Our great-grandfathers built bathhouses from logs. Modern logs are processed on a machine and acquire an attractive appearance. Baths continue to be built from simple logs, time-tested and rounded. Both options are suitable and have their advantages. But what diameter of log is needed for a bathhouse? How not to make mistakes and choose the right material? Will the walls freeze in winter if a small section is used? We'll talk about all this in more detail below.

The log for the bathhouse is selected with the correct diameter so that the walls do not freeze and retain heat well.

Stage 5. Preparing tools

Preparation of round timber Round timber must be harvested at sub-zero temperatures, that is, in winter.

It is at this time that the amount of moisture in the wood is minimized, therefore, during drying the material will deform and crack less. In order to ensure the durability of the log house, certain sections of logs (the so-called butt logs) are used during construction. These sections start from the rhizome and end at the crown. Such butt logs are denser (which compares favorably with the tops) and there are practically no knots in them. Selection criteria also include the round shape and degree of curvature of the trunk. In both cases, a defect is an error exceeding 1 cm per linear meter.

Harvesting logs for a log house

The same applies to diameter. For example, the diameter of the base of the log is 35 cm, while the top is 25 cm or less. Such round timber is categorically not recommended for use in construction.

Logs for a log house

Finally, pay attention to the type of wood. Ideally, coniferous trees (spruce, larch, etc.) should be used for a bathhouse. Larch is characterized by resistance to moisture, although in extreme cases you can resort to the “pine-spruce” combination, in which the first few crowns are erected from pine. And if only spruce is used in construction, then the material must be treated several times with an antiseptic.

Perform further actions in accordance with the previously drawn up project. You can create such a project yourself, find it on the Internet, or order it from specialists. It is with the help of this document that you can calculate the required amount of consumables, determine the area and shape of the base.

To work you will need the following equipment:

- chisel;

Chisel - carpenter's axe;

Carpenter's Ax - medium power chainsaw;

- plumb line;

Plumb - level;

Laser level - electric drill;

Cordless drill/driver - mallet;

Wooden mallet - "trait".

Trait (tool)

We will pay special attention to the last tool - the “line”. For manufacturing you will need steel wire with sharpened ends. Bend the wire in half so that it takes the shape of a compass; you can additionally secure the handle. This tool will be needed when marking logs.

Which height do you prefer?

Centuries of experience have shown that the universal ceiling height in a bathhouse is 2.2 m. This means that when choosing a log house you should not listen to the manufacturer’s reasoning that small dimensions will help save heat. Please note that:

- floor joists cut between the second and third crown (0.35 cm of total height is lost);

- the attic floor is installed in the penultimate crown (minus 0.16 m);

- the thickness of the floorboard is from 3 to 5 cm, and the lining on the ceiling is about 2 cm;

- The shrinkage of the building is usually 1 cm from each crown (minus another 0.15 m).

Attention! Taking these design features into account, it turns out that the bathhouse frame needs to be selected with a height of 2.9-3.0 m.

Dimensions of the bathhouse and the diameter of the rounded log for its log house

The area of the territory on which the bathhouse will be built also influences what diameter of log is best for the bathhouse. For example, on a small summer cottage it is not advisable to build a bulky structure from thick logs. It will take up too much space and will focus attention on itself rather than on the house.

In such cases, it is better to assemble a log house for a bathhouse from a log with a diameter of 18÷20 cm with additional external insulation, which will not be required if the cottage is used only in the warm season. In addition, small sizes (for example, the classic miniature version of 3x3 m) allow you to quickly warm up rooms and economically maintain the temperature.

And if the bathhouse consists of several rooms or floors (most often the upper attic), then without good thermal resistance of the walls it is impossible to warm them up. In such cases, it is better to use logs with a diameter of more than 25 cm. Do not forget about the annual check of the density of the inter-crown seams and, if necessary, restore it. This will allow, even using a smaller diameter of the log for the bathhouse than calculated according to calculations, to ensure the required thermal insulation coefficient of the wall.

We suggest you familiarize yourself with: Heat exchanger for a bath on a pipe

What is a log house?

A log house is a structure made of crowns of logs, stacked one on top of the other and secured at the corners into grooves. Each log is adjusted to each other to create an even structure. Wooden saunas are very popular; many people love the unique aroma of wood when heated. Tannins are beneficial for the body.

The walls of a log bathhouse warm up faster, they “breathe” and absorb moisture well. The connections of chopped log crowns can be insulated with jute tape, linen tow, felt or moss.

wooden log house

It is necessary to install a shallow strip foundation. There is also an option for screw piles. To protect the log from getting wet, foundation ventilation is required. To do this, vents are placed on all sides, and in the cold season they are closed. Don't skimp on roof overhangs. The higher the building, the longer the overhangs are needed.

The distance between the building and other buildings is specified in regulations. Compliance with the rules is verified by government agencies. There are distance standards that apply only to baths, regardless of their materials. A log bathhouse must be treated with a fire retardant and antiseptic. Each time after using the bath, it must be ventilated.

Stage 2. Timber processing

Processing a log for scraping

Step 1. After the consumables have been delivered to you (or you have cut and delivered them yourself), they need 25-30 days to rest.

Step 2. Next, carefully examine and sort through the logs - keep only the highest quality ones, and discard defective or damaged ones.

Step 3. Then start processing. First, peel the bark from the logs (do this carefully so that they do not crack), leaving a little of it on the sides - about a 15-centimeter strip on each side.

Step 4. After processing, place the logs in storage approximately 25 cm from the surface of the ground. You can stack it however you like - in stacks, packs, etc., the main thing is that the distance between the logs is 7-10 cm.

Scheme for preparing logs for building a log house

Width 6m

With a 6m long wall of the bathhouse, you can easily accommodate all the necessary rooms: a steam room, a washing room, and a relaxation room. Many people also make an attic, expanding the usable area of the building.

Options 6 by 4 m

The most popular size of a log bathhouse is 4x6 m. This option is already suitable for a large family. It is ordered quite often. If you carefully study the projects, it will become clear why: such a bathhouse can comfortably accommodate from 4 to 8 people.

Interestingly, the customer can determine the location of the fifth wall independently.

If you want a standard steam room, aim for a distance of 150 cm from the wall.

If you want a large steam room and washing area with a shower, sink, and toilet, move the wall 250 cm.

With this option, a large stove is installed, the room warms up quickly. The rest room in the log house of the bathhouse is 4 by 6 m, even with this arrangement it turns out to be small - 13.4 m2.

If your plans include inviting large companies with a mandatory visit to the steam room, then you will have to think about a log house with a width of 6 m. You can increase the dimensions of the building endlessly: add a terrace, arrange a veranda with a winter garden, a second floor, an attic with a balcony under the roof... Log houses with a width 6 m allows you to perform such manipulations.

Advantages of log bathhouses made of thick rounded logs

When using logs with different diameters, the log houses built from them will, in addition to thermal properties, differ:

- the required volume of material,

- the cost of one log,

- number of inter-crown joints.

Despite the fact that thicker logs are more expensive, less of them are required in a log house (per unit height). For example, the difference in the volume of purchased material with a diameter of 20 cm and 30 cm is on average 50%. Therefore, the cost of a bathhouse made of thick timber will not be much more, but the comfort of staying in it will be significantly higher.

In proportion to the decrease in the number of crowns in a log house made of thicker logs, the number of joints between them also decreases. This achieves savings when caulking (on the purchase of material and payment for work). Therefore, we can recommend that when deciding what diameter of logs you need for a bathhouse, you should be guided: first of all, by the climatic features in the region, and secondly, by the results of a price analysis of several projects made from materials of different sizes (you need to choose the one that will cost the least in construction, operation and maintenance ).

Advice from Ivanovich

Our expert, an experienced builder and a seasoned bathhouse regular, Yuri Ivanovich, reveals secrets that are worth listening to.

- Don't overpay for the foundation. This construction is quite light; traditional monolithic pillars and a good sand bed 40 cm deep are quite sufficient.

- Do not settle for a ceiling height of 180 cm. Such a bathhouse is not cozy and cramped. The minimum ceiling height should be 210 cm. It is better to order a log house one or two crowns higher.

- Do not cover the roof with roofing felt; use durable, modern material right away.

- Cut out openings for windows and doors after the frame shrinks, after a year. And it will be easier to move whole logs for felling. If you really need it, cut a passage three or four logs high.

A bathhouse furnished with your own hands is an excellent proof of the owner’s wealth and a cozy place to relax. After completing the troublesome construction, you can rest peacefully for years, relaxing your soul and body.

Stage 4. Waterproofing the base

Waterproofing a strip foundation

Treat the surface of the foundation with molten bitumen and lay a layer of roofing material on top. After the bitumen has completely dried, repeat the procedure. As a result, you will have reliable two-layer waterproofing.

Waterproofing with mastic

Conclusion

Now you know how to choose the optimal diameter of a log for permanent residence, so that you feel cozy and comfortable in your home. But I would like to remind you that the building has many places that are sources of heat loss, even if you choose a log house of the required size. These elements include door and window openings, because a lot depends on the quality of the product!

In order for the house to be warm, you need to take into account a lot of specific points at the design stage: floor, walls, ceilings, basement (if any), openings

In the video presented in this article you will find additional information on this topic.

Stage 7. Doors and window openings

We specifically started talking about openings after construction was completed, since there are two options for their arrangement.

Installation of a casing for installing windows and doors in a log house

- In the first case, holes are created after the completion of construction work. At the same time, in the crowns located in the places of future openings, first leave small gaps (the dimensions of the latter depend on the size of the mounted products). Once you've finished laying the logs, simply cut the openings with a chainsaw.

- In the second case, leave openings during the construction process. This is very labor-intensive and expensive, since you will use bars with notches at the ends and special grooves.

How to install a window in a log house

Window installation

Bath windows

Doors for a bathhouse made of logs

Therefore, we advise you to give preference to the first option.

How to choose the best one

The desire to buy a huge log house for a bathhouse is understandable; you want everything at the same time: a large steam room, a washing room with a shower, a room for family or friendly gatherings, a place to relax on the second floor... The list goes on and on. But then the oven intervenes.

How long does it take to warm up the steam room to operating temperature? How much fuel is needed to heat rooms? Practical owners begin to count and limit themselves in their desires and settle on a standard log house width of 3 or 4 meters.

Next, a puzzle is solved with the location of the main blocks: steam room, washing room, locker room, rest area.

Stage 8. Caulking logs

Types of tools and caulking methods

After shrinkage is completed, the log house is caulked. To do this, prepare the following equipment:

- hammer;

- caulk (made of wood or metal).

Proceed to work only after the insulation has completely dried. First, twist the material (tow or moss) into a rope, then hammer it between the crowns with a hammer and caulk.

Caulk

You can use tape jute - in this case, the material is simply fixed with nails or a mounting stapler.

Primary and secondary caulking of a log house

Building area

Ideally, each bathhouse visitor should have from 1.3 to one and a half square meters of space in the dressing room or 1 m2 in the steam room. The optimal washing area for one person is 2.25-2.4 sq.m. More than 80 cm of free space should be left between the shower stall (or a bench in a soap room, the dimensions of the bench are 0.5 x 0.9 meters) for ease of movement. In fact, this area can be slightly increased for greater comfort.

The optimal usable area of a bathhouse for 2-3 people with three rooms (shower room, dressing room and the steam room itself with an area ratio of 1.5: 2: 1) is approximately 10 square meters.

How do you know if the planned area will be enough for you? The easiest way is to outline all the walls and partitions in steps. In winter, it is better to do this in the snow, and in summer, mark with sand or pull ropes.

“Tread down” the dimensions of the future bathhouse on the snow

Stage 9. Roof

Construction of a roof on males with layered rafters

As soon as the tree shrinks, you can begin building the roof. If you do this earlier, the roof will simply collapse.

Step 1. Place wooden beams on the wall framing (we have already talked about this).

Step 2. Fix the beams and attach the rafter legs to them in 1 m increments. In the ridge part, cut the rafters at the appropriate angle for the connection.

Step 3. Nail a solid board deck to the rafters (if you plan to use rolled roofing material) or make a sheathing (if you use slate, tiles, etc.).

Step 4. Install the roofing according to the instructions for the specific material.

Step 5. Cover the ridge with galvanized sheet steel to protect it from aggressive environmental influences.

Step 6. Cover the roof gables with siding or clapboard.

How to sew up a pediment

After this, proceed to further planned work - pouring a concrete screed or building a wooden floor (in the second case, the logs are cut into the logs of the second crown and fixed), install insulation, carry out interior finishing and arrangement of the steam room according to your project.

An example of a log house with a shingle roof

Advantages and disadvantages

Any wooden house is good for its light weight and environmental friendliness. A log building has its own characteristics. In what ways is a log inferior to timber?

- The log is less technologically advanced, the stand made from it is more difficult and slower;

- When such a bathhouse (log house) is built, the layout is adjusted to the length of the log;

- At the junction of the crowns, the thickness of the wall is equal to the width of the groove and, accordingly, approximately half the diameter of the log. This negatively affects heat retention in the room.;

Advantages of a log house for a bath:

- The closed joints of the crowns and the external appearance of the log house make it possible to refuse cladding;

- A log, unlike timber, does not have through cracks through the middle.

Construction Features

The construction of the bathhouse takes place using traditional technologies that have been proven over many centuries.

The process takes place in several stages:

the frame is assembled on the prepared site and maintained to complete the main shrinkage and remove excess moisture;

when the material is stabilized (aging requires from a year to a year and a half), a roof is built (a rafter system and roof are installed) and the walls are caulked;

install (or build) a stove;

They carry out interior finishing and, if necessary, sheathe the walls on the outside.

The above list deliberately does not indicate the process of drawing up a project, since it is often ignored - they make a bathhouse “like a neighbor’s”. However, if it is planned to build a more spacious room with a complex architecture or configuration, the availability of a project becomes a mandatory requirement.

Construction of a log house

The log house is assembled using the usual method - the logs are laid in pairs in the transverse direction, forming a rectangular box. For a more dense installation, a small groove is cut out on each of them, into which the upper part of the lower crown fits. When building a bathhouse from “turned” (rounded logs), all assembly elements (gutters and corner recesses) are manufactured in a factory manner, and the work process is noticeably accelerated.

If you use an ordinary peeled log, you have to do it yourself to clean the trunks from bark and make all the recesses, grooves and gutters. As a rule, traditional technologies are used, but they are enhanced with modern tools. For example, electric or chainsaws are used, which significantly increase the quality and speed of assembly.

Corner connections

There are several options for corner connections:

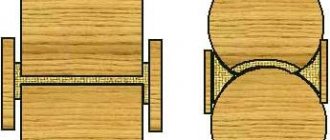

"into the bowl" (or "into the cloud")

This is one of the main options for interlocking logs. Its principle is to make a semicircular recess at the end of the log, into which the lower part of the upper crown will fit. At the same time, there are many options for such a connection - “in half a tree”, “in an oval comb”, “in a fat tail”, etc.;

"in a big way"

Another name for this compound is Siberian bowl. The manufacturing technique resembles the half-tree method, but the notch is made not in the upper, but in the lower part of the log;

"to the brink"

This is a modification of the “hollow” assembly method, but the ends of the logs are trimmed along the edges, which makes the end of the wall acquire a more even surface.

In addition, the connection of corners “into the paw” is often found. This can be any of the options already discussed, but without the protruding ends of the logs.

This type of locking connections is more economical, but for some users it is important to create an attractive appearance of the log house. Therefore, they prefer castles with protruding ends of the logs.

Compliance with the region's climate

Firstly, you need to understand that two quantities play an important role in maintaining heat in a log house:

- Diameter of a rounded log.

- The width of the groove selected for assembling the structure.

The figure shows important dimensions of lumber

Important! The assembly units of a wooden frame bear the greatest heat losses (the formation of cold bridges is possible). Therefore, in addition to the ratio of the width of the groove to the thickness of the log, the tightness of the fit to the lower crown is of great importance.

The main problem of any building is heat loss during the cold months of the year.

GOST for the construction of wooden residential buildings recommends the optimal size of the groove width depending on the minimum winter temperatures characteristic of the development region:

- At an outside temperature of -20 degrees Celsius, the groove width is 130 mm or more.

- When the thermometer marks -30 (even for a short time) – the groove width is from 150 mm.

- In areas with particularly harsh winters (-40 degrees) - no less than 170 mm.

Reducing heat loss through the groove is possible by caulking these areas (in the photo, ordinary tow is replaced with jute rope)

The majority of noteworthy enterprises involved in the production of kits for construction from rounded logs have taken the groove selection rate as 0.5-0.75 times the diameter of the lumber. This means that for the regions of the first group, the optimal log frame will be about 260 mm.