that you need to know about in advance. Otherwise, you can harm the tree. You need to use special moss, which is quite expensive. In addition, it must be in a strictly defined condition (not overdried, but not too wet) so that the wood does not begin to rot, and the moss itself does not crumble due to extreme dryness. It is difficult to work with, but if done correctly, this material perfectly seals the house.

4. Linen wool. As the name implies, this material is made from flax fibers. Technically, its qualities are good (it works quickly with moisture, absorbs and releases it if necessary, warms well and, of course, is safe for health), but its useful life does not exceed several years. In addition, it needs to be further processed. There is also a chance that it will harbor insects.

5. Modern sealants. As for acrylic sealants, this is a breakthrough in modern home construction. The use of this material will reduce heating costs significantly.