The caulking of the log house provides reliable insulation of the house for the entire period of its operation. This operation is no less important than the construction of a log house; if you treat it formally, you can end up with a cold, uncomfortable and drafty house.

Unlike brick and concrete, wood is a special building material; wood is sensitive to the conditions in which it is located. Properly caulking a wooden house means creating normal conditions for construction wood and ensuring the longevity of the structure. In addition to solving problems of insulation, caulking protects wood from excess moisture and dampness, rotting, damage by microorganisms and insects.

Wooden houses are traditionally caulked with materials of natural origin; one of the most popular is insulation made from fibers of the jute plant. In wooden house construction, insulation made from this plant, exotic for Europe and America, confidently displaces other materials; jute is widely used by Canadian and Scandinavian builders.

Why choose jute

The reason for the popularity of jute fibers is their low price and good performance; on the Russian market, jute competes with traditional Russian flax. When the question arises: how to caulk a house made of timber, preference is increasingly given to jute. Cottages, economy class residential buildings, bathhouses and outbuildings are insulated using jute.

In the countries of South Asia, three “harvests” of jute are obtained from one plot per year with a yield of about 2 tons per hectare; Asian producers are able to fully satisfy the needs of the world market for this product; the advantages of jute material include:

- Environmentally friendly, fibers do not split and do not form dispersed dust,

- The fibrous mass is homogeneous, does not cake,

- Jute tape is compressed to 1-2 mm without disturbing the geometry,

- Jute insulation is hygroscopic, protects the log house from excess moisture,

- Jute can be used to caulk houses made of logs, beams, profiled and edged timber.

As a disadvantage, it is noted that wet jute mass can create a favorable environment for microorganisms and insects. To eliminate this drawback, manufacturers use preservative and antiseptic impregnations; you should pay attention to this when purchasing material.

Depending on the density, jute insulation is divided into tow tape, batting and felt. The material is rigid and elastic, tends to maintain its original shape, which requires attention and certain skills when using it.

Why decorate the walls of a wooden building with rope?

To finish a wooden house from the outside, clapboard or siding, brick, imitation timber or block house are used. But a log house is often chosen precisely because it looks great in its natural form, without additional finishing. Experts advise painting the walls of the log house with paint or tinting impregnation (it will preserve the beauty of the wooden building), but one aesthetic drawback will certainly remain - unsightly gaps of different thicknesses between the logs of the log house.

To preserve the original woody appearance of a log house and properly disguise the seams, you can use rope. A rope of a certain thickness is twisted from natural fibers. Sold in a package in the form of a coil, from which it must be unwound during the fastening process. You can attach it using special nails or glue (heat gun). Jute rope is required not only for aesthetics but also for practical purposes.

1.1. Technical tasks

Large gaps are exposed to the elements, so rounded log buildings need to be properly protected. For this purpose, not only a sealant is used, but also special decorative ropes. You can buy a reel of any size inexpensively in numerous hypermarkets - the affordable cost is one of the advantages of this material. The fastening is applied in one layer.

The external joint requires sufficient attention. Quite often the first row of weatherstripping in an older building will need to be refinished. The quality of exterior finishing affects the comfort of living in such a house.

An important property of finishing is additional insulation, sound insulation and protection of a wooden house from drafts. Thanks to the dense rope, which is placed in the seams of the log house, the wooden house is not blown through and retains heat longer, and the owner saves on heating.

With this protection, dust and moisture do not get into the seams. The liquid, going through a cycle of freezing and thawing, due to constant humidity, completely destroys the tree. And the natural structure of the jute fibers of the rope absorbs water well, but does not release it.

This is interesting.

The rope is made from flax and hemp processing waste, and accordingly, it is characterized by the quality of natural raw materials.

It is inexpensive, so in Russia it has gained wide popularity in the exterior and interior decoration of wooden houses. Decorative cords made from raw materials of natural origin are successfully used to achieve an antique effect when building a new home. It is worth considering that if tow or other soft insulation sticks out even slightly from the joints between logs, birds are hunting for it. Birds steal such finishing materials to build nests. The rope will block their access - this is another useful property.

1.2. Decor of a log house from the inside with rope

Protruding inter-crown insulation is simply ugly. Even if, after assembling a house from a log, the material is compacted very tightly into the seams, it will be visible due to the uneven edges of the logs. The photo shows that a rope of medium thickness allows you to hide a narrow section, but leave the noble texture of the wooden building visible.

Natural jute rope is highly popular in wooden low-rise housing construction. Increasingly, people are using natural materials, including jute cord, for the construction and decoration of houses. They help to create a solid, but not pretentious style and give the house a cozy old-fashioned flavor. Jute rope is also used for finishing and decorating the inside of a log house.

For external and internal decorative finishing, it is recommended to use approximately the same materials. This will help you find and maintain the style of a wooden building. This material is used for any buildings assembled from logs:

- house;

- country house;

- bath;

- cottage;

- summer cuisine;

- economic block.

A cable with a small diameter is not only laid in the seams between the crowns of the log house, but also installed instead of baseboards indoors. It is also convenient for them to design crosshair corners. It is difficult to install anything to these places, but the flexible weaving tightly hugs the logs, and the result is very neat seams (see photo)

How to properly caulk a log house with jute

A house made of lumber of natural moisture is caulked in two stages: during the construction of a log house and after its shrinkage, the first operation is called primary caulking, the second - finishing. Primary caulking is done in two steps: jute tape is laid between the crowns during the construction of the log house, after the walls are erected, the seams are processed clean. When laying jute tape between logs or beams, you must adhere to the following rules:

- The surfaces of the crown before caulking are cleaned of adhering dirt, shavings and sawdust, the jute tape is rolled out along one side of the wall, and secured every meter with a construction stapler. When laying in parts, the edges are joined end to end,

- The tape is cut along the side edge of the beam, in a log house - along the line of the laying groove,

- The dowels are driven through the jute tape, an incision is made crosswise at the puncture site,

- The operations are repeated on the next crown.

The initial finishing caulking begins after laying the walls and installing the roof; caulking begins from the bottom crown. The material is driven into the inter-crown joints to a state of elasticity using a special tool, after completing work on the first crown, move on to the second. The operation is labor-intensive and requires diligence and considerable effort. According to builders' prices, the cost of this work is up to 100 rubles per meter.

After completing the work on the outside, the operation is repeated from the inside of the house; the technology for insulating a house made of timber from the outside and inside does not differ. The time spent on caulking a one-story 8x8 house can be 5-7 days.

It is important. If you caulk each wall separately, you may encounter the following problem: each processed seam increases the inter-crown distance by 3-4 mm, a fully processed wall of a house made of 200x200 timber with a height of 16 crowns will become higher by 5-7 cm, which can lead to distortions in corner connections.

Methods of caulking

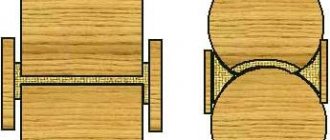

When caulking completely, jute batting is driven into the cracks using interventional crowns; the operation is performed in two ways:

- “In a stretch” - a twist-pigtail of jute batting with a diameter of 20-25 mm is driven into the crack, in this way seams with large gaps are caulked,

- “To the set” - the cracks are caulked with tape insulation 5-7 mm wide, the edges of the tape are hammered into the crack one by one, then the middle part is recessed.

The craftsmen recommend laying jute tape between the crowns with an overlap of up to 60-70 mm, the free edge is wrapped, tucked into the gap and caulked “into the set”. In difficult cases, the insulation is hammered into the stretch, and the seam is finished off as a set.

After the house has been subjected to shrinkage, the previously laid layer of insulation is deformed, the inter-crown cracks open, and at this stage of caulking the log house, the work must be done virtually all over again. During the shrinkage process, deep longitudinal cracks-sinuses will appear in the body of the beam; such cracks are caulked with flax tow and sealed with sealant; for individual cracks, thermal insulation with flax material is more effective.

Preparatory work

Impregnation of wood with antiseptic

Since jute is a durable material, there may be no need for re-caulking, which saves time and money. But still, in order for a self-made caulking to last a long time and reliably seal your home, it must be installed correctly. To do this, you need to prepare in advance, prepare your tools. You should choose jute of a width that matches the width of the gaps between the logs.

To prevent the logs from rotting and collapsing, the cracks should be properly treated before caulking. For this purpose, special wood antiseptics are used. The sealant should be placed only in dry cracks. It is best to carry out caulking in the summer, warm dry spring or autumn. The air temperature should not be below +10° C, there should be no rain. Too hot weather is also not suitable, as the logs dry out unnecessarily, which can result in overuse of jute.

Jute materials are easily torn by hand. Without using any special means, you can install the seal yourself quickly and easily. But such a finish will not have a completely aesthetic appearance, so it cannot be used for walls that carry a decorative load. To make caulked walls look neater, the pieces of insulation need to be identical and have smooth edges. To do this, the jute must be cut with a sharp knife or scissors. Therefore, the tools should be sharpened in advance.

You need to squeeze the sealant into the gap carefully, using a special metal caulk, which visually resembles a small chisel. If one is not available, it can be replaced with a thin chisel. To drive the seal into the gap, you will also need a hammer and a rubber mallet. If the gaps are small, then you can use a jute rope of small diameter. If the rope is narrow and the gaps are large, then it is better to fold it several times.

How to caulk the corners of a log house with jute

When caulking a log house, special attention is paid to the corners; this largely determines whether the house will be warm or not. The easiest way to work is with corners cut into a bowl. In this case, the oblo is part of a log or beam, the jute tape is laid on a common surface, as a result, each seam of the corner lock receives its own layer of insulation.

When chopping into a paw, the elements of the castle are caulked in different ways; in general, the principle is followed: each joint must be caulked.

Finishing caulking is done in order, simultaneously with the crowns.

Which sealant for cracks is better to choose?

Lnovatin

In order for log houses to preserve the internal microclimate, retain heat and keep out moisture and cold, they need to be specially treated - caulked, that is, plug the cracks between the logs. When building housing, wood is placed on moss for better adhesion, but this is not enough to plug all the holes between the building materials. When drying, additional cracks form in the logs. Therefore, it is necessary to caulk the log house not only immediately during construction, but also a couple of years after construction, when the logs are completely dry and all unnecessary cracks come out.

It is very easy to caulk a log house with your own hands, using natural materials and simple tools. Common materials for log caulking are:

- flax wool;

- wool felt;

- tow;

- jute.

They have their advantages and disadvantages, knowing which you can choose the most suitable material.

Flax wool is a product of crushing and pressing flax. The material prevents the logs from rotting, but is short-lived. Wool felt is warm, but crumbly and loose. Therefore, moisture easily penetrates through the felt, as a result of which the logs are easily covered with rot. Tow can also accumulate excess moisture and cause logs to rot.

Jute is soft wood fibers gathered into a bundle. It is produced from shrubs of the linden family, growing in Asia. The wood product is the most modern and durable material compared to its plant and animal counterparts. Jute fibers are stronger than fishing line and fit together tightly enough to prevent excess moisture from entering the house.

Since this material is completely natural, it is absolutely harmless, does not emit toxic fumes and does not cause allergic reactions in the residents of the house. Unlike linen and felt, jute is resistant to rot and moths, and it protects logs from birds.

The main advantage of the material is its hygroscopicity. The fiber absorbs excess moisture from the logs, so the log house does not rot. In dry weather, jute releases accumulated moisture to the wood, so it does not crack. The disadvantage of jute is that it consists of wood fibers, and therefore reacts to changes in weather conditions in the same way as wood: it shrinks in dry weather and swells in wet weather.

How to choose a jute ribbon

Jute insulation is selected according to density, thickness and width. A high-density jute tape is laid between the crowns; when shrinking, the low-density insulation cakes more; the width is chosen according to the size of the timber; for rounded logs - according to the size of the laying groove. Experts recommend:

- Lay the edged timber with jute tape 20-25 mm thick; under pressure its thickness will be no more than 4 mm;

- For dry planed timber, use a tape 10-12 mm thick, which shrinks to 2 mm.

Intervention seams are caulked with a material of lower density; to fill cracks, jute batting with a density of 500-600 grams per square meter is used.

Characteristics of VILATERMA

| The name of indicators | Values |

| Density, kg/m3 | 25 — 41 |

| Wide operating temperature range, °C | -60 — +82 |

| Low water absorption, % in 24 hours, less | 1 |

| Vapor permeability, mg/mchPa | 0,0029 |

| Thermal conductivity, W/μ | 0,0345 |

| Impact noise reduction index, dB | 21 — 28 |

| Modulus of elasticity, mPa | 0,55 |

| Water absorption by mass, % no more | 3-3.5 |

Caulking Tools

The toolkit includes:

- A stackable caulk with a blunt blade for working “as a set”; it is better to have two types of tools: with a 10-centimeter blade for caulking crowns and a 2-centimeter blade for cracks;

- The road worker for laying twists “in a stretch” has a wide blade thickened towards the bottom. A semicircular notch is made along the entire length of the blade;

- Breaking caulking with a wedge-shaped blade is driven into the cracks to widen them.

The tool is made of hardwood or soft metal and has a handle that is comfortable for work. A mallet is used as a percussion instrument - a hammer with a wooden or rubber striker.

Caulking order

Assembling a log frame with excess clearance to account for shrinkage

Good for the old days, i.e. Experienced and hardworking peasants caulked the log house, newly built from their own timber, twice: during the construction process, in rough form, and after its completion. They received timber for construction from the master or owner (monastery, land administration) selectively, and a smart man of that time, even before felling the timber, knew how it would settle and dry out. Therefore, when processing logs for a log house, the craftsman removed the excess on their edges (protruding ends) (item 1 in the figure on the right). The log dries faster at the ends and, under the pressure of the juices in the middle, tends to bend upward, as a result of which, already in the spring after winter, the crowns lay tightly on top of each other, pos. 2. Then the organic sap of the tree began to bituminize, the logs acquired additional elasticity and subsequently the log house settled evenly vertically.

If the timber was purchased externally, then no amount of experience will help you accurately predict the shrinkage of the logs. Almost all carpenters today are in this position, so the log house is caulked three times:

- Initially rough - in the process of construction;

- Initially outright - immediately upon completion;

- Secondary - after a winter or a year, the cracks that appear are caulked.

Note: under no circumstances should you remove excess logs from spans - as they dry out, they will tend to bend upside down, the corners will weaken and the entire structure will lose strength.

Advice from the experts

Caulk with jute rope

- The walls of a house made of edged timber do not always have an attractive appearance; it is almost impossible to lay insulation between the crowns without unevenness, so it will not be possible to caulk the frame “string by thread”. You can decorate the facade using jute rope, which is laid over a layer of inter-crown insulation; the rope is secured with clapboard nails.

- After finishing caulking, it is advisable to treat the crown gaps with an antiseptic; the domestic drug “Neomid” is an effective remedy. The product provides long-term protection of insulation made from natural materials from rotting, fungus and insects. It has a liquid consistency and is applied with a brush.

- If the frame is sanded after shrinkage, finishing caulk is carried out last - after sanding of the walls is completed.

Video: lesson on proper caulking

Note: hereinafter we adhere to the following. terminology: caulk – a special tool for caulking work and also the caulking process itself; caulk – materials for caulking.

Most of today's carpenters build conscientiously. But if one of them has to dismantle an old log house made of wild logs, he will understand that it is not only inter-crown insulation that needs to be caulked. It is also a kind of “solder”, which over time “glues” the frame together into a kind of monolith, extremely resistant to operational loads, external conditions and pests. It is not always possible to “tear” an old log house for scrapping with hand tools; you have to use special equipment. And if the building is intended for a museum, it can be completely removed from the foundation, taking out the windows and removing the doors from their hinges, loading it onto a vehicle, reloading it 2-3 more times along the way, and it will arrive intact: the cambium of a wild tree with caulk form a very strong seam . Treated lumber does not “glue” as firmly, but it is sufficient for the structure to last for more than 120-150 years. This article is about how to caulk a log house for a service life exceeding the standard.

The final touch - sanding

Caulking has not yet completed the construction of the log house until it is ready for flooring, installation of the attic floor, roof, installation of windows, doors, partitions, for finishing and equipment - it is desirable to sand the log house, but it is necessary to sand the inside. Especially - chopped from wild logs, debarked by hand.

Sanding a frame with sandpaper is extremely time-consuming, tedious, and this damages the outer most resistant layers of the wood. The frame is sanded using a hand-held universal grinder with nylon brushes. Worse - grinder with them; drive is too powerful. But the main thing here is still brushes for sanding wood, see video review:

Video: review of nylon brushes for sanding logs

Sanding a log frame with a brush is actually a controversial issue: the brush removes the bead of caulk, see fig.:

Sanding a log frame with a nylon brush

It is definitely clear that it is better not to touch the outside of the log house with a brush. However, there is a way to polish the outside of a log house - this is abrasive blasting. The abrasive used is... baking soda, which does not harm either the wood or the caulk. Of course, during your work you must observe all the safety precautions necessary for abrasive blasting. But the process itself can be carried out with a homemade sandblasting machine (sandblasting), because soft abrasive powder is used, see video:

General requirements for inter-crown insulation

Regardless of the material of manufacture, inter-crown insulation must meet standard operational requirements.

- Elasticity and density of insulation. The material must compensate for changes in the size of the cracks and not lose its original properties throughout the entire period of operation of the structure. The absence of natural shrinkage is an additional advantage.

- Low thermal conductivity. Values cannot exceed these tree parameters.

- The ability to breathe. The insulation should not hermetically separate the crowns; the wood breathes, gives off and absorbs moisture. The process cannot be interrupted after the space between the crowns has been insulated.

- Resistance to external influences. The insulation should not rot, and various insects should not live in it. The highest quality materials have an insect repellent effect.

- Safety for residents. All environmental characteristics must comply with sanitary requirements.

Interventional insulation for timber must be of high quality

Summarizing the above

The caulking of the bathhouse, according to all the rules, retains thermal energy in the bathhouse and significantly extends its service life.

Improperly carried out work on insulating a building will lead to its rapid cooling, rotting of the log house and the breeding of pests in it. Remodeling takes a lot of time, effort and material costs. Properly performed work will help increase the service life of the bathhouse. The erected structure will delight you for many years with its warmth, power and solidity.

Proper insulation of a bathhouse can be the key to its good quality and optimal heat retention. You can caulk the walls of such a building yourself, thereby significantly saving money

It is important to know well the basic rules of the process. Typically, such work extends significantly over a long period.

Note that the basic process of insulating a bathhouse has become a tradition; it is no different from the methods that were used by our distant ancestors during the reign of kings and monarchs. The process of caulking a bathhouse seems to be a complex and painstaking process that requires a lot of time and effort. Its implementation must be approached only with certain knowledge and practical work skills.