Decorative stone allows you to decorate corners beautifully and unusually.

How to finish the corners of the walls so that they turn out smooth, durable and beautiful? Previously, I was often interested in this question, but now, having gained experience, I will tell you how the finishing of corners is carried out - external corners inside and outside the building. I am sure that this information will help beginners cope with the task.

The corners of the walls in the home should be strong and beautiful

Cylindrical logs combine harmoniously and very interestingly with modern plumbing fixtures. Wood cladding is complemented by shelves or tables made of glass, countertops made of porcelain stoneware and elements made of metal. Wooden furniture that helps create a cozy and homely environment, wicker laundry baskets and wrought-iron shelves look no less attractive.

Design Features

When decorating a house, take into account the following nuances:

- The best option for construction is wood, which is harvested in Karelia or Finland. Due to the low temperature, the annual tree rings are denser and therefore the logs are very strong.

- Insufficiently large windows will make the atmosphere in the room too oppressive and dark.

- The space should not be filled with unnecessary pieces of furniture, so that the basis of the interior, in the form of walls, floor and ceiling, is not lost against the general background.

- The interior furnishings are thought out to the smallest detail and include only structural elements.

- The main advantage of such an interior is the ability to combine all natural materials and thereby create a natural and harmonious environment.

How to decorate the corners of an apartment beautifully and, if possible, functionally in a non-standard layout? In this case, the designer faces a difficult task - he needs to save space or make an inconvenient corner useful. The solution lies, for example, in arranging a corner with furniture that turns it into a place for reading, relaxing, or a house for animals.

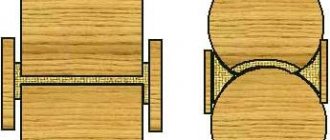

"Butt"

This is the easiest way to form corners and does not require labor-intensive cutting. It is enough just to saw off the ends of the beams at an angle of exactly 90°. When laying, the end of one beam rests against the side edge of the other and is fixed using spiked plates, nails or staples, and the T-shaped nodes are fastened with metal corners. The next row is laid in such a way that the joints of the lower beams are covered.

So, a butt connection is easy to perform and takes relatively little time. But, unfortunately, it also has disadvantages, which often outweigh its advantages. With such installation, it is extremely difficult to achieve tight pressing of the beams and ensure strict perpendicularity of their location. Even if you saw off the ends as evenly as possible, cracks will inevitably form at the joints that have to be sealed, but this only slightly reduces heat loss.

And the strength of such fastening leaves much to be desired. Under heavy loads, there is a risk of displacement and even complete rupture of the unit. For these reasons, the butt joint technology is practically not used in the construction of residential buildings. But for the construction of utility and garden buildings it is quite acceptable.

Types of decorative corners

Corners can be considered a universal finishing material; they are used in the bathroom, in the kitchen, in the nursery and even on the balcony. Corners decorate not only walls, but also fireplaces, stoves, and furniture. The appearance of the corners and their technical characteristics directly depend on the material from which they are made. The material also determines the scope of use of the corners. Depending on the material and area of use, there are several types of corners:

Metal

The most popular metal angles are made from aluminum, brass and steel. This type of corner is rarely used for finishing residential premises - more often in furniture production. Brass and steel corners have a smooth polished surface.

The aluminum profile can also be natural, polished, or anodized with a coating of any color. Such corners are usually used to match the material with which the walls are finished.

Wooden

This type includes models made of bamboo, cork, MDF or natural wood. They are mainly used for finishing external and internal corners of walls lined with clapboard, natural boards or similar material, but are also applicable for finishing wallpaper of any kind. Corners made of natural wood are made from different types of wood, are additionally painted, varnished, and can sometimes have on the surface patterns.Wooden corners are an excellent solution for attic balconies and bathhouses lined with wood. Such corners are fastened with secret nails and/or carpentry PVA. The disadvantages include low ductility and high fragility, which makes it impossible to use such corners in rooms with uneven walls, and therefore corners.

Silicone

This type of corner is suitable for framing the joints of wallpaper or painted surfaces. In addition to aesthetics, the silicone profile will make the corners less dangerous when it comes to a children's room.

In addition, it is resistant to water, so it is used in the bathroom; it can be mounted even on an uneven surface due to its flexibility. To attach such corners, an adhesive corner base is used.

The downside of silicone corners is their instability to household chemicals, which makes maintenance more difficult. For cleaning you should use non-aggressive products.

Polyurethane

Such corners are produced by pressing; they have a smooth surface and complex relief. Such profiles are wear-resistant, they are not afraid of moisture and temperature changes. Unlike plastic, they are thicker, which can complicate the installation process, but polyurethane profiles are easy to paint if necessary. Polyurethane corners imitate gypsum stucco, wood texture, and come in plain white or with gold-plated ornaments. Fits perfectly into a classic interior. Polyurethane glue is used to attach them.

Corners made of decorative stone

Elements made of stone are usually used to decorate the facades of houses, but if the interior of the apartment also has stone trim, such profiles will fit organically here too. You need to choose flat stones, they will add aesthetics to the structure. The stone corner combines harmoniously with decorative plaster, wooden panels, and even ordinary wallpaper.

How to decorate the corners of walls in an apartment: photo The easiest to use is decorative flexible stone. The material is lightweight, but durable, and can be mounted on any surface using liquid nails.

Flexible stone, despite its lightness, is a very durable and wear-resistant material. Under the influence of hot air, stones become soft and pliable, so they can be attached at any angle, even at imperfect angles. This stone has a rough surface and varied texture, and is resistant to mechanical stress.

Flexible artificial stone can be mounted directly on the corner. Ready-made corner elements are also quick to install. This L-shaped tile imitates stone, consists of a short and a long part of the brick. The same elements can be used to decorate arches and slopes.

Corner elements of artificial stone based on gypsum. For wall cladding without using ready-made corner elements, the edges of decorative stones are cut at an angle of 45 degrees and brought together with this part.

Further work is carried out according to the usual scheme - the seams are rubbed with cement grout. For internal corners, only the second option with sawing is applicable, since ready-made corner internal elements are not produced.

Ways to fasten the lining

How to seal cracks with sealant

Eliminating cracks and cracks using sealing is the most common method due to its accessibility and ease of installation. Sealants firmly connect the walls of the wood gap. To prevent the product from getting onto the surface of the wood, cover the edges of the crack with masking tape. Then a strand of tow or jute or fabric for compaction is placed in the cracks and inter-crown joints. And the sealant is applied on top using a spatula or a gun.

When applying sealant, seams, joints and cracks are not completely filled to the brim. The composition is applied so that it comes into contact at two points of the tree and connects two opposite edges. The sealant is left for at least six hours, and after hardening, the sealed cracks are painted over to obtain a more aesthetic appearance.

If the product does get on the clean surface of a log or beam during work, remove it with fine sandpaper after drying. The masters of the MariSrub company efficiently and quickly seal a wooden house, which ensures reliable hydro- and thermal insulation, and also prevents the wood from drying out and the appearance of cracks or crevices.

The most optimal solution for a wooden house is acrylic sealant. This is an environmentally friendly and safe product without odor. It is not afraid of temperature changes and dampness, reliably fastens the walls of wood and eliminates cracks or crevices. Silicone sealant cannot be used for a wooden house due to its harmful composition. In addition, such material cannot be painted, and it will ruin the appearance of the wood. The most popular brands are Neomid and Eurotex, made in Russia.

Read also How to care for industrial

What happens if you don't close the corners

If you ignore the stage of insulating the corners of the log house, in addition to the lack of comfort during your stay, there is guaranteed to be a distortion of the shape of the structure, which will become askew over time, dampness and elements of rotting wood will appear.

What happens if you don't close the corners from the outside? External insulation allows you to more effectively maintain comfort in the house compared to internal insulation, therefore it is more important. If you cut a corner of logs or beams without sufficient experience, then there is a high probability of defects appearing after construction, in particular large gaps during shrinkage. The situation is corrected with the help of wedges. They are cut from the same type of wood as the log house. Errors in sealing corners will also lead to serious problems. For external insulation, you cannot use polyurethane foam, which will accumulate moisture over time and cause dampness in the wood. When choosing sealants, you should not use silicone or acrylic types due to the high likelihood of peeling or cracking. You should pay close attention to the internal and especially external corners, since they become the paths for cold penetration if the insulation is improper. Insulation of a wooden house using Warm seam technology

In order to understand which materials are best used to make a staircase in your home, you can study in advance the interior decoration projects of wooden houses, photos of which are quite accessible. And based on them, decide what is best to use for the task at hand.

With root thorn

The tenon joint, or warm corner as it is otherwise known, is an advanced butt joint technology that can help prevent walls from moving and drafts. But in this case, rather labor-intensive processing of lumber is required - the formation of tenons and grooves at the ends of the beams.

A tenon joint involves cutting one of the timbers to be joined to form a rectangular tenon, the width of which is usually 1/3 the width of the timber. A corresponding groove is made on the opposite side of the other beam and these elements are joined during installation. This method of cutting corners requires reinforcement with dowels.

How to finish the interior decoration of a wooden house: options, photos

Recently, the interior decoration of a wooden house with imitation timber is one of the most popular, and photos of such finishing can be easily found on the pages devoted to the topic of interior finishing work. This is especially true when it comes to a country house or dacha.

Interior finishing of a wooden house Everyone knows that all finishing work that is carried out both inside and outside the house helps protect the structure from the negative effects of external factors. It is also a great way to give your home a unique and strong design. Such an interior is always filled with coziness and is very comfortable for life.

Interior decoration of a house made of profiled timber As for the finishing of a wooden house, it must be of sufficient quality. It is worth noting that not all materials are suitable for wooden buildings. Therefore, they must be selected with the utmost care, taking into account the fact how they will behave during further operation.

Log house from high-quality rounded logs In the case where the house was built from high-quality rounded logs or from profile timber, then the facade can simply be treated with paint. The paint has good protective properties, so the wood will not deteriorate so quickly. But if we are talking about laminated veneer lumber, then even paint treatment is not necessary, because the timber itself has already been processed under special industrial conditions and has a fairly high appearance from an aesthetic point of view. This material itself is quite beautiful and is used to decorate the house both inside and outside.

Log house made of laminated veneer lumber. But be that as it may, you should approach the finishing work in a wooden house with special care. After all, this process is a mandatory step in the arrangement of wooden structures.

Interior decoration of a wooden house with a blockhouse Recently, interior decoration of a wooden house with a blockhouse has been carried out. Photos with examples of such works are publicly available, and everyone has the opportunity to familiarize themselves with them. In principle, now you can find examples of completely different finishes and see for yourself how beautiful this or that work looks.

Perfect joining of internal corners

What to do with the old facade

It is clear that when a new house is being built, all stages of construction are thought out in advance. But there are situations when it is necessary to carry out finishing work after the premises have been in use. Let's say that quite often there is a need to finish an old wooden house. It may be durable and reliable, but it still needs to be processed. By the way, it is the exterior finishing that most often requires re-processing.

Covering a wooden house with sidingFor example, a reliable and strong, as well as attractive house from the inside, looks old and shabby from the outside. In this case, you should immediately update the facade. This will increase its service life. By the way, when the interior or exterior decoration of an old wooden house is planned, it is better to look through photos with examples of such work in advance. Then you will have an idea of what exactly the customer wants to receive as a result of the work on arranging his home.

Finishing the facade of the house If we are talking about interior decoration, then any material can be used here. And it doesn’t matter whether it is used for decorative purposes or for construction. The most important thing to pay attention to is environmental friendliness and quality of materials. They must have good vapor barrier functions, so that air circulation will not be impaired. This will preserve the typical microclimate that is characteristic of wooden houses.

High-quality interior finishing of a wooden house But in any case, before starting work, you should understand which task is performed first, and what can be done later.

What to do first

The most important stage of finishing work is the arrangement of the foundation.

Brick for finishing a wooden house This can be done in this way:

- natural or artificial stone is used;

- brick for finishing;

- panels that perform decorative functions;

- siding of any kind, etc.

Artificial stone for finishing a wooden house The next stage is arranging the facade. Here, materials are most often used that help achieve the “wet facade” effect. Also, do not forget about the use of insulation materials.

Mineral wool for finishing a wooden house

- Styrofoam;

- mineral wool;

- glass wool

Foam plastic for finishing a wooden house Of course, it is best to use the first two options, then you will be able to preserve all the vapor barrier features that wood has and ensure the comfort and environmental friendliness of the building.

Glass wool for finishing a wooden house If we talk about interior work in the house, then for these purposes you should choose exactly those materials that have good fire resistance, do not emit toxic substances and meet all environmental standards. You also need to pay attention to ensure that they do not lose their density and do not cake after vertical installation. That is why many experts recommend checking with a hardware store for what purposes this or that insulation is intended, and be sure to indicate what the house that needs to be insulated is built of.

Siding for finishing a wooden house

How to decorate the walls

After you have sorted out the insulation a little, you should decide what exactly the walls of the building will be finished with. Most often, for wooden structures, materials are used that can be used to perform “dry” wall finishing. To do this, they are attached to the surface using a special frame. The main advantage of “dry” finishing is that it does not allow the wood to deteriorate; there is no need to wet it again and apply a lot of unnecessary substances to it.

Decorative bricks for finishing a wooden house If this type of work is used to decorate the facade, then to all the above advantages it is worth adding the fact that it is easy to place insulation under this type of finishing. This can be either mineral wool or polystyrene foam. It is worth noting that today this is the most relevant way to make your home cozy, energy-saving and practical.

Interior of a wooden house using decorative bricksBut these are not all possible options. Sometimes designers use decorative bricks for wall cladding. But again, if the house is built of timber, then it is almost impossible to complete such work. As a rule, each client independently chooses the most suitable type of finishing materials. For example, you can look through photos, of which there are a lot on the Internet, choose a design for the interior decoration of a wooden house from ready-made options, or decide which one is best to choose for your purposes.

The use of decorative stone in the interior of a modern living room

All about interior decoration

In this process, it is important to consider factors such as:

- what kind of material was used to build the house itself;

- what design preferences does the owner of the building have;

- what financial resources does the customer have?

Scheme for installing façade siding on wooden sheathing. It is important to remember that if laminated timber or logs were used to build the house, then the interior finishing may not be performed. In other cases, you can cover the walls with plasterboard or siding. This way it will be possible to hide all communication structures and any defects in the walls. And, of course, don’t forget about additional thermal insulation. It is also of great importance.

Again, every interested client can view the options for interior finishing of a wooden house in the photo. There are a lot of them both on the Internet and on the pages of specialized printed sources. You can also ask for the opinion of a professional designer or builder who does similar work. And based on the information received, one can draw conclusions about exactly how to carry out the internal wall cladding, and what material is best to choose for this purpose.

Interior decoration of a house made of rounded logs

What material is best to use

As mentioned above, before choosing a material for interior decoration, you should weigh all factors. For example, you need to understand what the house itself is built of, how old the construction is, and so on. The interior decoration of a wooden house with plasterboard is carried out if it is not built from timber. It is worth noting that drywall can improve the thermal insulation of walls, thereby the house will not cool or heat up so quickly. This is one of the cheapest and easiest ways to give the interior a stylish look and at the same time not deprive it of practicality.

Drywall for interior decoration of a wooden house If we talk about wall insulation, then you should not think that absolutely all wooden houses need to be insulated. Let’s say that if insulation work has already been done on the outside, then there is no need to do this inside. By the way, it is external insulation that is considered the most effective.

Although there are cases when additional insulation is not required at all. This may be the case if the house is built of timber. True, here you should be extremely careful and prevent the formation of cracks between the beams.

Interior decoration of a wooden house with clapboard In addition to plasterboard, you can use other materials. This could be siding or decorative brick. Recently, the interior decoration of a wooden house with clapboard has become increasingly popular; photos with examples of such work can also be found on the Internet or in specialized sources of information.

Scheme of wall finishing with clapboard

What should be inside the house

Every modern person is accustomed to comfort and coziness. And even if he is on vacation in a country house, he still wants to enjoy all the benefits of civilization. That is why almost all wooden houses that are now being built have a bathroom and toilet.

Do-it-yourself calculations of the stairs to the second floor It is worth noting that the presence of a bathroom or shower is just as important as the opportunity to prepare breakfast in a comfortable kitchen or taste delicious tea on the summer veranda. The presence of all of the above premises is a huge advantage for a country house. But this is not the entire list of what should be in a comfortable home. If we are talking about two or more floors, then you need to make sure there is a convenient staircase in the building. Most often, the staircase is also made of wood. Although there are options when this structure is made of glass or metal. In this case, it all depends on the style that can be seen in the interior design, and on the personal preferences of the owners of the house.

Bathroom in a wooden house In order to understand which materials are best used to make a staircase in your home, you can study in advance the interior decoration projects of wooden houses, photos of which are quite accessible. And based on them, decide what is best to use for the task at hand.

Kitchen interior in a wooden house

Stages of work before finishing the corners of the log house

The finishing of the corners of the log house, as well as the entire house, begins after the initial shrinkage process, about a year after construction.

Directly finishing the corners inside and outside a wooden house can be done after performing the following work:

Grinding

Sanding a log house is designed to strip the logs of bark, remove small cracks, remove blue stains and prepare the house for protective treatment, which should be done on the ends and joints of the log house immediately after sanding.

Grinding corners is usually done manually with a chisel, since no tool is capable of sanding corner joints as well as can be done by hand.

Treatment with protective agents

If the treatment is carried out with a product that combines all types of protection, one layer is applied. If three different compositions are purchased, it is necessary to treat the wood in the following sequence: moisture protective, biological agent and fire retardant. Each layer is applied with your own tool and only after the previous one has completely dried.

Insulation

Corner joints are the most unprotected place in a log house, through which cold penetrates into the house. To avoid heat loss, the corners must be carefully caulked.

Typically, the corners of a log house, as well as the entire house, are caulked with natural materials: tow, jute, linen. Instead of caulking, you can use a modern insulation method - sealing the seams with sealant.

If in the future it is planned to cover the outside of a house made of timber with clapboard, siding or other material, you can adopt the following insulation method: the corner is completely covered with foil, the shiny side out, the foil can also be secured with a furniture stapler.

The appearance of the corners is not very presentable, but this does not matter, because the top of the house will be covered with decorative cladding, which will completely hide the insulation.

Other possible options for insulating external corners:

- basalt insulation;

- fiberglass;

- polystyrene foam;

- foamed polyethylene.

Dovetail

A type of tenon joint is the so-called “dovetail”. These are one of the most airtight, “warm”, and therefore popular locks for timber. True, it is also the most labor-intensive. In this case, both the tenon and the groove are shaped like a trapezoid, expanding outward. When docked, they form a strong, reliable unit that successfully withstands even the heaviest loads. By the way, dovetail technology is actively used in the furniture industry, in particular, in the assembly of drawers, which bear a high operational load.

Nageli

A dowel (translated from German as “nail”) is a fastening element used to hold beams together.

It can be made of wood or metal. In the first case, holes three crowns deep are drilled in the timber wall every 30-40 cm and rods made of wood denser than the log material are inserted into them. For maximum strength, the channels must be alternated in a checkerboard pattern. In the case of metal dowels, work is carried out according to a similar scheme. Fastening elements are made from pipe (reinforcing bars are not recommended). Unfortunately, when the log house dries out, the crowns can hang on the non-drying metal dowels

"Half a Tree"

The “half-tree” connection, as the name implies, involves cutting half the width of the beam. In the simplest version, they go at right angles, but to reduce airflow, the horizontal cutting line can be drawn with a slight slope. To enhance the reliability of the fasteners, wooden bushings are used, installed at the end of the cutting, as well as dowels and dowels. In the latter case, the length of the dowel must be calculated so that it penetrates at least three beams.

The “half-wood” technology is often used in house construction, but it should be kept in mind that the joints must be carefully insulated